With the development of science and technology, the automobile industry has achieved unprecedented development, promoting the update and iteration of automobile materials.

As the first choice material for automobile lightweighting, aluminum can effectively reduce the weight of the entire automobile and has been widely used in the following automobile industries:

- Car Body: Aluminum alloys, such as 6000 series (e.g., 6061 and 6063) and 5000 series (e.g., 5052), are often used for car body panels and structures to reduce weight while maintaining strength.

- Bumper: Bumpers may use aluminum alloys like 6000 series (e.g., 6061) for their impact-absorbing properties and lightweight characteristics.

- Engine Spare Parts: Various engine components may use aluminum alloys, such as 3000 series (e.g., 3003) or 5000 series (e.g., 5083), due to their heat resistance and high strength-to-weight ratio.

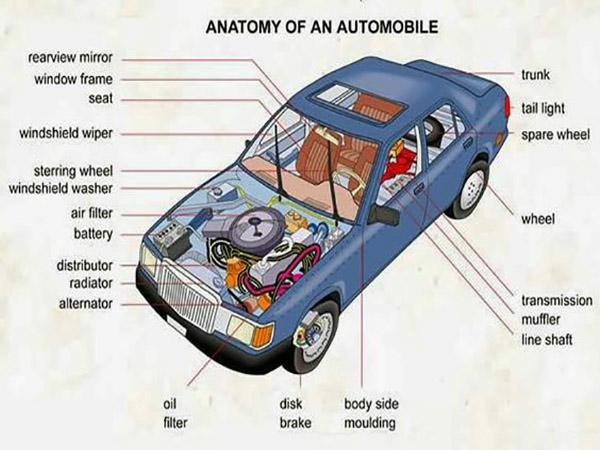

- Wheel: Aluminum alloy wheels are commonly made from 6000 series alloys like 6061 or 6063 for their lightweight and durable properties.

- Chassis Parts: Chassis parts may also use 6000 series aluminum alloys like 6061 or 6063 for their lightweight and corrosion resistance.

- Car Wire: While not a structural component, car wiring can use aluminum conductors due to their conductivity and lightweight properties.

- The production of new energy vehicles will increase year by year, and the demand for battery aluminum foil will continue to grow.

Development Trend of Automotive Aluminum

As environmental pollution problems become increasingly prominent, lightweight vehicles and low energy consumption are major trends in future automobile manufacturing.

With its light weight and excellent mechanical properties, metallic aluminum has become the preferred metal material for lightweight vehicles, and has also greatly promoted the development of electric new energy vehicles.

In the future, the proportion of new energy electric vehicles will continue to increase. As the main manufacturing metal material for new energy electric vehicles, the amount of aluminum used will also continue to increase. The London Commodity Research Institute predicts that the global aluminum consumption of hybrid vehicles and electric vehicles will be Reach 10Mt in 2030.

Due to the trend of lightweight vehicles, the amount of aluminum used in various components of traditional gasoline vehicles will also continue to increase. According to relevant statistics, the average aluminum consumption in the world's automobiles is increasing every year. It is expected that by 2025, the average aluminum consumption in the world's automobiles will increase from the current 15% to 20%, that is, the amount of aluminum used will reach 240kg.

Applications Forms of Automotive Aluminum

Aluminum alloys and aluminum-based composite materials are used in automobile manufacturing. Metal aluminum has low strength and is not suitable for making structural components alone. It is often necessary to add other metal elements to improve mechanical properties, prepare aluminum alloys, and then be used in automobile manufacturing.

The main metal elements added to aluminum alloys include copper, zinc, manganese, silicon, magnesium, etc. Among them, aluminum-magnesium alloys have the most application research. A magnesium-aluminum alloy can be prepared by placing aluminum ingots and magnesium ingots in protective gas and then melting them at high temperature.

1. Magnesium-aluminum alloy has the advantages of light weight, good cutting performance, strong damping, weldability, easy recycling, high specific stiffness and specific strength. It is widely used in instrument panels, steering wheels, transmissions, oil pans, and cylinder covers. There are many key components such as seat frame and wheel hub.

2. Aluminum gill alloy is an emerging alloy with the advantages of good reproducibility, high recovery rate, long effective time for deterioration, low equipment corrosion, low volatility, etc. It can be used in the production of automobile pistons, pump bodies, and wheel hubs. There will be more and more research and applications on automotive aluminum alloys in the future.

2. Aluminum-based composite materials are also a major research and development direction for future automotive aluminum materials. Aluminum-based composite materials are prepared by using metallic aluminum as a matrix and then adding one or more other materials through a special material preparation process.

Due to the combination with other metal materials, aluminum-based composite materials have better fatigue resistance, plasticity, wear resistance and toughness based on the characteristics of the original metallic aluminum.

An A1203/ZA1Si12CulMglNi1 composite piston was prepared using squeeze casting and gravity casting methods, and its mechanical properties are better than those of the conventional ZA1Si12CulMgINi1 alloy.

The American Ford Company has developed a SiCp/A1 aluminum-based composite brake disc, no longer using cast iron brake discs, and has mass-produced it and applied it to the front and rear wheels of Lincoln TownCar; the sports car (Elise) produced by Lotus Company The moving plate is also made of aluminum-based composite material.

At present, aluminum-based composite materials are widely used in automobile brake devices, manufacturing gear boxes, drive shafts, rocker arms and other automobile components. In the future, aluminum-based composite materials will be increasingly used in automotive parts.

Car Battery Aluminum Foil

The development of new energy vehicles will promote the rapid growth of demand. New energy vehicles have become an important measure to control smog and win the battle to defend the blue sky.

The development of new energy vehicles is an urgent task to promote the transformation and upgrading of the automobile industry and seize the commanding heights of international competition. It is also an important breakthrough for promoting green development and cultivating new development momentum.

Battery aluminum foil is an important material for power batteries. The basic structure of carp battery includes positive electrode, negative electrode, electrolyte and separator. Battery aluminum foil refers to the aluminum junction used as cathode material for carp ion batteries, or aluminum foil for carp battery current collectors. It is a finishing product in the aluminum foil product series.

At present, the commonly used alloy components of its mainstream products are: pure aluminum 1XXX series, thickness 0.010~0.020mm, status H18

In addition, products such as aluminum-plastic films for battery soft packages, tabs, modified carbon-coated foils, and electro-etched foils are available. Therefore, aluminum foil plays a vital role in the development of new energy vehicles.

New energy vehicle power batteries require aluminum foil, and the development goals of electric vehicles are energy saving, automation and driverless driving. It has even greater requirements to reduce the weight of the vehicle itself, and the characteristics of aluminum make it the undisputed vehicle of the moment. The preferred material for lightweighting, therefore, aluminum plays an increasingly important role in the development of new energy vehicles.