Marine Aluminum Plate for Ship Deck

Alloy: 5052/5083/5086/6061 Corrosion Resistance, Long Life

Ship Deck is the uppermost horizontal surface of a ship, usually above the main structural hull. This is the area where the crew and passengers walk or perform various activities on board.

The Ship Deck is versatile and can be divided into different tiers or sections, each with its specific purpose. The following are the main functions related to Ship Deck:

- Ship Deck provides a platform for ships to navigate, operate, and accommodate.

- It is designed to support the weight of crew, passengers, cargo, and equipment.

- The deck also acts as a working area for various onboard operations and activities.

Deck Layer

Depending on the size and type of vessel, there may be multiple deck levels. Common deck levels include the main deck, upper deck, forecastle deck, bridge deck, promenade deck, and sun deck. Each level may have a different function and serve a specific purpose.

Aluminum alloys such as 5086, 5052, or 6061 are often used for deck structures on small boats or yachts. These alloys provide strength, corrosion resistance, and lightweight properties, making them suitable for recreational boating applications.

Ship Deck Aluminum Alloy Material

Ship decks are often constructed using durable materials to withstand the harsh marine environment. Steel and aluminum are widely used for their strength, durability, and corrosion resistance. The deck structure consists of support beams, stringers, and other strengthening elements.

Aluminum alloys used for ship decks are usually marine grade aluminum such as 5083 or 5086. These alloys are known for their excellent corrosion resistance, high strength, and weldability.

Aluminum alloys used for ship decks generally have excellent corrosion resistance, high strength, and good weldability. The following are aluminum alloys commonly used in marine deck applications:

- Marine Grade Aluminum Alloy 5083: This alloy is widely used in the marine industry due to its excellent corrosion resistance in saltwater environments. It has high strength, good formability, and weldability. 5083 aluminum is commonly used for ship decks, superstructures, and hulls.

- Marine Grade Aluminum Alloy 5086: Similar to 5083, Aluminum Alloy 5086 has high corrosion resistance and good weldability. It is suitable for ship decks and other marine components and structures requiring strength and corrosion resistance.

- Marine Grade Aluminum Alloy 6061: Although not as corrosion resistant as 5083 or 5086, aluminum alloy 6061 is still used in some applications for marine decks. It has good strength, formability, and machinability. Alloy 6061 is typically used in small boats, yachts, and professional marine applications.

- Marine Grade Aluminum Alloy 5052: Aluminum alloy 5052 is known for its moderate strength, good corrosion resistance, and high fatigue strength. It is commonly used in small ships, yachts, and components such as hulls, decks, and superstructures.

These aluminum alloys are chosen for marine deck applications due to their lightweight, corrosion resistance, strength, and weldability. The choice of specific alloy depends on factors such as vessel size, intended use, operating conditions, and regulatory requirements.

Specification of Aluminum Deck Plate

| Specification | Range/Options |

|---|---|

| Marine-grade aluminum alloys | (e.g., 5083, 5086, 6061) |

| Thickness | Range: 2mm - 50mm |

| Width | Range: 500mm - 3000mm |

| Length | Range: 1000mm - 6000mm |

| Surface Finish | Smooth, mill finish, non-slip coating/treatment |

| Alloy Temper | H321, H116, O (annealed) |

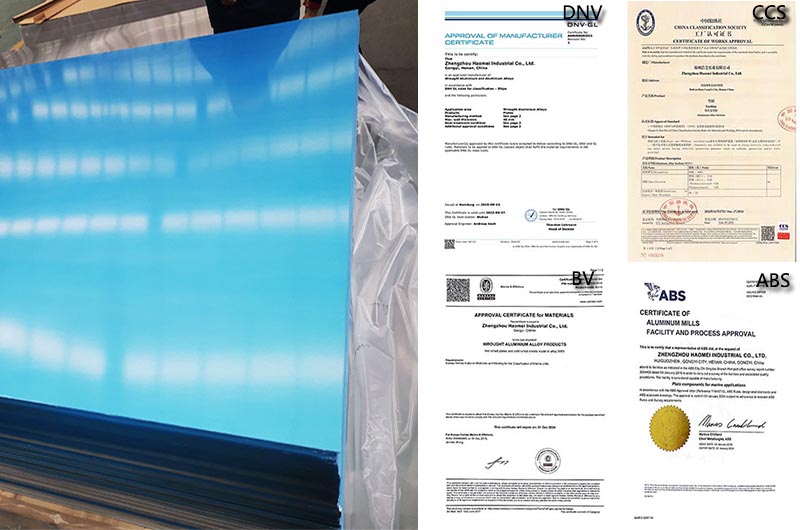

| Certification | ABS, DNV, Lloyd's Register, etc. |

Aluminum Plate for Ship Deck Properties

Aluminum sheets are often used in the construction of ship decks due to their ideal properties.

