Automotive Aluminum Plate

The main advantages of Automotive Aluminum Plates are light weight and good heat dissipation. It also has the advantages of corrosion resistance and a beautiful surface.

Market Analysis of Automotive Aluminum Plates

Governments around the world are implementing stringent emissions regulations to combat climate change, and lightweight materials like aluminum can help automakers meet these regulations by reducing vehicle weight and improving fuel efficiency.

For every 100 kg weight loss of a car, fuel consumption per 100 kilometers can be reduced by 0.4 liters, and carbon dioxide emissions can be reduced by 1 kg. Automotive lightweight presents a huge opportunity for the electric and hybrid vehicle market, which requires lightweight materials to maximize range and battery performance.

What is an Automotive Aluminum Plate?

Automotive aluminum plates refer to sheets or plates made from aluminum or aluminum alloys that are used in the construction and manufacturing of various components and structures in the automotive industry. Aluminum has become increasingly popular in the automotive sector due to its lightweight, high strength-to-weight ratio, corrosion resistance, and other desirable properties.

Why Choose Aluminum as a Car Material?

Aluminum was chosen as the material for the automotive industry for several key reasons:

1. Reduce car weight

Aluminum is much lighter than steel, reducing the overall weight of the vehicle. Lighter vehicles generally have better fuel efficiency, handling, and acceleration.

2. Improve vehicle fuel efficiency

Aluminum's lightweight nature helps improve a vehicle's fuel efficiency because it reduces the energy required to propel the vehicle. A lighter car requires less fuel to achieve the same performance, making it more environmentally friendly and more cost-effective to operate.

3. Friendly strength-to-weight ratio

Aluminum alloys have a high strength-to-weight ratio, which means they can provide the necessary structural strength while still being lightweight. This feature is critical to the safety and performance of modern vehicles.

4. Aluminum is corrosion-resistant and extends the life of the car

Aluminum naturally forms a protective oxide layer on its surface, which gives it excellent corrosion resistance. This resistance helps protect your vehicle from rust and extends its life.

5. After the car is scrapped, the aluminum can be recycled

Aluminum is highly recyclable, making it an environmentally friendly choice. Recycled aluminum retains its properties, so using it in vehicle manufacturing reduces the need for primary aluminum production and saves resources.

6. Good vehicle formability

Aluminum is a versatile material that enables complex and innovative designs. This flexibility allows automakers to create unique and aerodynamic vehicle shapes.

7. Reduce vehicle emissions

Light-duty vehicles powered by internal combustion engines produce fewer emissions because they require less fuel to operate. In electric vehicles (EVs), weight reduction can extend the vehicle's range on a single charge.

8. Relatively safe when a vehicle breaks down

Aluminum's high energy absorption capabilities make it a suitable choice for vehicle crash structures. It absorbs and dissipates impact energy, helping to keep passengers safe in the event of a crash.

9. Reduce vehicle noise

The strategic use of aluminum in vehicle manufacturing reduces noise and vibration, resulting in a quieter and more comfortable ride.

10. Improve car performance

In high-performance vehicles, the reduced weight of aluminum components can improve acceleration, handling, and overall driving dynamics.

While aluminum offers numerous advantages in the automotive industry, it is important to note that the selection of materials in vehicle structures often involves trade-offs and considerations of cost, manufacturing processes, and specific application requirements. As a result, automakers often use a combination of materials such as steel, aluminum, and composites to optimize vehicle performance and meet safety and regulatory standards.

What Alloys are used in Automotive Aluminum Plates?

Automotive aluminum panels are typically made from a variety of aluminum alloys, each selected for their specific properties and intended use in the vehicle. The following are some commonly used aluminum alloys in automotive sheet applications:

- 5xxx Series Alloys: Known for their excellent corrosion resistance, these alloys are commonly used in automotive body panels such as hoods, fenders, and doors. For example, 5182, 5083, 5052, 5754 alloys.

- 6xxx Series Alloys: These alloys have a good balance of strength and formability and are used in various structural and body parts of vehicles. Examples include alloys 6061 and 6063.

