Marine Aluminum for Keel

Alloy: 5083/5086 Specifications can be customized

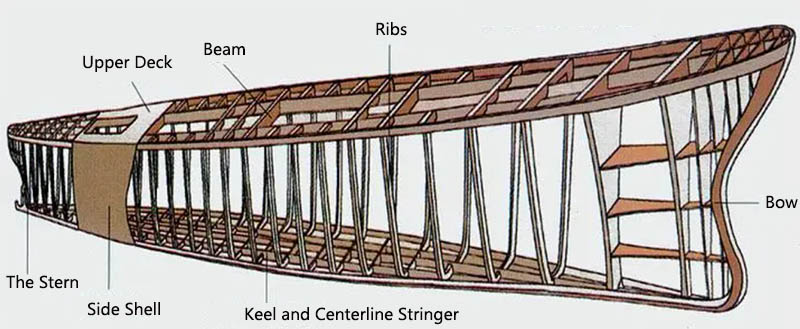

The keel is the basic structural component of a ship. It is the stringer or plate extending along the centerline of the hull from the bow (forward) to the stern (after). The keel is usually at the bottom of the hull and acts as the ship's pillar or spine.

The keel is usually made of high-strength material capable of withstanding the loads and stresses imposed on the vessel. Materials commonly used for keels include steel, cast iron, lead, and aluminum alloys.

Aluminum Profile for Keel

High-strength marine-grade aluminum alloys are often used for keel profiles due to their combination of strength, corrosion resistance, and reduced weight. The specific alloy chosen may depend on factors such as vessel size, operating conditions, and regulatory requirements. Alloys commonly used for keel profiles include:

- Aluminum Alloy 5083: This marine-grade aluminum alloy is known for its excellent corrosion resistance and high strength. It has good weldability and retains its properties in marine environments, making it suitable for keel applications. The strength and durability of the 5083 allow for a strong joist design while maintaining a relatively low weight.

- Aluminum alloy 5086: This alloy has similar properties to 5083, with excellent corrosion resistance and good strength. Alloy 5086 is also frequently used for joists.

| Properties/Alloy | 5083 | 5086 |

|---|---|---|

| Tensile Strength (MPa) | 275 | 240 |

| Yield Strength (MPa) | 240 | 205 |

| Elongation (%) | 12 | 12 |

| Brinell Hardness (HB) | 75 | 70 |

Tempering: The tempering designation of the aluminum alloys used for joist profiles can vary according to the required mechanical properties and machinability. Common state designations for keel profiles include:

- H116: This temper designation indicates a high-strength alloy that has been stabilized to increase resistance to stress corrosion cracking. It provides good mechanical properties for keel applications.

- H321: Similar to H116, the H321 temper indicates a high-strength alloy with increased stability and resistance to stress corrosion cracking. It is suitable for joists where enhanced performance and durability are required.

- O (Annealed): This state indicates that the aluminum alloy is in the annealed or soft state. It has good formability and ease of fabrication but may have lower strength compared to hardened and tempered. It can be suitable for some keel applications.

The specific alloy and state selection of aluminum keel profiles should be determined according to factors such as ship size, operating conditions, load-bearing requirements, and design considerations. Consulting a Naval Architect, Marine Engineer or Naval Construction Professional can provide valuable insight and advice on the most suitable alloy and condition of the keel profile for a particular application.

The keel is the structural element at the centerline of the bottom of the hull, extending from bow to stern. It serves a variety of purposes, including providing stability, improving directional control, and resisting lateral forces. The specific use of aluminum alloys in keel structures depends on factors such as the size and type of the vessel, design requirements, and intended use.

Marine Aluminum for Keel Applications

Aluminum keels are commonly used in all types of boats, but the suitability of aluminum as a keel material depends on several factors. Here are some considerations regarding the types of boats that are generally suitable or not suitable for aluminum keels:

Suitable for boats with aluminum keels:

- Small recreational boats: Aluminum keels are often used in small recreational boats such as fishing boats, skiffs, and small motor boats. These vessels typically operate in inland or coastal waters and can benefit from the lightweight, corrosion-resistant properties of aluminum keels.

