5052 Marine Aluminum Plate Sheet

Temper: H32/H34 Can withstand salt water corrosion Easy to fabricate and weld

What is Marine Grade 5052 Aluminum?

Marine grade 5052 aluminum is an aluminum alloy specifically designed for marine applications, it is a high-strength alloy with excellent corrosion resistance.

The marine grade designation for aluminum alloys indicates that the material meets certain specifications for use in marine applications, including corrosion resistance, weldability, and durability. In the case of 5052 aluminum, the marine grade designation means that the alloy contains certain elements that enhance its corrosion resistance, such as magnesium and chromium.

5052 marine grade aluminum is the strongest alloy among the more common non-heat treatable grades. Fatigue strength is higher than most aluminum alloys. Marine grade aluminum 5052 is the perfect alloy material for freshwater lake yachts and large marine diesel tanks.

5052 aluminum is also lightweight and easy to machine, making it a popular choice for boat builders and boat builders. It can be formed, welded, and machined to create custom components and structures, and is often combined with other marine-grade materials such as stainless steel and fiberglass to create high-performance boats and marine equipment.

5052 marine grade aluminum features

5052 marine grade aluminum has excellent processability, it can be drawn or formed into complex shapes, and has a bright, transparent anode coating with excellent finishing characteristics.

- 1. Marine grade aluminum 5052 is an ideal alloy material for freshwater lake yachts, with medium static strength and good corrosion resistance.

- 2. 5052 aluminum is more suitable for manufacturing large marine diesel tanks than 5083 marine aluminum.

- 3. In humid atmosphere, 5052 marine grade aluminum plate performs well.

5052 Marine Aluminum Plate Applicable Environment

5052 marine aluminum plate is suitable for the marine environment where the material is exposed to harsh conditions such as seawater and humidity. The alloy's high corrosion resistance makes it ideal for marine applications such as hulls, decks, and other structures that come into contact with salt water.

Alloy 5052 contains magnesium which gives it excellent corrosion resistance in marine environments. Additionally, the alloy is extremely durable and can withstand exposure to UV rays, extreme temperatures, and other environmental factors that can degrade other materials over time.

5052 marine aluminum plate is an excellent choice for a wide range of marine applications requiring high strength, durability, and corrosion resistance.

5052 Marine Aluminum Plate for Sale

5052 Marine Aluminum Sheet is available in a variety of sizes, thicknesses, and widths to meet the needs of a variety of marine applications. The size of the panels will depend on the specific requirements of the project and can be custom made to fit the exact dimensions required.

5052 Marine Aluminum Plate Size Range

- Thickness ranges from 0.125" (3.175mm) to 0.5" (12.7mm)

- Typically 36" (914.4mm) to 72" (1828.8mm) wide

- The length of the panels can also be customized to meet the requirements of the project.

5052 Marine Aluminum Plate Typical Sizes

- 4' x 8' (1219mm x 2438mm)

- 4' x 10' (1219mm x 3048mm)

- 5' x 10' (1524mm x 3048mm)

- 5' x 12' (1524mm x 3658mm)

- 6' x 12' (1828mm x 3658mm)

It is important to note that the availability of some sizes may vary by supplier or manufacturer. It is always advisable to check with the supplier or manufacturer to confirm availability and discuss custom size options if required.

5052 Aluminum Alloy Temper

Usually supplied in temper H32 or H34, heat treated to provide high strength and corrosion resistance.

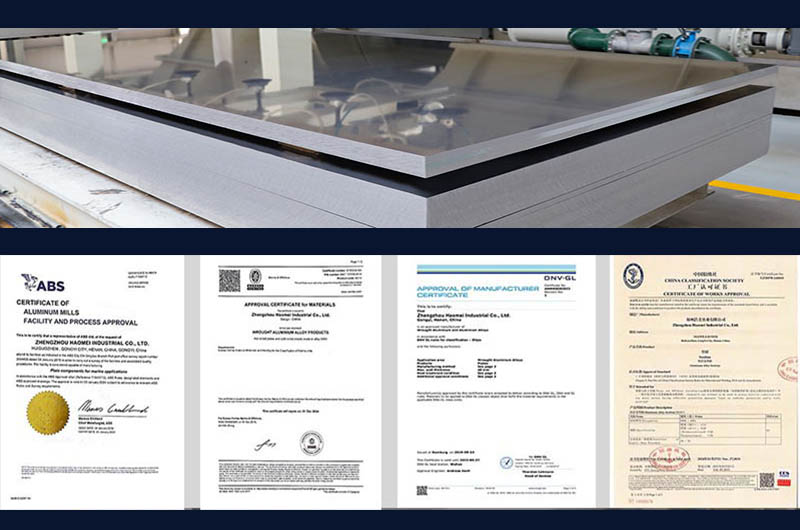

Certification

5086 marine aluminum plates can be certified by the International Organization for Standardization (ISO), American Bureau of Shipping (ABS), Det Norske Veritas (DNV), BV, CCS, and other third-party organizations.

