Marine Aluminum Honeycomb Panels

Alloy: 5052/5083/6061/7075 Sound Insulation, Corrosion Resistance

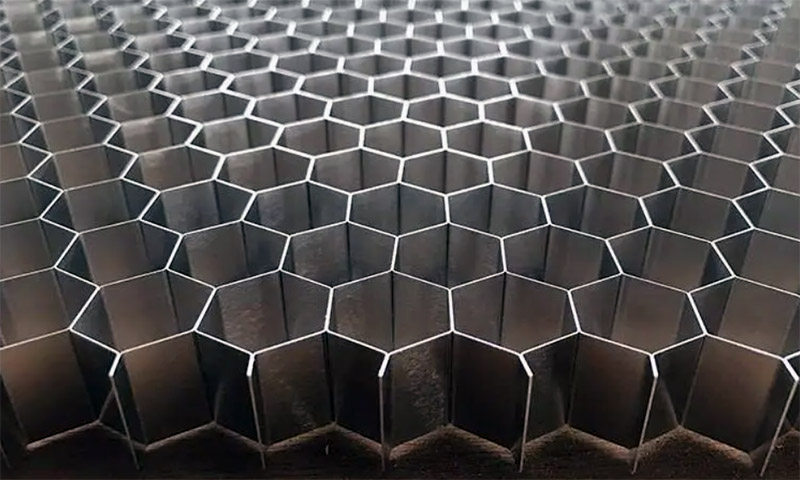

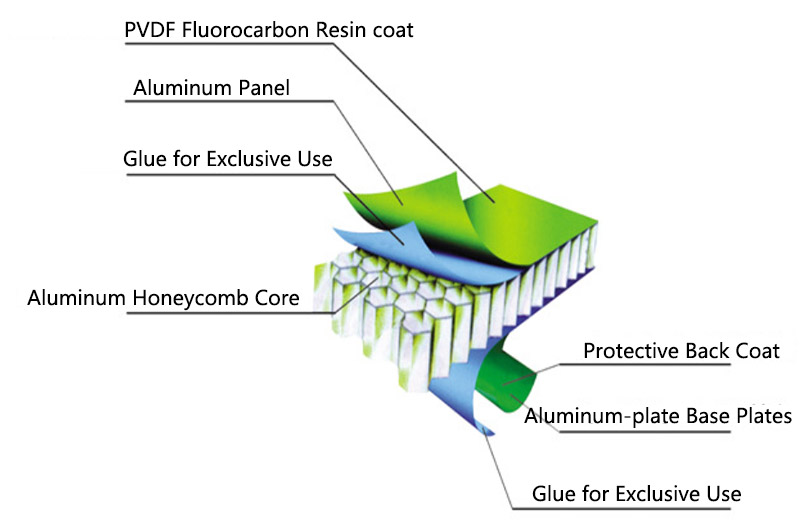

Marine Aluminum Honeycomb Panels are composite panels consisting of two aluminum panels bonded to a core made of the hexagonal aluminum honeycomb structure. These panels have the following characteristics:

- Light Weight

- Strong and Sturdy

Marine Aluminum Honeycomb Panels are ideal for a variety of marine applications where weight is reduced without compromising structural integrity.

Marine Aluminum Honeycomb Panels Properties

- Reduced Weight: The honeycomb core structure significantly reduces the weight of the panels while maintaining high strength for improved fuel efficiency and increased payload capacity.

- High strength-to-weight ratio: The honeycomb core provides excellent strength and rigidity, enabling the panels to withstand harsh conditions and dynamic loads in marine environments.

- Corrosion Resistance: Aluminum is inherently corrosion-resistant, and marine-grade aluminum alloys provide increased resistance to seawater and other corrosive elements commonly found in marine environments.

- Acoustic and Thermal Insulation: The honeycomb core effectively blocks sound transmission and provides thermal insulation for increased comfort on board.

- Design Flexibility: Aluminum honeycomb panels can be machined into a variety of shapes, sizes, and configurations, allowing custom designs to meet specific marine application requirements.

These panels are commonly used in marine applications such as ship and yacht construction, shipbuilding, ferry interiors, offshore structures, and other marine architectural elements.

It is important to select marine grade aluminum alloys and ensure that the panels meet the relevant industry standards and certifications for marine applications to ensure optimum performance and longevity in marine environments.

Marine Honeycomb Panels Aluminum Alloy

Aluminum honeycomb panels for marine applications are usually made from marine grade aluminum alloys. The specific alloy chosen depends on factors such as desired strength, corrosion resistance, and other performance characteristics. Some common alloys used for aluminum honeycomb panels in marine applications include:

- Aluminum alloy 5052 honeycomb panel: Aluminum alloy 5052 is famous for its excellent corrosion resistance, high strength, and good weldability. Honeycomb panels made from this alloy are widely used in marine applications including shipbuilding, yacht interiors, bulkheads, and cabinets.

- Aluminum Alloy 5083 Honeycomb Panel: Aluminum alloy 5083 is highly regarded for its excellent corrosion resistance and high strength. It is typically used in marine environments where durability and resistance to saltwater exposure are critical. Honeycomb panels made from this alloy are used in hull, deck, superstructure, and interior applications.

