5083 Marine Aluminum Plate Sheet

Temper: O/H111/H116/H321 Precise Size The surface of the board is smooth

What is a Marine Grade Aluminum 5083 Plate?

Marine Grade Aluminum 5083 Plate is a high-strength and corrosion-resistant aluminum alloy commonly used in marine and offshore applications. It has excellent resistance to seawater and industrial chemicals and maintains its strength even in extreme environments.

5083 aluminum plate is one of the more commonly used marine aluminum plates. It can be used for the sides, keels, decks, and other parts of ships. Currently, 5083 aluminum plates can be used in everything from fishing boats and fishing boats to yachts, cruise ships, giant ships, and transport ships.

5083 aluminum alloy contains magnesium, which has high strength and excellent corrosion resistance. It is also relatively light and has good weldability, making it an ideal material for hulls, decks, and other marine structures.

5083 aluminum plate is a commonly used aluminum plate for shipbuilding among many aluminum plates. It is generally used in the H116/H321/H112 state. It is mostly used with a length and width of 2 meters × 6 meters. It has high toughness, corrosion resistance, and weldability, and meets the weight requirements of construction. Strict boat types offer great options.

Marine grade aluminum 5083 sheet generally conforms to ASTM B209 and MIL-DTL-32422 specifications and is available in a variety of thicknesses, widths, and lengths. It is often surface-coated to further enhance its corrosion resistance and durability in marine environments.

5083 marine aluminum plate is suitable for harsh marine environments such as seawater and corrosive industrial environments. This is because of its excellent resistance to corrosion and stress cracking, making it highly resistant to damage from seawater and other harsh chemicals. It is also able to maintain its strength and formability at low temperatures, which is important for applications in cold marine environments.

5083 Marine Aluminum Plate Sizes

5083 Marine Aluminum Plate is available in a variety of sizes, thicknesses, and widths to meet the diverse needs of marine applications.

- Standard thickness range: 0.2mm-500mm

- Standard width range: 500mm-2800mm

5083 Marine Aluminum Plate Typical Dimensions

Here are some common sizes of 5083 marine aluminum plates:

| Product | Size | Dimensions (mm) |

|---|---|---|

| 5083 Marine Aluminum Plate | 4ft x 8ft | 1219mm x 2438mm |

| 5084 Marine Aluminum Plate | 4ft x 10ft | 1219mm x 3048mm |

| 5085 Marine Aluminum Plate | 5ft x 10ft | 1524mm x 3048mm |

| 5086 Marine Aluminum Plate | 5ft x 12ft | 1524mm x 3657mm |

| 5087 Marine Aluminum Plate | 6ft x 10ft | 1829mm x 3048mm |

| 5088 Marine Aluminum Plate | 8ft x 20ft | 2438mm x 6096mm |

It is important to note that custom sizes and thicknesses are also available, depending on the supplier.

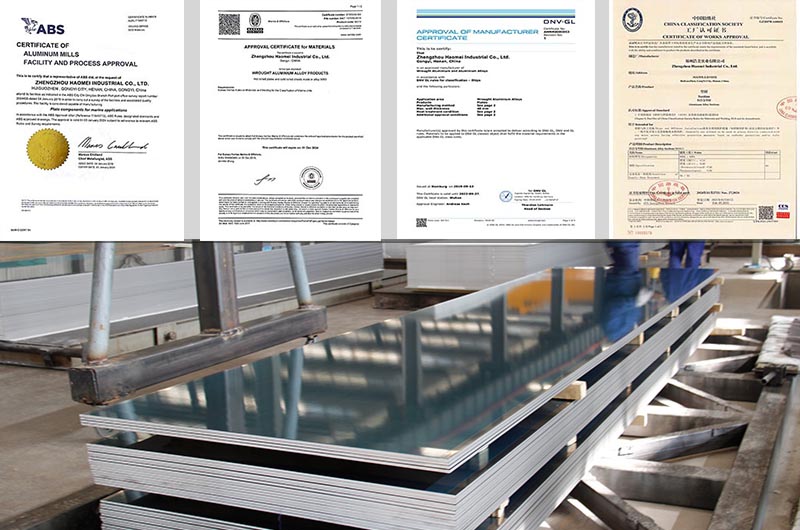

Certification

Marine grade 5083 aluminum plate should be certified by DNV, BV, or ABS classification society to ensure its quality and suitability for marine environment.

