Black aluminum sheet is commonly used in a variety of applications including signage, decorative panels, architectural elements, automotive parts, and more. Here are some key characteristics:

- Alloys: Alloys used for black aluminum sheets can vary, such as 3003 or 5052 aluminum alloys.

-

Alloy state: Aluminum sheet is usually in H14 or H24 temper, which has good formability and machinability.

- Finish: Black aluminum panels are often painted or finished with black for a smooth, matte look. Some Sheets may also have an anodized black finish for added durability and corrosion resistance.

- Common uses: Black aluminum panels are commonly used in interior and exterior applications where a black, modern or industrial aesthetic is desired. They are used in architectural elements, signage, decorative panels, electronic enclosures, trim and a variety of other applications.

Specific alloys, tempers, finishes, and common uses may vary by manufacturer, supplier, and individual project requirements.

Typical Black Aluminum Sheet

.040 Black Aluminum Sheet

- Alloy: Alloys commonly used for .040 black aluminum sheet can vary, such as 3003 or 5052 aluminum alloys.

- Alloy state: Aluminum sheet is usually in H14 or H24 temper, which has good formability and machinability.

- Gauge: 0.040 Black Aluminum Sheet is approximately 0.040" or 1.02mm thick.

- Common Uses: .040 black aluminum sheet is commonly used for signage, automotive components, interior design elements, decorative panels, and other applications requiring a black aesthetic.

1 8 Black Anodized Aluminum Sheet

- Alloy: The alloy used for 1/8 black anodized aluminum sheet can vary, such as 5005 or 6061 aluminum alloy.

- Alloy Condition: Aluminum sheet is usually in T3 or T6 temper, offering different levels of strength and hardness.

- Specifications: 1/8 black anodized aluminum sheet is approximately 0.125" or 3.18mm thick.

- Finish: 1/8 black anodized aluminum sheet is anodized to create a black, corrosion resistant finish.

- Common Uses: 1/8 Black Anodized Aluminum Sheet is commonly used in architectural applications, aerospace components, electronic enclosures, decorations, and more.

125 Black Anodized Aluminum Sheet

- Alloys: Alloys commonly used for 125 black anodized aluminum sheet can vary, such as 6061 or 7075 aluminum alloys.

- Alloy Condition: Aluminum sheet is usually in T6 temper condition, which has high strength and hardness.

- Gauge: 125 black anodized aluminum sheet is approximately 0.125" or 3.18mm thick.

- Finish: 125 black anodized aluminum panels are anodized to create a black, corrosion-resistant finish.

- Common Uses: 125 Black Anodized Aluminum Sheet is commonly used in aerospace applications, industrial machinery, automotive parts, and other high-strength applications where a black finish and durability are important.

4 X 8 Aluminum Diamond Plate Sheet Black

- Alloy: 4 x 8 Black Aluminum Diamond Plates Commonly used alloys can vary such as 3003 or 6061 aluminum alloys.

- Alloy Condition: Aluminum sheet is usually in the H22 or T6 temper, depending on the specific alloy.

- SPECIFICATIONS: Sheet measures 4' x 8' (48" x 96"), thickness may vary depending on specific application and requirements.

- Common Uses: 4 x 8 Black Diamond Aluminum Sheet is commonly used for flooring, wall cladding, truck beds, tool boxes, and other applications that require a durable and visually appealing black surface.

Black Aluminum Sheet 4x10

- Alloy: Alloys commonly used for 4x10 size black aluminum sheets may vary, such as 5052 or 6061 aluminum alloys.

- Alloy state: Aluminum sheet is usually in H14 or H24 temper, which has good formability and machinability.

- SPECIFICATIONS: Sheet measures 4' x 10' (48" x 120"), thickness may vary depending on specific application and requirements.

- Common Uses: 4x10 size black aluminum sheet is commonly used for larger signage, building panels, facades and other applications requiring larger dimensions and a black finish.

Types of Black Aluminum Sheets Surface Treatments or Finishes

Black Aluminum Diamond Plate Sheets

- Alloys: Alloys commonly used for black aluminum diamond sheets can vary, such as 3003 or 6061 aluminum alloys.

- Alloy Condition: Aluminum sheet is usually in the H22 or T6 temper, depending on the specific alloy.

- Specifications: The thickness and size of the black diamond aluminum plate can vary according to the specific application and requirements.

- Common Uses: Black Diamond Aluminum Sheet is commonly used for flooring, wall cladding, truck beds, tool boxes and other applications that require a durable and visually appealing black surface with extra slip resistance.

Black Anodized Aluminum Sheet

- Alloys: Alloys commonly used for black anodized aluminum sheet can vary, such as 5005 or 6061 aluminum alloys.

- Alloy Condition: Aluminum sheet is usually in T3 or T6 temper, offering different levels of strength and hardness.