- Aluminum Alloy 6061 Honeycomb Panels: Although not specifically a marine grade alloy, aluminum alloy 6061 is sometimes used in honeycomb panels in marine applications. It has good strength, excellent machinability, and moderate corrosion resistance. It can be used in non-structural marine interior applications where weight reduction is required.

- Aluminum alloy 7075 honeycomb Panels: Aluminum alloy 7075 is a high-strength alloy with good corrosion resistance. It is primarily used in high performance marine structures where superior strength and stiffness are required. Honeycomb panels made from this alloy are used in specialized marine applications where weight reduction and structural integrity are critical.

The state and specifications of the alloys used in aluminum honeycomb panels for marine applications may vary according to the specific requirements and standards of the project. However, the marine grade aluminum alloys used for honeycomb panels are usually in the T6 temper.

The T6 temper refers to the solution heat treatment and artificial aging condition, which provides the alloy with higher strength and hardness. This tempering process involves heating the alloy to a specific temperature followed by rapid cooling to achieve the desired properties.

Some common specifications for marine grade aluminum alloys used in honeycomb panels include:

- ASTM B209: This specification covers aluminum and aluminum alloy sheets and plates, including marine grade alloys, and outlines the required mechanical and chemical properties.

- MIL-DTL-32119: This military specification specifies requirements for aluminum alloy honeycomb core materials used in marine applications. It covers core cell size, density, strength, adhesion, and other performance characteristics.

These alloys provide a balance of strength, corrosion resistance, and other desirable properties for marine environments. It is important to consult the manufacturer or supplier to select the alloy most suitable for a particular marine application, taking into account factors such as exposure to salt water, operating conditions and performance requirements.

Marine Aluminum Honeycomb Panels Applications

Marine Aluminum Honeycomb Panels have a variety of uses in the marine industry. Here are some common uses of aluminum honeycomb panels in marine applications:

- Ship and yacht construction: Aluminum honeycomb panels are used in the construction of hulls, decks, bulkheads, cabins, and other structural components. These panels provide a lightweight yet strong solution that helps improve performance, and fuel efficiency and increase payload capacity.

- Internal Paneling: Aluminum honeycomb panels are used for internal paneling of ships and yachts. They are used on wall panels, ceilings, partitions, and other interior surfaces. These panels are durable, and beautiful and can be customized with different finishes, textures, and colors.

- Doors and hatches: Aluminum honeycomb panels are used to manufacture doors and hatches in marine applications. These panels provide strength, rigidity, and resistance to impact and corrosion, ensuring reliable and long-lasting door and hatch systems.

- Furniture and Fixtures: Aluminum honeycomb panels are used to make light and durable boat furniture and fixtures. They are used in cabinets, countertops, tables, seating, and other interior accessories.

- Sound and heat insulation: Aluminum honeycomb panels with sound-absorbing or heat-insulating properties are used in marine applications to enhance sound and heat insulation. These panels help reduce noise transmission and improve thermal insulation for greater comfort on board.

- Floating structures: Aluminum honeycomb panels are used to build floating structures such as pontoon bridges, floating docks, and offshore platforms. The lightweight nature of the panels allows for buoyancy while maintaining structural integrity.

Aluminum honeycomb panels in marine applications offer advantages such as reduced weight, increased strength, corrosion resistance, design flexibility, and improved performance, making them suitable for a wide range of marine construction and interior applications.

Recommended content you might be interested in

-

5083 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5083 marine aluminum sheets meet the required standards and specifications.

-

5086 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other ship classification certifications. The 5086 ship plate is stable, corrosion-resistant, and can withstand harsh marine environments.

-

5052 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5052 marine aluminum sheets meet the required standards and specifications.

-

6082 marine aluminum plate is an aluminum alloy commonly used in marine applications. Like other marine-grade aluminum alloys, 6082 has a variety of properties that make it well suited for use in ships and other marine structures.

-

5754 marine aluminum plate is a deformed aluminum-magnesium alloy known for its excellent performance in the marine industry.

-

One of the key benefits of 5456 marine aluminum plate is its excellent corrosion resistance in saltwater and seawater environments. This resistance to salt water corrosion is critical to ensuring the longevity and structural integrity of marine components.

-

5383 aluminum alloy is commonly used in the construction of ships and other marine structures because they can withstand the harsh conditions of salt water and provide good structural integrity.

-

5454 aluminum plate exhibits excellent corrosion resistance, especially in marine environments. It effectively resists the corrosive effects of salt water and seawater, making it ideal for prolonged exposure to these conditions.

-

5059 marine grade aluminum plate meets specific industry or international standards, such as those set by American Bureau of Shipping (ABS), Det Norske Veritas (DNV), CCS or other organizations.

You might like the following content

-

5083 Aluminum Plate Sheet

5083 aluminum plate is a non-heat treatable alloy with high strength and corrosion resistance. We offer a wide range of sizes, thicknesses, and specifications at affordable prices to meet customer-specific needs.

-

5052 Aluminum Plate Sheet

5052 aluminum plate is mainly composed of magnesium and chromium. It has good processability, medium static strength, high fatigue strength, and good weldability. The fatigue strength of 5052 aluminum alloy is higher than most aluminum alloys.

-

7075 Aluminum Plate Sheet

7075 is one of the strongest aluminum alloys available, with an excellent strength to weight ratio. 707 Aluminum Plate is ideal for highly stressed aircraft components.