5754 Marine Aluminum Plate

Temper: H111/H112/H22 High Strength

Introduction to 5754 Marine Aluminum Plate

Aluminum alloys like 5754 have revolutionized the way we design and build marine structures. They offer a unique combination of strength, lightweight properties and corrosion resistance, which are critical for a variety of marine applications. 5754 marine aluminum plate is a deformed aluminum-magnesium alloy known for its excellent performance in the marine industry.

5754 marine grade aluminum plate has excellent corrosion resistance, especially to seawater and industrially polluted atmospheres. 5754 aluminum alloy has the characteristics of moderate strength, good corrosion resistance, good weldability, and easy processing and forming. This high strength makes 5754 very suitable for ship applications that require both strength and seawater corrosion resistance.

5754 marine grade aluminum plate has excellent corrosion resistance, especially to seawater and industrially polluted atmospheres. Aluminum alloy 5754 marine grade aluminum plate is commonly used in shipbuilding, marine applications, and finishing industry equipment.

5754 aluminum is a deformed alloy that can be formed by rolling, extrusion and forging. One disadvantage of this aluminum is that it is not heat treatable and cannot be used for casting.

5754 marine grade aluminum alloy plate is a low magnesium marine aluminum alloy used in the shipbuilding industry. It has good weldability and moderate strength, especially high high temperature adaptability, making it the alloy of choice for storing hot liquids.

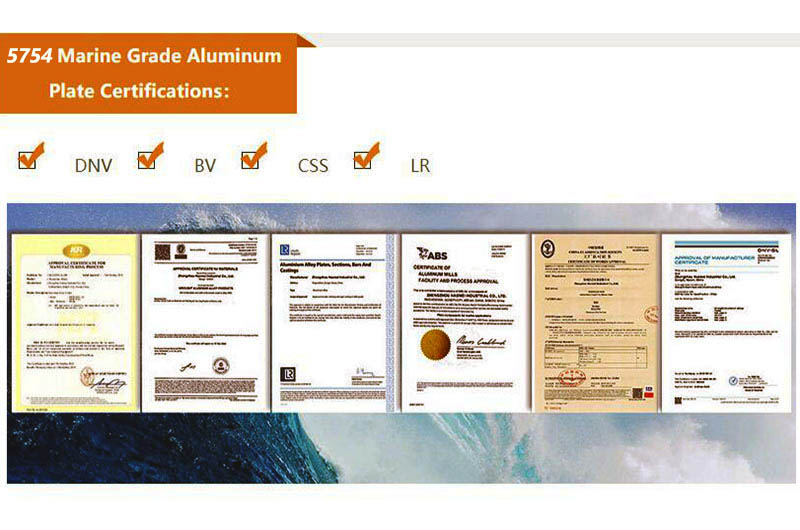

5754 Marine Aluminum Plate Certificates

Haomei Aluminum's marine grade 5754 aluminum plate is the main product in the field of marine aluminum plate and plays an important role in ship manufacturing. Certificates from classification societies such as BV, DNV/GL, CCS, ABS, LR, KR, and RINA can be provided upon request.

5754 Marine Grade Aluminum Plate Specifications

| Product | Thickness(mm) | Width(mm) | Length(mm) |

|---|---|---|---|

| Thick plate | 6~260 | 800~4300 | 1000~38000 |

| Aluminum sheet | 0.2~6 | 1000~2600 | 1000~12000 |

| Aluminum coil | Hot rolled coil | 2.2~12 | 1480~2600 |

| Cold rolled coil | 0.2~3.5 | 500~2600 | |

| Temper | O, H111. H112, H116, H24, H32, H321 | ||

| Certificate | DNV, NK, CCS, ABS, BV, LR | ||

Features of 5754 Marine Grade Aluminum Plate

- Good corrosion resistance: 5754 marine aluminum plate has good corrosion resistance. 5754 aluminum alloy is a stronger material than 5251 and has good processability. Its main characteristic is that the alloy offers excellent resistance to seawater and industrial chemical corrosion.

- High strength: 5754 marine aluminum plate has high strength and can provide sufficient structural strength to meet the working load and stress requirements of ships in different waters and harsh environments.

- Good weldability: 5754 marine aluminum plate has good weldability, which facilitates the welding process during ship construction and repair to achieve structural connection and repair.

- Good processing performance: 5754 marine aluminum plate is easy to process and shape, and can be cut, bent, stretched, etc. to meet different ship design and manufacturing requirements.

