Is Aluminum Sheet Good for Roofing?

Yes, aluminum panels are commonly used for roofing in many applications and can be used for thermal insulation. It has several advantages that make it a popular choice for roofing materials.

-

Lightweight: Aluminum is a lightweight material that is easier to handle and install than heavier roofing materials like steel or concrete. This lightweight feature reduces loads on the roof structure, allowing greater design flexibility and potentially reducing construction costs.

- Corrosion Resistance: Aluminum has excellent corrosion resistance, especially when compared to other metals. It forms a natural oxide layer on its surface that provides a protective barrier against moisture, air and other corrosive elements. This corrosion resistance ensures the longevity and durability of aluminum roofing panels, even in harsh environments or coastal locations.

- Weather resistance: Aluminum is highly resistant to weathering, such as UV radiation, temperature fluctuations and extreme weather conditions. It will not rust or degrade in sunlight, ensuring that aluminum roofs retain their appearance and structural integrity over time.

-

Formability: Aluminum is highly malleable and easily formed into different shapes and profiles, allowing versatility in roof design. It can be rolled into sheets to form a standing seam profile, or corrugated for structural strength and drainage.

- Recyclability: Aluminum is a highly sustainable and environmentally friendly material. It is 100% recyclable without any loss of quality, making it the first choice for those looking for an environmentally friendly roofing solution. Aluminum's recyclability reduces the need for new raw materials and minimizes the environmental impact associated with roof replacements.

- Reflectivity: Aluminum has high reflectivity properties, which means it can effectively reflect sunlight and reduce heat gain. This reflective property helps keep buildings cooler, reduces air conditioning energy consumption and increases overall energy efficiency.

- LONG LIFE AND LOW MAINTENANCE: Aluminum shingles have a long lifespan, often exceeding 50 years when properly installed and maintained. They require minimal maintenance, making them a cost-effective long-term option.

Which is the Best Aluminum Sheet for Roofing?

Choosing the best aluminum roofing sheet depends on several factors, including the specific requirements of your roofing project and your personal preferences. When choosing aluminum panels for roofing, there are several factors to consider:

- Specifications: The thickness of the aluminum plate is measured by its specifications. The proper gauge will depend on factors such as roof size, expected loads, and local weather conditions. Thicker gauges provide greater strength and durability, but they can be heavier and more expensive.

- Alloys: Aluminum sheets are available in different alloys, each with its own properties. The most commonly used roofing alloy is 3003, which has good corrosion resistance and formability. Also suitable are 5005 and 5052 alloys, known for their strength and fatigue resistance.

- Coating: Some aluminum panels used for roofing come with a protective coating or finish. These coatings enhance the durability, corrosion resistance and aesthetics of the panels. Common coatings include polyester, PVDF (polyvinylidene fluoride), and SMP (silicon-modified polyester). The choice of coating will depend on your specific requirements.

- Profiles: Aluminum roofing panels are available in different profiles or shapes such as standing seam, corrugated or flat. The profile you choose will depend on the roof's architectural style, design preferences and functional requirements.

What is the Disadvantage in using Aluminum Roofing Sheet?

- It can be more expensive than other roofing materials such as asphalt shingles or corrugated metal sheets.

- Aluminum is a softer metal than steel, so it may be more likely to be dented or damaged by heavy blows such as hailstones.

It is important to consider these factors and consult a roofing professional to determine if an aluminum sheet roof is right for your specific needs and situation.

How Thick is Aluminum for Roofing?

The thickness of aluminum sheets used for roofing can vary according to specific requirements and applications. The gauge (thickness) of aluminum shingles is usually measured in inches or millimeters.

In general, aluminum shingles range in thickness from approximately 0.018 inches (0.46 mm) to 0.032 inches (0.81 mm) for both residential and commercial roofing applications. Thicker sheets, such as 0.040 in. (1.02 mm) or thicker, are available for specific architectural or industrial uses requiring extra strength or durability.

