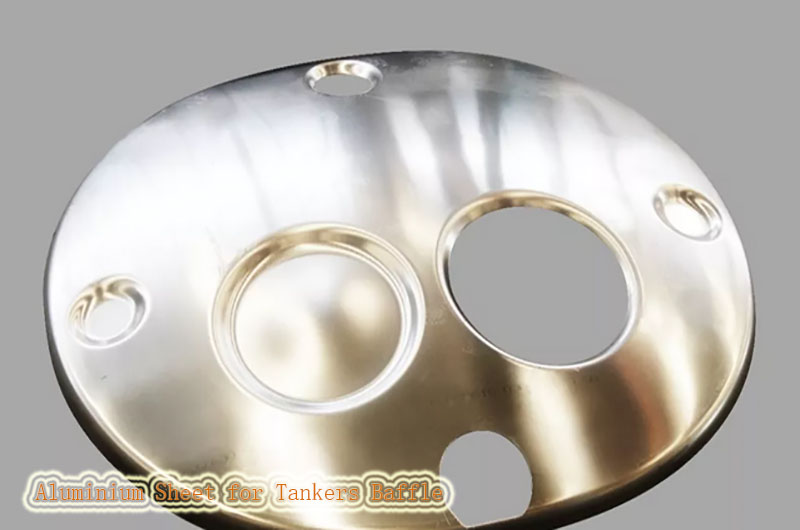

Aluminum Plate for Tankers Baffle

Alloy: 5052/5083/6061 Safe, Leak-proof

Tankers Baffle refers to the partitions or barriers inside fuel tanks that help control the movement of liquid cargo during transportation. The purpose of the baffle is to minimize sloshing or movement of liquid fuel inside the tanker, which can affect the stability and handling of the vehicle.

Baffles are often strategically placed within the tank body to form compartments or sections. These compartments help reduce the ability of fluid to move from side to side, front to back, or in any other undesired direction. By restricting the movement of fuel, baffles can help keep tankers stable and balanced, especially during acceleration, deceleration, and cornering.

The exact design and location of the baffles may vary, depending on factors such as the size and shape of the tank, the type of fuel being transported, and regulatory requirements. Baffles can be configured as vertical plates, horizontal baffles, or a combination of both, depending on the desired effect and the behavior of the particular liquid being conveyed.

By incorporating baffles into the tank truck design, the risk of fuel fluctuations, sloshing, or shifting can be reduced. This improves the overall safety and handling of the vehicle, minimizing the potential for instability and the effect of fluid movement on vehicle dynamics.

Aluminum Plate Advantages for Tankers Baffle

There are several advantages to using aluminum plates for tank baffle:

-

Lightweight

Aluminum is much lighter than other materials commonly used for fenders, such as steel. The lightweight nature of aluminum helps reduce the overall weight of the tanker, increasing payload capacity and improving fuel efficiency.

-

Corrosion Resistance

Aluminum has excellent corrosion resistance, especially when compared to materials such as steel. This is especially beneficial for tankers carrying corrosive liquids, as aluminum baffles can withstand the effects of corrosion and maintain their structural integrity over time.

-

Formability

Aluminum is highly formable and can be manufactured into the complex shapes and designs required for baffles. This formability enables the production of custom-shaped baffles that fit precisely within tanks, optimizing separation and increasing effectiveness in controlling liquid movement.

-

Weldability

Aluminum is easy to weld, which facilitates the assembly and installation of tank car fenders. The weldability of the aluminum plates allows a secure connection between the baffle and the tank structure, ensuring their stability and functionality.

-

Recyclability

Aluminum is a highly recyclable material, making it an environmentally friendly choice. The aluminum panels used for the sound insulation panels can be recycled after the end of their service life, reducing waste and saving resources.

-

Compatibility with Fuels

Aluminum is chemically inert and will not react with most types of fuel, making it suitable for tankers. It ensures that the baffle does not introduce contaminants or interact with the fuel, maintaining the quality and integrity of the fluid being conveyed.

