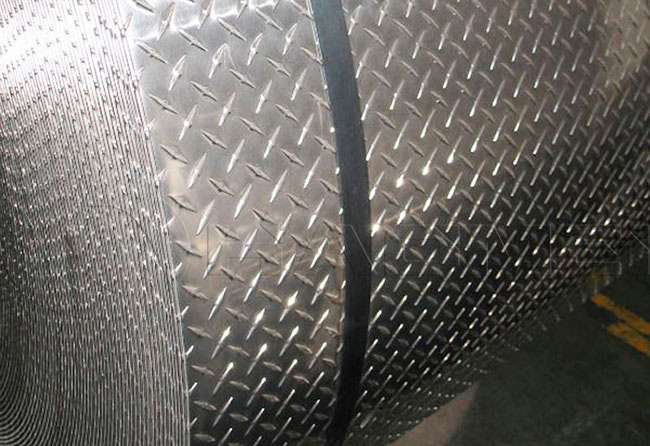

4x8 diamond aluminum plates are aluminum panels with a diamond pattern embossed on them, typically 4 feet (48 inches) wide and 8 feet (96 inches) long. Here are some details about the alloys, conditions, general specifications, finishes and common uses of 4x8 Diamond Aluminum Sheet:

- Alloy: The commonly used alloy for 4x8 aluminum diamond plate is 3003 aluminum alloy, which has good corrosion resistance and moderate strength.

-

Alloy Condition: 3003 aluminum alloy is usually in H22 or H24 temper, which has good formability and machinability

- General Specifications: 4x8 Diamond Aluminum Sheets range in thickness from 0.025 to 0.125 inches (0.64 to 3.18 mm). Diamond patterns on paper can come in different sizes, usually between 1/16 and 3/16 inch.

-

Surface treatment: The surface of the 4x8 aluminum diamond plate can have different finishes and treatments, including:

- Polished: The aluminum sheet retains its natural appearance without any additional surface treatment.

- Anodized: Aluminum panels are anodized to form a protective oxide layer and provide enhanced durability and color options.

- Painted Finish: Aluminum panels are painted for added protection, beauty and customization.

-

Common Uses: 4x8 Diamond Aluminum Sheets are widely used for their durability, slip resistance, and aesthetic appearance. Some common uses include:

- Trailer Floors: Used to provide a strong, non-slip surface on trailer floors.

- Truck Bed Liners: Applied to truck beds to prevent damage and provide traction.

- Wall panels: Used as decorative or protective wall cladding in garages, workshops and commercial spaces.

- Steps and Stairs: Use as treads on stairs and walkways for added safety.

- Toolboxes and Storage Boxes: Use to build sturdy and durable toolboxes and storage boxes.

Typical 4x8 Aluminum Diamond Plate

Black Diamond Plate Sheets 4x8

- Alloy: The alloy commonly used for black diamond plate is 3003 aluminum alloy.

- Alloy Condition: 3003 aluminum alloy is usually in H22 or H24 temper, which has good formability and machinability.

- Specifications: 4x8 size black diamond panels are available in various thicknesses ranging from 0.025 to 0.125 inches (0.64 to 3.18 mm) with a raised diamond pattern.

- Finish: Sheets are usually painted with a black finish by powder coating or anodizing to provide a sleek and attractive appearance while providing additional corrosion resistance.

- Common Uses: Black Diamond Sheet is commonly used for decorative purposes, wall cladding, flooring, and applications requiring a sleek black aesthetic.

1/4 Aluminum Diamond Plate 4x8

- Alloy: A common alloy for 1/4 inch thick aluminum diamond plates is 6061 aluminum alloy.

- Alloy Condition: 6061 aluminum alloy is usually in the T6 temper, which provides excellent strength and hardness.

- Specifications: 1/4" thick 4x8 size aluminum diamond plate featuring a raised diamond pattern known for durability. Measures 4 feet (48 inches) wide and 8 feet (96 inches) long.

- Surface Treatment: Sheets may be satin finished, or may be further treated with anodizing or other coatings for added corrosion protection.

- Common Uses: 1/4-Inch Diamond Aluminum Sheet is commonly used in heavy-duty applications such as truck tool boxes, flooring in industrial settings, equipment protection, and trailer flooring.

1/8 Aluminum Diamond Plate 4x8

- Alloy: A common alloy for 1/8 inch thick aluminum diamond plates is 3003 aluminum alloy.

- Alloy Condition: 3003 aluminum alloy is usually in H22 or H24 temper, which has good formability and machinability.

- Specifications: The 4x8 size 1/8" thick diamond aluminum plate has a raised diamond pattern and is thinner than the 1/4" variant. Measures 4 feet (48 inches) wide and 8 feet (96 inches) long.