The appropriate thickness of the roofing aluminum sheet will depend on factors such as the size of the roof, local weather conditions (including wind and snow loads), and the specific design and structural requirements of the project. Be sure to consult a roofing professional or refer to the manufacturer's recommendations to determine the appropriate thickness for your particular roof application.

When it comes to aluminum sheets for roofing, there are several factors to consider. Here is some information about aluminum sheets commonly used in roofing applications:

- Alloy: Aluminum shingles are typically made from aluminum alloys such as 3003, 3004, or 3105. These alloys have excellent corrosion resistance and durability.

- Alloy Condition: Aluminum roofing sheets are usually supplied in H14 or H16 condition, which offer good formability and strength.

- Thickness: The thickness of aluminum sheets used for roofing can vary according to specific application and design requirements. Common thicknesses range from 0.024" (0.6mm) to 0.040" (1.0mm).

- Coating: Aluminum shingles often have a protective coating to improve their performance and durability. Common coatings include polyester, PVDF (polyvinylidene fluoride) or SMP (silicon modified polyester).

- Profiles: Aluminum roofing panels are available in a variety of profiles including standing seam, corrugated or flat. The choice of profile depends on the desired aesthetics, structural requirements and drainage capabilities.

- Finishes: Aluminum shingles may come in different finishes such as plain milled or painted finishes in various colours. Finishes can enhance the appearance and longevity of your roof.

- Common uses: Aluminum shingles are commonly used in residential, commercial, and industrial roofing applications. They provide lightweight, durable and weather-resistant solutions for roofs, including pitched roofs, flat roofs and architectural finishes.

Typical Aluminum Roofing Sheets

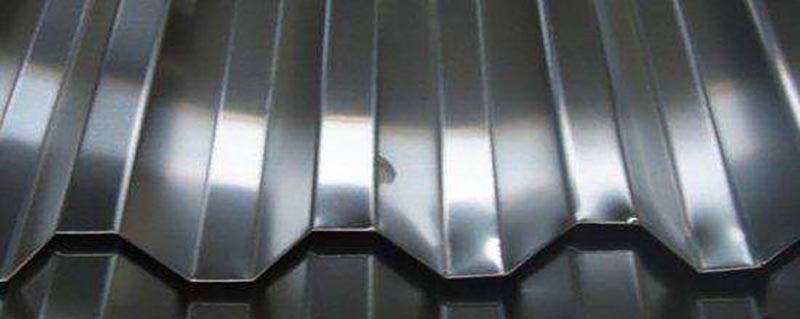

Corrugated Aluminum Roofing Sheets

Aluminum corrugated roof is known for its durability, light weight and corrosion resistance.

- Alloy: The alloys commonly used for corrugated aluminum roofing sheets are usually 3003 or 3004.

- Condition: The aluminum alloys used are usually in the H14 or H24 temper, which provides good formability and strength.

- Finish: Sheets may be satin finished, or they can be coated with polyester or PVDF for added durability and aesthetics.

- Gauge: Aluminum Corrugated Roof Panels may vary in thickness, but a common gauge is 0.032 inches (0.81 mm).

- Common Uses: Aluminum Corrugated Roof Panels are widely used in residential and commercial roofing applications, including homes, warehouses, agricultural buildings, and industrial structures.

Step Tiles Aluminum Roofing Sheet

Step Tiles Aluminum Roofing Sheet features its unique stepped design that provides an aesthetically pleasing appearance while maintaining the functionality of a durable roofing material.

- Alloy: The alloy used for step tile aluminum roofing panels is usually 3003 or 3105.

- Condition: The aluminum alloys used are usually in the H14 or H24 temper.

- Finish: Sheets may be satin finished, or they can be coated with polyester or PVDF for added durability and aesthetics.

- Gauge: Stepped Aluminum Roof Sheets come in a variety of thicknesses, with common gauges ranging from 0.024" (0.61mm) to 0.032" (0.81mm).

- Common uses: Aluminum stepped roofing panels are commonly used in residential and commercial construction, especially in areas where stepped profiles are preferred for architectural reasons. They combine strength, durability and aesthetics.