5083 Marine Aluminum Alloy Temper

- 5083 marine aluminum plate is usually supplied in O (annealed) or H32 (work hardened and stabilized) temper.

- The O state is soft and ductile, easy to form and weld.

- The H32 temper is harder and has better corrosion and fatigue resistance.

Surface Treatment

5083 marine aluminum sheet is available in a variety of finishes including burnished, brushed, anodized, and powder coated.

5083 Marine Aluminum Plate Packaging

Usually, 5083 marine aluminum sheet is packed with protective film to prevent damage during transportation. Sheets are usually wrapped in plastic or kraft paper, and then packed on wooden pallets or crates.

Equivalent 5083 Marine Aluminum

5083 marine aluminum plate is equivalent to several other aluminum alloys, including 5086, 5454, and 5456, all used in marine applications due to their excellent corrosion resistance and high strength.

5083 Marine Aluminum Plate Advantages

Compared with other aluminum alloys, 5083 aluminum alloy has the following advantages in marine applications:

- Excellent corrosion resistance: 5083 aluminum alloy has excellent corrosion resistance in marine environments, especially in salt water environments.

- High strength: 5083 aluminum alloy has high strength and is suitable for ship applications with high load-bearing capacity requirements.

- Weldability: 5083 aluminum alloy has good weldability, is easy to manufacture, and connects with other materials.

- Formability: 5083 aluminum alloy has good formability and is easy to form into complex parts and structures.

- Lightweight: 5083 aluminum alloy is relatively lightweight compared to other materials of similar strength and durability, helping to reduce overall weight and improve fuel efficiency in marine applications.

- Machinability: 5083 aluminum alloy has good machinability and can be easily machined into custom parts for marine applications.

5083 Marine Aluminum Plate Data

Mechanical Properties

- Tensile strength: 275MPa (40ksi)

- Yield strength: 125MPa (18ksi)

- Elongation: 12%

Physical Properties

- Density: 2.66 g/cm³ (0.096 lb/in³)

- Melting point: 570-640°C (1058-1184°F)

5083 Marine Aluminum Chemical Composition

| Element | Percentage (%) |

|---|---|

| Aluminum | 93.5-96.5 |

| Magnesium | 4.0-4.9 |

| Manganese | 0.40-1.0 |

| Chromium | 0.05-0.25 |

| Iron | 0.0-0.4 |

| Zinc | 0.0-0.25 |

| Titanium | 0.15 max |

| Other | 0.0-0.15 |

5083 Aluminum for Boat Structures

5083 Marine Aluminum Sheet is a versatile material for marine applications. It is commonly used in hulls, superstructures, and other structures requiring high strength, durability, and corrosion resistance in harsh marine environments.

5083 marine aluminum plate is commonly used in various parts of marine structures because of its high corrosion resistance and strength. Some examples of parts and specifications are:

Boat Hulls

5083 marine aluminum plate is commonly used in the construction of boat hulls of all shapes and sizes. Depending on the size of the hull, the thickness can vary from 2mm to 100mm.

Decks and Superstructures

5083 Marine Aluminum Sheet is also used in the construction of decks and superstructures due to its high strength and durability. Thickness ranges from 1.5mm to 30mm.

Pressure Vessel

5083 marine aluminum plate is also used in the construction of pressure vessels due to its high strength and corrosion resistance. Thickness ranges from 6mm to 100mm.

How to Choose a Marine Aluminum Plate?

The thickness of 5083 marine aluminum alloy plates is determined by the hull structure, ship specifications, and usage parts. When choosing marine aluminum plates, you need to consider a variety of factors:

1. From the perspective of lightweighting the hull, thin plates are generally used as much as possible.

2. Considering the depth of corrosion of the plate during use, the commonly used marine aluminum plates include thin plates of more than 1.6mm and thick plates of more than 30mm.

