5454 Aluminum Plate for Tankers

Industry Standards:ABS/DNV Safe/Long Life

In the world of transportation, tankers play a crucial role in the safe and efficient movement of liquids and gases. These massive vessels are designed to transport a wide range of substances, including oil, chemicals, and even food products.

To ensure the safety and reliability of these tankers, the choice of materials is of utmost importance. Among the various materials available, 5454 aluminum plate has emerged as a popular choice due to its exceptional properties and benefits.

Aluminum plate has become an indispensable material in tank truck manufacturing, and its lightweight properties have become a global trend. According to statistics, more than 90% of aluminum alloy tank trucks in Europe, the United States, Australia, Japan and other countries use aluminum plates as the main raw material.

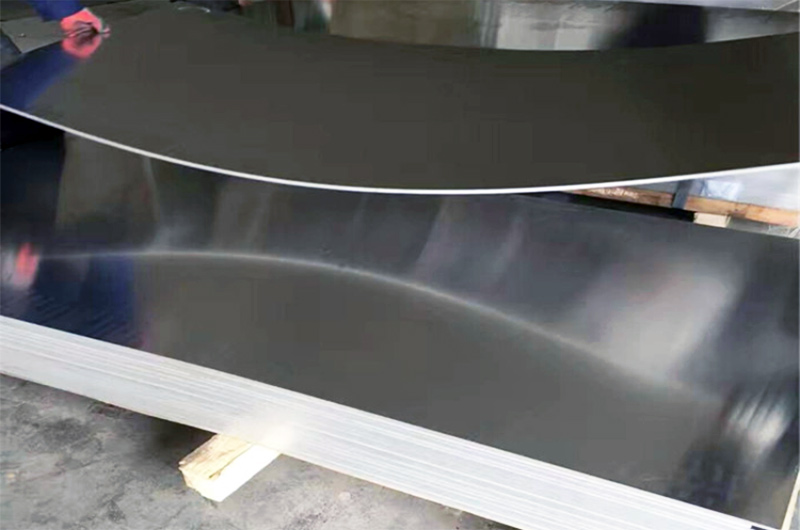

The use of aluminum plates on tank trucks can not only reduce fuel consumption and tire wear during transportation, but also reduce daily operation and maintenance costs. Usually, the length of the aluminum plate used is generally within 12.5 meters, the width is within 2.2 meters, and the common thicknesses are 5, 6, 7, 8mm and other specifications.

5454 aluminum plate belongs to the 5xxx series of aluminum alloys, which are known for their excellent corrosion resistance and strength. Specifically, it is an aluminum-magnesium alloy, with magnesium as its primary alloying element. This alloy is often used in marine and industrial applications where corrosion resistance and durability are crucial.

Specifications of 5454 aluminum sheet plate for tanker

| Alloy | 5454 |

| Temper | O, H111, H32 |

| Thickness | 3.00-12.00mm |

| Width | 1000-2600mm |

| Length | 2000-12000mm |

| Standard | EN14286, ASTM B209 |

5454 aluminum plate for tank car structure

5454 aluminum plate is a common choice for tank trucks. It is a typical rust-proof aluminum with high strength, about 20% higher than 5052 aluminum plate, and can adapt to harsh corrosive environments. This aluminum plate is widely used in aluminum tank bodies, tank truck bulkheads, tank truck Wash Boards, etc.

5-6mm 5454-H32/H111 aluminum plate for Tank Body

The tank truck body is made of 5-6mm 5454-H32/H111 aluminum plate. The aluminum plate in this state has been heat treated and has good strength and hardness, making it suitable for the manufacture of tanks. This thickness is sufficient to support the structure of the tank and provide sufficient durability and stability.

7-7.2mm 5454-O aluminum plate for Tankers Head

For the tank truck head, it is recommended to use 7-7.2mm 5454-O aluminum plate. The aluminum plate in this state is in a soft state and is easier to form, making it suitable for manufacturing the head, especially when the head needs to be stamped and formed. This thickness ensures sufficient strength and stability for the head.

