Aluminum checker plate, also known as aluminum tread plate or aluminum diamond plate, is a type of lightweight and durable sheet material made from aluminum.

The surface of the Aluminum Checker Plate has a unique pattern of raised lines or diamonds, including:

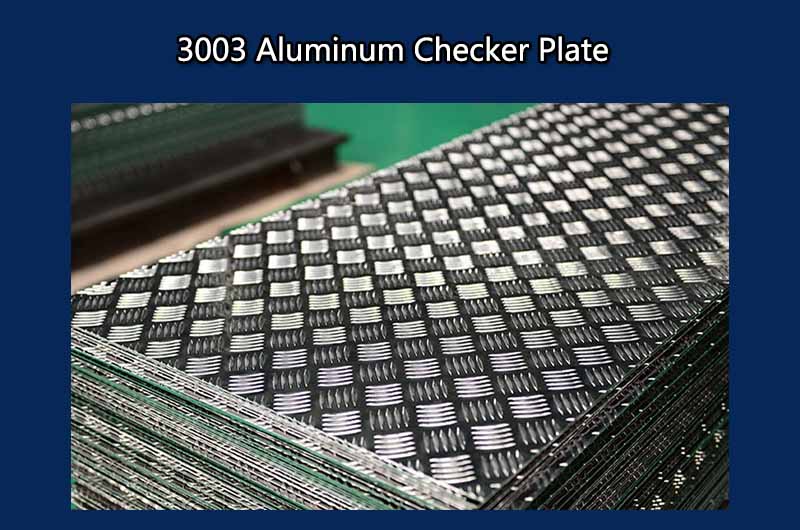

- 3003 Aluminum Checker Plate

- 5052 Aluminum Checker Plate

- 5083 Aluminum Checker Plate

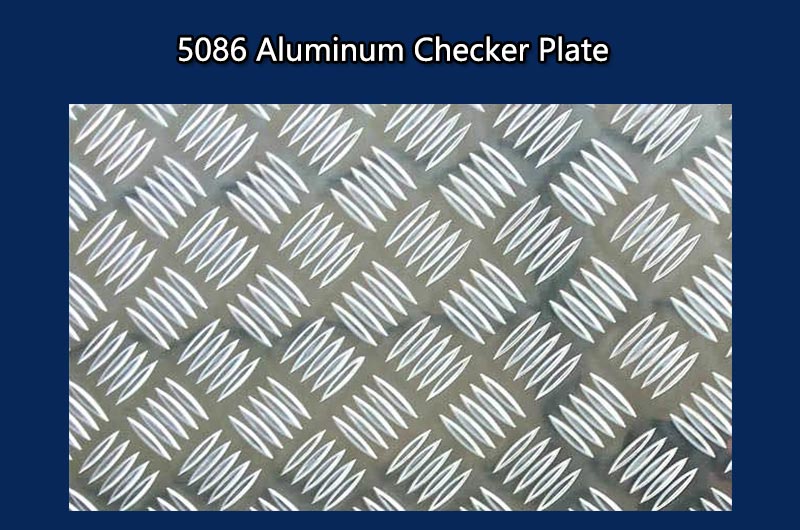

- 5086 Aluminum Checker Plate

- 5754 Aluminum Checker Plate

- 1100 Aluminum Checker Plate

- 6063 Aluminum Checker Plate

- 6061 Aluminum Checker Plate

This blog will analyze the characteristics of these Aluminum Checker Plates to help you choose the right Aluminum Checker Plate.

3003 Aluminum Checker Plate

3003 Aluminum Checker Plate is typically used in indoor and outdoor applications where corrosion resistance is important.

Advantages: good corrosion resistance, formability, weldability. Economical choice for general purpose applications.

Cons: Lower strength compared to some other alloys.

Features: Moderate strength, excellent processing performance, and certain resistance to atmospheric and chemical corrosion.

Mechanical Behavior :

- Tensile strength approximately 140 MPa (20, 000 psi)

- Yield strength approximately 115 MPa (17, 000 psi)

Applications: Indoor and outdoor floors, decorative surfaces, lightweight construction.

5052 Aluminum Checker Plate

5052 Aluminum Checker Plate Alloy 5052 has higher strength than 3003 and is also known for its good corrosion resistance. It is commonly used in marine environments and applications requiring higher strength.

Advantages: high corrosion resistance, excellent strength, good weldability, suitable for marine environment.

Cons: Slightly more expensive than some other alloys.

Features: High strength, excellent corrosion resistance, suitable for harsh environments.

Mechanical Behavior:

- Tensile strength approximately 215 MPa (31, 000 psi)

- Yield strength approximately 160 MPa (23, 000 psi)

Applications: Marine decks, truck beds, vehicle panels, steps in corrosive environments.

5086 Aluminum Checker Plate

5086 Aluminum Checker Plate It is suitable for aluminum checker plates used in ships and other marine structures.

Advantages: Similar advantages to 5083, including corrosion resistance and strength.

Disadvantages: Similar disadvantages to 5083.

Features: high corrosion resistance, good weldability, moderate strength.