- Excellent reliability: 5754 marine aluminum plate has undergone reasonable alloy design and heat treatment process, and its performance is stable and reliable. It can maintain a long life and good performance during the use of ships.

Property of 5754 Marine Grade Aluminum Plate

| Alloy Temper | Thickness mm | Tension strength RmMPa | Specified non-proportional elongation strength Rp0.2 Mpa | Elongation % | |

| 5754 O | 3.00-50.00 | 190-240 | ≥80 | ≥18 | ≥17 |

| 5754 H111 | 3.00-50.00 | 190-240 | ≥80 | ≥18 | ≥17 |

| 5754 H22, H32 | 3.00-6.00 | 220-270 | ≥130 | ≥11 | - |

| 5754 H112 | 6.00-12.50 | ≥190 | ≥100 | ≥12 | - |

| >12.50-25.00 | ≥190 | ≥90 | - | ≥10 | |

| >25.00-50.00 | ≥190 | ≥80 | - | ≥12 | |

Chemical Composition of 5754 Marine Aluminum Plate

The chemical composition of an alloy is a key factor in determining its properties and suitability for a specific application. In the case of 5754 marine aluminum plate, its typical composition consists of the following elements:

| Element | Composition Range |

| SI | 0.40% |

| FE | 0.40% |

| MN | 0.50% |

| MG | 2.6-3.2% |

| CR | 0.30% |

| Other | 0.05% |

Aluminum alloy 5754 marine grade aluminum plate has excellent corrosion resistance, especially to seawater and industrially polluted atmospheres. It is stronger than 5251. This high strength makes 5754 ideally suited for marine applications requiring a combination of strength and resistance to seawater corrosion.

The quality of 5754 marine aluminum plate fully meets the world's marine grade standards: CCS, DNV, NK, CCS, ABS, BV, LR, KR.

Common Specs of 5754 Marine Grade Aluminum Plate

| Temper | Thickness (mm) | Common size |

|---|---|---|

| 5754 h111 marine aluminum plate | 3.00-50.00 | 1250×2500mm |

| 5754 h111 marine aluminum plate | 6.00-50.00 | 1250×2500mm |

| 5754 h111 marine aluminum plate | 3.00-6.00 | 1250×2500mm |

| 5754 h111 marine aluminum plate | 3.00-50.00 | 1000×2000mm |

| 5754 h111 marine aluminum plate | 6.00-50.00 | 1000×2000mm |

| 5754 h111 marine aluminum plate | 3.00-6.00 | 1000×2000mm |

| 5754 h112 marine aluminum plate | 3.00-50.00 | 1250×2500mm |

| 5754 h112 marine aluminum plate | 6.00-50.00 | 1250×2500mm |

| 5754 h112 marine aluminum plate | 3.00-6.00 | 1250×2500mm |

| 5754 h112 marine aluminum plate | 3.00-50.00 | 1000×2000mm |

| 5754 h112 marine aluminum plate | 6.00-50.00 | 1000×2000mm |

| 5754 h112 marine aluminum plate | 3.00-6.00 | 1000×2000mm |

| 5754 h22 marine aluminum plate | 3.00-50.00 | 1250×2500mm |

| 5754 h22 marine aluminum plate | 6.00-50.00 | 1250×2500mm |

| 5754 h22 marine aluminum plate | 3.00-6.00 | 1250×2500mm |

| 5754 h22 marine aluminum plate | 3.00-50.00 | 1000×2000mm |

| 5754 h22 marine aluminum plate | 6.00-50.00 | 1000×2000mm |

| 5754 h22 marine aluminum plate | 3.00-6.00 | 1000×2000mm |

| 5754 h32 marine aluminum plate | 3.00-50.00 | 1250×2500mm |

| 5754 h32 marine aluminum plate | 6.00-50.00 | 1250×2500mm |

| 5754 h32 marine aluminum plate | 3.00-6.00 | 1250×2500mm |

| 5754 h32 marine aluminum plate | 3.00-50.00 | 1000×2000mm |

| 5754 h32 marine aluminum plate | 6.00-50.00 | 1000×2000mm |

| 5754 h32 marine aluminum plate | 3.00-6.00 | 1000×2000mm |

Application of 5754 Marine Aluminum Plates in Ship Components

5754 marine grade aluminum plate is widely used in welded structures, storage tanks, pressure vessels, ship structures and offshore facilities, and transportation tanks, requiring excellent processing performance, excellent corrosion resistance, high fatigue strength, high weldability and moderate Static intensity situations.