5-6mm 5454-O aluminum plate for Wash Board

Wash Board is generally located at the bottom of the tank and is used to clean residue or waste. It is recommended to choose 5454-O aluminum plate with 5-6 mm. Similar to the can body, the aluminum plate in this state is easier to form and is suitable for manufacturing Wash Boards. Appropriate thickness can ensure that the Wash Board is not easily damaged during use.

| Alloy-Temper | 5454-H32/H111 | 5454-O | 5454-O |

| thickness | 6mm-8mm | 7mm/7.2mm | 5-6mm |

| application | Tanker body | Bulkhead | Wash board |

| Material share | 60% of a tank | 15% of a tank | 25% of a tank |

| Surface quality - deviation | Top - strict size | Top - strict thickness | As required |

Advantages of 5454 aluminum plate for tank trucks

- 1. Strong crack resistance: Because there are fewer hard and brittle compounds in the 5454 aluminum plate, cracks are less likely to occur during its processing, making it more suitable for the manufacturing process of tank trucks.

- 2. Excellent plasticity: 5454 aluminum plate has good plasticity and has a low tendency to weld twill, which makes it easier to shape into the required tank structure during processing.

- 3. Corrosion resistance and high strength: 5454 aluminum plate has excellent corrosion resistance and high tensile strength. Compared with steel, its corrosion resistance is better. This ensures that the tank is less susceptible to corrosion when transporting various liquids or liquefied gases.

- 4. No protective layer required: Tanks made of 5454 aluminum alloy do not require additional protective layers because they have good corrosion resistance, which simplifies the tank truck manufacturing process and reduces maintenance costs.

- 5. High safety performance: Aluminum can truck panels have good electrical conductivity and energy absorption properties. In the event of an accidental collision, no sparks will be generated, thereby reducing the possibility of dangerous accidents such as explosions.

Applications of 5454 Aluminum Plate in Tankers

5454-H32 aluminum plate for insulated tank truck

For insulated tankers, 5454 aluminum panels are used to build the tank structure to ensure it can withstand the rigors of transportation and maintain the integrity of the insulation.

Bright Finish 5454 Aluminum Plate for Pneumatic Tank Trailer

For pneumatic tank trailers, the glossy surface on 5454 aluminum panels not only enhances aesthetics, but also provides additional corrosion resistance and easier cleaning, which is important for maintaining hygiene standards in industries such as food or pharmaceutical transportation.

5454 Aluminum Plate for Chemical Tankers

5454 aluminum plate is often used for the construction of chemical tanker components, such as the tank shell and bulkheads.

Chemical tankers are designed to transport a variety of chemicals, many of which can be highly corrosive. Its excellent corrosion resistance ensures the safe transportation of chemicals without the risk of structural deterioration.

5454 Aluminum Plate for Oil Tankers

Oil tankers are essential for the global energy industry, as they transport crude oil and refined petroleum products across the seas. The use of 5454 aluminum plate in the construction of oil tanker hulls helps protect against the corrosive effects of seawater and the substances being transported. Additionally, the alloy's strength ensures the structural integrity of the vessel even under the immense weight of the cargo.

5454 Aluminum Plate for Food Tankers

5454 aluminum plate is not limited to industrial applications. It is also suitable for food-grade tankers, which are used for transporting various liquid and dry food products. The corrosion-resistant properties of this alloy ensure that the transported food items remain uncontaminated and safe for consumption.

5454 Aluminum Plate for LNG (Liquefied Natural Gas) Tankers

LNG tankers are specialized vessels designed to transport natural gas in its liquefied state. The low-temperature requirements of LNG demand materials that can withstand extreme cold while maintaining their structural integrity. 5454 aluminum plate, with its excellent low-temperature properties, is a preferred choice for the construction of LNG tanker components.

The Popularity of 5454 Aluminum Plate in Tanker Manufacturing

The widespread adoption of 5454 aluminum plate in tanker construction can be attributed to several key factors:

1. Cost-Effective

5454 aluminum is an economically viable choice for tanker manufacturers. Its cost-effectiveness stems from its durability and longevity, which reduce maintenance and repair costs over the lifespan of the tanker.

2. Lightweight

Despite its strength, 5454 aluminum plate is relatively lightweight. This characteristic contributes to fuel efficiency in tankers, as the vessel's weight is a critical factor in determining fuel consumption. Lighter tankers can carry more cargo while consuming less fuel, making them more environmentally friendly and cost-efficient.

3. Sustainability

The aluminum industry has made significant strides in sustainability and recycling. Aluminum is 100% recyclable, and the production of recycled aluminum requires significantly less energy compared to primary aluminum production. This aligns with the global shift towards eco-friendly and sustainable practices, making aluminum an attractive choice for tanker construction.

4. Compliance with Industry Standards

5454 aluminum plate meets the stringent requirements and standards set by organizations such as the American Bureau of Shipping (ABS), Det Norske Veritas Germanischer Lloyd (DNV GL), and other classification societies. Tankers constructed with 5454 aluminum plate can meet and exceed industry safety and quality standards.

