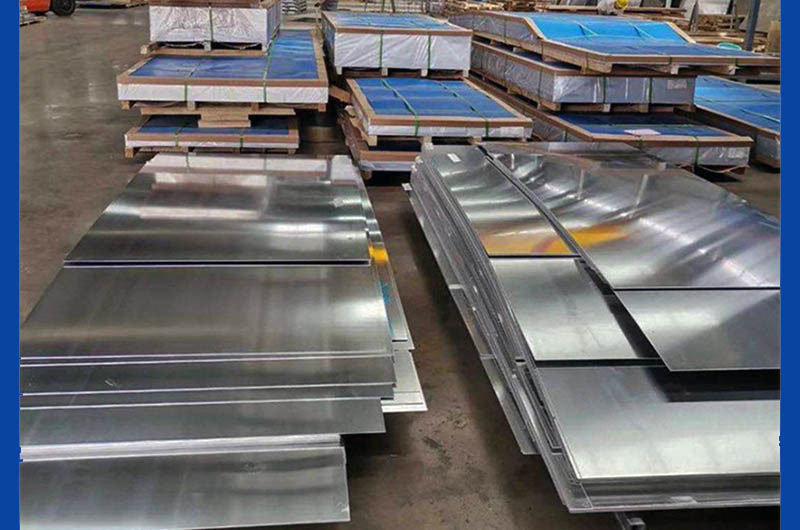

One of the increasingly important components in semi-truck design is aluminum sheeting, specifically the choice of aluminum alloys. Choosing the right alloy can have a significant impact on a semi-truck's efficiency, fuel economy and overall performance.

Here are some key areas where aluminum alloys are used in these heavy-duty vehicles:

a. Body Panels and Structures

Aluminum alloys are employed extensively in the construction of semi truck body panels and structures. These components must be lightweight yet robust, as reducing the truck's overall weight translates to improved fuel efficiency and increased payload capacity. The choice of the right aluminum alloy ensures the required structural integrity while shedding unnecessary pounds.

b. Trailer Construction

Aluminum alloys are commonly used in trailer construction, which is an integral part of the semi truck. Trailers must be durable, corrosion-resistant, and lightweight to maximize cargo capacity and minimize fuel consumption. Specific aluminum alloys are chosen to achieve the ideal balance of these qualities.

c. Fuel Tanks

Aluminum alloys are the preferred material for semi truck fuel tanks. These tanks are exposed to harsh road conditions and require resistance to corrosion. The right aluminum alloy ensures that the fuel tanks remain in good condition, contributing to their extended lifespan and minimizing maintenance costs.

d. Chassis and Frame

The chassis and frame of a semi truck provide the structural backbone, supporting the entire vehicle and its cargo. Aluminum alloys are often used to reinforce these areas, enhancing the truck's overall strength and stability while keeping weight to a minimum.

Choosing the Right Aluminum Alloy for Semi Truck

The selection of the appropriate aluminum alloy is a critical decision in the design and manufacturing of semi trucks. Several aluminum alloys are commonly used in this industry, each offering specific advantages and trade-offs. Let's take a closer look at some of the most common aluminum alloys used in semi trucks and their applications:

a. 6000 Series Alloys

The 6000 series of aluminum alloys are some of the most widely used in the automotive and trucking industries. These alloys are highly versatile, offering a balance of strength, formability, and corrosion resistance. Among the most notable alloys in this series are:

- 6061 Aluminum Alloy: Known for its exceptional strength and corrosion resistance, 6061 is frequently used for truck body panels, structures, and frames. It is particularly suitable for applications requiring high strength and weldability.

- 6063 Aluminum Alloy: This alloy is prized for its excellent extrudability, making it a popular choice for the manufacturing of various components, such as trim and moldings.

b. 5000 Series Alloys

Alloys from the 5000 series are known for their exceptional corrosion resistance, making them an ideal choice for semi trucks that endure harsh environmental conditions. The primary alloy in this series is:

5052 Aluminum Alloy: Renowned for its outstanding corrosion resistance, 5052 is often used in the construction of semi truck fuel tanks, where exposure to moisture and road elements is a constant concern.

c. 7000 Series Alloys

The 7000 series of aluminum alloys are known for their high strength and exceptional durability. While they are not as commonly used as the 6000 series, they find application in specific truck components that require exceptional strength, such as chassis and frames.

7075 Aluminum Alloy: This high-strength alloy is used in critical structural components, where strength and rigidity are paramount. Its use is especially prevalent in applications that require superior fatigue resistance.

