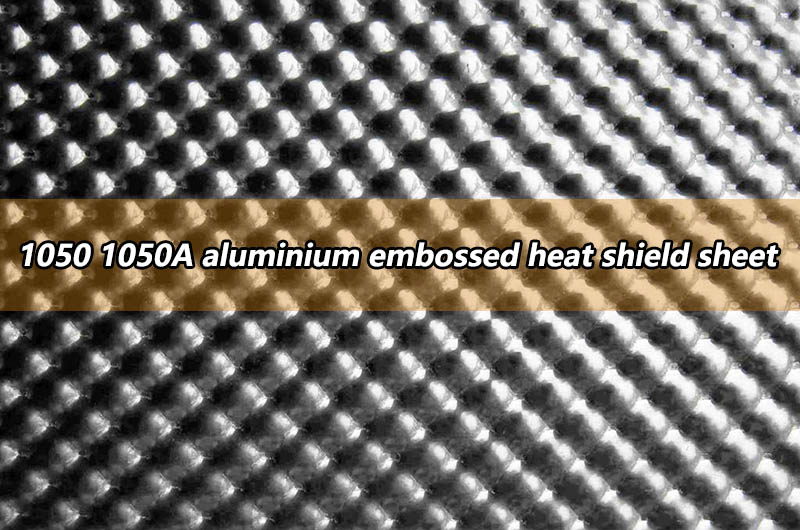

1050 and 1050A aluminum embossed insulation panels are commonly used in various industries for thermal insulation and protective purposes. 1050 and 1050A Aluminum Embossed Insulation Panels are aluminum products designed specifically for thermal insulation and thermal management applications.

key point

- Efficient heat dissipation: Aluminum's high thermal conductivity ensures efficient heat dissipation, protecting adjacent components from damage.

- Customization: Sheet thickness, size and embossing pattern can be customized to meet specific application requirements.

- Durability: Aluminum corrosion resistance and structural strength ensure long-term performance even in harsh environments.

- Installation: Easy to cut, shape and install, making it ideal for a variety of applications.

1050 1050A aluminum embossed heat shield sheet Specifications

- Material: Aluminum alloy 1050 or 1050A (purity 99.5%)

- Thickness: Typically ranges from 0.3 mm to 3.0 mm

- Surface: embossed to enhance heat dissipation and structural strength

- Size: Various sizes available according to customer requirements

- Surface Treatment: Usually satin-finished, or may be coated for additional properties

1050 1050A aluminum embossed heat shield sheet Advantages

- 1. Thermal insulation: Aluminum is an excellent thermal conductor and can effectively dissipate heat away from sensitive components.

- 2. Light weight: Aluminum is light and easy to handle and install.

- 3. Corrosion resistance: Aluminum has natural corrosion resistance, ensuring a long service life in various environments.

- 4. Embossed surface: The embossed surface enhances structural rigidity and facilitates better heat dissipation.

- 5. Malleability: Aluminum can be easily formed into different shapes and can be customized according to specific requirements.

- 6. Cost-Effectiveness: Aluminum is generally more cost-effective than other materials, providing a good value for thermal shielding applications.