- 7xxx Series Alloys: These heat-treatable alloys are used in high-performance automotive components requiring high strength and stiffness. Alloy 7075 is a well-known example.

- 2xxx Series Alloys: This series of alloys contains copper as the primary alloying element and is used in applications where high strength is critical. While they are not as common in automotive applications as other series, they may be used in specialized parts.

- 3xxx Series Alloys: Due to their excellent thermal conductivity, these alloys are often selected for use in automotive heat exchangers such as radiators and condensers. Alloy 3003 is a common choice in this category.

- 5xxx/6xxx Series Hybrid Alloys: Some aluminum alloys used in automotive applications are hybrid alloys that combine properties of the 5xxx and 6xxx series. These alloys provide a balance of strength and corrosion resistance.

- Aluminum-lithium alloys: Although not commonly used in mainstream automotive applications, aluminum-lithium alloys are lightweight and can improve the performance of specialized automotive components.

-

5182 Automotive Aluminum Plate Sheet

5182 Automotive Aluminum Plate Sheet has a flat shape, high quality, good corrosion resistance, good weight reduction, and energy-saving effects, and its safety and comfort are better provided.

-

5083 Automotive Aluminum Plate Sheet

5083 Automotive Aluminum Plate Sheet has good formability and can be easily formed into various auto parts by rolling, bending, stamping, and other processes.

-

5754 Automotive Aluminum Plate Sheet

5754 Automotive Aluminum Plate Sheet has good formability and can be easily formed into various automotive parts by rolling, bending, and stamping processes. It can be formed into complex shapes while maintaining its strength and integrity.

These aluminum alloys are chosen for their specific properties, and they find use in various parts and components throughout an automobile. The selection of the alloy depends on the requirements of each part, such as strength, corrosion resistance, formability, and thermal conductivity, to ensure optimal performance, safety, and durability of the vehicle.

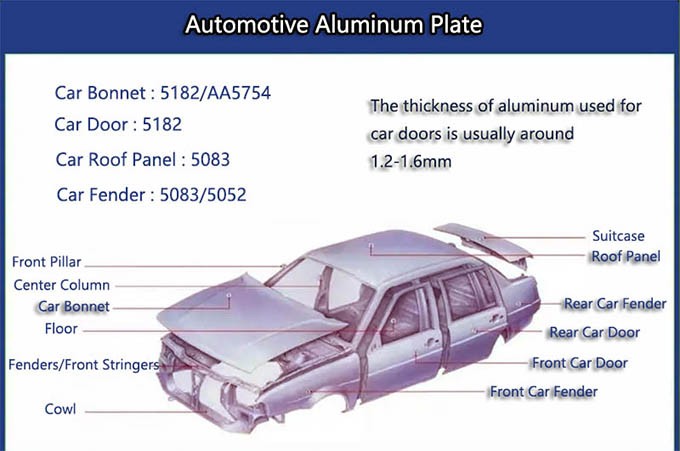

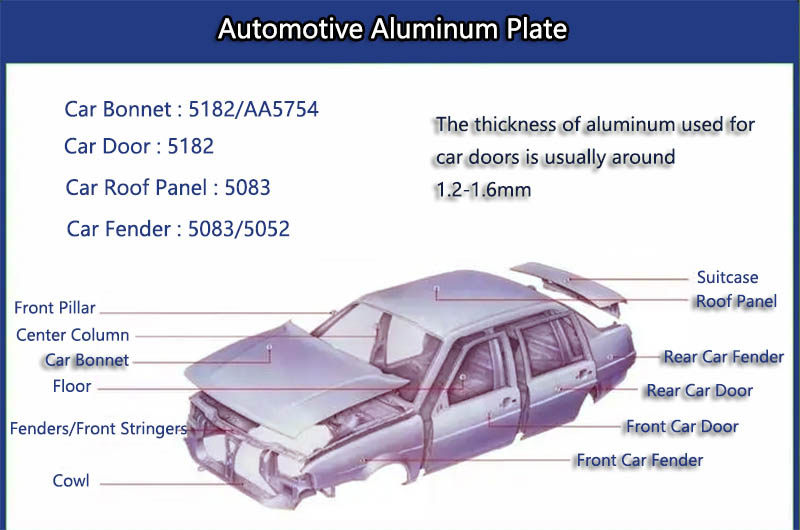

Which Structures of Automobiles are Made of Aluminum?

