Aluminum tooling plate, also known as aluminum cast plate or aluminum fixture plate, is an aluminum plate designed for tooling, mold making and precision machining applications. It is a flat, dimensionally stable sheet with high strength and excellent machinability.

One of the main characteristics of aluminum tool plates is their excellent dimensional stability, meaning it retains its shape and flatness even under heavy loads and machining operations. This property makes it ideal for applications requiring high precision and tight tolerances.

Aluminum tool plates are also known for their machinability, allowing them to be easily cut, drilled, milled and shaped using standard machining tools. It has good surface finish capabilities and can be machined to tight tolerances.

Aluminum Tooling Plate Specifications

- Alloy: Aluminum tool plates are usually made of high-quality aluminum alloys, such as 6061 or 7075 aluminum alloys. These alloys were chosen for their excellent mechanical properties and machinability.

- Alloy Condition: Aluminum tool plates are usually supplied in T6 temper for high strength and hardness. T6 temper by solution heat treatment and artificial aging to improve mechanical properties.

- Flatness Tolerance: Common flatness tolerances for aluminum tooling plates range from ±0.005 inches per foot (or ±0.4 mm per meter) to ±0.010 inches per foot (or ±0.8 mm per meter). However, depending on the exact grade and thickness, tighter tolerances may apply.

- Aluminum Tooling Plate Thickness: Common thicknesses range from 1/4 inch (6.35 mm) to 4 inches (101.6 mm) or more. Specific thickness options may vary by manufacturer, and custom thicknesses are available upon request.

- Specifications: Aluminum tool plates are available in various thicknesses, widths and lengths to suit different applications. Common thicknesses range from 1/4 inch to 4 inches or more.

- Surface Finish: Aluminum tool plates usually have a smooth honed finish, which is the natural finish of aluminum machining. However, some manufacturers may offer additional surface treatments or coatings for enhanced corrosion or abrasion resistance.

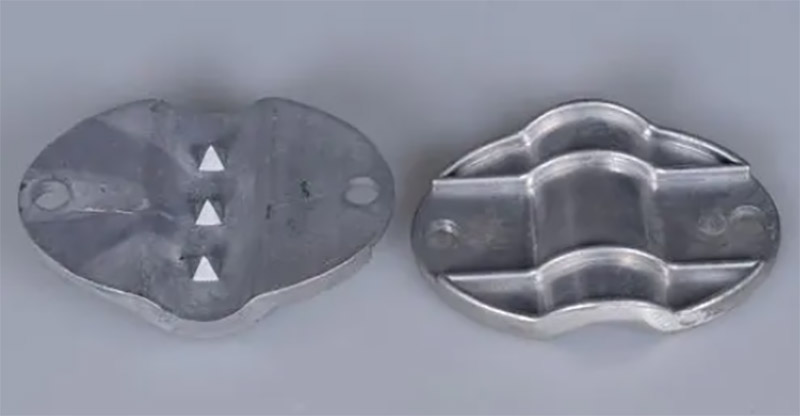

Typical Aluminum Tooling Plate

Cast Aluminum Tooling Plate

- Thickness: Cast aluminum tool plates are available in a variety of thicknesses, typically ranging from 1/4" (6.35mm) to 8" (203.2mm) or larger.

- Flatness: Cast aluminum tool plates are known for their excellent flatness, typically meeting tight flatness tolerances of ±0.005 inches per foot (or ±0.4 mm per meter) or better.

- Tolerances: Tolerances for cast aluminum tool plates may vary by specific grade and manufacturer. Common tolerances include thicknesses of ±0.005 inches (or ±0.127 millimeters).

- Surface Finish: Cast aluminum tooling plates usually have a satin finish, which is the natural surface state after the casting process. It may have slight texture or roughness due to the casting process.

- Common applications: Cast aluminum tooling plates are often used in aerospace, automotive, mold manufacturing, precision machining and other industries. It is suitable for applications requiring high dimensional stability, flatness and deformation resistance.