-

Durability

Aluminum panels have good strength and durability, enabling the baffle to withstand the dynamic forces encountered during transportation. They effectively control fluid movement and maintain their structural integrity in a variety of road conditions.

Overall, the use of aluminum plates for tanker baffles offers advantages such as weight reduction, corrosion resistance, formability, weldability, recyclability, fuel compatibility, and durability. These advantages help transport liquids safely and efficiently while maintaining the structural integrity of the tanker.

Aluminum Plate for Tankers Baffle Specifications

Aluminum Alloys for Tanker Baffles

Select an aluminum alloy suitable for the intended application and environment. Common alloys used for tanker baffles include 5052, 5083, and 6061. Each alloy has its own specific properties and ability to be used in different conditions.

Aluminum Plate Thickness for Tanker Baffles

Determine the appropriate thickness according to the type of liquid to be transported, the size and shape of the tank, and regulatory requirements. Thicker sheets provide greater strength and stiffness but also add weight.

Tempering

The tempering of aluminum sheets is specified according to the required strength and formability. Common tempers for tanker baffles include H32 (strain hardened and stabilized) or O (annealed).

Width and Length

Specify the desired aluminum sheet size based on the size and design of the baffle and tank. Make sure the sheet is large enough to cover the necessary area and allow for proper fabrication and installation.

Surface Finish

Consider the surface finish required for aluminum panels. Options include rolled finish (rolled), brushed finish, or coated finish. The surface finish may depend on aesthetic preference, functional requirements, and corrosion resistance.

Compliance

Ensure that the specified aluminum plate complies with relevant industry standards and regulations for tanker fenders. These standards may include specific requirements for strength, corrosion resistance, weldability, and other performance factors.

Testing and Certification

Consider any testing or certification requirements that aluminum panels need to meet. This may involve obtaining certification or documentation to ensure compliance with industry standards and regulations.

Manufacturers and suppliers must be consulted to determine the most suitable specifications for aluminum plates for tanker baffles. They can provide guidance on your specific application requirements and help ensure that the selected aluminum sheet meets the necessary specifications and performance standards.

Typical Aluminum Plate for Tanker Baffle

There are several aluminum alloys available for Tanker Baffle, each with its own suitability for different environments. The following introduces several commonly used aluminum alloys for tanker baffles, their applicable environments, and specific application examples:

-

5052 Aluminum Plate for Tankers Baffle

5052 Aluminum Plate for Tankers Baffle5052 aluminum alloy has good corrosion resistance and formability. It is commonly used for baffles in tankers carrying non-corrosive liquids such as water, milk, or food grade products. Alloy 5052 is suitable for general purpose baffles in various industries.

-

5083 Aluminum Plate for Tankers Baffle

5083 Aluminum Plate for Tankers BaffleAlloy 5083 is highly regarded for its excellent corrosion resistance, high strength, and weldability. It is commonly used as baffles in tankers carrying aggressive or corrosive liquids including chemicals, acids, or certain oils. Examples include chemical tankers, acid tankers, or oil transport tankers.

-

5086 Aluminum Plate for Tankers Baffle

5086 Aluminum Plate for Tankers BaffleAlloy 5086 is similar to alloy 5083 in terms of corrosion resistance and weldability. It is commonly used as baffles in tankers carrying brine, brine, or other corrosive liquids. Examples include seagoing tankers, brine transport tankers, or corrosive liquid tankers.

-

5454 Aluminum Plate for Tankers Baffle

5454 Aluminum Plate for Tankers BaffleAlloy 5454 has excellent corrosion resistance and good strength. It is commonly used for baffles in tankers carrying non-corrosive and mildly corrosive liquids such as fuel, petroleum products, or water. Examples include fuel tankers, petroleum transport tankers, and water tankers.

-

6061 Aluminum Plate for Tankers Baffle

6061 Aluminum Plate for Tankers BaffleAlloy 6061 is known for its high strength and good corrosion resistance. It is commonly used as baffles in tankers transporting dry bulk materials such as cement, grain, powder, or granular matter. Examples include bulk powder tankers or cement transport tankers.