Chemical composition of 1050 1050A aluminium embossed heat shield sheet

| Element | Composition (%) |

| Aluminum, Al | ≥99.5 |

| Silicon, Si | ≤0.25 |

| Zinc, Zn | ≤0.070 |

| Magnesium, Mg | ≤0.050 |

| Copper, Cu | ≤0.050 |

| Titanium, Ti | ≤0.050 |

| Manganese, Mn | ≤0.050 |

| Iron, Fe | ≤0.40 |

| Other (each) | ≤0.030 |

Physical properties of 1050 1050A aluminium embossed heat shield sheet

| Properties | Density | Melting point |

| Metric | 2.705 g/cm3 | 640°C |

| Imperial | 0.09772 lb/in3 | 1184°F |

Mechanical behavior of 1050 1050A aluminium embossed heat shield sheet

| Properties | Metric |

| Tensile strength (@diameter 12.7 mm/0.500 in) | 75 MPa |

| Elongation at break | 32% |

| Elastic modulus | 73 GPa |

| Shear strength | 50 MPa |

| Hardness, Brinell | 20 |

| Hardness, Vickers | 22 |

Thermal properties of 1050 1050A aluminium embossed heat shield sheet

| Properties | Thermal conductivity |

| Metric | 121-193 W/mK |

| Imperial | 838-1338 BTU in/hr.ft2.°F |

1050 1050A aluminum embossed heat shield sheet applications

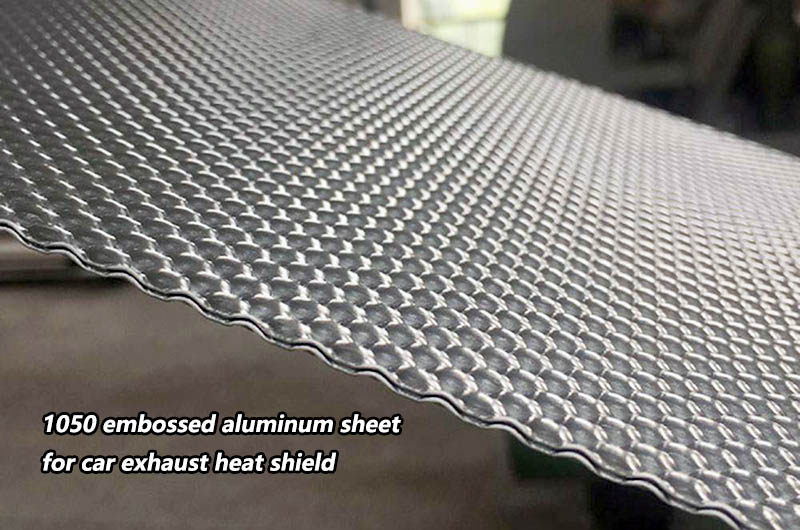

- 1050 aluminum embossed heat shield sheet for automotive industry: Used as a heat shield for exhaust systems, engine compartments and chassis to protect sensitive components from high temperatures.

- 1050 aluminum embossed heat shield sheet for aerospace: Used on aircraft to protect electronic components, wiring and fuel lines from engine heat.

- 1050 aluminum embossed heat shield sheet for home appliances: Use in ovens, grills, and HVAC systems to prevent heat damage to surrounding structures.

- 1050 aluminum embossed heat shield sheet for electronics: Used in electronic devices such as laptops, smartphones, and LED lights to dissipate heat generated by internal components.

- Industrial Machinery: Used on machinery and equipment to protect operators from high temperatures and maintain optimal operating conditions.

1050 1050A aluminum embossed heat shield sheet production process

- Material selection: The production process first selects high-quality aluminum alloy 1050 or 1050A. These alloys are primarily composed of aluminum and are approximately 99.5% pure.

- Aluminum ingot smelting: The selected aluminum alloy is smelted at high temperature in a furnace. The molten aluminum is then transferred to a casting mold to form an ingot of the desired size and shape.

- Rolling process: Aluminum ingots are heated and rolled multiple times through a series of rolling mills to achieve the required thickness and flatness. This rolling process also helps align aluminum grains to improve mechanical properties.

- Embossing: After rolling, the aluminum plate passes through an embossing machine. These machines apply pressure through embossing rollers to create a pattern or texture on the surface of the paper. The embossed pattern not only enhances aesthetics, but also increases structural strength and promotes better heat dissipation.

- Trimming and Cutting: After embossing, use a cutter or scissors to trim and cut the aluminum sheet to the desired size. This step ensures that the board meets the specified dimensional requirements for its intended application.

- Surface treatment (optional): Depending on the application and customer preference, aluminum panels can have surface treatments such as coating or anodizing to further enhance their properties. Coatings can provide additional corrosion resistance or improve heat-reflective properties, while anodizing adds a protective oxide layer to the surface.

- Quality Control: Throughout the production process, strict quality control measures are implemented to ensure that the thickness, surface finish, embossing pattern and mechanical properties of the aluminum plates meet the required standards. This usually involves inspections at various stages of production to identify and correct any defects or deviations from specifications.

- Packaging and Shipping: Finally, the finished aluminum embossed insulation panels are securely packaged to prevent damage during shipping.

Case appreciation

- 1. Car Exhaust Heat Shield: Installed between the exhaust manifold and body to prevent heat transfer to sensitive components and the passenger compartment.

- 2. Oven Liner: Placed under the oven, it protects kitchen cabinets from heat damage and improves energy efficiency by reflecting heat back into the oven.

- 3. Electronic Enclosure: Integrated into the housing of an electronic device to dissipate heat generated by processors, batteries, and other components.

- 4. Industrial Furnaces: Used as a lining or barrier to protect workers from radiant heat and maintain a constant temperature within the furnace.

1050 and 1050A Aluminum Embossed Insulation Panels provide effective insulation, lightweight construction and versatility for a variety of applications across industries, making them a popular choice for thermal management and protection needs.