5383 Marine Aluminum Plate

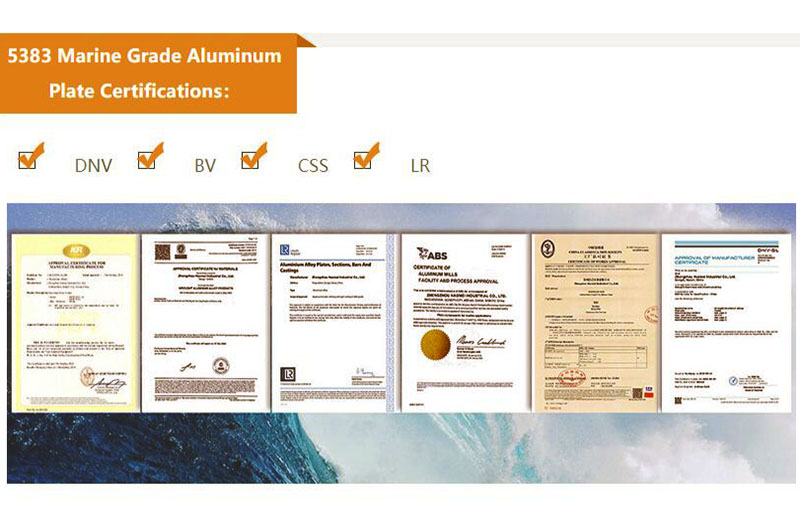

Temper: h116,h32 Certification: ABS/DNV/CCS

5383 Marine Aluminum Sheet is commonly used in marine applications due to its corrosion resistance and high strength. 5383 aluminum alloy is commonly used in the construction of ships and other marine structures because they can withstand the harsh conditions of salt water and provide good structural integrity.

5383 aluminum plate is an upgraded version of alloy 5083, which optimizes shipbuilding productivity and ship performance. 5383 aluminum plate is a type of deformed aluminum alloy with magnesium as the main alloy additive. 5383 aluminum plate has higher corrosion resistance, increased durability, fatigue strength and good welding performance.

5383 improves mechanical properties, increasing strength by 10% compared to 5083, and improves performance by reducing the number of weld vessels or dimensions and increasing the yield point of welded structures by 15%.

Haomei Aluminum's marine grade 5383 aluminum plate is the flagship product in the field of marine aluminum plates and plays an important role in ship manufacturing. Certificates from BV, DNV/GL, CCS, ABS, LR, KR, RINA and other classification societies can be provided upon request.

Common Product Names 5383

The full name of 5383 aluminum alloy is AA5383 in the United States, EN AW-5383 in Europe, and the UNS number is A95383. Additionally, the EN chemical name is AlMg4, 5Mn0, 9.

When to Choose 5383 Aluminum Plate?

You may consider choosing 5383 aluminum plate for marine applications under the following conditions:

- High Corrosion Exposure: If your project involves components that are frequently exposed to salt water or corrosive marine environments, 5383 is an excellent choice due to its superior corrosion resistance.

- Structural components: When you require high-strength aluminum for structural components of a ship, such as hulls, superstructures or bulkheads, the H116 status of 5383 is suitable.

- Welded Construction: If your application requires welding aluminum components, the weldability of 5383 may be advantageous.

Characteristics of 5383 aluminum

Since Zr is added to the 5383 alloy composition, Zr can combine with Al to form an Al3Zr phase, which can significantly increase the strength and recrystallization temperature of the 5383 aluminum alloy. Therefore, compared with 5083 aluminum alloy, 5383 aluminum alloy has higher strength and better welding performance.

The addition of Zr element only increases the production cost of 5383 aluminum alloy by about US$20/ton, so 5383 aluminum alloy has the potential to replace 5083 aluminum alloy.

Specifications of Marine Grade 5383 Aluminium Plate

| Alloy | Temper | Thickness (mm) | Width (mm) | Application |

|---|---|---|---|---|

| 5383 | O/H111/H112/H116/H321 | 10-50 | ≤3600 | Marine, ship |

| 5383 | O, H111 | 3–10 | ≤2600 | tanker |

| 5383 | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, H116, H321 | 0.5-500 | 20-2650 | LNG storage tanks, gas storage cylinders, GIS shells, car body skins, flange materials, etc. |

5383 Marine Aluminum Welding

5383 aluminum alloy is a type of forged alloy that is easily weldable and formable.

