1050 Aluminum Plate Sheet

Temper: H24/H14/H18/O Quality Assurance

1050 aluminum is a commercially pure aluminum alloy belonging to the 1xxx series. It is known for its excellent corrosion resistance, high thermal conductivity, and good electrical conductivity. The "1050" designation indicates that the alloy is composed of 99.5 percent aluminum with minor amounts of other elements.

When referring to 1050 aluminum sheets, it usually refers to a flat sheet of aluminum produced in a specific thickness. Here are some key properties and applications of 1050 aluminum sheet:

1050 Aluminum Plate Characteristics

- 1. The chemical composition and mechanical properties of 1050 aluminum plates and 1060 series products are similar, and they are basically replaced by 1060 aluminum plates and strips in applications.

- 2. Since 1050 aluminum does not contain other technical elements, the production process is relatively simple and the price is relatively cheap.

- 3. 1050 aluminum plate has the characteristics of high plasticity, corrosion resistance, and good electrical and thermal conductivity, but low strength, not strengthened by heat treatment, poor machinability, and can accept contact welding and gas welding.

1050 Aluminum Plate Specifications

| Category | Pure aluminum (AL 99.5% or more) |

|---|---|

| Status | H24, H14, H12, H26, H18, O |

| Thickness | 0.2mm-500mm |

| Width | 1000/1220/1250/1500/2000mm/2650mm |

| Length | 2000 mm or 2500 mm (maximum) |

| Production Standards | ASTM B209, EN 485, GB/T 3880 |

| Equivalent to 1050 | AA 1050, Al99.5, EN AW-1050A |

| Surface Treatment | Mill Finish, Anodized Finish |

1050 Aluminum Plate Sheet weldability

When welding 1050 itself or alloys of the same subgroup, the recommended filler wire is 1100. When welding alloys 5083 and 5086 or 7XXX series alloys, the recommended wire is 5356. For other alloys, use 4043 filler wire.

1050 Aluminum Plate Sheet Fabrication

- Processing Properties - Cold: Excellent

- Machinability: Poor

- Solderability - Gas: Excellent

- Weldability – Arc: Excellent

- Solderability – Resistance: Excellent

- Brazeability: Excellent

- Solderability: Excellent

1050 Aluminum Plate Sheet Mechanical Properties

Sheet 0.2mm to 6.00mm

BS EN 485-2

| Tensile Strength | 65 -95 MPa |

| Proof Stress | 20 Min MPa |

| Hardness Brinell | 20 HB |

Physical Characteristics of 1050 Aluminum Plate

- Tensile Strength = 105 - 145 MPa

- Proof Stress = 85 Min MPa

- Hardness Brinell = 34 HB

- Elongation = A-12 Min %

- Density = 2.71 g/cm³

- Melting Point = 650 °C

- Thermal Expansion = 24 x10^-6 /K

- Modulus of Elasticity = 71 GPa

- Thermal Conductivity = 222 W/m.K

- Electrical Resistivity = 0.0282 x10^-6 Ω .m

1050 Aluminum Plate Chemical Composition

| Chemical Element | % Present |

|---|---|

| Si | 0.25 |

| Fe | 0.4 |

| Cu | 0.05 |

| Mn | 0.05 |

| Mg | 0.05 |

| Zn | 0.05 |

| Ti | 0.03 |

| Other (Each) | 0.0 - 0.05 |

| Aluminium (Al) | Balance |

1050 Aluminum Plate Weight Calculation

The weight of a 1050 aluminum plate depends on its dimensions (length, width, and thickness). To calculate the weight of a 1050 aluminum plate, you can use the following formula:

Weight (in pounds) = Length (inches) x Width (inches) x Thickness (inches) x Density of Aluminum (in pounds per cubic inch)

The density of aluminum is approximately 0.098 pounds per cubic inch (lb/in³).

