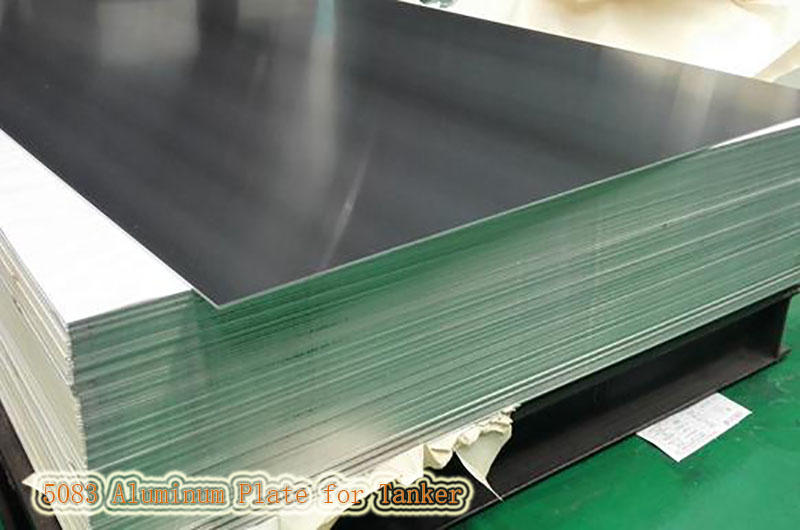

5083 Aluminum Plate for Tanker

Corrosion Resistance, Stable Performance Safety, Lower Costs Provide cost-effective solutions

5083 aluminum plate is a high-strength, corrosion-resistant aluminum alloy that is commonly used in Tanker construction. It belongs to the 5xxx series of aluminum alloys known for an excellent combination of strength, corrosion resistance, weldability and formability.

5083 aluminum sheet is suitable for use in a variety of environments, including marine environments, chemical processing plants, and oil refineries. Its high corrosion resistance, especially in saltwater environments, makes it ideal for tankers.

In addition to corrosion resistance, 5083 aluminum plate also has good weldability, which makes it easy to process into tanker parts. It also has good formability and high strength, helping to ensure the durability and longevity of the tanker.

5083 aluminum sheet is a versatile material suitable for use in a variety of environments, making it an excellent choice for tanker vessels.

5083 Aluminum Plate for Tanker Advantage

Compared to other aluminum alloys, 5083 aluminum alloy has some unique advantages that make it the first choice for tanker construction. Here are some advantages of 5083 aluminum alloy over other aluminum alloys:

- Corrosion resistance: 5083 aluminum alloy has superior corrosion resistance compared with other aluminum alloys, especially in salt water environment. This makes it ideal for tanker construction where there is frequent contact with corrosive materials.

- High strength: 5083 aluminum alloy has excellent strength and toughness compared with other aluminum alloys. This means it can withstand the stress and strain of prolonged use without cracking or breaking.

- Weldability: Compared with other aluminum alloys, 5083 aluminum alloy has high weldability. This makes it easier to manufacture and build tanker components, reducing overall build time and costs.

- Lightweight: 5083 aluminum alloy has a low density, which makes it lighter than other aluminum alloys commonly used in tanker construction. This reduces the weight of the tanker and improves fuel efficiency.

- Durability: The high strength and corrosion resistance of 5083 aluminum alloy ensures the longevity of the tanker, making it a more durable choice for the long term.

The unique combination of properties offered by 5083 aluminum alloy compared to other aluminum alloys makes it the best choice for tanker construction.

5083 Tanker Aluminum Plate for Sale

5083 aluminum plate for tank trucks is available in a variety of specifications including typical dimensions, certifications, surface treatments and packaging. The following are some common specifications of 5083 tank truck aluminum plate:

5083 Tanker Aluminum Alloy

5083 Tank Truck Aluminum Plate is available in a variety of alloys including 5083-H116, 5083-H111 and 5083-H321.

Typical Size

Typical dimensions of 5083 aluminum plate for tankers may vary from manufacturer to manufacturer and can be customized to meet specific customer needs.