Aluminum IBR Roof Sheeting

Aluminum IBR Roof Sheeting is known for its durability, strength and corrosion resistance. Inverted box rib design provides structural integrity and enhances water drainage.

- Alloy: Alloys used for aluminum IBR (Inverted Box Rib) roof panels are typically 3004 or 3105.

- Condition: The aluminum alloys used are usually in the H14 or H24 temper.

- Finish: Sheets may be satin finished, or they can be coated with polyester or PVDF for added durability and aesthetics.

- Gauge: Aluminum IBR Roof Sheets are available in a variety of thicknesses, with a common gauge being 0.032 in. (0.81 mm).

- Common Uses: Aluminum IBR roof panels are commonly used in residential, commercial and industrial buildings. It is often chosen for its aesthetics and efficient drainage.

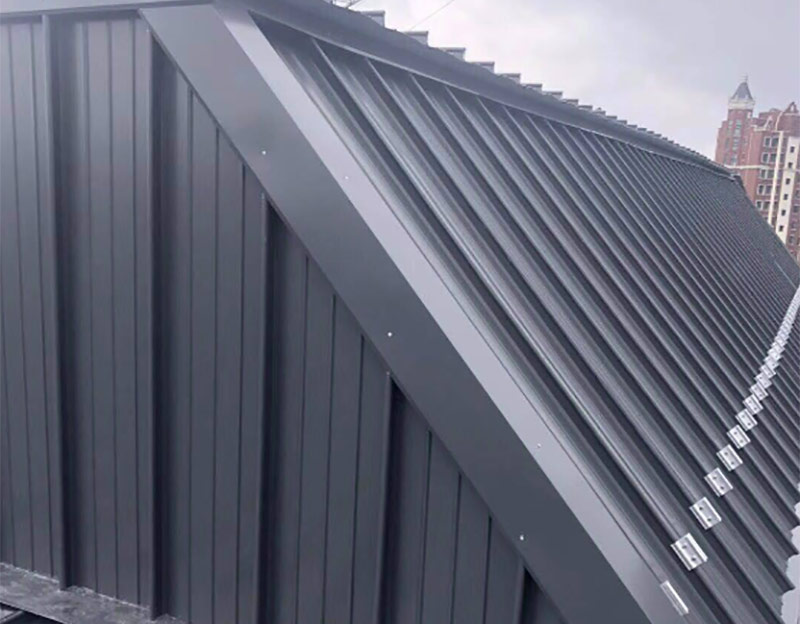

Long Span Aluminum Roofing Sheet

Long Span Aluminum Roofing Sheet is designed for large roofs with a combination of strength, durability and weather resistance.

- Alloy: Alloys used for long span aluminum roof panels are typically 3004 or 3105.

- Condition: The aluminum alloys used are usually in the H14 or H24 temper.

- Finish: Sheets may be satin finished, or they can be coated with polyester or PVDF for added durability and aesthetics.

- Gauge: Long-span aluminum roof panels come in a variety of thicknesses, with a common gauge of 0.032 in. (0.81 mm).

- Common uses: Long-span aluminum roof panels are often used in industrial and commercial buildings, such as factories, warehouses, shopping malls, exhibition halls, etc. that require long-span roofs.

24 Gauge Corrugated Aluminum Roofing

24 Gauge Corrugated Aluminum Roofing offers durability, weather resistance and traditional corrugated profiles.

- Alloy: The alloy commonly used for 24 gauge corrugated aluminum roofing is usually 3003 or 3004.

- Condition: The aluminum alloys used are usually in the H14 or H24 temper.

- Finish: Sheets may be satin finished, or they can be coated with polyester or PVDF for added durability and aesthetics.

- Specifications: 24 gauge corrugated aluminum roofing is approximately 0.024" (0.61mm) thick.

- Common Uses: 24 gauge corrugated aluminum shingles are commonly used for residential and light commercial roofing projects including homes, garages, sheds and small industrial buildings.