1. Deck and Superstructure

a. Ship Decking:

- Example: 5754 marine aluminum plates are commonly used as decking material on ships. They provide a robust and corrosion-resistant surface for the ship's deck, ensuring safety and durability. The non-slip properties of 5754 aluminum make it particularly well-suited for this application.

- Why 5754: The non-slip surface and corrosion resistance of 5754 aluminum plates ensure a safe and long-lasting deck surface that can withstand the harsh marine environment.

b. Superstructure Components:

- Example: Ship cabins, pilot houses, and other superstructure components often incorporate 5754 marine aluminum plates. Their lightweight nature, combined with corrosion resistance, is valuable for the construction of these upper sections of the vessel.

- Why 5754: The lightweight properties of 5754 aluminum contribute to stability and fuel efficiency, while its corrosion resistance ensures the longevity of the ship's upper structure.

2. Hull and Bulkheads

a. Ship Hull:

- Example: 5754 marine aluminum plates are used in the construction of the ship's hull, particularly in areas where corrosion resistance and weight reduction are crucial. This application is prevalent in smaller boats and naval vessels.

- Why 5754: 5754's corrosion resistance and high strength-to-weight ratio make it an excellent choice for boat hulls, contributing to improved fuel efficiency and maneuverability.

b. Bulkheads:

- Example: Bulkheads, which divide the ship's interior into compartments, often feature 5754 aluminum plates. These components are essential for maintaining the ship's structural integrity and ensuring safety.

- Why 5754: The lightweight yet strong properties of 5754 aluminum plates are advantageous for constructing bulkheads. Their corrosion resistance is critical for maintaining the ship's structural integrity.

3. Marine Piping and Tubing

- Example: 5754 marine aluminum plates are utilized in the construction of marine pipes and tubing for various fluid systems on ships, including fuel lines, cooling systems, and hydraulic lines. The corrosion resistance and formability of 5754 aluminum make it an ideal choice for conveying fluids in the marine environment.

- Why 5754: The corrosion resistance and formability of 5754 aluminum are essential for constructing pipes and tubing that can withstand the corrosive effects of saltwater and provide long-lasting performance.

4. Handrails and Safety Equipment

- Example: Handrails and safety equipment on ships are often made from 5754 marine aluminum plates. These components must ensure safety and withstand the corrosive effects of saltwater and marine environments.

- Why 5754: The corrosion resistance and formability of 5754 aluminum make it well-suited for manufacturing safety equipment and handrails that ensure the safety of crew and passengers.

5. Fishing Equipment

- Example: Fishing vessels use 5754 marine aluminum plates for various components, including rod holders, storage bins, equipment brackets, and fish cleaning tables. These components must withstand the corrosive effects of saltwater and provide long-lasting performance.

- Why 5754: The corrosion resistance of 5754 aluminum ensures that fishing equipment remains durable and operational in the challenging marine environment.

6. Cargo Holds and Containers

- Example: Cargo ships and vessels use 5754 marine aluminum plates in the construction of cargo holds and containers. The lightweight properties of 5754 contribute to increased cargo capacity and fuel efficiency.

- Why 5754: 5754 aluminum's high strength-to-weight ratio and corrosion resistance make it a preferred choice for cargo holds and containers, optimizing the vessel's cargo capacity and overall efficiency.

7. Fuel Tanks and Storage

- Example: Ships use 5754 marine aluminum plates in the construction of fuel tanks and storage containers. The alloy's corrosion resistance is crucial for preventing fuel contamination and ensuring vessel safety and efficiency.

- Why 5754: The corrosion resistance of 5754 aluminum is essential for maintaining the integrity of fuel storage systems on ships, preventing contamination and ensuring safety.

8. Propeller Blades

- Example: Propeller blades on marine vessels are often made from 5754 aluminum due to the alloy's high strength-to-weight ratio. These blades must endure the forces of water and remain corrosion-resistant to maintain vessel performance.

- Why 5754: Propeller blades must withstand the corrosive effects of water while providing efficient propulsion. 5754's strength and corrosion resistance make it suitable for this critical application.

These examples demonstrate the versatility of 5754 marine aluminum plates in ship construction and various components. Their unique combination of corrosion resistance, lightweight properties, and high strength-to-weight ratio contributes to the efficiency, safety, and longevity of marine structures and vessels. From ship decking to bulkheads, handrails, and safety equipment, 5754 aluminum plays a vital role in ensuring the reliability and performance of ships in demanding marine environments.

Haomei Aluminum is a large-scale 5754 aluminum plate manufacturer. 5754 aluminum plate is one of Haomei Aluminum’s advantageous products.