- Thickness: 6mm - 200mm

- Width: up to 2650mm

- Length: up to 12000mm

Certification

5083 tanker aluminum plates are usually certified by the manufacturer to EN 10204 3.2, confirming the chemical composition and mechanical properties of the material.

Surface Treatment

5083 Tanker Aluminum Sheet is available in different surface treatments including Mill Finish, Polished, Brushed, Anodized, Powder Coated.

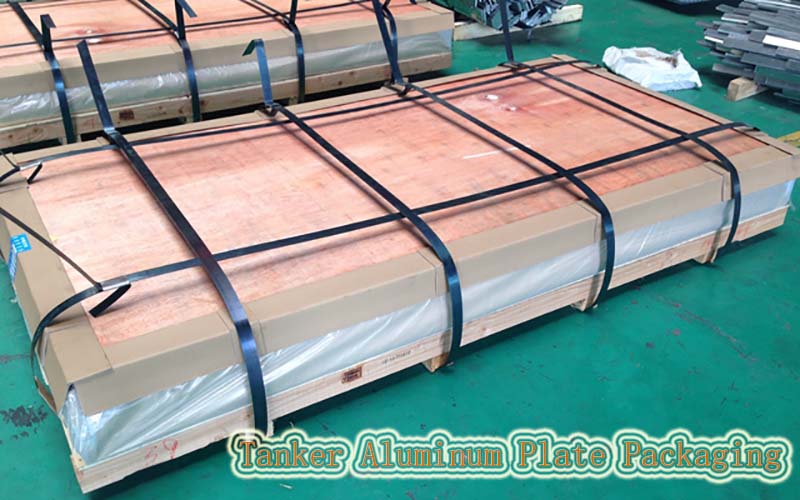

Packaging

5083 aluminum sheets for tank trucks are usually packed in wooden pallets or crates to ensure safe transportation and handling.

5083 Aluminum Tank Truck Sheet can also be customized to meet specific requirements such as size, shape, and surface finish. It is also important to note that this material is widely used in the construction of tankers and specific requirements may vary depending on the application and regulatory standards.

5083 Tanker Aluminum Plate Data

Mechanical Properties (at room temperature)

- Tensile Strength: 275 MPa (40 ksi) min

- Yield Strength: 125 MPa (18 ksi) min

- Elongation: 10% min

Physical Properties

- Density: 2.68 g/cm³ (0.097 lb/in³)

- Melting Range: 570-640 °C (1058-1184 °F)

It should be noted that the specific data of 5083 tank truck aluminum plate may vary according to the specific requirements of the manufacturer and application.

Chemical Composition 5083 Tanker Aluminum

| Element | Composition (wt. %) |

| Si | 0.40 max |

| Fe | 0.40 max |

| Cu | 0.10 max |

| Mn | 0.40 - 1.00 |

| Mg | 4.0 - 4.9 |

| Cr | 0.05 - 0.25 |

| Zn | 0.25 max |

| Ti | 0.15 max |

| Others | 0.05 max each, 0.15 max in total |

5083 Aluminum Plate for Tanker Structure

Because 5083 aluminum plate has excellent mechanical properties and corrosion resistance, 5083 aluminum plate can be used to manufacture various parts of the tank car structure. Here are some specific examples of parts and their corresponding alloys:

-

5083 Aluminum Plate for Tanker Body

5083 Aluminum Plate for Tanker BodyTanker Body is the main body of the Tanker that loads the cargo. Typically, 5083-H111 or 5083-H116 alloys are used for Tanker bodies due to their high strength to weight ratio and excellent corrosion resistance.

-

5083 Aluminum Sheet for Tankers Baffle

5083 Aluminum Sheet for Tankers BaffleBaffles are used to control the movement of liquid within the tank car and can be fabricated from 5083-H111 or 5083-H116 alloy.

-

Al 5083 for Tanker Head

Al 5083 for Tanker HeadTanker Lid and Cover for access to the cargo hold. These are usually made of aluminum alloy 5083-H111 for good strength and corrosion resistance.

-

5083 Aluminum Sheet for Bulkheads

5083 Aluminum Sheet for BulkheadsBulkheads are the walls that separate the different compartments within tankers and they can be made using either 5083-H111 or 5083-H116 alloy.