5. Longevity

Tankers are substantial investments for their operators, and their lifespan significantly impacts the return on investment. 5454 aluminum plate's corrosion resistance and durability ensure the long-term performance and safety of tankers, extending their operational life.

Chemical composition of 5454 aluminum plate for tank trucks

| Alloy | 5454 |

| Si | 0.25 |

| Fe | 0.4 |

| Cu | 0.1 |

| Mn | 0.50-1.0 |

| Mg | 2.4-3.0 |

| Cr | 0.05-0.20 |

| Zn | 0.25 |

| Ti | 0.2 |

| Standard | EN573(WT%) |

Mechanical properties of 5454 aluminum plate for tank trucks

| Alloy | 5454 | |

| Temper | H32 | |

| Yield Strength | Rp0.2(Mpa) | ≥250 |

| Tensile Strength | Rm(Mpa) | ≥180 |

| Elongation | A50(50%) | ≥8 |

Considerations of 5454 Aluminum Plate for Tankers

While 5454 aluminum plate offers numerous advantages for tanker construction, there are some challenges and considerations to keep in mind:

1. Welding Expertise

Working with aluminum alloys requires specific welding techniques and expertise.

2. Initial Material Cost

While 5454 aluminum is cost-effective in the long run due to its durability and reduced maintenance, the initial material cost can be higher than some other materials. However, the long-term savings often outweigh the upfront investment.

3. Surface Treatment

To maximize the corrosion resistance of 5454 aluminum, proper surface treatments such as anodizing or painting may be required, especially in harsh environments.

4. Material Sourcing

Ensuring a consistent and reliable supply of 5454 aluminum plate may require establishing robust supplier relationships, especially for large-scale tanker manufacturing operations.

Conclusion

5454 aluminum plate has emerged as a preferred material for the construction of tankers due to its exceptional properties, including corrosion resistance, strength, weldability, and formability. Its applications range from chemical and oil tankers to food-grade and LNG tankers, serving diverse industries.

The popularity of 5454 aluminum plate in tanker manufacturing is driven by its cost-effectiveness, lightweight nature, sustainability, compliance with industry standards, and its ability to extend the operational life of tankers. Despite some challenges, such as the need for welding expertise and initial material costs, the long-term benefits of using 5454 aluminum in tanker construction far outweigh these considerations.

As the transportation industry continues to evolve and prioritize sustainability and safety, 5454 aluminum plate remains a reliable and versatile choice for constructing the tankers that are integral to global trade and logistics. Its ability to withstand the harshest conditions while providing economic and environmental benefits makes it a material of choice for the future of tanker manufacturing.

Recommended content you might be interested in

-

5182 Aluminum Plate for Tanker

Specifically designed for tankers, our 5182 aluminum plate offers excellent corrosion resistance and high strength for reliable leak and splash protection.

-

5083 Aluminum Plate for Tanker

Our products meet the quality standards and complete specifications, choosing the right Tanker Aluminum Plate will not deteriorate or cause pollution in harsh environments.

-

5754 Aluminum Plate for Tankers

5754 Aluminum Plate for Tankers Its light weight, corrosion resistance, durability and formability make it an ideal material for all types of tankers.

-

5059 Aluminum Plate for Tankers

The use of 5059 Tanker aluminum plates may become more widespread in tanker construction, contributing to a safer, more cost-effective and environmentally friendly transportation industry.

You might like the following content

-

5454 Aluminum Plate Sheet

The strength of 5454 antirust aluminum is about 20% higher than that of 5052, and its characteristics are roughly the same as that of 5154, but its corrosion resistance is better than that of 5154 in severe environments.

-

5454 h32 Aluminum Plate Sheet

5454 h32 aluminum plate It has medium to high strength and excellent weldability, 5454 h32 has very good corrosion resistance, especially to seawater and general environmental conditions.

-

5454 h34 Aluminum Plate Sheet

5454-H34 Aluminum is 5454 aluminum in H34 condition. To achieve this temper, the metal needs to be strain hardened and then stabilized to a strength somewhere between annealed (O) and fully hard (H38).

-

5454 h111 Aluminum Plate Sheet

5454-H111 Aluminum is 5454 Aluminum in H111 condition. To achieve this temper, the metal is strain hardened below the strength allowed by H11 (1/8 hardness). 5454 H111 aluminum plate has good corrosion resistance and good formability.