If you have the dimensions of the plate, you can plug them into the formula to calculate the weight. For example, if you have a 1050 aluminum plate that is 24 inches in length, 12 inches in width, and 0.25 inches in thickness:

Weight = 24 inches x 12 inches x 0.25 inches x 0.098 lb/in³ = 70.56 pounds

So, a 1050 aluminum plate with these dimensions would weigh approximately 70.56 pounds.

1050 aluminum sheet is a product of the pure aluminum sheet series. Its chemical composition and mechanical properties are similar to those of the 1060 series products. It is basically replaced by 1060 aluminum sheet and strip in application.

-

1050 h18 Aluminum Plate Sheet

Purchase high-quality raw materials, ensure the use of pure aluminum, and strictly control the alloy composition. This helps to guarantee the desired properties and performance of the 1050 h18 aluminum plate.

-

1050 h24 Aluminum Plate Sheet

Production Capacity: With advanced production facilities and equipment, the Aluminum 1050 h24 Sheet Plate produced is an aluminum plate with precise dimensions, a smooth surface, and consistent thickness. Capable of meeting different customer requirements, including custom sizes and specifications.

-

1050 h14 Aluminum Plate Sheet

Competitive Price: Haomei Aluminum offers competitive prices for 1050 h14 Aluminum Sheet Plates while guaranteeing high quality.

Typical 1050 Aluminum Plate Applications

Grade 1050 aluminum is suitable for most general sheet metal processing. Has medium strength and excellent corrosion resistance. Alloy 1050 is also known for its high ductility and highly reflective surface. This is suitable for applications requiring a decorative effect.

1050 aluminum plate is usually used for:

- chemical industry

- Pharmaceutical industry

- architectural flash

- lamp reflector

- panel

- kitchen utensils

Additionally, we recommend applying a plastic coating to one or both sides of all aluminum panels to help protect the surface during shipping.

General Application: Due to its good formability, corrosion resistance, and electrical conductivity, 1050 aluminum sheet is used in various industries. Some common uses include signage, decorative applications, kitchenware, reflectors, chemical equipment, and roofing.

The hot-selling 1050 aluminum plate series is widely used in all walks of life for its excellent characteristics. The following are some common applications of 1050 aluminum sheet:

1050 Aluminum Plate for Electrical Industry

1050 aluminum plate is widely used in the electrical industry due to its high conductivity. It is used in electrical conductors, bus bars, transformer windings, and capacitor housings.

- Condition: O (annealed) or H14 (semi-hard)

- Surface Preparation: General surfaces may not require preparation in most cases. However, for some applications requiring enhanced conductivity or insulation, surface treatments such as anodizing or chemical passivation are available.

1050 Aluminum Plates for Building and Construction

1050 aluminum plate is used in architectural applications such as trim panels, curtain walls, and roofing because of its lightweight, corrosion resistance, and ease of fabrication.

- Condition: O (annealed) or H14 (semi-hard)

- Finish: Generally the finish may be left buffed for a smooth and shiny look. In some cases, anodizing or other protective coatings may be applied to increase corrosion resistance or for decorative purposes.

1050 Aluminum Plate for Chemical Industry

The chemical resistance of 1050 aluminum makes it suitable for use in chemical equipment and storage tanks, where it can withstand exposure to a wide range of chemicals.

- Condition: O (annealed) or H14 (semi-hard)

- Surface treatment: Generally, the surface can be polished. If additional chemical resistance is required, surface treatments such as chemical passivation or specialty coatings can be applied.

1050 Aluminum Plate for Heat Exchangers

The high thermal conductivity of 1050 Aluminum makes it an ideal material for heat exchangers and fins where efficient heat transfer is required.

- Condition: O (annealed) or H14 (semi-hard)

- Surface treatment: Generally, the surface can be polished. To improve heat transfer and corrosion resistance, the aluminum surface may undergo techniques such as anodizing or chemical treatment.