In terms of replacing the 5083 aluminum plate in the construction of the tank car, other aluminum alloys such as 5052, 5454 or 5754 can be used according to the specific requirements and operating conditions of the tank car. However, it is important to consider the mechanical properties and corrosion resistance of these alloys before choosing a substitute. Additionally, any alternative materials must meet regulatory standards for tanker construction.

How to Choose Aluminum Plate for Tanker

Corrosion Resistance Comparison

- 5083 aluminum plate: It has excellent corrosion resistance and can resist the erosion of many chemical substances, especially suitable for the transportation of liquid chemicals and petroleum products.

- 5754 aluminum plate: It has good corrosion resistance and can resist the erosion of most chemical substances, but it is slightly inferior to 5083 aluminum plate.

- 5454 aluminum plate: It has good corrosion resistance and can resist the erosion of most chemical substances, but it is also slightly inferior to 5083 aluminum plate and 5754 aluminum plate.

5083 aluminum plate has the best performance in terms of corrosion resistance, and it is also the most widely used aluminum plate material for tank trucks. The 5754 aluminum plate and 5454 aluminum plate are lighter than the 5083 aluminum plate, and are suitable for some tank truck parts that require lightweight. Which material to choose needs to be decided according to the specific application and requirements.

Comparison of Mechanical Properties

- 5083 aluminum plate: high strength, good weldability, strong corrosion resistance. It is one of the most commonly used aluminum sheet materials for tankers, mainly used for tanks, bulkheads, tops and bottoms of tankers.

- 5754 aluminum plate: lighter than 5083 aluminum plate, with better corrosion resistance, it can be used as a substitute for 5083 aluminum plate. 5754 aluminum plate is usually used in oil tanks and liquid tanks of tankers.

- 5454 aluminum plate: lighter than 5083 and 5754 aluminum plates, it has good weldability and corrosion resistance, and is widely used in structural parts such as hulls and hulls of oil tankers.

5083 aluminum plate has the best corrosion resistance and is the most widely used aluminum plate material for tankers. Although 5754 and 5454 aluminum sheets are lighter than 5083 aluminum sheets, they are suitable for certain tanker components that require lightweight materials. The choice of which material to use depends on the specific application requirements.

Recommended content you might be interested in

-

5182 Aluminum Plate for Tanker

Specifically designed for tankers, our 5182 aluminum plate offers excellent corrosion resistance and high strength for reliable leak and splash protection.

-

5454 Aluminum Plate for Tankers

To ensure the safety and reliability of these tankers, the choice of materials is of utmost importance. Among the various materials available, 5454 aluminum plate has emerged as a popular choice due to its exceptional properties and benefits.

-

5754 Aluminum Plate for Tankers

5754 Aluminum Plate for Tankers Its light weight, corrosion resistance, durability and formability make it an ideal material for all types of tankers.

-

5059 Aluminum Plate for Tankers

The use of 5059 Tanker aluminum plates may become more widespread in tanker construction, contributing to a safer, more cost-effective and environmentally friendly transportation industry.

You might like the following content

-

5083 Aluminum Plate Sheet

5083 aluminum plate is a non-heat treatable alloy with high strength and corrosion resistance. We offer a wide range of sizes, thicknesses, and specifications at affordable prices to meet customer-specific needs.

-

5083 H32 Aluminum Plate Sheet

5083 H32 aluminum plate has excellent corrosion resistance, good weldability, and high strength. The surface of the 5083 h32 Aluminum Plate has no oil spots, no waves, no scratches, no roll marks, and meets the production standards.

-

5083 h116 Aluminum Plate Sheet

5083 H116 aluminum plate is often used in the marine field because of its high low-temperature strength and corrosion resistance, which can extend the service life of the ship. Because of its light weight, it can better increase the ship's speed.

-

5083 h111 Aluminum Plate Sheet

5083 aluminum is the strongest non-heat-treatable aluminum alloy. 5083 H111 aluminum is known for its superior performance in extreme environments, and 5083 O H111 sheet is used in marine and shipbuilding applications.