The commonly used grades of automotive aluminum sheets are 5XXX series and 6XXX series, of which 6000 series account for a large proportion, and 5000 series are mostly inner panels and some reinforcements.

In addition to the all-aluminum body, the most widely used aluminum panels in other subsystems are the four-door and two-cover system.

| Application | Alloy | Properties |

|---|---|---|

| Outer Panel | 6016/6014/6022/ | Excellent hemming performance |

| Inner Panel | 5182/6016 | Good formability and appearance |

| Structural Parts | 6061/6016 | Excellent hardness |

| Small Bracket | 5754/5454 | Relatively low strength |

| Reinforcement | 6111 | High strength, poor corrosion resistance |

| Part | Application |

|---|---|

| Automotive Aluminum Plate for Car Body | Car Doors |

| Engine Cover / Car Front and Rear Cover | |

| Car Fender | |

| Car Roof Panel | |

| Car Bottom Guard | |

| Automotive Aluminum Plate for Car Chassis | Car Wheels |

| EV Battery Tray | |

| Chassis Components | |

| Automotive Aluminum Plate for Power System | Automotive Aluminum Plate for Fuel Tank |

| Heavy Truck Air Tank | |

| Power Battery Shell Material | |

| Aluminum Foil for Battery Cells | |

| Battery Cover | |

| EV Power Battery Pack | |

| Automotive Aluminum for Car Heat Shield | protects sensitive components from high temperatures |

Automobile aluminum sheets are used in various parts of automobiles due to their light weight, high strength and corrosion resistance. Here are some common types of automotive aluminum sheets:

Automotive Aluminum Plate for Car Body

Aluminum is used in Car Body for its lightweight properties, which can reduce weight, improve fuel efficiency and enhance performance without compromising structural integrity.

Automotive Aluminum Plate for Car Body includes products for the manufacture of doors, hoods, fenders, roof panels and other body panels.

- Alloys: The alloys used for car bodies are typically 5xxx series aluminum such as AA5052 or AA5754.

- Alloy Condition: H32/H34 temper, which provides a balance between strength and formability.

- Aluminum Thickness: The thickness of aluminum used in car doors is usually around 1.2-1.6mm.

-

Automotive Aluminum Plate for Car Door

Purpose: Structural integrity and lightweight design

Alloy: 5xxx series (e.g., 5182, AA5052, AA5754)

State of the Alloy: H32 or H34

Thickness: 1.2-1.6 mm

-

Automotive Aluminum Plate for Car Roof Panel

Purpose: Aesthetics, support, and weight reduction

Alloy: 5xxx series (e.g., 5083)

State of the Alloy: H116 or H321

Thickness: 1.0-1.5 mm

-

Automotive Aluminum Plate for Car Fender

Purpose: Protection, aesthetics, and weight reduction

Alloy: 5xxx series (e.g., 5083, 5052)

State of the Alloy: H32 or H34

Thickness: 1.0-1.5 mm

-

Automotive Aluminum Plate for Car Bonnet

Purpose: Protection and weight reduction

Alloy: 5xxx series (e.g., AA5182, AA5754)

State of the Alloy: H32 or H34

Thickness: 0.8-1.2 mm

Automotive Aluminum Plate for Car Bottom Guard

- Purpose: Undercarriage protection and impact resistance

- Alloy: 5xxx series (e.g., 5083, 5754 )