- Specifications: Thickness and dimensions of black anodized aluminum sheet can vary according to specific application and requirements.

- Finish: Black anodized aluminum panels are anodized to create a black, corrosion-resistant finish.

- Common Uses: Black anodized aluminum sheet is commonly used in architectural applications, electronics enclosures, decorative trim, and other projects that require a durable black finish and enhanced corrosion resistance.

Black Brushed Aluminum Sheet

- Alloys: Alloys commonly used for black brushed aluminum sheet can vary, such as 3003 or 5052 aluminum alloys.

- Alloy state: Aluminum sheet is usually in H14 or H24 temper, which has good formability and machinability.

- Specifications: Black brushed aluminum sheet thickness and dimensions can vary according to specific applications and requirements.

- Surface treatment: Black brushed aluminum sheet has a brushed texture and black finish, usually achieved by mechanical brushing or chemical process.

- Common Uses: Black brushed aluminum sheet is commonly used in interior design, signage, decorative panels, appliances, and other applications that require a sleek black finish with a textured appearance.

Black Painted Aluminum Sheet

- Alloys: Alloys commonly used for black painted aluminum panels can vary, such as 3003 or 5052 aluminum alloys.

- Alloy state: Aluminum sheet is usually in H14 or H24 temper, which has good formability and machinability.

- Specifications: Thickness and dimensions of black painted aluminum sheet can vary according to specific application and requirements.

- Finish: Blackened aluminum panels are painted or coated with black for a smooth consistent black finish.

- Common Uses: Black painted aluminum sheet is commonly used in architectural applications, automotive parts, signage, and other projects that require a solid black appearance with increased durability and weather resistance.

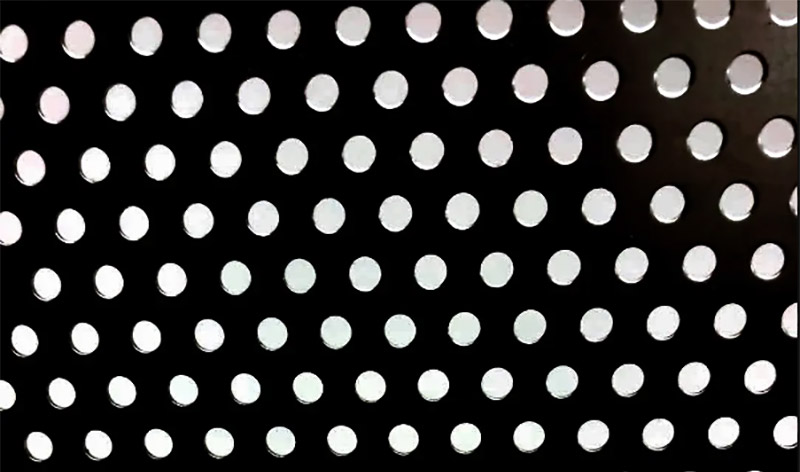

Black Perforated Aluminum Sheet

- Alloys: Alloys commonly used for black perforated aluminum sheet can vary, such as 3003 or 6061 aluminum alloys.

- Alloy state: Aluminum sheet is usually in H14 or H24 temper, which has good formability and machinability.

- Specifications: The thickness and size of the black perforated aluminum sheet can vary according to the specific application and requirements. The perforations can be of different sizes and patterns.

- Finish: Black perforated aluminum panels may be painted or coated with black for a consistent black finish.

- Common Uses: Black perforated aluminum panels are commonly used in architectural applications, HVAC systems, trim panels, sound insulation, and other projects that require airflow, visibility, and a black appearance.

Gloss Black Aluminum Sheet

- Alloys: Alloys commonly used for gloss black aluminum panels can vary, such as 3003 or 5052 aluminum alloys.

- Alloy state: Aluminum sheet is usually in H14 or H24 temper, which has good formability and machinability.

- Specifications: Thickness and dimensions of gloss black aluminum sheets can vary according to specific applications and requirements.

- Finish: Gloss black aluminum panels feature a glossy, reflective black finish that enhances aesthetics.

- Common Uses: Gloss black aluminum sheet is commonly used for automotive parts, signage, interior design and other applications that require a high-gloss, glossy black appearance.

Matte Black Aluminum Sheet

- Alloys: Alloys commonly used for matte black aluminum sheets can vary, such as 3003 or 5052 aluminum alloys.

- Alloy state: Aluminum sheet is usually in H14 or H24 temper, which has good formability and machinability.

- Specifications: Thickness and dimensions of matte black aluminum sheets can vary according to specific applications and requirements.

- Finish: Matte black aluminum panels have a non-reflective, textured black finish that reduces glare and provides a soft look.

- Common uses: Matte black aluminum sheet is commonly used in interior design, furniture, electronics enclosures, and other applications that require a low-gloss, textured black surface.