Marine Aluminium Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, along with a rigorous quality control system, to ensure that marine aluminum sheets meet the required standards and specifications.

What is Marine Aluminum Plate?

Marine aluminum is an aluminum alloy designed and manufactured for use in marine environments. The harsh conditions of salt water and exposure to moisture and humidity can cause many metals to corrode and degrade, but marine aluminum is specially formulated to resist corrosion and provide long-lasting performance in these conditions.

Marine aluminum alloys typically contain higher levels of corrosion-resistant elements such as magnesium, manganese, and zinc than standard aluminum alloys. This improves their saltwater corrosion resistance, making them more suitable for use in marine environments.

Marine aluminum is used in a variety of marine applications including hulls, decks, masts, rigging, and other components. Its lightweight nature and high strength-to-weight ratio make it an attractive choice for marine designers and builders looking to improve the performance, fuel efficiency, and handling capabilities of boats and other vessels.

Marine aluminum is a special type of aluminum alloy designed to withstand the harsh and corrosive conditions of the marine environment, providing long-lasting performance and durability in boats and other marine applications.

Why the Boat use Aluminum?

There are many reasons for the use of aluminum in ships. It has become a popular material for various types of ships in the marine industry. The following is the main reason why aluminum is commonly used in ship construction:

1. Aluminum exhibits strong corrosion resistance in saltwater

Aluminum has excellent corrosion resistance, especially in a marine environment that is exposed to salt water which may be highly corrosive. The protective oxide layer formed on the aluminum surface helps prevent rust and corrosion, making it very suitable for long-term exposure to water.

2. Aluminum weight is lighter than steel

Compared with other materials such as steel, aluminum is relatively light. This lightness means increased buoyancy, better fuel efficiency, and higher overall performance. Lightships are also easier to transport and launch.

3. Aluminum has a good strength-weight ratio

It provides sufficient structural strength while reducing the weight of the boat. This makes the ship more agile and mobile.

4. Good aluminum durability for ship plates

Aluminum is known for its durability, impact, and abrasion resistance. It can withstand the harsh marine environment, including encountering rocks, fragments, and turbulent seawater.

5. Low maintenance cost

Compared with other materials such as wood, aluminum boats usually need less maintenance. They do not need to spray paint or seal regularly, which can reduce long-term ownership costs.

6. Highly formability

Aluminum is highly available. Ship designers can create various hull shapes and configurations to optimize performance and stability. It is easy to make and can build a customized ship for specific uses.

7. Marine-grade aluminum is recyclable

Recyclable: Aluminum is a recyclable material, which is consistent with sustainability and environmental considerations. The recycled aluminum can be used to make new ships or components.

8. Aluminum boats are easy to repair

Once damaged, aluminum boats are relatively easy to repair, weld, or modify. This can extend the service life of the ship and reduce maintenance costs.

9. Cost benefits and friendly

Although the initial cost of aluminum ships may be higher than other materials, long-term cost benefits, low maintenance costs, and durability often make it an attractive investment for the owner of the ship.

It is worth noting that although aluminum has many advantages, the choice of shipping materials depends on specific needs and preferences. Different materials, such as glass fiber, wood, and composite materials, also have their own advantages, which may be more suitable for certain applications or ship types.

What are the Advantages of Boat Aluminum Plate?

The aluminum plate for ships, especially the aluminum plate designed for the application of the ship, has a variety of unique advantages in addition to the general advantages of using aluminum in ship construction. These advantages make ship aluminum the first choice for various ships. The following are the specific advantages of ship aluminum:

1. High-intensity alloy: After careful design of the ship's aluminum alloy, it can provide excellent strength while maintaining the lightweight characteristics of aluminum. This enables a solid, durable and solid hull and structure.

2. Excellent weldability: Marine aluminum alloy is highly soldering and can create complex water-tight structures. The welding joint can be as strong as the substrate, which enhances the overall integrity of the ship.

3. Enhanced corrosion resistance: Marine aluminum alloys are usually treated or coated to further improve their resistance to saline corrosion and other bad marine environments. This ensures lasting performance and reduces maintenance needs.

4. High-performance alloy: After special preparation of aluminum alloy for ships, it can provide excellent performance characteristics, such as improving impact resistance, improving fatigue intensity, and enhancing fracture toughness. These attributes help improve security and reliability.