- State of the Alloy: H116 or H111

- Thickness: 2.0-3.0 mm

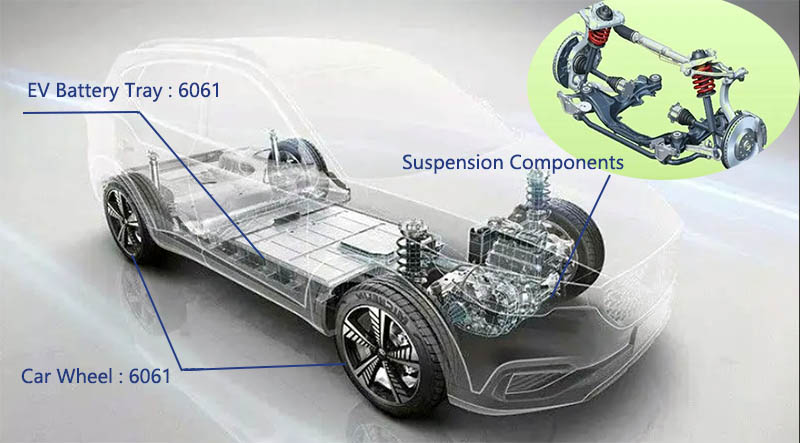

Lightweight Chassis Aluminum Plate for Automobiles

Bottom plate: The structure of the vehicle bottom plate is made of aluminum plate, which not only improves the strength but also reduces the weight.

Automotive Aluminum Plate for Car Chassis is commonly used to enhance the strength, durability and reduce weight of vehicle chassis. The specific alloy and thickness of the aluminum sheet used in the chassis of an automobile may vary depending on the design and engineering requirements of the manufacturer.

- Alloys: Usually from the 5xxx or 6xxx series such as 5052, 6061 or 6063

- Alloy state: T6 or T651

- Thickness: Varies based on specific chassis design and requirements

-

Automotive Aluminum for Car Wheels

Automotive Aluminum for Car WheelsPurpose: Lightweight design, improved fuel efficiency, enhanced performance

Alloys: Usually from the 6xxx or 7xxx series, such as 6061 or 7075

Alloy state: T6 or T7

-

Automotive Aluminum Plate for EV Battery Tray/Floorboard

Automotive Aluminum Plate for EV Battery Tray/FloorboardPurpose: Lightweight, durable and safe platform for housing and securing electric vehicle batteries

Alloys: Usually from the 5xxx or 6xxx series, such as 5052 or 6061

Alloy state: H32 or H34

-

Automotive Aluminum for Chassis Components

Automotive Aluminum for Chassis ComponentsAluminum for automotive chassis parts (subframe, suspension parts):

Purpose: Reduce weight, improve handling and structural integrity

Alloys: Usually from the 5xxx or 6xxx series, such as 5052 or 6061

Alloy state: T6 or T651

Automotive Aluminum Plate for Lightweight Power System

Automotive aluminum sheets for lightweight powertrains are commonly used to manufacture lightweight components for vehicle powertrains. It is used to reduce weight while maintaining the necessary strength and efficiency of the electrical system.

Aluminum sheet has excellent properties such as high strength to weight ratio, corrosion resistance and electrical conductivity. It plays a vital role in improving fuel efficiency, improving power delivery and optimizing overall vehicle performance.

The specific application and design of lightweight powertrains may vary by vehicle type and powertrain configuration. It may include components such as lightweight battery housing, Aluminum plate for fuel tank, Heavy truck air tank, Power battery shell material, Battery cover, Electric vehicle (EV) power battery pack, power distribution unit, electrical connectors, and wiring harnesses. The use of automotive aluminum sheet in these components helps achieve weight reduction, enhances electrical conductivity and improves overall power system efficiency.

-

Automotive Aluminum Plate for Fuel Tank

Purpose: corrosion resistance, weight reduction

Alloys: 5052, 5083, 3003, 5a05

Thickness: 0.30-600mm

Width: 150-600mm

-

Aluminum Plate for Heavy Truck Air Tank

Purpose: durable and lightweight design

Alloy: 5083

Thickness: 0.30-600mm

Width: 150-600mm

-

Automotive Aluminum for Power Battery Shell

Purpose: Lightweight, protection and thermal management

Alloy: 3003, 6061

Thickness: 0.20-4.5mm

Width: 20-2650mm

-

Automotive Aluminum Foil for Battery Cells

Purpose: Electrical conductivity and thermal management

Alloys: 1235, 1060, 1070

Thickness: 0.014/0.015/0.016mm

Width: 280-120mm

-

Automotive Aluminum Plate for Battery Cover

Purpose: Lightweight, protective and aesthetic purposes

Alloy: 5754

Thickness: 0.15-600mm

Width: 20-2650mm

-

Electric Vehicle (EV) Power Battery Pack

Purpose: To house and organize battery modules

Alloy: 8021, 8079

Thickness: 0.014-0.2mm

Width: customized

Automotive Aluminum for Car Heat Shield

Automotive aluminum for automotive heat shields is specifically designed for use as vehicle heat shields. It is used to protect sensitive components from the high temperatures generated by the engine or exhaust system. The aluminum material has excellent heat resistance, lightweight properties and durability, making it ideal for this application.