Aluminum Sheets for Roofing Application

Aluminum Sheet for Caravan Roof

Aluminum Sheet for Caravan Roof offers lightweight construction, durability and weather resistance.

- Alloy: Commonly used alloys for caravan roof aluminum panels are usually 3003 or 5052.

- Condition: The aluminum alloys used are usually in the H14 or H24 temper.

- Finish: Sheets may be satin finished, or they can be coated with polyester or PVDF for added durability and aesthetics.

- Specifications: The thickness of aluminum caravan roof panels can vary according to specific requirements, but common specifications range from 0.040 inches (1.02 mm) to 0.063 inches (1.60 mm), depending on the size and structural needs of the caravan.

Aluminum Roof Gazebo

Aluminum Roof Gazebo is characterized by lightweight construction, corrosion resistance and resistance to the outdoor elements.

- Alloys: The alloys commonly used for roof gazebo aluminum panels are usually 6061 or 6063.

- Condition: The aluminum alloy used is usually in the T6 or T651 temper, providing excellent strength and stiffness.

- Finish: Sheets may be satin finished, or they can be coated with polyester or PVDF for added durability and aesthetics.

- Specifications: The thickness of the roof gazebo aluminum sheet can vary according to the size and structural requirements of the gazebo. Common gauges range from 0.040" (1.02mm) to 0.125" (3.18mm).

Aluminum Roof Patio

Aluminum Roof Patio offers lightweight construction, weather resistance and durability for outdoor applications.

- Alloys: Alloys commonly used for roof deck aluminum panels are usually 3003 or 6061.

- Condition: The aluminum alloy used is usually in H14 or T6 temper.

- Finish: Sheets may be satin finished, or they can be coated with polyester or PVDF for added durability and aesthetics.

- Specifications: The thickness of aluminum sheets for roof terraces can vary according to the size and structural requirements of the terrace. Common gauges range from 0.040" (1.02mm) to 0.125" (3.18mm).

Aluminum Pergola

Aluminum Pergola offers lightweight construction, corrosion resistance and durability for outdoor applications.

- Alloy: The alloys commonly used for pergola panels are usually 6061 or 6063.

- Condition: The aluminum alloy used is usually in the T6 or T651 temper, providing excellent strength and stiffness.

- Finish: Sheets may be satin finished, or they can be coated with polyester or PVDF for added durability and aesthetics.

- Specifications: The thickness of the aluminum sheet used for the pergola can vary according to the size and structural requirements of the pergola. Common gauges range from 0.040" (1.02mm) to 0.125" (3.18mm).

Aluminum Roof Flashing

Aluminum Roof Flashing is flexible, weather resistant and durable to form a waterproof barrier in roofing applications.

- Alloy: The alloys commonly used for aluminum roof flashing are usually 3003 or 3105.

- Condition: The aluminum alloys used are usually in the H14 or H24 temper.

- Finishes: Flashings can be satin finished or coated with polyester or PVDF for enhanced durability and aesthetics.

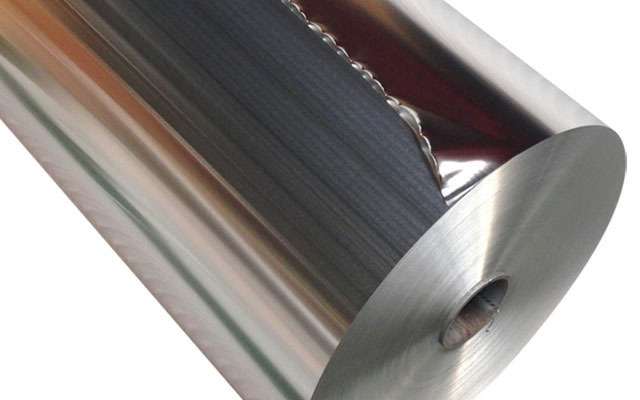

Aluminum Foil Sheet for Roof

Aluminum foil is not usually used alone as a roofing material. However, aluminum foil can be used as a component or insulation in some types of roofing systems.