5. Low-thermal expansion: The thermal expansion coefficient of ship aluminum alloy is low, which means that they are not easy to expand and shrink due to temperature fluctuations. This stability is crucial for maintaining structural integrity under different weather conditions.

6. Design flexibility: The molding and easy manufacturing of aluminum allow innovation and customized ship design. Designers can optimize the shape of the hull, deck layout, and internal space to meet specific requirements, whether it is a leisure ship, a commercial ship, or a military ship.

7. Fuel efficiency: The lightweight characteristics of aluminum help improve fuel efficiency and enable the ship to achieve higher speed and longer cruise distance at the same engine power.

8. Resale value: Aluminum ships often retain their resale value well. Their durability, corrosion resistance, and low maintenance requirements make them an attractive choice for second-hand buyers.

9. Reduce noise and vibration: Due to its inherent damping characteristics, aluminum vessels can provide quieter and stable navigation, reducing the noise and vibration generated by engine operation and wave impact.

10. Fire safety: Aluminum is non-flammable and has high melting points, which can improve the level of fire safety on the ship.

These advantages make ship aluminum a great choice for various marine applications, from leisure ships and luxury yachts to merchant ships and military vessels. The intensity, durability, and corrosion resistance of ship aluminum collection can ensure reliable and lasting performance on the water.

Marine Aluminum Plate Specifications

Marine aluminum sheets are widely used in the marine industry for their excellent corrosion resistance, high strength-to-weight ratio, and lightweight properties. The following are some common specifications of marine aluminum sheets:

Marine Aluminum Alloys

There are several aluminum alloys suitable for marine applications including 5083, 5086, 5454, and 6061. The alloy most commonly used for marine aluminum plates is 5083, which is known for its high strength and excellent corrosion resistance in seawater environments.

-

5083 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5083 marine aluminum sheets meet the required standards and specifications.

-

5086 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other ship classification certifications. The 5086 ship plate is stable, corrosion-resistant, and can withstand harsh marine environments.

-

5052 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5052 marine aluminum sheets meet the required standards and specifications.

-

6082 Marine Aluminum Plate

6082 marine aluminum plate is an aluminum alloy commonly used in marine applications. Like other marine-grade aluminum alloys, 6082 has a variety of properties that make it well suited for use in ships and other marine structures.

-

5754 Marine Aluminum Plate

5754 marine aluminum plate is a deformed aluminum-magnesium alloy known for its excellent performance in the marine industry.

-

5456 Marine Aluminum Plate

One of the key benefits of 5456 marine aluminum plate is its excellent corrosion resistance in saltwater and seawater environments. This resistance to salt water corrosion is critical to ensuring the longevity and structural integrity of marine components.

-

5383 Marine Aluminum Plate

5383 aluminum alloy is commonly used in the construction of ships and other marine structures because they can withstand the harsh conditions of salt water and provide good structural integrity.

-

5454 Marine Aluminum Plate

5454 aluminum plate exhibits excellent corrosion resistance, especially in marine environments. It effectively resists the corrosive effects of salt water and seawater, making it ideal for prolonged exposure to these conditions.

-

5059 Marine Aluminum Plate

5059 marine grade aluminum plate meets specific industry or international standards, such as those set by American Bureau of Shipping (ABS), Det Norske Veritas (DNV), CCS or other organizations.

Marine Aluminum Plate Typical Sizes

Marine aluminum sheets are available in various sizes depending on the application.

Common thickness: 0.5 mm - 100mm

The standard size of marine aluminum plate is (custom size can also be ordered)

| Marine Aluminum | Typical Sizes |

| Marine Aluminum Plate | 4' x 8' |

| Marine Aluminum Plate | 4' x 10' |

| Marine Aluminum Plate | 5' x 10' |

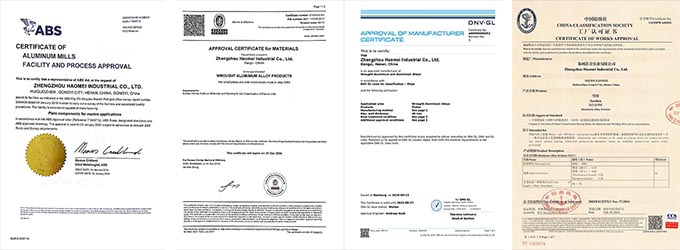

Marine Aluminum Plate Certifications

Aluminum marine panels must meet specific standards and certifications to ensure their suitability for marine environments. The most common certifications for marine aluminum sheets are the American Bureau of Shipping (ABS) and Det Norske Veritas (DNV).