Automotive Aluminum for Car Heat Shield

| Alloy | Thickness/mm | Width/mm |

|---|---|---|

| 1050-O | 0.03-1.2 | 500-1000 |

| 3005-O | 0.5 | |

| 5754-O | 0.3 |

Note that heat shields in vehicles come in many forms and designs, including those made entirely of aluminum or containing layers of aluminum. The specific alloy, thickness and construction of automotive aluminum used for automotive heat shields may vary depending on the vehicle's requirements, engine configuration and design considerations.

Aluminum for Other Automobiles

| Audio | 5052-H32, 1.44×1200×Cmm. |

|---|---|

| Engine Radiator | 5182-O, T: 0.4-0.8mm, W: 500-1000mm |

| Vacuum booster pump | 5754-O, T: 1.0-1.3mm, W: 500-1200mm |

| 5182-O, T: 1.0-1.3mm, W: 500-1200mm | |

| B pillar decorates | 3005-H22, T: 1.0-1.3mm, W: 100-300mm |

| 5754-O, T: 1.0-1.3mm, W: 100-300mm | |

| Sealing strip | 5754-H24, 3105-H28, T: 0.4-0.6mm, W: 100-500mm |

| Battery Cover / Seats | Cover: 5754-O, 1.2×1035×1200mm |

| Seat: 5754-O, 3.5×340×740mm |

Automotive Aluminum Plate Selection Guide

When selecting automotive aluminum panels for a specific application in a vehicle, several factors need to be carefully considered to ensure that the selected aluminum panels meet the performance, safety, and cost requirements of the component or part. These factors include:

- 1. Consider strength and durability

- 2. Whether the weight loss goal is achieved

- 3. Consider corrosion resistance in salt and moisture environments

- 4. Consider the ease with which aluminum sheets can be formed, stamped, or welded to create the required components

- 5. Consider heat resistance and whether the aluminum plate will be exposed to high temperatures

- 6. Determine the compatibility of the selected aluminum with the joining methods (e.g. welding, gluing) required for the component

- 7. Consider the recyclability of your chosen aluminum alloy

- 8. Evaluate the cost of aluminum panels, including material costs and manufacturing processes

- 9. Ensure that the selected aluminum plate meets the relevant safety and regulatory standards for automotive parts

- 10. If appearance is important, consider the finish and appearance of the aluminum plate

The United States, Japan and Germany are the countries where the most aluminum alloys are used in automobiles. The main advantages of automotive-grade aluminum are light weight and good heat dissipation. It also has the advantages of corrosion resistance and beautiful surface.

| Car Model | Aluminum Alloy Used in Components |

|---|---|

| Alfa Romeo 4C | Aluminum alloy body structure |

| Chevrolet Silverado | Doors, Hood, Tailgate - Aluminum alloy |

| Audi A8 | Aluminum space frame structure |

| Tesla Model S | Aluminum alloy body construction |

| Lexus LC500 | Hybrid structure of aluminum alloy and carbon fiber materials |

The automotive industry is increasingly focused on vehicle lightweighting, and aluminum sheet offers significant weight advantages over traditional steel, making it an attractive option for automakers.

Below is a list of some automakers and the material grades (qualified alloys) they mainly supply or certify.

| Car Company | Automotive Aluminum Alloy |

|---|---|

| NIO | 5182-O, 5754-O, 7075-H18 |

| GM | 5182-O, 5754-O, 6000-IH |

| Volkswagen | TL090, TL091, TL094 |

| YUNTONG | 6022-T4P, 6016-T4P, 5182-O |

| JIANGLIANG | 6016-T4P, 5182-O |

| GEELY | 6014-T4P, 5182-O, 5754-O |

| BEIQI | 5754-O, 6022-T4P, 5182-O |

| EVERGRANDE | 5182-O |

| LI | 5754-O |

| CHANGAN | 5182-O, 5754-O, 6016-T4P |

| AION | 5182-O, 6022-T4P |

Note that this list may change over time.

