Global demand for liquefied natural gas (LNG) has been growing steadily as it gains recognition as a cleaner, more efficient energy source.

There has been a significant shift in recent years to the use of aluminum sheets with alloy covers for the construction of LNG storage tanks. This innovative approach to LNG tank construction is transforming the industry by offering numerous advantages in terms of safety, weight reduction and efficiency.

LNG Storage Tank Construction Materials

Ensuring the safety and integrity of LNG during transportation is critical. This responsibility falls squarely on the design and construction of LNG storage tanks, which have evolved over the years to meet the growing demands of the LNG industry.

There are several materials involved in the construction of LNG storage tanks:

- Stainless steel

- nickel

- aluminum

Stainless steel LNG tanks are heavy and require extensive insulation to maintain the low temperatures required to store LNG. This added weight reduces the payload capacity of the transport vehicle and increases fuel consumption.

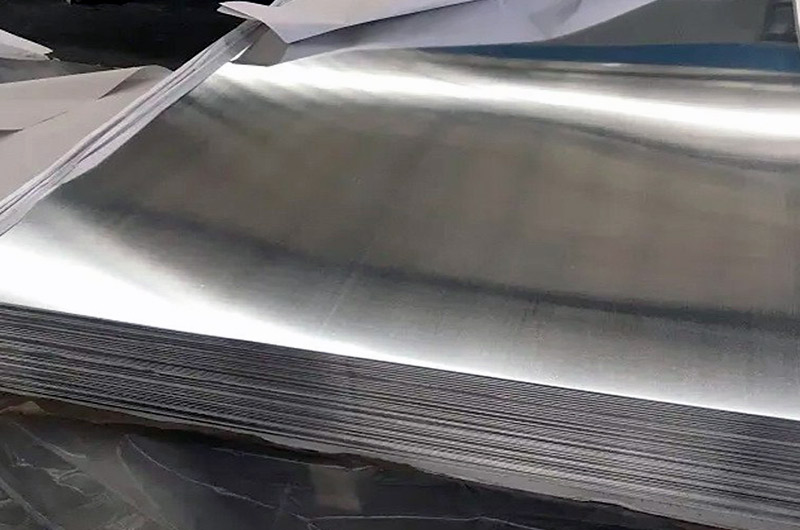

In contrast, aluminum sheets have become a game-changing solution for LNG tank construction. The advantages of using aluminum are manifold, but the specific alloy employed and the use of alloy caps represent key aspects of this transformation.

LNG Storage Tank Alloy Selection

Aluminum plates used in LNG tank construction are typically made from specific aluminum alloys designed to withstand the extreme conditions associated with cryogenic LNG storage.

The most commonly used aluminum alloy for this purpose is 5083, an alloy known for its exceptional combination of properties that make it ideal for LNG storage tank applications.

5083 Aluminum Plate for LNG Tank

5083 Aluminum Plate has excellent corrosion resistance, excellent weldability and excellent strength, especially at low temperatures. These properties make it ideal for building LNG storage tanks.

5083 Aluminum Plate for LNG Tank Features

Let’s dive into the key reasons why 5083 alloy stands out:

1. Corrosion resistance

In LNG's harsh corrosive environment, where temperatures can drop to -162°C (-260°F), corrosion resistance is critical.

Alloy 5083 offers excellent corrosion resistance, ensuring the long-term durability and safety of LNG storage tanks. This is a critical factor in preventing leaks and maintaining the integrity of LNG cargoes.

2. Low temperature strength

The ability to maintain structural integrity at low temperatures is a major requirement for LNG storage tanks.

Alloy 5083 offers impressive strength at low temperatures, ensuring the tank can withstand extreme conditions without compromising safety.

3. Weldability

The construction of LNG storage tanks involves complex welding to achieve the necessary shapes and joints.

Alloy 5083 is known for its excellent weldability, allowing for precise and reliable welding processes that are critical to the integrity and safety of LNG storage tanks.

4. Reduce weight

One of the outstanding advantages of 5083 alloy is its low density. Significant weight savings compared to other materials such as stainless steel.

Weight reduction creates a domino effect, increasing the payload capacity of transport vehicles and reducing fuel consumption. It also minimizes the need for extensive support structures.

5. Efficient thermal insulation

Aluminum's low thermal conductivity contributes to efficient insulation of LNG storage tanks. This feature helps maintain the low temperatures required for LNG storage, reducing the need for excessive insulation, thereby saving space and weight.

6. Easy to manufacture

Aluminum plates made from 5083 alloy are relatively easy to machine, allowing efficient and precise fabrication of LNG storage tanks. This not only reduces production time but also helps save costs.

7. Sustainability

In a world focused on sustainability, aluminum’s environmental credentials are becoming increasingly important. Aluminum cans are lighter than steel cans, resulting in lower fuel consumption and reduced carbon emissions.

Alloy 5083, the alloy selected for LNG storage tanks, provides the best balance of structural integrity, corrosion resistance and weight reduction, making it the industry’s first choice.

However, the innovative approach to LNG tank construction is not limited to alloy selection; it extends to the use of alloy caps, which is a transformative approach.

Advantages of Aluminum Plates with Alloy Covers for LNG Tank

While 5083 alloy forms the core of LNG tank construction, the application of alloy lids represents an ingenious way to further enhance the safety and performance of the tank.

Alloy caps are usually made of materials such as aluminum or stainless steel and are applied to the inner surface of LNG storage tanks to form a sandwich-like structure. This design has several compelling advantages:

- Enhanced safety: Alloy covers provide an extra layer of protection for LNG cargoes. It acts as a barrier between the aluminum can and the LNG, reducing the risk of direct contact. This additional layer adds extra safety, especially in the event of minor structural damage to the tank's interior surface.

- Improve thermal insulation: Using an alloy cover can enhance the thermal insulation performance of the tank. This allows for better temperature control, reduces LNG losses due to boil-off gases, and minimizes the need for additional external insulation.

- Reduced Penetration: The alloy cover further reduces the penetration of cargo through the tank wall. This is especially important to prevent the escape of methane, a potent greenhouse gas. Reducing infiltration contributes to safety and environmental responsibility.

- Maintenance and Repair: When the inner surface of the tank is damaged or worn, the alloy lid is easier to replace or repair than the tank itself. This reduces maintenance costs and downtime.

- Versatility: The use of alloy caps enables versatility in tank design. It can customize the properties of the inner surface, such as corrosion resistance, which can be adjusted to the specific requirements of the LNG being transported.

- Optimize cargo quality: The use of alloy covers helps prevent contamination of the inner tank surfaces, thus maintaining the quality and purity of LNG.

The combination of Alloy 5083 and alloy caps creates a synergy that optimizes LNG tank construction for safety, efficiency and environmental responsibility.

Conclusion

Using aluminum sheets with alloy caps to build LNG tanks is a revolutionary solution that changes the way LNG is transported.

The selection of Alloy 5083, known for its excellent corrosion resistance, low temperature strength and weldability, forms the basis for this innovation. The application of alloy caps to the inner surface of the tank enhances safety, insulation and environmental responsibility.

Developments in LNG tank design have led to safer, lighter, more efficient and environmentally friendly solutions. It increases payload capacity, reduces fuel consumption and minimizes the environmental impact of LNG transportation. These innovations not only advance technology but are in line with the global push for sustainable development and responsible energy transportation.

As demand for LNG continues to grow, the use of aluminum plates with alloy covers in LNG tank construction will play a vital role in ensuring the safe and efficient delivery of this precious energy to consumers around the world.