5383 has excellent weldability in all standard methods, especially GMAW (MIG) and GTAW (TIG). Filler alloy 5356 is the most common filler alloy, depending on the alloy joining combination. Other 5xxx series filler alloys are available in varying strengths.

5383 Marine Aluminum Corrosion Resistance

Marine Grade 5383 is tested in accordance with ASTM B928 to ensure the product shows no signs of spalling corrosion. Intergranular corrosion (IGC) and stress corrosion (SCC) testing (acid interacid testing ASTM G44 and G67) and ASSET testing (ASTM G66) performed on 5383 base material and weld metal samples showed significantly better resistance than standard 5083-H116. Corrosion properties. Accelerated (artificial aging at 100C for 7 days) and natural exposure (marine atmosphere and immersion) have proven that the long-term corrosion resistance of 5383 is significantly improved over 5083-H116/H321.

Mechanical Properties of 5383 Marine Aluminium Plate

The typical states commonly used for 5383 marine grade aluminum plates are:

- 5383 h32 marine aluminum plate

- 5383 H116 marine aluminum plate

| Alloy and Temper | Thickness mm | Tensile Strength | Elongation (% min in 50mm) | ||||

| Over | Up to | Ultimate Rm (MPa) | Yield Rp (MPa) | ||||

| Min | Max | Min | Max | ||||

| 5383-H321 | 3 | 50 | 305 | 380 | 220 | – | 10 |

| 5383-H116 | 3 | 50 | 305 | – | 220 | – | 10 |

Cold Forming of 5383 Aluminum Sheet Bend radii

Recommended Minimum Bend Radii for 90-Degree Cold Forming of Sheet of 5383 (Reference test method – ASTM E290) Thickness (t)

| Temper | 3mm-6mm | 6mm – 12.5mm | 12.5mm – 40mm |

| 5383 O | 1.5t | – | – |

| 5383 H111 | – | 2.5t | – |

| 5383 H321 | 2t | 2.5t | 4t |

| 5383 H116 | 2t | 2.5t | 4t |

How to Choose 5383 Marine Grade Aluminum Plate?

5383 H32 marine aluminum plate

5383 h32 aluminum plate provides good formability and medium strength. 5383 h32 marine aluminum plate is typically used in applications where strength and corrosion resistance are important, such as marine environments.

5383 H116 marine aluminum plate

5383 H116 aluminum plate provides excellent corrosion resistance and high strength, making it ideal for marine applications where the aluminum will be exposed to harsh saltwater conditions and needs to withstand higher stresses.

The choice between H32 and H116 will depend on the specific requirements of your marine application.

- H116 has better corrosion resistance and higher strength, making it more suitable for structural components that bear heavy loads and corrosive marine environments.

- H32 has good formability and can be used in less demanding applications where formability is a priority.

5383 Marine Aluminum Plate Chemical Composition

- Magnesium (Mg): To enhance the strength and corrosion resistance of 5383 alloy.

- Manganese (Mn): Manganese is often added to improve grain structure and mechanical properties.

- Chromium (Cr): Adding chromium further enhances the corrosion resistance of 5383 aluminum.

- Zinc (Zn): Zinc may be present in small amounts to provide additional strength.

| Element | Composition (%) |

|---|---|

| Aluminum (Al) | 90.7 |

| Magnesium (Mg) | 4.5 |

| Manganese (Mn) | 0.7 |

| Chromium (Cr) | 0.1 |

| Copper (Cu) | 3.3 |

| Iron (Fe) | 0.35 |

| Zinc (Zn) | 0.2 |

| Titanium (Ti) | 0.15 |

| Silicon (Si) | 0.4 |

| Other Elements | 0.05 (each) max |

5383 Marine Aluminum Alloy Applications

5383 aluminum alloy is a high-strength alloy known for its excellent corrosion resistance and is suitable for marine environments. It is frequently used in shipbuilding, offshore platforms and other marine structures.

5383 marine grade aluminum plate is widely used in high-speed ships, such as hydrofoils, hovercrafts, speedboats, cruise ships, sailboats, catamarans, sea cruise ships, etc. The application parts include ship decks, hull parts, ship sides, bottom shells, engine seats, decks, and roofs. and side plate ships, etc.

5383 aluminum plate is mainly used in the shipbuilding industry, examples are as follows:

- 1. Stronger welded aluminum structures such as ship hulls and cruise ship superstructures.

- 2. Small ships less than 50m in length.

- 3. Work boat with strong hardness.

- 4. Interior partitions and decoration of luxury yachts.