3. To prevent slipping, the deck adopts a pattern board.

4. Consider safety.

5083 h116 marine aluminum plate has medium strength, good processing performance, excellent weldability, fatigue resistance, no crack defects, and can still meet the strength and corrosion resistance requirements after processing, ensuring the safety of ships.

5. Consider the price.

5083 h111 marine aluminum plate is an aluminum-magnesium alloy. Its production process is relatively complex and the requirements for equipment are relatively high. Therefore, the price is higher than ordinary aluminum plates.

6. Consider performance stability: Marine aluminum plates in the 5083 h321 state have good performance stability.

Marine aluminum plates are divided into marine aluminum plates, inland river aluminum plates, and yacht aluminum plates. Different applications have different performance requirements for the corresponding aluminum plates.

The alloy used in marine aluminum plates is multi-purpose 5083 h111 marine aluminum plates

Aluminum plates for inland rivers are mostly 5454 marine aluminum plates

For domestic park boats, ordinary 5052 marine aluminum plates are more suitable.

What are the differences between the Different Temper of 5083 Marine Aluminum Plates?

The H state is a common state of finished aluminum plates. It means that the aluminum plates have been work-hardened to increase their strength. The following is subdivided into multiple states.

- The 5083 h111 state is suitable for products that have undergone a moderate amount of work hardening after final annealing, but the degree of work hardening is not as good as the H11 state.

- The 5083 H112 state is suitable for the free processing state of hot-rolled plates and hot-formed products.

- The 5083 H116 status is suitable for products made of 5 series alloys with magnesium content ≥4.0%.

- The performance stability of the 5083 h321 state is good.

Typical 5083 Marine Aluminum Plate

5083 marine aluminum plate is available in a variety of tempers or tempers, and the choice of temper depends on the specific application and performance requirements.

-

5083 O Marine Aluminum Plate

5083 O Marine Aluminum PlateO (annealed) is a softer state, suitable for forming and bending.

O state: The 5083-O aluminum plate has good formability, high corrosion resistance, and excellent weldability.

O is commonly used for hulls, bulkheads, and internal components of small boats.

-

5083 H111 Marine Aluminum Plate

5083 H111 Marine Aluminum PlateH111 is relatively soft in state and has good ductility, but its strength is limited. Suitable for forming and welding as well as for products requiring bending and forming.

H111 It can be used for non-structural parts in the shipbuilding industry, such as boat decks and furniture.

H111 state: 5083-H111 aluminum plate also has good corrosion resistance and welding performance.

-

5083 H116 Marine Aluminum Plate

5083 H116 Marine Aluminum PlateH116 is a medium-strength temper with good formability, weldability, and corrosion resistance.

H116 state: 5083-H116 aluminum plate has high strength, good weldability, and corrosion resistance. Widely used in shipbuilding and other industries.

H116 is commonly used in structural parts of small and medium-sized ships, such as hulls, bulkheads, decks, etc.

-

5083 H321 Marine Aluminum Plate

5083 H321 Marine Aluminum PlateH321 is a high-strength temper with excellent corrosion resistance for structural applications in harsh marine environments.

H321 state: 5083-H321 aluminum plate has excellent resistance to stress corrosion cracking, good welding performance, and high strength.

H321 It is generally used in the manufacture of hulls, superstructures, and large ship structures such as tanker hulls, pressure vessels, and offshore platforms.

5083 Marine Aluminum Plate Production Process

Commonly used 5083 marine aluminum plates include 5083 h111, 5083 h116, and 5083 h321. 5083 marine aluminum plates are mass-produced by hot rolling, winning unanimous praise from users and obtaining relevant certifications.

The production of 5083 marine aluminum plates usually includes the following main steps, which can ensure the quality and performance of the product and obtain relevant certifications.

- Raw material preparation: Select high-quality 5083 aluminum alloy material to ensure that it meets relevant standards and requirements.

- Smelting and casting: The 5083 aluminum alloy material is heated to the appropriate temperature and then smelted. The smelted liquid aluminum can be cast into aluminum plate blanks of different sizes and shapes.