Mechanical Behavior:

- Tensile strength approximately 270 MPa (39, 000 psi)

- Yield strength approximately 120 MPa (17, 000 psi)

Applications: Marine applications, truck bodies, hulls and decks.

5083 Aluminum Checker Plate

5083 Aluminum Checker Plate Like 5086, alloy 5083 is also used in marine applications. It has high strength and excellent corrosion resistance, making it suitable for harsh environments.

Advantages: outstanding corrosion resistance, high strength, good weldability, very suitable for marine applications.

Cons: Limited availability and higher cost.

Features: High strength, excellent corrosion resistance, especially in salt water conditions.

Mechanical Behavior:

- Tensile strength approximately 275 MPa (40, 000 psi)

- Yield strength approximately 125 MPa (18, 000 psi)

Applications: Shipbuilding, ship decks, structural components in marine environments.

5754 Aluminum Checker Plate

5754 Aluminum Checker Plate is known for its excellent corrosion resistance and high strength. It is commonly used in transportation applications such as bodywork and trailers.

Advantages: good corrosion resistance, high strength, wide range of uses.

Disadvantages: Not as corrosion resistant as 5083 or 5052 in marine environments.

Features: high strength, good formability, resistance to atmospheric and chemical corrosion.

Mechanical Behavior:

- Tensile strength approximately 190 MPa (28, 000 psi)

- Yield strength approximately 105 MPa (15, 000 psi)

Applications: Vehicle components, shipbuilding, general structural use.

1100 Aluminum Checker Plate

1100 Aluminum Checker Plate is softer and less strong, so it is suitable for applications where formability and corrosion resistance are more important than high strength.

Advantages: good corrosion resistance, high strength, wide range of uses.

Disadvantages: Not as corrosion resistant as 5083 or 5052 in marine environments.

Features: high strength, good formability, resistance to atmospheric and chemical corrosion.

Mechanical Behavior:

- Tensile strength approximately 190 MPa (28, 000 psi)

- Yield strength approximately 105 MPa (15, 000 psi)

Applications: Vehicle components, shipbuilding, general structural use.

6063 Aluminum Checker Plate

6063 Aluminum Checker Plate Similar to 6061, alloy 6063 is used in applications requiring good strength and excellent finishing characteristics. It is commonly used for decorative purposes and architectural applications.

Pros: Good finishing properties, moderate strength.

Cons: Lower strength compared to some other alloys.

Features: moderate strength, excellent extrudability, good surface finish.

Mechanical Behavior:

- Tensile strength approximately 145 MPa (21, 000 psi)

- Yield strength approximately 80 MPa (11, 000 psi)

Applications: Building panels, decorative trim, lightweight non-load-bearing uses.

6061 Aluminum Checker Plate

6061 Aluminum Checker Plate is known for its high strength and excellent machinability. It is commonly used for structural components, including aluminum checker plates for heavy-duty applications.

Advantages: high strength, excellent machinability, good corrosion resistance.

Cons: Less corrosion resistance compared to some other alloys.

Features: high strength, good machinability, good corrosion resistance.

Mechanical Behavior:

- Tensile strength approximately 290 MPa (42, 000 psi)

- Yield strength approximately 240 MPa (35, 000 psi)

Applications: Heavy duty floors, industrial platforms, structural components.

Aluminum Checker Plate not only has a decorative appearance, but also enhances its slip resistance and durability.

8 Considerations for Choosing an Aluminum Checker Plate

Which Aluminum Checker Plate is better? How to choose your Aluminum Checker Plate? Consider these factors when choosing an Aluminum Checker Plate.

Choosing the right Aluminum Checker Plate for your specific application involves considering 8 factors to ensure optimum performance and durability. The following guidelines can help you make an informed decision:

NO1. Application Requirements

Learn about the uses of Aluminum Checker Plates. Is it suitable for indoor or outdoor use? Will it be exposed to aggressive environments like salt water or chemicals? Determine load bearing requirements and any safety considerations such as slip resistance.

NO2. Corrosion Resistance

If your application involves exposure to moisture or corrosive substances, give preference to alloys with excellent corrosion resistance. Alloys 5083 and 5052 are particularly suitable for marine and harsh environments.

NO3. Strength Requirements

Consider the weight or load that the Aluminum Checker Plate needs to support. For heavy-duty applications, alloys such as 6061 and 5086, which have higher strength properties, may be more suitable.

NO4. Formability and Machinability

Depending on your manufacturing needs, consider the alloy's formability (ability to form without cracking) and machinability (ease of machining). Alloys such as 3003 and 6063 are known for good formability, while 6061 has excellent machinability.

NO5. Budget and Availability

Different alloys have different costs. Consider your budget while also considering the availability of alloys in your area. More common alloys may be more readily available and cost-effective.

NO6. Aesthetic Considerations

If appearance is important, consider the visual appeal of Aluminum Checker Plate surface patterns and finishes. Certain applications require an attractive appearance, such as architectural uses.

NO7. Environmental Conditions

Consider the environmental conditions your Aluminum Checker Plate will face, including temperature changes and weather elements. Certain alloys excel in extreme conditions.

NO8. Weldability

If your project involves welding, make sure the chosen alloy has good weldability. Some alloys are easier to weld than others.