5454 Marine Aluminum Plate

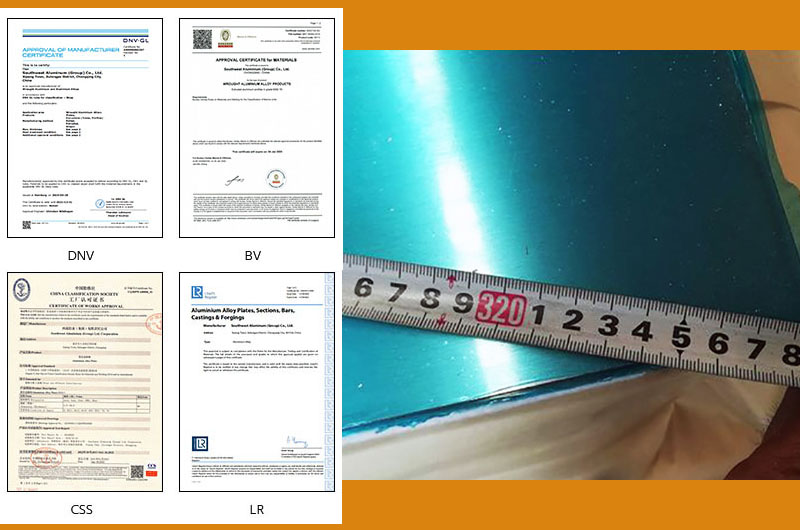

Temper: h22 Certification: ABS/DNV/CCS

Aluminum is a versatile material with a wide range of applications, including use in the maritime and marine industry.

Marine aluminum alloys have unique properties that make them ideal for use on ships, vessels, offshore platforms and other marine structures. Among these alloys, 5454 aluminum stands out for its excellent corrosion resistance, strength and formability. It is a wrought aluminum-magnesium alloy that is closely related to 5456, but has a slightly different chemical composition that gives it unique properties.

5454 marine aluminum plate is an aluminum-magnesium alloy with slightly higher strength than 5052 marine grade aluminum plate, as well as better corrosion resistance and weldability, especially at high temperatures. This material, like 5154, combines medium-to-high strength and excellent weldability, and is often used in pressure vessels, ships and other fields that require welded structures.

As a sister alloy to 5083, 5454 has lower stress corrosion levels in the 150°F to 300°F range. Common uses include tankers, car bodies, and chemical processing tanks.

In harsh marine environments, when structures and components such as hulls and decks are exposed to seawater, 5454 performs well and can resist saltwater corrosion, improving the durability and overall performance of the ship. Compared with traditional ship building materials, 5454 has a lower density and weight, which can reduce ship weight, increase load-bearing capacity and fuel efficiency, and improve maneuverability and navigation performance. At the same time, it can also meet the requirements of various geometric shapes and sizes of the hull, and can undergo a variety of processing techniques to adapt to the needs of different ship designs.

Marine grade 5454 aluminum plate can withstand corrosion in seawater and humid environments. This allows the ship to be used for extended periods of time in harsh marine environments without being easily damaged. It can also provide the structural support needed by the hull, increasing its strength and stability. This improves the overall performance and durability of the vessel.

Performance Characteristics of 5454 Marine Aluminum Plate

To understand why 5454 marine aluminum plate is favored in marine construction, let’s take a look at its key performance features:

1. Corrosion Resistance

5454 aluminum plate exhibits excellent corrosion resistance, especially in marine environments. It effectively resists the corrosive effects of salt water and seawater, making it ideal for prolonged exposure to these conditions.

2. Strength

This alloy has good tensile and yield strengths, ensuring that marine structures built with 5454 aluminum can withstand harsh marine conditions.

3. Extensibility

5454 marine aluminum plate has excellent ductility, which means it can withstand the dynamic stresses experienced by ships and structures, such as those caused by waves, wind and cargo handling.

4. Machinability

It can be machined and processed easily, facilitating efficient manufacturing processes and enabling the production of complex marine components.