ABS, BV, CCS, DNV, KR, LR, NK, RINA

Marine Aluminum Plate Surface Treatment

Marine aluminum sheets can be given a variety of surface treatments to improve their corrosion resistance and appearance. The most common surface treatments for marine aluminum panels are anodizing and painting.

Marine Aluminum Plate Packaging

Aluminum marine panels are often packaged in wooden pallets or crates to protect the panels during shipping and handling.

Aluminum marine panels are available in a variety of sizes, must meet specific certifications, can be finished, are usually packed in wooden pallets or crates, and are available in a variety of aluminum alloys such as 5083, 5086, 5454, and 6061.

Applicable Environment for Marine Aluminum Plate

The marine environment refers to various aquatic ecosystems found in marine, lakes, rivers, and other water bodies. These environments use different aluminum alloys according to their characteristics. The following are common types:

1. Saltwater (marine) Environment

Ocean: The vast saltwater body covering the surface of the earth. The ocean is divided into major basins, such as the Atlantic Ocean, the Pacific Ocean, the Indian Ocean, and the Arctic Ocean.

Ocean: small saltwater surrounded by land, such as the Mediterranean, Red Sea, and the Baltic Sea.

2. Freshwater (inland) Environment

Lake: Inland freshwater body, from small ponds to large lakes (such as five major lakes in North America).

River: The flow of freshwater, usually originating from the mountains, flows to the sea, and eventually flows into the ocean.

| Marine Aluminum | Applicable Environment |

|---|---|

| 5052 Marine Aluminum Plate | Freshwater and saltwater |

| 5052 Marine Aluminum Plate | Saltwater |

| 5086 Marine Aluminum Plate | Saltwater |

| 6061 Marine Aluminum Plate | Freshwater |

| 7075 Marine Aluminum Alloy | Freshwater environment |

How to Choose Boat Aluminum Plate?

Choosing the right aluminum plate for your boat is essential to ensure safety, durability, and performance.

Multiple factors need to be considered by choosing a suitable ship plate:

- 1. Determine the purpose of your boat

- 2. Consider the thickness of the aluminum plate

- 3. Consider corrosion resistance

- 4. Consider welding

- 5. Weight consideration factors

- 6. Budget restriction

- 7. Credit local regulations

The choice of ship aluminum plates may vary according to the specific use of the ship. The following is a list of different aluminum alloys commonly used in ships. According to its applicability to various types of ships:

1. Leisure Boat

5052 aluminum alloy: This alloy is a good choice for small casual ships such as fishing boats and cruise ships. It has achieved a good balance between corrosion resistance, weldability, and cost benefits.

2. Saltwater and Fishing Boat

5083 aluminum alloy: 5083 is known for its excellent corrosion resistance and is a popular choice for ships used in the saltwater environment. It has high strength and durability, suitable for offshore and deep-sea fishing vessels.

3. High-performance Boat

6061 aluminum alloy: This alloy is appreciated for its high stretch strength and good corrosion resistance. Because of its lightweight and high strength, it is often used for high-performance vessels, speedboats, and rowing.

4. Workboat

5086 aluminum alloy: ships used for work, such as patrol boats, work boats, and work boats, benefit from the strength, corrosion resistance, and good welding of 5086 aluminum.

5. Commercial Ship

5456 aluminum alloy: commercial vessels such as ferries and passenger ships can use 5456 aluminum because it has excellent corrosion resistance and strength, suitable for commercial applications that require harsh.

6. Ship House

5052 or 5083 aluminum alloy: These alloys are usually selected for the construction of shiphouses because they have good performance balance, including corrosion resistance and weldability.

7. Pontoon Boat

5052 or 6061 aluminum alloy: Floating ships can benefit from the corrosion resistance of 5052 or the strength and rigidity of 6061, depending on the design and expected use.

8. Sailing Boat

6061 aluminum alloy: The mast and other structural components of the sailboat require strong and lightweight materials, which makes 6061 aluminum a suitable choice for these applications.

9. Canoe/kayak Construction

5052 or 5056 aluminum alloy: These alloys are easy to weld and resistant to make light canoe and kayak.

10. Rubber Boats and Inflatable Boats

3003 or 5052 aluminum alloy: These alloys are used for small ships, boats, and inflatable boats due to their lightweight characteristics and corrosion resistance.