- Aluminum Hull Boats: If the boat has an aluminum hull, it is usually appropriate to have an aluminum keel as well. Aluminum hulled vessels, including aluminum sailboats, aluminum catamarans, and some aluminum power boats, can utilize aluminum keels for consistent material compatibility and corrosion resistance.

- Expedition and adventure boats: Vessels designed for expedition or adventure purposes, such as expedition yachts or offshore cruising sailboats, can benefit from the strength, durability, and corrosion resistance of aluminum keels. These boats often face challenging conditions and long voyages, so an aluminum keel was a suitable choice.

Boats not suitable for aluminum keels:

- Large Merchant Ships: Very large commercial vessels, such as cargo ships, tankers, or large passenger ships, often require a keel made of stronger materials such as steel due to the enormous loads and stresses they are subjected to. Aluminum keels may not provide the necessary strength and structural integrity for such large and heavy vessels.

- High-performance racing sailboats: High-performance racing sailboats, such as racing yachts or hydrofoils, often require a keel with specific design features to optimize speed and performance. Materials such as carbon fiber or composites are widely used for their lightweight and high stiffness properties, while aluminum may not provide the required weight and stiffness requirements.

- Heavy Displacement or Steel Boats: Heavy displacement boats, especially those with steel hulls, often have steel keels of choice for consistent material compatibility and strength. Steel keels are better able to withstand the extra weight and stresses associated with large displacement hulls.

It is important to consult a ship designer, naval architect, or marine engineer when considering whether an aluminum keel is suitable for a particular vessel. They can evaluate a vessel's design, size, intended use, and operating conditions to determine the most suitable keel material and construction for optimum performance, durability, and safety.

Recommended content you might be interested in

-

5083 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5083 marine aluminum sheets meet the required standards and specifications.

-

5086 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other ship classification certifications. The 5086 ship plate is stable, corrosion-resistant, and can withstand harsh marine environments.

-

5052 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5052 marine aluminum sheets meet the required standards and specifications.

-

6082 marine aluminum plate is an aluminum alloy commonly used in marine applications. Like other marine-grade aluminum alloys, 6082 has a variety of properties that make it well suited for use in ships and other marine structures.

-

5754 marine aluminum plate is a deformed aluminum-magnesium alloy known for its excellent performance in the marine industry.

-

One of the key benefits of 5456 marine aluminum plate is its excellent corrosion resistance in saltwater and seawater environments. This resistance to salt water corrosion is critical to ensuring the longevity and structural integrity of marine components.

-

5383 aluminum alloy is commonly used in the construction of ships and other marine structures because they can withstand the harsh conditions of salt water and provide good structural integrity.

-

5454 aluminum plate exhibits excellent corrosion resistance, especially in marine environments. It effectively resists the corrosive effects of salt water and seawater, making it ideal for prolonged exposure to these conditions.

-

5059 marine grade aluminum plate meets specific industry or international standards, such as those set by American Bureau of Shipping (ABS), Det Norske Veritas (DNV), CCS or other organizations.

You might like the following content

-

5086 Aluminum Plate Sheet

5086 aluminum is not strengthened by heat treatment, but rather becomes stronger by strain hardening or cold machining of the material. 5086 aluminum sheet is commonly used in marine, cryogenic, pipeline, military, chemical and gas/oil/petroleum applications.

-

5083 Aluminum Plate Sheet

5083 aluminum plate is a non-heat treatable alloy with high strength and corrosion resistance. We offer a wide range of sizes, thicknesses, and specifications at affordable prices to meet customer-specific needs.

-

5083 h116 Aluminum Plate Sheet

5083 H116 aluminum plate is often used in the marine field because of its high low-temperature strength and corrosion resistance, which can extend the service life of the ship. Because of its light weight, it can better increase the ship's speed.

-

5086 h32 Aluminum Plate Sheet

5086-H32 Aluminum is 5086 aluminum in the H32 condition. To achieve this state, the metal is strain-hardened and then stabilized to about one-fourth the strength between annealed (O) and fully hard (H38).

-

5086 h116 Aluminum Plate Sheet

5086 h116 aluminum plate sheet complies with industry standards and specifications, with a smooth surface and no defects at competitive prices.