5. Impact Resistance

The alloy maintains its mechanical properties even at sub-zero temperatures, which is critical for ships sailing in colder waters

Params of 5454 marine grade aluminum plate

- Alloy grade: 5454

- Status: O, H111, H112, H24, H32, H34, H36, H38

- Size: T(1.5-120) XW(1000-3100) X (1000-13000)mm

- Certificate: CCS, DNV, NK, CCS, ABS, BV, LR, KR.

- Production standard: ASTM B928/B928M-15, ASTM B928/B928M-21, ISO 12215-5:2019

- Product features: long width, corrosion resistance, small elastic modulus, easy to weld, easy to process, no low temperature brittleness, no magnetism.

- Application: Aluminum is the first choice material for designers of high-speed ferries, LNG spherical storage tanks, hydrofoils, marine work boats, yachts and other high-speed vessels. It is widely used in ship side plates, bottom plates, portholes, ship container loads, etc. Boards, side panels, etc.

The tolerance of 5454 marine grade aluminum plate sheet

| Thickness | 3.00-20.00 | >20.00-50.00 |

| Width | 1 000-2 400 | 1 000-3 500 |

| Length | 1 000-11 000 | 1 000-20 000 |

Mechanical Properties of 5454 Marine Aluminum Plate

5454 marine aluminum plate exhibits excellent mechanical properties that make it well-suited for marine applications:

| Alloy Temper | Thickness mm | Tensile strength RmMPa | Extension strength RP0.2/Mpa |

| 5454 O | 3.00-6.00 | 215-285 | ≥85 |

| >6.00-12.50 | 215-285 | ≥85 | |

| >12.50-50.00 | 215-285 | ≥85 | |

| 5454 H111 | 3.00-6.00 | 215-285 | ≥85 |

| >6.00-12.50 | 215-285 | ≥85 | |

| >12.50-50.00 | 215-285 | ≥85 | |

| 5454 H22, H32 | 3.00-6.00 | 250-305 | ≥180 |

| 5454 H112 | 6.00-50.00 | ≥220 | ≥125 |

Chemical Composition of 5454 Marine Aluminum Plate

| Element | Composition Range (%) |

|---|---|

| Aluminum (Al) | 95.7% - 97.4% |

| Magnesium (Mg) | 2.4% - 3.0% |

| Manganese (Mn) | 0.3% - 0.9% |

| Chromium (Cr) | less than 0.10% |

| Zinc (Zn) | less than 0.25% |

| Copper (Cu) | less than 0.10% |

| Iron (Fe) | less than 0.40% |

| Silicon (Si) | less than 0.25% |

| Titanium (Ti) | less than 0.20% |

Applications of 5454 marine grade aluminum plate on ship hull

5454 marine grade aluminum plates are widely used in the manufacture of various ships, including but not limited to yachts, fishing boats, commercial ships, etc. It is often used as hull plates and structural parts, and is also used to manufacture floating docks, platforms, pontoons and other offshore structures. This aluminum plate has excellent corrosion resistance and strength properties to handle the challenging conditions found in offshore environments.

In addition to its applications in ship hulls and structures, 5454 marine-grade aluminum sheets are also used in the manufacture of marine equipment and components, such as fuel tanks, hatch covers, bulkheads and deckhouses. Its excellent corrosion resistance ensures long-term use in marine conditions, improving the durability and life of the ship.

Due to aluminum's lightweight properties, this type of aluminum sheet is also ideal for building lightweight, high-speed vessels such as ferries and passenger ships. Its use can reduce the weight of ships, improve fuel efficiency and increase operating speed.

In addition, 5454 marine grade aluminum plates are also suitable for naval and military ships, such as patrol boats, fast attack boats and other special ships. Its strength, corrosion resistance and lightweight properties make it ideal for military applications requiring high performance and durability.

10 Reasons to Choose 5454 Marine Aluminum Plate

- 1. Welding strength: 5454 marine aluminum plate maintains its strength in welded joints, which is critical to the structural integrity of marine components. This ensures that the welded structure can withstand the dynamic stresses and loads encountered at sea.

- 2. Anodizing ability: Aluminum alloys, including 5454, are very suitable for anodizing processes. Anodizing further enhances the alloy's corrosion resistance and provides a protective surface finish, making it more durable in marine environments.