The Benefits of Selecting the Right Aluminum Alloy for Semi Truck

Choosing the right aluminum alloy for a semi truck's components offers numerous advantages, each contributing to enhanced efficiency, performance, and cost-effectiveness. Let's explore these benefits in more detail:

a. Weight Reduction

Reducing weight is a primary advantage of using the right aluminum alloy in semi trucks. These vehicles are designed to carry heavy loads, and every pound saved on the truck's structure translates to increased payload capacity and improved fuel efficiency. A lighter truck consumes less fuel and reduces operating costs for trucking companies.

b. Fuel Efficiency

Improved fuel efficiency is a critical goal for the trucking industry, given the high operational costs associated with fuel consumption. The lightweight nature of aluminum alloys directly contributes to better fuel efficiency. Modern semi trucks leverage advanced aerodynamics and aluminum components, working in tandem to reduce drag and enhance fuel economy.

c. Durability and Corrosion Resistance

The correct aluminum alloy choice ensures the durability and corrosion resistance necessary for semi trucks that often traverse various weather conditions and road environments. Resistance to rust and corrosion guarantees that the truck's structural integrity is maintained, contributing to a longer service life and reduced maintenance costs.

d. Eco-Friendly

Reducing a semi truck's weight not only benefits the operator economically but also has positive environmental implications. Lighter trucks emit fewer greenhouse gases, making them more environmentally friendly. As the transportation industry focuses on sustainability and reducing its carbon footprint, the use of the right aluminum alloy aligns with these goals.

e. Improved Cargo Capacity

Reducing the weight of the truck itself means more room for cargo. For the trucking industry, this directly translates to higher profits, as more goods can be transported in a single trip. The use of the right aluminum alloy allows for a larger payload without compromising structural integrity.

f. Better Resale Value

The durability and corrosion resistance of the right aluminum alloy ensure that a semi truck maintains its appearance and functionality over time. This, in turn, can improve its resale value. Trucking companies often consider the long-term value of their assets, making the selection of the right aluminum alloy an attractive choice.

Considerations in Choosing Aluminum Plate for Semi Truck

While the benefits of selecting the right aluminum alloy are significant, it's crucial to consider certain factors when making decisions about materials and design in the trucking industry:

a. Cost

The cost of different aluminum alloys can vary significantly. Some high-strength alloys may be more expensive than others. However, the long-term benefits in terms of fuel efficiency and durability often outweigh the initial investment.

b. Repair and Maintenance

Different aluminum alloys may require specialized equipment and expertise for repair and maintenance. Not all repair shops are equipped to work with all types of aluminum alloys, so it's important to consider the availability of skilled technicians and repair facilities.

c. Compatibility with Steel

Semi trucks often have a combination of steel and aluminum components. Ensuring compatibility and preventing galvanic corrosion between these materials can be a complex engineering challenge. Proper design and engineering considerations are necessary to address this issue.

d. Impact Resistance

While aluminum alloys are strong and lightweight, not all alloys offer the same level of impact resistance. In situations where a truck is subjected to significant force or impact, such as in an accident, the choice of the right alloy can affect how well the components withstand deformation and damage.

e. Recycling

Aluminum is recyclable, but the recycling process can be energy-intensive. While the sustainability benefits of aluminum are clear, its environmental footprint can still be a concern in terms of recycling and production processes. Choosing alloys that are more easily recycled can mitigate this concern.

Real-World Applications of Aluminum Plate for Semi Truck

The use of specific aluminum alloys in semi trucks is not just a theoretical concept—it is already a common practice in the industry. Several major truck manufacturers have adopted aluminum alloys extensively in their designs. Let's take a look at some real-world applications:

a. Freightliner Cascadia

The Freightliner Cascadia is one of the most popular semi trucks on the road, known for its fuel efficiency and innovative design. The Cascadia features an aluminum cab structure, which provides exceptional strength while keeping weight to a minimum. This application showcases the use of advanced aluminum alloys to create a robust yet lightweight vehicle.

b. Volvo VNL

Volvo's VNL series of semi trucks also leverage the advantages of aluminum alloys. The lightweight yet durable nature of aluminum allows these trucks to offer improved fuel efficiency and enhanced cargo capacity, contributing to lower operating costs and increased profitability for trucking companies.

c. Peterbilt 579

Peterbilt's 579 is another example of a semi truck that utilizes aluminum alloys in its construction. The use of aluminum in the 579's cab and other key components ensures a strong and lightweight vehicle, which translates to a competitive edge in terms of fuel efficiency and cargo capacity.

Conclusion

In the world of semi trucks, the choice of the right aluminum alloy for various components is a critical decision that directly impacts efficiency, fuel economy, and overall performance.

The selection of the appropriate alloy can significantly reduce weight, improve fuel efficiency, enhance durability, and reduce maintenance costs.

The trucking industry's growing emphasis on sustainability and environmental responsibility further underscores the importance of choosing the right materials.