In response to global climate change and growing energy concerns, governments around the world have mandated that automobile manufacturing industries increase fuel efficiency, reduce energy consumption and minimize pollution.

Q: In response to these requirements, what is the focus of improving vehicle performance?

A: The focus is on reducing the weight of the car itself.

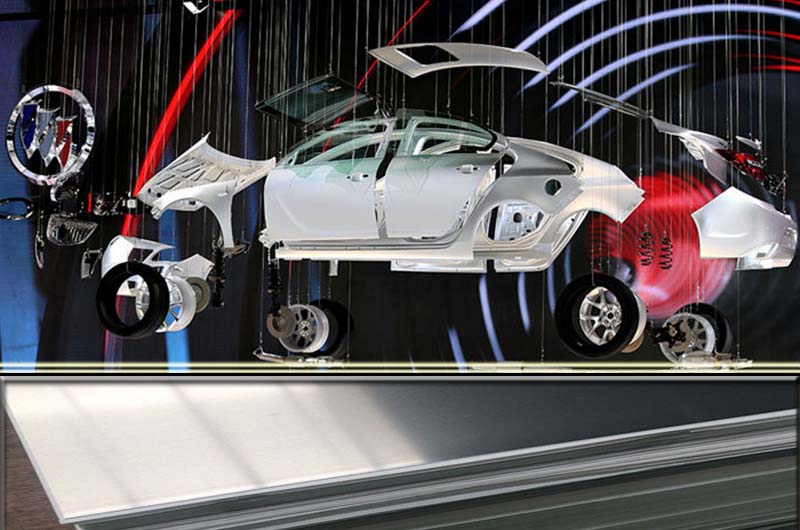

Q: What are the main ways to achieve lightweight vehicles?

A : The main way is to develop small-displacement vehicles and rationalize the vehicle structure and parts structure.

At present, steel is mostly used in automobiles. With the continuous increase of energy saving and consumption reduction this year, the proportion of rigid materials used in automobiles has gradually decreased, while the application of light alloys such as aluminum, magnesium, and composite materials has increased significantly.

Q: How does aluminum alloy compare to steel as an automotive material?

A: Aluminum alloys have several advantages over steel, including low density, good strength and elasticity, good impact resistance, and high recycling rates.

The following are some application trends of aluminum in automobiles

| Automotive Application | Examples of Components | Benefits |

| Body and Structural | Body panels, hoods, doors, roofs, trunk lids | Reduced weight, improved fuel efficiency, reduced emissions |

| Chassis and Suspension | Control arms, knuckles, subframes, suspension links | Weight reduction, improved handling, ride quality, reduced unsprung weight |

| Powertrain Components | Engine blocks, cylinder heads, transmission cases, oil pans | Weight reduction, increased fuel efficiency, improved performance |

| Wheels | Aluminum alloy wheels | Weight reduction, improved aesthetics, better heat dissipation, increased brake clearance |

| Battery Enclosures | Battery enclosures in electric vehicles | Lightweight, effective heat dissipation, improved efficiency and range |

| Crash Management Systems | Bumper beams, impact bars | Enhanced crash safety, minimized weight gain |

Here are some applications of 1050 aluminum in automobiles:

1050 Aluminum is a commercially pure aluminum alloy with excellent corrosion resistance, high electrical conductivity and good formability. While it may not be as common in the automotive industry compared to other aluminum alloys like 6061 or 5052, it still has some applications in cars.

1050 Aluminum for Automobile Engine Heat Shield

The main function of the automobile engine heat shield is heat insulation and high temperature resistance, which can increase the temperature of the exhaust gas and increase the power.

Thickness: 0.12-1.5mm

Performance characteristics of automobile engine exhaust pipe heat shield

- Excellent heat insulation effect, high and low temperature resistance (high temperature resistance 1200 ℃, extreme cold and low temperature resistance -70 ℃), good heat insulation effect

- It has chemical stability and is resistant to corrosion by various chemical liquids such as acids, alkalis, salts, chemical additives, etc.;

- Self-cleaning: no engine oil stains and hydrophobic performance;

- Fire-resistant and flame-retardant (fire-resistant class A non-combustible, national standard GB8624-2006, German standard DIN4102, A1 class)

- Aging resistance, weather resistance, rain and snow erosion resistance, sunshine resistance, good vibration resistance

- Easy to disassemble, easy to install, easy to clean, easy to maintain;

- High strength, that is, soft and tough, and fit closely with the exhaust pipe;

- Tailor-made according to the position of the exhaust pipe

- It can be used repeatedly, has a long service life, and is energy-saving, environmentally friendly, low-carbon, and recyclable and has high value for reuse.

1050 H12 Aluminum Plate for License Plate

License plates are usually made of materials with high durability, such as 1050H12 aluminum alloy with higher strength and corrosion resistance.

1050 H12 aluminum has a specific level of hardness and mechanical properties. In many regions, license plates are often made of materials such as aluminum alloy, stainless steel, or plastic with a reflective coating. These materials offer improved resistance to abrasion, corrosion and fading while meeting specific requirements and regulations set by authorities.

| Physical Characteristics | Value |

| Tensile Strength | 55-75 MPa |

| Yield Strength | 35 MPa (minimum) |

| Elongation | 30% (minimum) |

| Density | 2.7 g/cm³ |

| Melting Range | 640-660°C |

1050 Automotive Decorative Aluminum

1050 aluminum can be used for decorative purposes in automotive applications. While it may not be as commonly used as other aluminum alloys such as the 3xxx or 5xxx series, 1050 aluminum can provide a lightweight and aesthetically pleasing option for automotive trim elements.

Some examples of automotive trim aluminum applications include:

- Trim and Forming: 1050 aluminum can be used for interior and exterior trim such as window frames, door handles, dashboard trim and grille inserts. Its formability allows for complex designs and shapes, enhancing the overall appearance of the vehicle.

- Emblems and Badges: Decorative Emblems and Badges on vehicles are usually made of aluminum. 1050 aluminum can be used for logos, branding and other decorative elements on car bodies.

- Wheel Covers: Aluminum wheel covers or hubcaps can be made from 1050 aluminum. Stylish and lightweight, these covers are an alternative to traditional steel covers and enhance the visual appeal of your wheels.

- Interior: 1050 aluminum can be used for a sleek, modern look on a variety of interior components such as speaker grilles, dashboard trim or center console trim.

1050 Aluminum for Heat Exchangers

1050 Aluminum can be used in the construction of heat exchangers, especially in the air conditioning and cooling systems of vehicles. Its high thermal conductivity enables efficient heat transfer, making it suitable for such applications.

Automotive Radiator

Radiator: Aluminum radiators are commonly used in modern vehicles due to their light weight and good heat dissipation. 1050 aluminum can be used in the construction of radiator components, although other stronger aluminum alloys may be more prevalent.

It is important to note that the specific application of 1050 aluminum in an automobile may vary by manufacturer, design choices and industry trends. Different aluminum alloys are usually selected according to the specific properties and performance requirements of different automotive components.