Surface Treatment

A range of finishes are available, including satin, brushed, anodized, or painted, depending on specific application requirements.

5052 Marine Aluminum Plate Packaging

Usually supplied on wooden pallets or crates to prevent damage during shipping and handling.

Equivalent 5052 Marine Aluminum

There are several aluminum alloys similar to 5052 that are used in marine applications including 5083 and 5086.

5052 marine aluminum plate is commonly used in shipbuilding, marine structures, and other applications that require high strength, corrosion resistance, and durability in harsh marine environments. The alloy is versatile and can be formed, welded, and machined as needed to create custom shapes and components.

You might like the following content

-

5052 Aluminum Plate Sheet

5052 aluminum plate is mainly composed of magnesium and chromium. It has good processability, medium static strength, high fatigue strength, and good weldability. The fatigue strength of 5052 aluminum alloy is higher than most aluminum alloys.

-

5052 h32 Aluminum Plate Sheet

5052 H32 aluminum plate has higher fatigue strength than most alloys, 5052H32 aluminum plate has excellent corrosion resistance, especially in marine applications, and has excellent machinability.

-

5052 h34 Aluminum Plate Sheet

5052 h34 aluminum plate has enhanced corrosion resistance, workability, strength, good formability and weldability.

-

5052 h38 Aluminum Plate Sheet

5052-H38 aluminum is 5052 aluminum in H38 condition. This is the strongest state usually produced by strain hardening and stabilization. It is closely related to H18.

5052 Marine Aluminum Plate Characteristic

5052 Marine Aluminum Plate Corrosion Resistance

- 5052 marine aluminum has good corrosion resistance in marine environments but is not as strong as other marine aluminum alloys.

- 5083 marine aluminum has excellent corrosion resistance and is widely used in the construction of hulls and other marine structures.

- 5086 marine aluminum has good corrosion resistance and high strength, suitable for use in harsh marine environments.

5052 Marine Aluminum Plate Weldability

- 5052 marine aluminum has good weldability but may require preheating to avoid cracking.

- 5083 marine aluminum has excellent weldability and can be welded using a variety of techniques including MIG, TIG and friction stir welding.

- 5086 marine aluminum has good weldability but may require preheating or annealing to avoid cracking.

5052 Marine Aluminum Plate Strength

- 5052 marine aluminum has good strength, but not as strong as other marine aluminum alloys.

- 5083 marine aluminum has high strength and is often used to build ship hulls and other marine structures.

- 5086 marine aluminum has high strength and is suitable for harsh marine environments.

It is important to note that the specific properties of each marine aluminum alloy may vary depending on factors such as temper, thickness and manufacturing process. Additionally, the suitability of each alloy for a particular marine application will depend on the specific requirements and conditions of that application.

5052 Marine Aluminum Plate Data

5052 marine aluminum plate is a high strength, corrosion resistant alloy ideal for use in marine environments. It is commonly used in shipbuilding, shipbuilding and other marine applications where strength, durability and corrosion resistance are critical. The alloy is versatile and can be formed, welded and machined as needed to create custom shapes and components.

Mechanical Properties

| Alloy | Thickness mm | Tensile strength RmMPa | Extension strength RP0.2/Mpa | Elongation % | |

| A50 mm | A | ||||

| 5052 O | 3.00-6.00 | 175-215 | ≥65 | ≥18 | |

| >6.00-50.00 | 170-215 | ≥65 | ≥19 | ||

| 5052 H111 | 3.00-6.00 | 175-215 | ≥65 | ≥18 | |

| >6.00-50.00 | 170-215 | ≥65 | ≥19 | ||

| 5052 H22, H32 | 3.00-6.00 | 210-260 | ≥130 | ≥10 | |

| 5052 H112 | 6.00-12.50 | ≥190 | ≥80 | ≥7 | |

| >12.50-50.00 | ≥170 | ≥70 | - | ||

Physical Properties

- Density: 2.68g/cm3

- Melting point: 607 °C (1125 °F)

5052 Marine Aluminum Plate Chemical Composition

| Element | Percentage Range |

|---|---|

| Aluminum (Al) | 95.5% - 97.5% |

| Magnesium (Mg) | 2.2% - 2.8% |

| Chromium (Cr) | 0.15% - 0.35% |

| Iron (Fe) | 0.4% max |

| Manganese (Mn) | 0.1% max |

| Zinc (Zn) | 0.1% max |

| Silicon (Si) | 0.25% max |

| Copper (Cu) | 0.1% max |

| Titanium (Ti) | 0.15% max |

| Others | 0.05% max each, 0.15% max in total |

5052 Aluminum Plate for Boat Structures

The most common temper of 5052 marine aluminum plate is H32, which provides good strength and corrosion resistance. Other states such as H34 or H36 may also be used depending on specific application requirements.