- Surface Treatment: Sheets may be satin finished, or may be further treated with coatings or finishes to enhance their appearance or provide additional corrosion protection.

- Common Uses: 1/8" Diamond Aluminum Sheet is commonly used in a variety of applications including trailer walls, body panels, trim uses, and protective covers.

1/16 Aluminum Diamond Plate 4x8

- Alloy: 1/16 inch thick aluminum diamond plate commonly used alloy is 3003 aluminum alloy.

- Alloy Condition: 3003 aluminum alloy is usually in H22 or H24 temper, which has good formability and machinability.

- Specifications: 1/16" thick 4x8 size diamond shaped aluminum plate with a raised diamond pattern, relatively thin and lightweight. Measures 4 feet (48 inches) wide and 8 feet (96 inches) long.

- Surface Treatment: Sheets may be satin finished, or may be further treated with coatings or finishes to enhance their appearance or provide additional corrosion protection.

- Common Uses: 1/16" Diamond Aluminum Sheet is often used in applications that require a lightweight, durable material, such as wall coverings, ceilings, craft projects, and small decorative elements.

3/16 Aluminum Diamond Plate 4x8

- Alloy: A common alloy for 3/16 inch thick aluminum diamond plates is 6061 aluminum alloy.

- Alloy Condition: 6061 aluminum alloy is usually in the T6 temper for excellent strength and hardness.

- Specifications: The 4x8 size 3/16" thick aluminum diamond plate has a raised diamond pattern and is thicker than the 1/8" variant. Measures 4 feet (48 inches) wide and 8 feet (96 inches) long.

- Surface Treatment: Sheets may be satin finished, or may be further treated with anodizing or other coatings for added corrosion protection.

- Common Uses: 3/16" Aluminum Diamond Plates are commonly used in heavy-duty applications that require greater strength and durability, such as trailer floors, ramps, stairs, and industrial countertops.

Note that specific alloys, tempers, specifications, finishes and uses may vary depending on the specific requirements of the manufacturer, supplier and application.

Aluminum Diamond Plate 4x8 Application

- Trailer Floor: 4x8 Diamond Aluminum Sheet (3003 Alloy), 0.125" thick, with a raised diamond pattern and a honed finish.

- Truck Bed Liner: 4x8 Diamond Aluminum Sheet (3003 Alloy), 0.080" thick, with a raised diamond pattern and a black powder coat finish.

- Wall Panel: 4x8 diamond aluminum sheet (3003 alloy), 0.063" thick with raised diamond pattern and anodized silver finish.

- Stair Treads: 4x8 diamond shaped aluminum sheet (3003 alloy), 0.125" thick with raised diamond pattern and black painted finish.

- Tool Box Construction: 4x8 diamond shaped aluminum sheet (3003 alloy), 0.080" thick with raised diamond pattern and satin finish.

Note that specific alloys, tempers, specifications, finishes and uses may vary depending on the specific requirements of the manufacturer, supplier and application.

Will Aluminum Diamond Plate Rust?

Aluminum diamond plate is known for its excellent corrosion resistance, which means it is highly resistant to rust. This is mainly due to the natural formation of a protective oxide layer on the surface of aluminum when it is exposed to oxygen. This oxide layer acts as a barrier, preventing further oxidation and rust.

Unlike steel, which can rust when exposed to moisture and air, aluminum diamond plates are less prone to rust. It is commonly used in outdoor and marine applications exposed to moisture and other corrosive elements.

However, it is important to note that although the aluminum diamond plate itself does not rust, it may affect the appearance and condition of the plate if it comes into contact with other metals or corrosive materials. For example, if aluminum diamond plates come into contact with iron or steel particles or come into contact with acids, it can cause surface discoloration or corrosion.

To maintain the appearance and longevity of the diamond aluminum plate, regular cleaning is recommended, avoiding contact with corrosive materials, and considering applying a protective coating or finish as needed.

Cost of 4x8 Sheet of Aluminum Diamond Plate

The cost of a 4x8 diamond aluminum sheet can vary based on a number of factors including alloy, thickness, and supplier. Additionally, market conditions and location can affect pricing.

The cost of a 4x8 aluminum diamond plate is that anodized or coated diamond plates have a higher cost compared to regular ground plates, thicker plates and higher grade alloys tend to be more expensive.

It should be noted that the price may vary greatly depending on specific requirements such as alloy type, thickness, surface treatment and order quantity. To obtain accurate and up-to-date pricing, it is best to consult a supplier, who will be able to provide you with a specific quote based on your requirements and current market conditions.