Remember that the construction of ships involves a combination of different aluminum components, including hulls, frameworks, and other structural components. For different parts of the ship, the choice of aluminum alloy and plate thickness may be different to achieve the balance required between performance, weight, and durability.

The appropriate aluminum plate is only an integral part of a well-structured ship. Other factors such as design, welding quality, and construction methods also play an important role in determining the overall performance and safety of the ship.

Typical Marine Aluminum Plate

Aluminum marine panels can be made from a variety of aluminum alloys, the specific alloy used depending on the application and environmental conditions. The following introduces several alloys commonly used in marine aluminum plates, their properties, and applicable environments:

| Marine Aluminum | Typical Marine structures |

|---|---|

| 5052 Marine Aluminum Plate | Boat marine structural hulls, decks, and railings |

| 5052 Marine Aluminum Plate | hull, superstructure, and pressure vessels |

| 5086 Marine Aluminum Plate | hulls, decks, and railings |

| 6061 Marine Aluminum Plate | boat components, fittings, and hardware |

| 7075 Marine Aluminum Alloy | boat parts and accessories |

Choosing the right alloy for a particular marine environment is important, based on factors such as water type, temperature, salinity, and exposure to other elements such as wind, sunlight, and marine life. It is also important to consider the specific application and performance requirements when selecting the appropriate alloy for marine aluminum sheet.

Aluminum for Boat Structures

- Marine Aluminum Plate for Ship Deck

- Marine Aluminum for Keel

- Marine Aluminum Extrusions for Masts

- Marine Aluminum Extrusions for Portholes

- Marine Aluminum Welding Wire

- Marine Aluminum Honeycomb Panels

- Marine Grade Aluminum Checker Plate

Marine aluminum plates are widely used in various parts of ship structures due to their lightweight, high strength, and corrosion resistance. Here are some common components of marine structures that use aluminum and the alloys used:

| Component | Suitable Alloys |

|---|---|

| Boat Hulls | 5083, 5086, 5456 |

| Deck and Superstructure | 5083, 5086, 6061, 6082 |

| Masts and Spars | 6061, 6063 |

| Fittings and Hardware | 6061, 6063, 7075 |

| Applications | Alloy |

|---|---|

|

ship's side hull plating ship's bottom hull plating |

5083, 5086, 5456, 5050 |

| Keel | 5083 |

| Ribs | 5083 |

| Bulkhead | 5083, 6061 |

| Engine Mounting | 5083 |

| Deck | 5052, 5083, 5086, 5454 |

| Wheelhouse | 5083, 6N01, 5052 |

| Bulwark | 5083 |

| Smokestack | 5083, 5052 |

| Top and Side Panels of Maritime Shipping Containers | 3003, 3004, 5052 |

| Porthole or Portlight | 5052, 5083, 6063, AC7A |

| Gangway or Boarding Ladder | 5052, 5083, 6063, 6060 |

| Mast | 5052, 5083, 6063, 6060 |

| Structural Materials of Maritime Shipping Containers | 6063, 6061, 7003 |

-

Marine Aluminum Plate for Ship Deck

5052/5083/5086/6061 plates provide excellent structural integrity, fire resistance, and low maintenance requirements, ensuring the safety and operational efficiency of vessel decks in demanding marine applications.

-

Marine Aluminum for Keel

When using aluminum as keels in marine applications, high-strength aluminum alloys are often preferred because of their combination of strength, corrosion resistance, and reduced weight.

-

Marine Aluminum Extrusions for Masts

Masts are tall vertical structures on boats and sailboats that support sails and rigging. They are an essential part of the navigation system and play a vital role in harnessing the power of the wind to propel ships forward.

-

Marine Aluminum Extrusions for Portholes

5083 aluminum alloy is often used for larger portholes or those exposed to harsh marine conditions. 6061 aluminum alloy is commonly used for small to medium portholes or portholes on boats and ships operating in less extreme marine environments.

-

Marine Aluminum Welding Wire

Aluminum marine welding wire is designed for good weldability, resulting in strong and reliable welded joints. They should provide good arc stability, minimal spatter and suitable flow characteristics during welding.

-

Marine Aluminum Honeycomb Panels

Marine Aluminum Honeycomb Panels can be machined into a variety of shapes, sizes, and configurations, allowing custom designs to meet specific marine application requirements.

