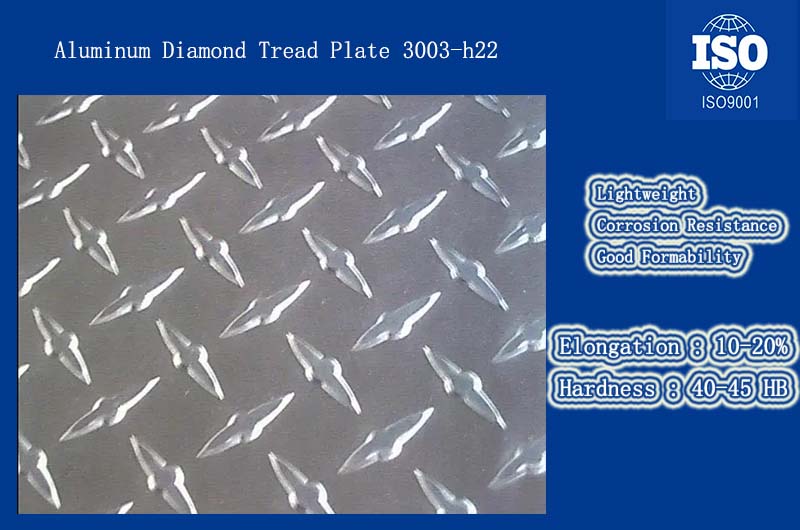

Aluminum Diamond Tread plate 3003-H22 is an aluminum alloy plate with diamond-shaped pattern on the surface. "3003" refers to the alloy composition, mainly composed of aluminum and a small amount of manganese. The "H22" mark indicates the tempering process and hardness level of the plate.

- Aluminum: Aluminum is a lightweight, corrosion-resistant metal that is widely used in various industries due to its good properties.

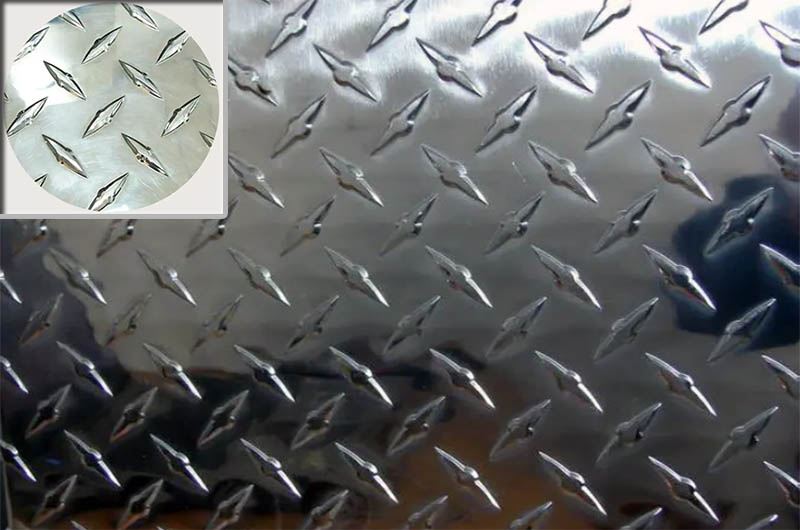

- Diamond tread plate: refers to the pattern on the surface of the aluminum plate, which resembles a series of raised diamonds or diamonds. The diamond pattern provides improved traction and slip resistance, making it suitable for applications requiring a non-slip surface such as industrial floors, stairs, tool boxes and vehicle treads.

- 3003: This is the alloy designation for the specific aluminum alloy used in the sheet. It consists of approximately 98% aluminum, 1% manganese and trace amounts of other elements. The addition of manganese improves the strength and corrosion resistance of the alloy.

- H22: The "H22" temper designation indicates the specific heat treatment and hardness level applied to the aluminum sheet during the manufacturing process. H22 refers to the strain hardened and partially annealed temper, which provides moderate strength and good machinability.

Aluminum Diamond Tread Plate 3003-h22 Mechanical Properties

| Property | Value |

| Tensile Strength | 90-130 MPa |

| Yield Strength | ~70 MPa |

| Elongation | 10-20% |

| Modulus of Elasticity | ~69 GPa |

| Hardness | 40-45 HB |

Aluminum Diamond Tread Plate 3003-h22 Properties

Aluminum Diamond Pedals 3003-H22 have a variety of characteristics and are suitable for a variety of applications. The following are the main properties of this material:

- Lightweight: Aluminum has a low density, so it weighs less than many other metals. This characteristic is advantageous in applications where weight reduction is required, such as in the transportation or aerospace industries.

- Corrosion Resistance: Aluminum has excellent corrosion resistance, especially in environments exposed to moisture or certain chemicals. The presence of manganese in the 3003-H22 alloy further enhances its corrosion resistance.

- Strength: While not as strong as some other aluminum alloys, 3003-H22 still provides reasonable strength and structural integrity for many applications. It is strong enough to meet the load-bearing purposes in all walks of life.

- Formability: Aluminum Diamond Pedal 3003-H22 has good formability making it easy to shape, bend or form into desired configurations. This property makes it suitable for applications requiring custom shapes or designs.

- Non-slip surface: The diamond-shaped tread pattern on the surface of the board provides excellent traction and slip resistance. This makes it ideal for applications where a firm foothold or non-slip surface is critical, such as industrial floors, stairs or vehicle treads.

