Q: Why are electric heaters used more and more widely today?

Answer: With the improvement of people's living standards, people's requirements for comfort are also getting higher and higher. As an efficient and convenient heating equipment, the scope of application of electric heaters is constantly expanding.

Q: What are the advantages of electric heaters compared to traditional heating methods?

Answer: Electric heaters no longer rely on traditional heating systems such as gas or central heating, so they are more convenient to install and use. In addition, electric heaters have better heating effects and are easy to clean, providing a more comfortable heating experience.

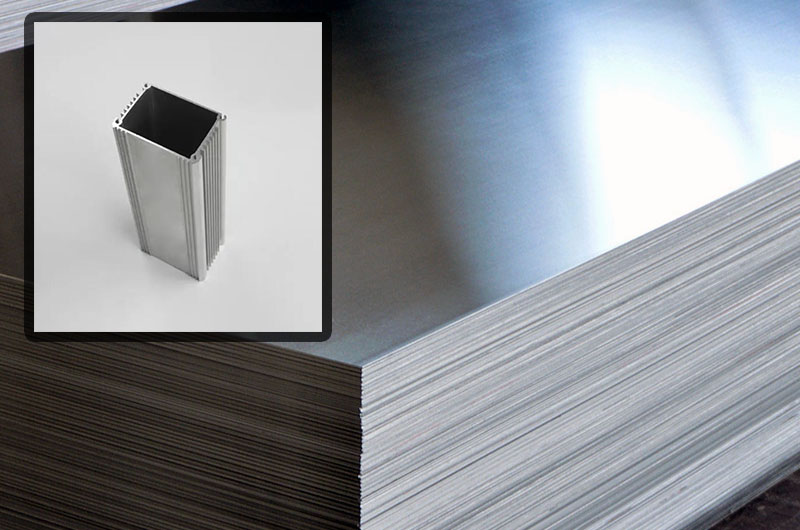

Q: What aluminum plate is used for electric heater casing?

Using 1050 aluminum as the electric heater shell is a suitable choice because of its excellent thermal conductivity, corrosion resistance and formability.

Factors for choosing 1050 aluminum plate for electric heater shell

- 1. Thermal conductivity: 1050 aluminum has good thermal conductivity, which means it can transfer heat efficiently. This property is crucial for an electric heater to effectively distribute heat to its surface.

- 2. Corrosion Resistance: 1050 aluminum is corrosion resistant, which is very important for heaters that may be exposed to moisture or changing environmental conditions.

- 3. Light weight: Aluminum is lightweight compared to other metals, making the heater easier to handle and transport.

- 4. Cost-Effectiveness: Compared to other materials, 1050 aluminum is relatively cheap, making it a cost-effective choice for mass-produced products such as electric heaters.

- 5. Ease of manufacturing: Aluminum is relatively easy to process and can be formed into a variety of shapes and sizes, allowing for flexibility in design and manufacturing.

- 6. Aesthetics: Aluminum can be surface treated in different ways, such as anodizing or powder coating, to enhance its appearance and make the heater visually appealing.

The choice of 1050 aluminum sheet for an electric heater housing may depend on its combination of thermal properties, durability, cost-effectiveness and ease of fabrication.

specifications of 1050 aluminum plate for electric heater casing

- Thickness: 0.1-500

- Width: 100-2650

- Length: 500-16000

- Material status: O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38

- Typical applications: PS board base, signs, lamps, nameplates, radiators, etc.

Chemical composition of 1050 aluminum plate for electric heater shell

| Chemical Element | % Present |

| Si | 0.25 |

| Fe | 0.4 |

| Cu | 0.05 |

| Mn | 0.05 |

| Mg | 0.05 |

| Zn | 0.05 |

| Ti | 0.03 |

| Other (Each) | 0.0 - 0.05 |

| Aluminium (Al) | Balance |

1050 aluminum plate performance for electric heater shell

| Physical Property | Value |

| Density | 2.71g/cm3 |

| Melting Point | 650°C |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 71GPa |

| Thermal Conductivity | 222W/m.K |

| Electrical Resistivity | 0.0282 x10^-6 Ω.m |

| Mechanical Property | Value |

| Tensile Strength | 105 - 145 MPa |

| Proof Stress | 85 Min MPa |

| Hardness Brinell | 34HB |

| Elongation | A - 12 Min % |

What are the advantages of using 1050 aluminum plate for electric heater casing?

- 1. Excellent thermal conductivity: 1050 aluminum plate has excellent thermal conductivity and can quickly conduct the heat generated by the electric heater to the surface of the shell to achieve effective heat dissipation and improve heating efficiency.

- 2. Lightweight design: The low density of aluminum alloy materials makes the electric heater shell relatively lightweight and easy to install and move, while reducing the cost and difficulty of transportation and installation.

- 3. Corrosion resistance: Aluminum alloy has good corrosion resistance and is not easily affected by environmental factors such as oxygen, thereby extending the service life of the electric heater, reducing the frequency of maintenance and replacement, and saving maintenance costs.

- 4. Beautiful appearance: The aluminum plate has a beautiful appearance and color, which can improve the overall appearance and texture of the electric heater and make it more in line with the needs of modern home decoration.

- 5. Ease of processing: Aluminum alloy is easy to process and is convenient for technicians to cut, shape and process. Electric heating shells of various shapes and sizes can be produced according to design requirements to meet the personalized needs of different users.

- 6. Relatively low price: Compared with other materials, the price of aluminum alloy is relatively low, making aluminum electric heaters more cost-effective and deeply welcomed and favored by market users.

Precautions

- 1. Strength: 1050 aluminum has lower strength compared to other alloys, so it may not be suitable for applications requiring high mechanical strength.

- 2. Temperature limitations: Although aluminum has good thermal conductivity, it has a lower melting point compared to steel or other metals. Therefore, it may not be suitable for applications involving extremely high temperatures.

1050 aluminum may be a suitable choice for electric heater housings, especially in applications where thermal conductivity, corrosion resistance, formability and cost-effectiveness are important considerations.

Direct selling manufacturer of 1050 aluminum plate for heating shell

Haomei Aluminum is a large-scale direct-selling manufacturer. All products are at ex-factory prices and there are no excessive circulation links. Taking users as our starting point, we control the price of our products at a relatively low level while ensuring product quality.

Haomei Aluminum keeps product prices at an affordable level, which can better meet the needs of users and allow more users to enjoy high-quality products. At the same time, the direct sales model also allows us to control costs more effectively, ensuring that we can provide users with more benefits while ensuring our own profitability.

How to ensure product quality?

Answer: We carry out strict quality control on each product, using high-quality raw materials and advanced production technology. At the same time, we have a complete quality inspection system to ensure that products meet relevant standards and user needs. Users can buy with confidence, we guarantee that the quality of each product is guaranteed.

For more product details, users can consult online to obtain it, or call the consultation hotline: 157-3734-7116 to obtain it quickly!