-

Marine Grade Aluminum Checker Plate

The Marine Grade Aluminum Checker Plate we offer meets quality standards, has stable performance, competitive price, and specifications can be customized.

Specifications for marine aluminum sheets may vary depending on the specific application and performance requirements. Common specifications for marine aluminum sheets are thickness, width, length, and tempering. The most common temperature for marine aluminum plates is H116 which means the aluminum is stress-relieved with a minimum tensile strength of 16 ksi (110 MPa) and a minimum yield strength of 10 ksi (70 MPa).

What are the Problems often Encountered in the use of Aluminum Plates for Ships?

During the use of boat aluminum plates, various problems and challenges will occur due to factors such as harsh marine environments and large amounts of use. The following are some common problems encountered during the use of vessel aluminum plates:

1. Corrosion

Corrosion is one of the most important challenges in marine applications. Especially salt water, which has strong corrosiveness for aluminum. Over time, aluminum will cause erosion, surface corrosion, and even more severe structural corrosion, thereby damaging the integrity of the structure.

2. Electric corrosion

When aluminum is in contact with heterogeneous metals (such as steel or stainless steel), electric puppets may occur. This is caused by the difference in the potential between the metals, which can cause the rapid corrosion of aluminum.

3. Scale

Marine creatures, such as rattan pots and algae, can be attached to the surface of the aluminum plate. This dirt will not only affect the performance of the containerd joints in the aluminum structure of the ship must have high quality to maintain structural integrity. Welding defects such but also exacerbate the problem of corrosion due to the accumulation of moisture on aluminum.

4. Welding Defect

The welded joints in the aluminum structure of the ship must have high quality to maintain structural integrity. Welding defects such as cracks or non-melting may occur and weaken the structure.

5. Fatigue

The ship is affected by the cycle load from waves and engine vibration. This may cause fatigue cracks in the aluminum structure, especially in high-stress areas.

6. Impact Damage

The collision with water or grounding objects may cause impact damage to aluminum hulls or plates, causing dental, client, or structural damage.

7. Material Degradation

Over time, even if there is no corrosion, aluminum will degrade material degradation due to factors such as UV (UV) exposure, chemical exposure, or temperature fluctuations.

8. Wear and Tear

Daily use such as launch and docking may cause aluminum plate wear, especially in high-contact areas such as keels or heads.

9. Maintenance Challenge

Proper maintenance is essential for solving and preventing many of them. However, due to channel restrictions, underwater work, and demand for special equipment and coating, maintenance in the marine environment may be challenging.

10. Electricity

When the electrical system on the ship is not properly maintained, aluminum may be easily affected by electrical problems such as electrical puppets or turbine current corrosion.

In order to alleviate these problems, the following measures can be taken:

- Regular inspection, cleaning, and anticorrosive treatment.

- Choosing the correct aluminum alloy, protective coating, and construction methods can significantly affect the life and performance of the aluminum plate for ships.

- Correctly designed cathode protection systems (such as sacrifice anode) also help prevent corrosion problems.

- Regular monitoring and solving problems in a timely manner are critical to ensure the safety and reliability of ships.

Marine Aluminum Plate Frequently Asked Questions Answers

1. How to Prevent Corrosion of Marine Aluminum plates?

The anti-corrosion strategy includes the application of protection coating, the use of cathode protection systems (such as sacrifice anode), daily cleaning and maintenance, and avoiding contact with metal metals to prevent electric puppets from corrosion.

2. How to prevent electric puppet corrosion?

When the aluminum is in contact with the alien metal in the electrolyte (such as salt water), the electric puppet corrosion will occur. To prevent this, use insulation materials between metals, install sacrifice anodes, and avoid electrical contact between heterology metals.

3. How long should a boat·s aluminum board be checked and maintained?

Regular inspections and maintenance of aluminum plates for ships are essential. The frequency of inspection depends on factors such as usage, environmental conditions, and ship types, but it is generally recommended to check and maintain before the rowing season.

4. Can marine aluminum plates be welded?

Yes, the marine aluminum plate can be welded. Welding is usually used for ship construction and maintenance. It is important to follow the correct welding program to ensure that the welding is firm and durable.

If your ship needs welding during the construction or maintenance process, consider using aluminum alloys that are easy to weld.