- 5. Large ships exceeding 50m in length.

5383 has many applications on ships:

- 5383 marine aluminum plates

- 5383 marine aluminum sheets

- 5383 marine aluminum profiles

- 5383 marine aluminum bars

- 5383 marine aluminum round bars

- 5383 marine aluminum hexagon bars

- 5383 marine aluminum square bars

5383 marine aluminum plate (EN AW-5383) is used in various marine applications due to its excellent corrosion resistance and moderate to high strength. Here are specific application areas and examples where 5383 marine aluminum plate is commonly utilized:

1.Ship Hulls

Application Example: The primary structure of a ship, the hull, often incorporates 5383 aluminum plate due to its high strength and corrosion resistance. This ensures the hull can withstand the rigors of saltwater environments.

2.Superstructures

Application Example: The upper decks and superstructures of ships, including cabins and control rooms, benefit from 5383 aluminum to reduce weight while maintaining structural integrity.

3.Bulkheads and Compartments

Application Example: Bulkheads and compartments within a ship, which help separate different sections of the vessel, often use 5383 aluminum plate to ensure durability and corrosion resistance.

4.Boat Building

Application Example: Smaller boats, yachts, and recreational vessels utilize 5383 aluminum plate for various components, including the hull, decks, and cabins, to enhance longevity and performance.

5.Offshore Platforms

Application Example: In offshore oil and gas platforms, 5383 aluminum plate can be used in structures, walkways, and equipment subjected to the corrosive effects of seawater.

6.Marine Equipment and Accessories

Application Example: Various marine equipment like davits, cranes, gangways, and ladders incorporate 5383 aluminum for its corrosion resistance and lightweight properties.

7.Underwater Components

Application Example: Diving bells, submersibles, and other underwater equipment use 5383 aluminum for components that come into direct contact with seawater.

8.Fishing Vessels

Application Example: Components such as fish holds, refrigeration units, and structures on fishing boats benefit from 5383 aluminum's resistance to saltwater and harsh marine conditions.

9.Marine Architectural Features

Application Example: Marinas, piers, and other waterfront structures often employ 5383 aluminum for architectural elements like railings, gangways, and decorative components.

10.Recreational and Cruise Ships

Application Example: Larger passenger vessels, such as cruise ships and ferries, use 5383 aluminum plate for various structural elements and interior applications, ensuring safety and aesthetics.

11.Naval and Military Vessels

Application Example: Military ships, including naval vessels and patrol boats, use 5383 aluminum in various applications, such as hulls, radar masts, and weapon systems, for its durability and lightweight properties.

These are just a few examples of where 5383 marine aluminum plate is applied in the marine industry. Its combination of strength and corrosion resistance makes it a preferred choice for components and structures that must endure the challenging conditions of the open sea and other marine environments.

Hot Topics Related to 5383 Marine Aluminum

- What is marine grade 5083 Aluminium?

- Is 6063 aluminum marine grade?

- What is the best marine grade aluminum?

- What is 3003 aluminum marine grade?

- 5383 aluminum

- marine grade aluminum 5083

- marine-grade aluminum

- is 3003 aluminum marine grade

- 3m marine aluminum polish

- 5083 aluminum suppliers

- marine grade aluminum 5083

- 5083 aluminum sheet price

- aluminum sheets for boat decking

Recommended content you might be interested in

-

5083 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5083 marine aluminum sheets meet the required standards and specifications.

-

5086 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other ship classification certifications. The 5086 ship plate is stable, corrosion-resistant, and can withstand harsh marine environments.

-

5052 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5052 marine aluminum sheets meet the required standards and specifications.

-

6082 marine aluminum plate is an aluminum alloy commonly used in marine applications. Like other marine-grade aluminum alloys, 6082 has a variety of properties that make it well suited for use in ships and other marine structures.

-

5754 marine aluminum plate is a deformed aluminum-magnesium alloy known for its excellent performance in the marine industry.

-

One of the key benefits of 5456 marine aluminum plate is its excellent corrosion resistance in saltwater and seawater environments. This resistance to salt water corrosion is critical to ensuring the longevity and structural integrity of marine components.

-

5454 aluminum plate exhibits excellent corrosion resistance, especially in marine environments. It effectively resists the corrosive effects of salt water and seawater, making it ideal for prolonged exposure to these conditions.

-

5059 marine grade aluminum plate meets specific industry or international standards, such as those set by American Bureau of Shipping (ABS), Det Norske Veritas (DNV), CCS or other organizations.