The choice of a specific alloy depends on factors such as cargo type, operating environment, regulatory compliance, and budgetary considerations. It is important to consult with an industry expert, engineer, or manufacturer to determine the most suitable alloy for a particular tanker baffle application based on intended use, cargo requirements, and industry standards.

How to Choose Aluminum Plate for Tanker Baffle

When selecting baffles for tankers, several factors should be considered. Here are some guidelines to help you choose the right tanker fender:

-

Cargo Type

Consider the type of cargo that will be transported in the tanker. Different liquids have different flow characteristics and may require different baffle designs. For example, baffles used to deliver low viscosity liquids may need to be designed differently than baffles used to deliver more viscous or denser liquids.

-

Fluid Motion Control

Determine the level of fluid motion control required. Baffles are used to minimize sloshing and movement of liquids within the tanker during transport. The design and placement of the baffles should be tailored to the specific liquid to effectively control its motion and maintain stability.

-

Tank Car Size and Shape

Consider the size and shape of your tank car when choosing a baffle. Baffles are designed to fit properly inside the tanker without impeding cargo flow or compromising the tanker's structural integrity.

-

Compliance

Ensure that the selected baffle complies with relevant regulations and industry standards. Regulations may dictate requirements for baffles, such as their size, material, and location, to ensure the safe transport of goods.

-

Material Selection

Select the appropriate material for the baffle. Common materials for baffles include aluminum and stainless steel. Factors such as corrosion resistance, durability, and compatibility with the cargo should be considered when selecting materials.

-

Baffle Design

Work with an engineer or professional experienced in tanker design to determine the best baffle design. Factors to consider include the number and location of baffles, their shape and size, and the integration of reinforcements or braces for added strength.

-

Test and Validation

Consider conducting tests or simulations to validate the selected baffle design. This helps ensure that the baffle effectively controls fluid movement and meets performance requirements in a variety of conditions.

By considering these factors and consulting with a provider, you can make an informed decision when selecting a fender for your tank truck. Properly designed and installed baffles will improve the stability, safety, and efficiency of liquid transfer.

Recommended content you might be interested in

-

5182 Aluminum Plate for Tanker

Specifically designed for tankers, our 5182 aluminum plate offers excellent corrosion resistance and high strength for reliable leak and splash protection.

-

5083 Aluminum Plate for Tanker

Our products meet the quality standards and complete specifications, choosing the right Tanker Aluminum Plate will not deteriorate or cause pollution in harsh environments.

-

5454 Aluminum Plate for Tankers

To ensure the safety and reliability of these tankers, the choice of materials is of utmost importance. Among the various materials available, 5454 aluminum plate has emerged as a popular choice due to its exceptional properties and benefits.

-

5754 Aluminum Plate for Tankers

5754 Aluminum Plate for Tankers Its light weight, corrosion resistance, durability and formability make it an ideal material for all types of tankers.

-

5059 Aluminum Plate for Tankers

The use of 5059 Tanker aluminum plates may become more widespread in tanker construction, contributing to a safer, more cost-effective and environmentally friendly transportation industry.

You might like the following content

-

5005 Aluminum Plate Sheet

5005 aluminum is a medium-strength aluminum alloy with a small amount of magnesium as the main alloying element. It has good formability and is often used in applications requiring anodized surface treatments.

-

5083 Aluminum Plate Sheet

5083 aluminum plate is a non-heat treatable alloy with high strength and corrosion resistance. We offer a wide range of sizes, thicknesses, and specifications at affordable prices to meet customer-specific needs.

-

5086 Aluminum Plate Sheet

5086 aluminum is not strengthened by heat treatment, but rather becomes stronger by strain hardening or cold machining of the material. 5086 aluminum sheet is commonly used in marine, cryogenic, pipeline, military, chemical and gas/oil/petroleum applications.

-

5454 Aluminum Plate Sheet

The strength of 5454 antirust aluminum is about 20% higher than that of 5052, and its characteristics are roughly the same as that of 5154, but its corrosion resistance is better than that of 5154 in severe environments.