5. What are the protective coatings recommended for shipping aluminum boards?

Common protective coatings include epoxy primers and marine-grade paints. These coatings are designed to prevent corrosion and UV exposure.

6. Can aluminum plates be used for hulls?

Yes, aluminum plates are usually used in hulls, which are light and corrosion-resistant alternatives to steel hulls. The choice of alloy and plate thickness depends on the size and use of the ship.

High-Quality Marine Aluminum Plate Supplier

- High-Quality Raw Material: Marine Aluminum Sheet Supplier uses high-quality raw materials to ensure the quality and durability of the product.

- Strict Quality Control: Haomei Aluminum has a strict quality control system to ensure that marine aluminum sheets meet the required standards and specifications.

- Professional production equipment: Suppliers use professional production equipment and technology to ensure the accuracy and consistency of products.

- Advanced surface treatment technology: Adopt advanced surface treatment technology to improve the corrosion resistance and durability of the product.

- Reliable Certifications: Manufacturers have reliable certifications, such as ISO 9001, to ensure that products meet the required quality standards.

- High-quality after-sales service: provide high-quality after-sales service and technical support to ensure customer satisfaction.

The following products may interest you

-

5083 aluminum plate is a non-heat treatable alloy with high strength and corrosion resistance. We offer a wide range of sizes, thicknesses, and specifications at affordable prices to meet customer-specific needs.

-

5083 H32 aluminum plate has excellent corrosion resistance, good weldability, and high strength. The surface of the 5083 h32 Aluminum Plate has no oil spots, no waves, no scratches, no roll marks, and meets the production standards.

-

5083 h116 Aluminum Plate Sheet

5083 H116 aluminum plate is often used in the marine field because of its high low-temperature strength and corrosion resistance, which can extend the service life of the ship. Because of its light weight, it can better increase the ship's speed.

-

5083 h112 Aluminum Plate Sheet

5083 h1112 aluminum has very good corrosion resistance and medium strength, and it is very suitable for welding. 5083 h112 aluminum plate can be used in transportation, pressure vessels, cryogenic equipment, towers and drilling platforms, gas/oil pipelines, ordnance and armor plates.

-

5083 h111 Aluminum Plate Sheet

5083 aluminum is the strongest non-heat-treatable aluminum alloy. 5083 H111 aluminum is known for its superior performance in extreme environments, and 5083 O H111 sheet is used in marine and shipbuilding applications.

-

5083-O aluminum is 5083 aluminum in the annealed state. It has the highest ductility compared to other variants of 5083 aluminum.

-

5086 aluminum is not strengthened by heat treatment, but rather becomes stronger by strain hardening or cold machining of the material. 5086 aluminum sheet is commonly used in marine, cryogenic, pipeline, military, chemical and gas/oil/petroleum applications.

-

5086-H32 Aluminum is 5086 aluminum in the H32 condition. To achieve this state, the metal is strain-hardened and then stabilized to about one-fourth the strength between annealed (O) and fully hard (H38).

-

5086 h116 Aluminum Plate Sheet

5086 h116 aluminum plate sheet complies with industry standards and specifications, with a smooth surface and no defects at competitive prices.

-

5052 aluminum plate is mainly composed of magnesium and chromium. It has good processability, medium static strength, high fatigue strength, and good weldability. The fatigue strength of 5052 aluminum alloy is higher than most aluminum alloys.

-

5052 H32 aluminum plate has higher fatigue strength than most alloys, 5052H32 aluminum plate has excellent corrosion resistance, especially in marine applications, and has excellent machinability.

-

5052 h34 aluminum plate has enhanced corrosion resistance, workability, strength, good formability and weldability.

-

The strength of 5754 aluminum is higher than that of 5251. 5754 aluminum plate is a high-strength non-heat-treatable alloy and has excellent corrosion resistance, good processability, and weldability.

-

The strength of 5454 antirust aluminum is about 20% higher than that of 5052, and its characteristics are roughly the same as that of 5154, but its corrosion resistance is better than that of 5154 in severe environments.

-

5456 anti-rust aluminum is a kind of heat-resistant hard aluminum, mainly used for parts working at 250-350°C, such as compressor blades, discs, and plate bearings, as well as welded parts working at room temperature and high temperature, such as containers, sealed warehouses, etc.

-

6082 aluminum plate is known as the strongest alloy among the 6000 series alloys. 6082 aluminum is lightweight, easy to form, and can be strengthened through heat treatment.