5083 Aluminum Tooling Plate

- Thickness: 5083 aluminum tool plates are available in a variety of thicknesses, typically from 1/4" (6.35mm) to 4" (101.6mm) or larger.

- Flatness: 5083 aluminum tool plates have good flatness, meeting standard flatness tolerances of ±0.015 inches per foot (or ±1.2 mm per meter) or better.

- Tolerances: Tolerances for 5083 aluminum tool plates may vary depending on specific manufacturer and customer requirements.

- Finishes: 5083 aluminum tool plates are available with a satin finish or with finishes such as anodizing or powder coating for enhanced corrosion resistance and aesthetics.

- Common Applications: 5083 aluminum tool plates are commonly used in marine applications, transportation, structural components and general machining applications.

6061 Aluminum Tooling Plate

- Thickness: 6061 aluminum tool plates are available in a variety of thicknesses, typically from 1/4" (6.35mm) to 8" (203.2mm) or larger.

- Flatness: 6061 aluminum tool plates have good flatness, typically meeting standard flatness tolerances of ±0.015 inches per foot (or ±1.2 mm per meter) or better.

- Tolerances: Tolerances for 6061 aluminum tool plates may vary depending on specific manufacturer and customer requirements.

- Finishes: 6061 aluminum tool plates are available with a satin finish or with a variety of finishes such as anodizing, painting or powder coating for improved corrosion resistance and appearance.

- Common Applications: 6061 aluminum tool plates are commonly used in aerospace, automotive, mold making and general machining applications. It has good machinability, weldability and strength properties.

Aluminum Tooling Plate 6082

- Thickness: Aluminum Tool Plate 6082 is available in a variety of thicknesses, typically ranging from 1/4" (6.35mm) to 8" (203.2mm) or greater.

- Flatness: Aluminum tool plate 6082 has good flatness, typically meeting standard flatness tolerances of ±0.015 inches per foot (or ±1.2 mm per meter) or better.

- Tolerances: Tolerances for 6082 aluminum tool plates may vary depending on specific manufacturer and customer requirements.

- Finishes: 6082 aluminum tool plates are available with a satin finish or with a variety of finishes such as anodizing, painting or powder coating for enhanced corrosion resistance and aesthetics.

- Common Applications: 6082 aluminum tooling plates are commonly used in industries such as automotive, aerospace, mold making, and general machining. It has good strength, machinability and corrosion resistance.

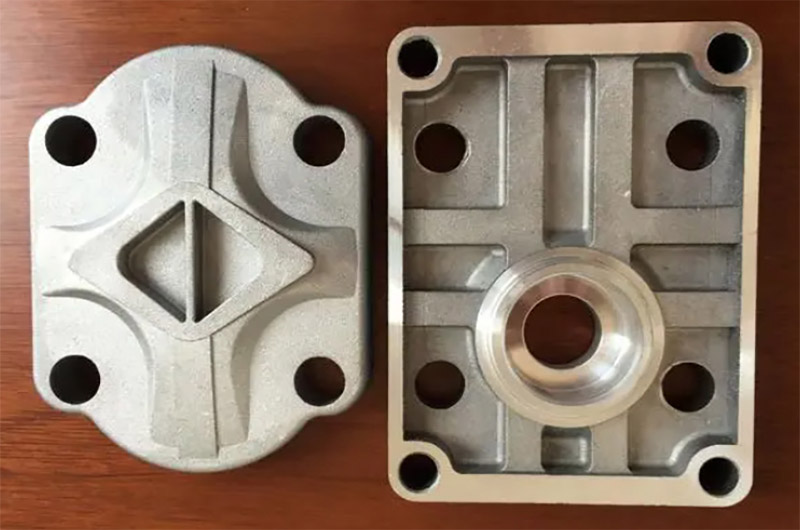

What is the Use of Tooling Plate?

- Common uses: Aluminum tooling plates are widely used in various industries such as aerospace, automobiles, ships, electronics, and mold manufacturing. Some common applications include:

- Tools and Fixtures: Aluminum tool plates are used to create jigs, fixtures and tool assemblies for precision machining and manufacturing processes.