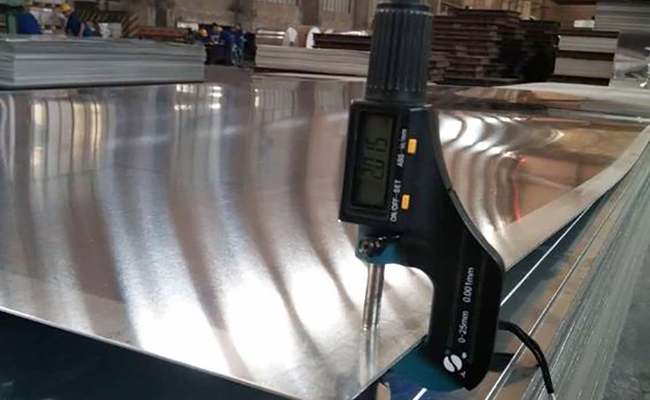

Haomei Aluminum 5754 ultra-wide and ultra-thick marine aluminum plate eliminates internal stress and does not deform when cut. The widest is 2650mm and the thickest is 500mm. It is one of the few domestic manufacturers that can produce ultra-wide and ultra-thick marine aluminum plates.

Hot Topics Related to 5754 Marine Aluminum

- What is marine grade Aluminium 5754?

- What is Aluminium 5754 grade material?

- What is 5754 aluminum used for?

- How strong is 5754 aluminum?

- 5754 aluminum sheet

- 5754 aluminum vs 5052

- 5754 aluminum equivalent

- aa5754 aluminium

- aw 5754

- 5754 aluminum

Recommended content you might be interested in

-

5083 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5083 marine aluminum sheets meet the required standards and specifications.

-

5086 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other ship classification certifications. The 5086 ship plate is stable, corrosion-resistant, and can withstand harsh marine environments.

-

5052 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5052 marine aluminum sheets meet the required standards and specifications.

-

6082 marine aluminum plate is an aluminum alloy commonly used in marine applications. Like other marine-grade aluminum alloys, 6082 has a variety of properties that make it well suited for use in ships and other marine structures.

-

One of the key benefits of 5456 marine aluminum plate is its excellent corrosion resistance in saltwater and seawater environments. This resistance to salt water corrosion is critical to ensuring the longevity and structural integrity of marine components.

-

5383 aluminum alloy is commonly used in the construction of ships and other marine structures because they can withstand the harsh conditions of salt water and provide good structural integrity.

-

5454 aluminum plate exhibits excellent corrosion resistance, especially in marine environments. It effectively resists the corrosive effects of salt water and seawater, making it ideal for prolonged exposure to these conditions.

-

5059 marine grade aluminum plate meets specific industry or international standards, such as those set by American Bureau of Shipping (ABS), Det Norske Veritas (DNV), CCS or other organizations.

You might like the following content

-

5754 Aluminum Plate Sheet

The strength of 5754 aluminum is higher than that of 5251. 5754 aluminum plate is a high-strength non-heat-treatable alloy and has excellent corrosion resistance, good processability, and weldability.

-

5754 h22 Aluminum Plate Sheet

5754 h22 aluminum refers to H22 tempered 5754 alloy. 5754 h22 Annealed to quarter hardness. Generally speaking, 5754 h22 alloy is widely used in welded structures, vehicles, marine applications, etc.

-

5754 h111 Aluminum Plate Sheet

5754 H111 aluminum plate is a rust-proof aluminum plate with good corrosion resistance. 5754 H111 aluminum has a wide range of uses and is mainly used in fields that require corrosion resistance such as ships and construction to improve the service life and safety of ships.

-

5454 Aluminum Plate Sheet

The strength of 5454 antirust aluminum is about 20% higher than that of 5052, and its characteristics are roughly the same as that of 5154, but its corrosion resistance is better than that of 5154 in severe environments.

-

5454 h32 Aluminum Plate Sheet

5454 h32 aluminum plate It has medium to high strength and excellent weldability, 5454 h32 has very good corrosion resistance, especially to seawater and general environmental conditions.

-

5454 h34 Aluminum Plate Sheet

5454-H34 Aluminum is 5454 aluminum in H34 condition. To achieve this temper, the metal needs to be strain hardened and then stabilized to a strength somewhere between annealed (O) and fully hard (H38).

-

5454 h111 Aluminum Plate Sheet

5454-H111 Aluminum is 5454 Aluminum in H111 condition. To achieve this temper, the metal is strain hardened below the strength allowed by H11 (1/8 hardness). 5454 H111 aluminum plate has good corrosion resistance and good formability.