- 3. Non-toxic and non-magnetic: Aluminum is non-toxic and non-magnetic, making it suitable for applications requiring these properties. This is especially important for industries such as fishing, where non-toxic materials are preferred to avoid seafood contamination.

- 4. Surface treatment: The surface of 5454 marine aluminum plate can be treated with various coatings and finishes to enhance its beauty and provide additional protection against environmental factors.

- 5. Lightweight Design: Aluminum is lightweight in nature, which helps improve the fuel efficiency and payload capacity of the ship. The weight savings achieved with 5454 marine aluminum plate can save costs and improve vessel performance.

- 6. Recyclability: Aluminum is a highly sustainable material as it can be recycled indefinitely without losing its properties. This recyclability is consistent with the growing focus on environmental sustainability in marine architecture.

- 7. Durability: The durability of 5454 marine aluminum plate is reflected in its long service life, even in challenging marine conditions. This longevity minimizes downtime for maintenance and repairs, thereby reducing operating costs.

- 8. Fire Resistance: Aluminum is naturally fire resistant, which is a valuable safety feature in marine applications where fire safety is a key consideration.

- 9. Processing Diversity: Aluminum alloys are versatile and can be easily processed into various forms, from sheets to complex structures, to meet the specific needs of different marine applications.

- 10. Material traceability: Manufacturers often provide detailed traceability of the materials they supply, ensuring quality control and compliance with specifications for marine construction projects.

These emphasize the overall advantages of 5454 marine aluminum sheet, making it an attractive and versatile material for a variety of marine projects, from recreational boats to commercial vessels and offshore installations. Its strength, corrosion resistance and adaptability to different surface treatments and finishes make it a reliable choice for marine engineers and architects.

Recommended content you might be interested in

-

5083 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5083 marine aluminum sheets meet the required standards and specifications.

-

5086 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other ship classification certifications. The 5086 ship plate is stable, corrosion-resistant, and can withstand harsh marine environments.

-

5052 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5052 marine aluminum sheets meet the required standards and specifications.

-

6082 marine aluminum plate is an aluminum alloy commonly used in marine applications. Like other marine-grade aluminum alloys, 6082 has a variety of properties that make it well suited for use in ships and other marine structures.

-

5754 marine aluminum plate is a deformed aluminum-magnesium alloy known for its excellent performance in the marine industry.

-

One of the key benefits of 5456 marine aluminum plate is its excellent corrosion resistance in saltwater and seawater environments. This resistance to salt water corrosion is critical to ensuring the longevity and structural integrity of marine components.

-

5383 aluminum alloy is commonly used in the construction of ships and other marine structures because they can withstand the harsh conditions of salt water and provide good structural integrity.

-

5059 marine grade aluminum plate meets specific industry or international standards, such as those set by American Bureau of Shipping (ABS), Det Norske Veritas (DNV), CCS or other organizations.

You might like the following content

-

5454 Aluminum Plate Sheet

The strength of 5454 antirust aluminum is about 20% higher than that of 5052, and its characteristics are roughly the same as that of 5154, but its corrosion resistance is better than that of 5154 in severe environments.

-

5454 h32 Aluminum Plate Sheet

5454 h32 aluminum plate It has medium to high strength and excellent weldability, 5454 h32 has very good corrosion resistance, especially to seawater and general environmental conditions.

-

5454 h34 Aluminum Plate Sheet

5454-H34 Aluminum is 5454 aluminum in H34 condition. To achieve this temper, the metal needs to be strain hardened and then stabilized to a strength somewhere between annealed (O) and fully hard (H38).

-

5454 h111 Aluminum Plate Sheet

5454-H111 Aluminum is 5454 Aluminum in H111 condition. To achieve this temper, the metal is strain hardened below the strength allowed by H11 (1/8 hardness). 5454 H111 aluminum plate has good corrosion resistance and good formability.

-

5456 Aluminum Plate

5456 anti-rust aluminum is a kind of heat-resistant hard aluminum, mainly used for parts working at 250-350°C, such as compressor blades, discs, and plate bearings, as well as welded parts working at room temperature and high temperature, such as containers, sealed warehouses, etc.