Here are a few ways aluminum foil can be used for roofing:

- Radiant Barrier: Sheets of aluminum foil can be used as a radiant barrier, reflecting heat away from the roof. This helps reduce heat transfer into the building, keeping it cool and reducing the need for air conditioning. Aluminum foil is often installed under roofing materials, such as under shingles or over insulation.

- Insulation: Aluminum foil can also be used as part of a roof insulation system. Roofs can be fitted with foil-faced insulation panels or felt, consisting of a layer of insulation and a layer of aluminum foil to enhance insulation and reduce heat loss.

- Vapor Barrier: In some roof systems, sheets of aluminum foil can be used as a vapor barrier. This helps prevent moisture from entering the building through the roof, protecting insulation and other components from damage.

How to Install Aluminum Roofing Sheets

Installing aluminum roof panels usually involves the following steps. Note that these are general guidelines and you must refer to the manufacturer's installation instructions for the shingle you are using.

- Safety precautions: Before starting any roofing project, make sure you have the necessary safety equipment such as gloves, goggles, and non-slip shoes. Use caution when working at heights and follow proper safety protocols.

- Prepare the roof: Make sure the roof surface is clean, smooth and free of any debris. Repair any existing damage or leaks and ensure the structural integrity of the roof. Install suitable underlayment or insulation if required by the manufacturer or local building codes.

- Measure and Mark: Measure the dimensions of the roof and mark the layout of the aluminum panels. Start at the bottom edge of the roof and work your way up. Allow for any necessary overhang or edge trimming as recommended by the manufacturer.

- Install eave flashing: Install eave flashing along the bottom edge of the roof to provide a waterproof barrier. Secure it with appropriate fasteners, such as screws or nails, as recommended by the manufacturer.

-

Install the first sheet: Start by placing the first aluminum roof sheet along the bottom edge of the roof, aligning it with the eave flashing. Secure the panels to the roof using appropriate fasteners, making sure they are placed in the designated areas specified by the manufacturer. Use neoprene or rubber gaskets with screws to create a watertight seal.

- Install subsequent panels: Continue installing the remaining aluminum panels, overlapping each panel according to the manufacturer's instructions. Make sure to align them properly and maintain consistent spacing between sheets. Use straight edges or chalk lines to maintain straight lines.

- Trim and Flashing: Cut and trim aluminum panels as needed to accommodate roof penetrations such as vents or chimneys. Install flashings, ridge caps, and sidewall flashings as recommended by the manufacturer to ensure waterproofing and a proper seal.

- Fastening and fixing: Fasten the aluminum panels to the roof structure using appropriate fasteners, such as screws or nails. Ensure proper spacing and fastener placement according to manufacturer's guidelines.

- Finishing touches: Install any additional accessories, such as gutter systems or ventilation components, as required. Check the roof for any loose or protruding fasteners, and make sure all edges and seams are properly sealed.

It is important to follow the manufacturer's specific instructions and guidelines for the specific aluminum shingle you are using, as installation methods may vary. Consulting a professional roofing contractor can provide valuable expertise and ensure proper and safe installation.

Popular Topics about Aluminum Roofing Sheets

- What are the disadvantages of aluminium roofing sheets?

- What is an aluminum roofing sheet?

- aluminum roofing sheets price

- aluminum roofing sheets near me

- aluminum roofing sheets ghana

- aluminum roofing sheets price in kerala

- types of aluminum roofing sheets

- how to install aluminum roofing sheets

- corrugated aluminum roofing sheets

- cost of aluminum roofing sheets in nigeria

- zinc aluminum roofing sheets

- used aluminum roofing sheets

- flat aluminum roofing sheets

- prices of aluminum roofing sheets in nigeria

- how many aluminum roofing sheets are in a bundle

- aluminum zinc roofing sheets

- aluminum long span roofing sheets

- aluminum metal roofing sheets

- aluminum corrugated roofing sheets

- metal roof panels

- metal roofing

- aluminum roof panels prices

- aluminum flashing roll