Lightweight advantages, emission regulations, the rise of electric vehicles, technological advancements, sustainability goals, and cost competitiveness combine to make automotive aluminum sheet a bright future in the automotive industry.

What problems are often encountered during the use of automotive aluminum plates?

During the use of automotive aluminum plates, you may encounter several common problems and challenges. These issues can affect the performance, safety, and longevity of your vehicle's aluminum components. Some common questions include:

1. Automotive aluminum is prone to corrosion

While aluminum is known for its corrosion resistance, it is not immune to corrosion, especially under certain conditions. Galvanic corrosion can occur when aluminum comes into contact with dissimilar metals or is exposed to acidic or salty environments.

2. Connection and welding cracks and deformation

Aluminum has different thermal properties compared to steel, which makes welding and joining more challenging. Without the proper techniques and equipment, problems such as welding cracks and deformation may occur.

3. Formability and stamping

Some aluminum alloys are not as formable as steel, which can create challenges in the stamping and forming processes used to produce automotive body panels. Specialized tooling and processes are often required to ensure correct molding and no defects.

4. The cost of using aluminum in automobiles is high

Although aluminum has many advantages, it is generally more expensive than steel. When using aluminum, the cost of materials and manufacturing processes can be higher, which affects the overall cost of the vehicle.

5. Aluminum recycling is more complicated when a vehicle is scrapped than when it is just recycled

Aluminum is highly recyclable, but the recycling process can be more complex than steel. Separating aluminum from other materials in end-of-life vehicles can be challenging and may impact recycling efficiency.

6. Difficulty in connecting dissimilar materials

In some automotive designs, aluminum parts need to be joined to steel or other materials. This can create challenges related to galvanic corrosion, different thermal expansion rates, and joint reliability.

7. Fatigue and cracking

Aluminum is susceptible to fatigue and stress corrosion cracking if not designed and manufactured properly. Components subjected to cyclic loads or exposed to corrosive environments must be carefully designed.

Frequently Asked Questions about Automotive Aluminum Plate?

1. How is corrosion prevented in automotive aluminum plates?

Corrosion in automotive aluminum plates is prevented through various means, including the use of corrosion-resistant alloys, surface treatments, coatings, and proper design to minimize galvanic corrosion when aluminum components come into contact with dissimilar metals.

2. Can aluminum plates be recycled in cars?

Yes, aluminum plates used in cars can be recycled. Aluminum is highly recyclable, and recycling aluminum components from end-of-life vehicles is an essential part of sustainable automotive manufacturing.

3. Are aluminum plates used in electric vehicles (EVs)?

Yes, aluminum plates are commonly used in electric vehicles (EVs) due to their lightweight properties, which help maximize battery efficiency and extend driving range. EVs often have a higher percentage of aluminum components.

4. What are some future trends in automotive aluminum plate usage?

Future trends may include the use of advanced aluminum alloys, increased use in electric and autonomous vehicles, further weight reduction to improve efficiency, and continued efforts to enhance recycling processes and sustainability.

Haomei's Partners in the Automotive Industry

It is worth noting that the specific grade, alloy and thickness of aluminum sheet used in automotive applications may vary depending on the specific requirements of the part or assembly.

The following products may interest you

-

5182 aluminum plate, which is a deformed alloy with good corrosion resistance, good weldability, corrosion resistance, medium strength and cold working properties.

-

5083 aluminum plate is a non-heat treatable alloy with high strength and corrosion resistance. We offer a wide range of sizes, thicknesses, and specifications at affordable prices to meet customer-specific needs.

-

The strength of 5754 aluminum is higher than that of 5251. 5754 aluminum plate is a high-strength non-heat-treatable alloy and has excellent corrosion resistance, good processability, and weldability.