Here are some key points about ship deck aluminum plates:

- Lightweight: Aluminum is a lightweight material that helps reduce the weight of the overall structure of the ship. This improves fuel efficiency and increases cargo capacity.

- Corrosion Resistance: Marine-grade aluminum alloy has excellent corrosion resistance in saltwater environments. This makes them ideal for ship decks exposed to seawater, preventing premature degradation and extending the life of the deck.

- Strength and stiffness: Although aluminum is light, it still has sufficient strength and stiffness properties to withstand the loads and stresses encountered on the deck of a ship. Select specific alloys and plate thicknesses to meet desired strength standards.

- Non-slip: Ship decks often require non-slip surfaces to ensure the safety of the crew. Aluminum decks can be treated or coated with non-slip materials or patterns to enhance traction and minimize the risk of accidents due to slipping.

- Weldability: Aluminum sheets can be welded easily, allowing efficient fabrication and installation of ship deck structures. When performed correctly, welded joints can provide high strength and integrity.

- Maintenance: Aluminum decks generally require less maintenance than other materials such as steel. The corrosion-resistant properties of aluminum reduce the need for frequent painting and protective coatings.

Ship decks have various access points to move between different areas of the ship. Stairs, ladders, gangways, and hatch covers provide access to the different deck levels and compartments.

Ship decks have safety features to ensure the safety of the crew and passengers. These may include non-slip surfaces, handrails, guardrails, and designated emergency evacuation routes.

Ship decks can be covered with a variety of materials to provide a suitable walking surface. Common deck coverings include teak, non-slip coatings, or other materials that have good traction and can withstand harsh weather conditions.

Ship deck configurations may vary depending on the type of ship, such as cargo ships, passenger ships, naval vessels, or special vessels such as cruise ships, tankers, or fishing vessels. The design and layout of a ship's deck are influenced by factors such as the ship's size, function, operational requirements, and regulatory standards.

Be sure to consult a Naval Architect, Marine Engineer, or professional shipbuilding professional for specific design requirements and regulations regarding ship deck construction. They can provide guidance on proper aluminum alloys, sheet thicknesses, structural design, and installation techniques for marine deck applications.

Recommended content you might be interested in

-

5083 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5083 marine aluminum sheets meet the required standards and specifications.

-

5086 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other ship classification certifications. The 5086 ship plate is stable, corrosion-resistant, and can withstand harsh marine environments.

-

5052 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5052 marine aluminum sheets meet the required standards and specifications.

-

6082 marine aluminum plate is an aluminum alloy commonly used in marine applications. Like other marine-grade aluminum alloys, 6082 has a variety of properties that make it well suited for use in ships and other marine structures.

-

5754 marine aluminum plate is a deformed aluminum-magnesium alloy known for its excellent performance in the marine industry.

-

One of the key benefits of 5456 marine aluminum plate is its excellent corrosion resistance in saltwater and seawater environments. This resistance to salt water corrosion is critical to ensuring the longevity and structural integrity of marine components.

-

5383 aluminum alloy is commonly used in the construction of ships and other marine structures because they can withstand the harsh conditions of salt water and provide good structural integrity.

-

5454 aluminum plate exhibits excellent corrosion resistance, especially in marine environments. It effectively resists the corrosive effects of salt water and seawater, making it ideal for prolonged exposure to these conditions.

-

5059 marine grade aluminum plate meets specific industry or international standards, such as those set by American Bureau of Shipping (ABS), Det Norske Veritas (DNV), CCS or other organizations.

You might like the following content

-

5083 Aluminum Plate Sheet

5083 aluminum plate is a non-heat treatable alloy with high strength and corrosion resistance. We offer a wide range of sizes, thicknesses, and specifications at affordable prices to meet customer-specific needs.

-

5052 Aluminum Plate Sheet

5052 aluminum plate is mainly composed of magnesium and chromium. It has good processability, medium static strength, high fatigue strength, and good weldability. The fatigue strength of 5052 aluminum alloy is higher than most aluminum alloys.

-

5086 Aluminum Plate Sheet

5086 aluminum is not strengthened by heat treatment, but rather becomes stronger by strain hardening or cold machining of the material. 5086 aluminum sheet is commonly used in marine, cryogenic, pipeline, military, chemical and gas/oil/petroleum applications.