- Hot continuous rolling: The aluminum plate blank undergoes a hot continuous rolling process, that is, the blank is continuously rolled through a rolling mill at high temperatures to the required plate thickness. This process requires strict control of temperature and rolling force to ensure the performance and surface quality of the final product.

- Cold roll preparation: After completing hot rolling, the aluminum plate may need to be cold rolled to further finely adjust its size and surface quality. This helps ensure that the 5083 marine aluminum plate reaches the specified standard size and flatness.

- Cutting and trimming: Cut the 5083 marine aluminum plate into the required length and width according to the user's requirements. This can be done with shears, saws, or other cutting equipment.

- Surface Treatment: Aluminum panels can undergo various surface treatments, such as anodizing, coating, or spraying, to improve their corrosion resistance and appearance.

- Testing and Quality Control: During the production process, various testing and quality control steps are required to ensure that 5083 marine aluminum plates comply with relevant standards and specifications. This includes physical property testing, chemical composition analysis, dimensional measurements visual inspection, etc.

- Packaging and Delivery: Finally, the 5083 marine aluminum sheets are packaged to ensure protection from damage during transportation and storage. The product can then be delivered to customers with critical acclaim and relevant certifications.

Recommended content you might be interested in

-

5086 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other ship classification certifications. The 5086 ship plate is stable, corrosion-resistant, and can withstand harsh marine environments.

-

5052 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5052 marine aluminum sheets meet the required standards and specifications.

-

6082 marine aluminum plate is an aluminum alloy commonly used in marine applications. Like other marine-grade aluminum alloys, 6082 has a variety of properties that make it well suited for use in ships and other marine structures.

-

5754 marine aluminum plate is a deformed aluminum-magnesium alloy known for its excellent performance in the marine industry.

-

One of the key benefits of 5456 marine aluminum plate is its excellent corrosion resistance in saltwater and seawater environments. This resistance to salt water corrosion is critical to ensuring the longevity and structural integrity of marine components.

-

5383 aluminum alloy is commonly used in the construction of ships and other marine structures because they can withstand the harsh conditions of salt water and provide good structural integrity.

-

5454 aluminum plate exhibits excellent corrosion resistance, especially in marine environments. It effectively resists the corrosive effects of salt water and seawater, making it ideal for prolonged exposure to these conditions.

-

5059 marine grade aluminum plate meets specific industry or international standards, such as those set by American Bureau of Shipping (ABS), Det Norske Veritas (DNV), CCS or other organizations.

You might like the following content

-

5083 Aluminum Plate Sheet

5083 aluminum plate is a non-heat treatable alloy with high strength and corrosion resistance. We offer a wide range of sizes, thicknesses, and specifications at affordable prices to meet customer-specific needs.

-

5083 H32 Aluminum Plate Sheet

5083 H32 aluminum plate has excellent corrosion resistance, good weldability, and high strength. The surface of the 5083 h32 Aluminum Plate has no oil spots, no waves, no scratches, no roll marks, and meets the production standards.

-

5083 h111 Aluminum Plate Sheet

5083 aluminum is the strongest non-heat-treatable aluminum alloy. 5083 H111 aluminum is known for its superior performance in extreme environments, and 5083 O H111 sheet is used in marine and shipbuilding applications.

-

5083 h112 Aluminum Plate Sheet

5083 h1112 aluminum has very good corrosion resistance and medium strength, and it is very suitable for welding. 5083 h112 aluminum plate can be used in transportation, pressure vessels, cryogenic equipment, towers and drilling platforms, gas/oil pipelines, ordnance and armor plates.

-

5083 h116 Aluminum Plate Sheet

5083 H116 aluminum plate is often used in the marine field because of its high low-temperature strength and corrosion resistance, which can extend the service life of the ship. Because of its light weight, it can better increase the ship's speed.

-

5083 o Aluminum Plate Sheet

5083-O aluminum is 5083 aluminum in the annealed state. It has the highest ductility compared to other variants of 5083 aluminum.