The thickness of 5052 marine aluminum plate can vary depending on the application, with typical thicknesses ranging from 0.5mm to 6mm.

5052 marine aluminum plate is commonly used in the construction of various marine components, including:

- Boat hulls and decks

- Bulkheads and frames

- Boat and ship superstructures

- Equipment mounting plates

- Dock and marina construction

- Offshore platform components

- Oil and gas industry equipment

Specifications for 5052 marine aluminum plate may vary by manufacturer or supplier, but typically include compliance with international standards such as ASTM B209 or AMS 4016. Surface treatments may include buffing, brushing or anodizing, depending on desired appearance and corrosion resistance. Packaging can be in roll or sheet form, depending on the specific requirements of the customer or application.

Mechanical properties of 5052 aluminium grade for marine use

5052 marine grade aluminum plate applications

5052 aluminum is one of the primary materials used in manufacturing large marine structures, including LNG tanker storage tanks and large marine diesel storage tanks. Widely used in statically loaded components working in liquid or gaseous media.

1. 5052 aluminum plate for hull manufacturing

Small freshwater lake yachts generally use 5052-H32 or 5052-O aluminum plates. Since fresh water is relatively less corrosive, the aluminum panels provide sufficient strength and durability while reducing manufacturing costs.

2. 5052 aluminum plate for ship air conditioning system

Ship air conditioners need to operate for long periods of time in high humidity and highly corrosive marine environments. To protect sheet metal parts from corrosion, 5052 aluminum sheets are an ideal choice due to their strong corrosion resistance.

3. 5052 aluminum plate for other ship parts

5052 aluminum plates can also be used to manufacture components such as cable trays, storage tanks, and cabin floors for ships. This aluminum plate not only has sufficient strength and corrosion resistance, but is also relatively lightweight, helping to reduce the overall ship weight and improve ship performance.

5052 marine aluminum plate is the material of choice for high-speed ships, such as fast ferries, yachts, offshore ships, etc. Widely used in the manufacture of ship sheet metal parts, bottom plates, portholes, bottom plates, and side plates.

The specific application areas of 5052 marine grade aluminum plates include high-speed ships, fast ferries, LNG spherical storage tanks, hydrofoils, marine work boats, yachts, as well as ship cable trays and ship bottom plates.

Recommended content you might be interested in

-

5083 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5083 marine aluminum sheets meet the required standards and specifications.

-

5086 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other ship classification certifications. The 5086 ship plate is stable, corrosion-resistant, and can withstand harsh marine environments.

-

6082 marine aluminum plate is an aluminum alloy commonly used in marine applications. Like other marine-grade aluminum alloys, 6082 has a variety of properties that make it well suited for use in ships and other marine structures.

-

5754 marine aluminum plate is a deformed aluminum-magnesium alloy known for its excellent performance in the marine industry.

-

One of the key benefits of 5456 marine aluminum plate is its excellent corrosion resistance in saltwater and seawater environments. This resistance to salt water corrosion is critical to ensuring the longevity and structural integrity of marine components.

-

5383 aluminum alloy is commonly used in the construction of ships and other marine structures because they can withstand the harsh conditions of salt water and provide good structural integrity.

-

5454 aluminum plate exhibits excellent corrosion resistance, especially in marine environments. It effectively resists the corrosive effects of salt water and seawater, making it ideal for prolonged exposure to these conditions.

-

5059 marine grade aluminum plate meets specific industry or international standards, such as those set by American Bureau of Shipping (ABS), Det Norske Veritas (DNV), CCS or other organizations.

What is the Best Grade of Aluminum for Marine Use?

The best grade of marine aluminum depends on the specific requirements of the application, but the two most commonly used marine aluminum alloys are 5083 and 5086. Both alloys have excellent corrosion resistance and high strength, making them suitable for harsh marine environments.

- 5083 marine aluminum is commonly used in the construction of hulls, superstructures and other components requiring high strength and good corrosion resistance. It also has good solderability and is less prone to cracking during manufacturing.

- 5086 marine grade aluminum is similar to 5083 in terms of corrosion resistance and strength, but is slightly stronger and has a lower magnesium content. This makes it more resistant to stress corrosion cracking and better suited for use in high stress or heavily loaded areas.

Other marine-grade aluminum alloys include 5052 and 6061, which also have good corrosion resistance and strength, but may not be as suitable for some marine applications as 5083 and 5086. Ultimately, the best aluminum grade for a particular marine application will depend on factors such as the specific requirements of the application, the environment in which the aluminum will be used, and the desired properties of the finished product.