- Machinability: 3003-H22 can be easily machined, welded and fabricated using common metalworking techniques. It can be cut, drilled, punched and bent effortlessly, allowing for easy fabrication and installation.

- Aesthetic Appeal: The glossy finish of aluminum diamond plate adds visual appeal to applications where appearance is important, such as architectural elements or decorative uses.

Note that specific properties may vary by thickness, temper and specific manufacturing process. Together these properties make Aluminum Diamond Pedal 3003-H22 a versatile and ideal material for a wide range of applications requiring strength, corrosion resistance, non-slip properties and ease of fabrication.

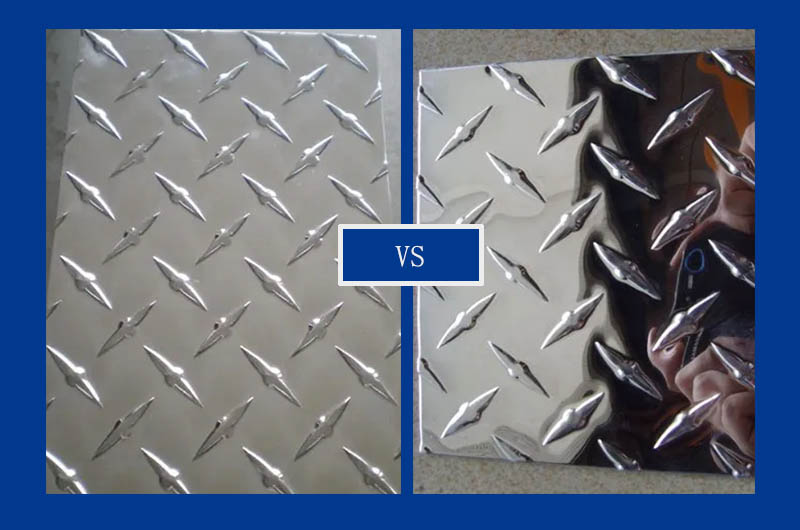

Aluminum Diamond Tread Plate Surface Types

- Grinding: Grinding refers to the surface appearance of an aluminum pedal as it comes straight from the mill without any additional treatments or finishes. It has a smooth and shiny surface, but does not have any particular texture or pattern.

- Bright Finish: A bright finish, as the name suggests, refers to a highly polished and reflective finish on patterned aluminum panels. It is achieved through a mechanical or chemical polishing process, resulting in a smooth, shiny and mirror-like appearance.

- Embossed Finish: An embossed finish consists of adding a textured pattern to the surface of an aluminum pedal. This can be achieved through mechanical processes such as rolling or pressing the board between patterned rollers, or using other techniques such as embossing stamps. The most common pattern for aluminum treads is the diamond pattern, but other patterns such as five bars and stucco are also available.

- Brushed finish: A brushed finish is achieved by brushing the surface of an aluminum pedal with an abrasive material to create a series of thin parallel lines or a brushed texture. This finish provides a unique and visually appealing appearance and is often used for decorative purposes.

It is important to note that different suppliers or manufacturers may offer additional surface treatments or finishes to the 3003-H22 Bright Aluminum Treads such as anodizing or coating processes to enhance durability, corrosion resistance or color options. The specific surface types available may vary depending on the supplier and the intended application of the aluminum tread.

Typical Applications of 3003-H22 Bright Aluminum Tread Plate

3003-H22 Bright Aluminum Treads are commonly used in a wide variety of applications requiring a combination of strength, durability and slip resistance. Here are some common applications:

- Flooring: Widely used as flooring in industrial environments, including warehouses, factories, workshops and garages. The raised diamond pattern provides excellent traction, reducing the risk of slipping in areas where oil, water or other slippery substances may be present.

- Stairs and Steps: Aluminum treads are commonly used on indoor and outdoor stairs and steps to improve safety and prevent accidents. Textured surface helps provide grip and stability when ascending or descending.

- Vehicle and Trailer Flooring: It is commonly used as a flooring material for trucks, trailers and recreational vehicles (RV). The anti-skid properties of the diamond tread pattern make it suitable for these applications where stability and traction are important.

- Tool boxes: Aluminum pedals are a popular choice for tool boxes and storage boxes. The rough surface texture not only enhances the look, but also helps prevent tools and other items from slipping during transport.

- Decorative Applications: The glossy finish of the 3003-H22 Bright Aluminum Tread makes it suitable for decorative use as well. It can be used in architectural elements, wall cladding and interior design to add visual appeal and textured surfaces.

- Treads and Treads: The non-slip properties of aluminum treads make them ideal for treads, step boards and entry ramps. These applications benefit from the extra traction and durability provided by the diamond pattern.

- Marine Applications: The corrosion-resistant properties of aluminum make it the first choice for marine environments. 3003-H22 Bright Aluminum Treads can be used on boat decks, gangways and other marine applications requiring a non-slip surface.

- Other Industrial Uses: It is also used in various industrial applications where a durable non-slip surface is required, such as platforms, workbenches, loading docks and mezzanines.

These are just a few examples of common applications for 3003-H22 Bright Aluminum Checkered Plate. Its versatility, strength and non-slip properties make it a popular choice in different industries.