- Moldmaking: Aluminum mold plates are used to make molds for injection molding, blow molding, and other molding processes. Its excellent dimensional stability and machinability make it ideal for creating precise and repeatable molds.

- Patternmaking: Aluminum tooling plates can be used to make patterns for metal castings such as sand casting or investment casting.

- Precision Machining: Aluminum tooling plates are machined into high-precision components that require tight tolerances and flatness.

- Structural Applications: In some cases, aluminum tooling plates are used as structural components in applications requiring high strength and lightweight construction.

What is the Difference between ATP-5 and MIC6 Aluminum?

ATP-5 and MIC6 are two commonly used grades of aluminum tooling plate, each with its own unique properties and characteristics. Here is a comparison between ATP-5 and MIC6:

Alloy Composition

- ATP-5: ATP-5 is an aluminum alloy mainly composed of aluminum (about 92.4%), magnesium (5.5%) and silicon (1.1%). It also contains small amounts of other elements to improve mechanical properties.

- MIC6: MIC6 is an aluminum alloy belonging to the Al-Si-Cu-Mg family. It consists of aluminum (about 91.7%), silicon (1.7%), copper (0.7%) and magnesium (0.5%). It also contains trace amounts of other elements.

Flatness and Dimensional Stability

- ATP-5: ATP-5 has excellent dimensional stability and flatness. It is known for its minimal deviation from flatness, making it suitable for applications requiring high precision and tight tolerances.

- MIC6: MIC6 is known for its excellent flatness and stability. It is manufactured to have extremely low internal stress, ensuring minimal deformation during machining or heat treatment.

Machinability

- ATP-5: ATP-5 is highly machinable for cutting, drilling, milling and shaping with ease. It produces clean and precise cuts, making it the first choice for tooling and machining operations.

- MIC6: MIC6 is also known for its excellent machinability. It provides good chip control, reduces tool wear, and provides a smooth surface finish during machining.

Heat Treatment

- ATP-5: ATP-5 can be heat treated to enhance its mechanical properties and hardness. Heat treatment processes such as artificial aging can improve the strength and dimensional stability of ATP-5.

- MIC6: MIC6 is a cast aluminum alloy that does not respond to heat treatment. Its properties are inherent in the as-cast condition and do not require any additional heat treatment processes.

Application

- ATP-5: ATP-5 is typically used in tooling, mold making, fixtures and precision machining applications requiring high dimensional stability and accuracy.

- MIC6: MIC6 is widely used in occasions with special requirements for flatness, such as high-precision systems such as optical platforms, semiconductor equipment, and testing equipment.

It is important to note that while ATP-5 and MIC6 have some overlapping properties, they may have minor differences in flatness tolerances, surface finish, and specific mechanical properties. It is recommended to consult the manufacturer's specifications or guides to select the grade that best suits your specific application requirements.

How Flat is Aluminum Tooling Plate?

Aluminum tool plates are known for their excellent flatness. It is manufactured with high precision to ensure minimal deviations from its surface flatness. Flatness tolerances for aluminum tooling plates are usually specified by the manufacturer or supplier.

The flatness of aluminum tooling plates is usually measured using specialized equipment, such as panels and dial gauges. The plate is placed on the platform and a dial gauge is used to measure any deviation or change in flatness across the surface.

The flatness of aluminum tooling panels is usually specified in terms of maximum allowable deviation, usually expressed in inches per foot or millimeters per meter. For example, common specifications for aluminum tooling plates might be within a flatness tolerance of ±0.005 inches per foot (or ±0.4 mm per meter).

It is important to note that exact flatness tolerances may vary depending on the grade, thickness and manufacturer of the aluminum tooling plate. Different applications may require different flatness, and manufacturer's specifications or guidelines must be consulted to ensure the flatness required for your specific application.

Overall, aluminum tool plates are designed and manufactured to provide a high degree of flatness, making them suitable for applications requiring precise and accurate machining, tool and mold making operations.