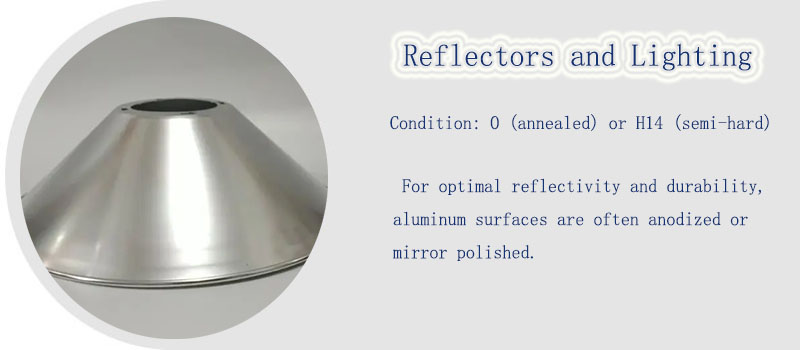

1050 Aluminum Plate for Reflectors and Lighting

Due to its high reflectivity, 1050 aluminum is commonly used in reflectors, lighting fixtures, and decorative lighting applications.

- Condition: O (annealed) or H14 (semi-hard)

- Surface treatment: Generally, the surface can be polished. For optimal reflectivity and durability, aluminum surfaces are often anodized or mirror polished.

1050 Aluminum Plates for Signs and Nameplates

1050 aluminum sheet is widely used in signage, nameplate, and labeling applications due to its ease of engraving, embossing, and stamping.

- Condition: O (annealed) or H14 (semi-hard)

- Surface Treatment: Typical surfaces may remain satin-finished, or may be anodized, painted, or screen-printed for durability and aesthetics.

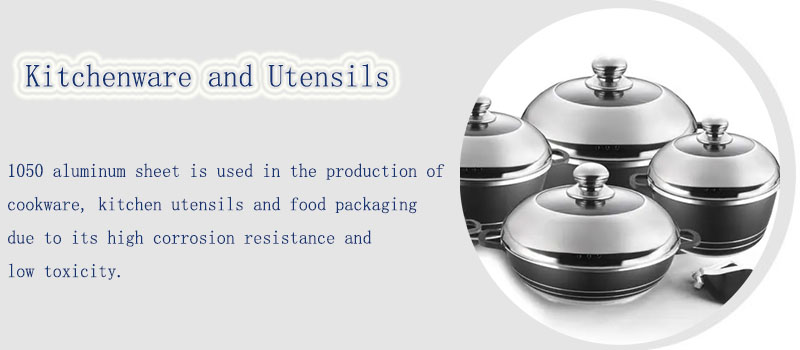

1050 Aluminum Plates for Kitchenware and Utensils

1050 aluminum sheet is used in the production of cookware, kitchen utensils, and food packaging due to its high corrosion resistance and low toxicity.

Surface Preparation: General Surfaces are usually left buffed. Depending on specific requirements, additional surface treatments such as anodizing or coatings can be applied for enhanced corrosion resistance or for decorative purposes.

1050 Aluminum Plate for General Manufacturing

The versatility of 1050 aluminum makes it suitable for general manufacturing uses such as automotive parts, radiators, HVAC components, and metal stamping.

Surface treatment: Generally, the surface can be polished. Depending on application requirements, surface treatments such as anodizing, painting, or powder coating can be used to enhance durability, appearance, or specific performance characteristics.

These are just some of the many applications for the popular 1050 aluminum sheet series. The specific applications and uses of 1050 aluminum sheets can vary according to industry requirements and specific characteristics of the product.

It's important to note that 1050 aluminum is not as strong as some other aluminum alloys and was chosen primarily for its excellent corrosion resistance and electrical conductivity. The specific properties of 1050 aluminum plates may vary depending on the manufacturing process, temper, and thickness.

People also searched for Aluminum Plate

-

1060 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 Aluminum Plate Sheet. Has rich expertise and experience in the production of aluminum plates.

-

1060 h12 Aluminum Plate Sheet

Quality Control Measures: Reliable Manufacturer of 1060 h12 Aluminum Plate Sheet ensures consistent production of high-quality Aluminum Sheet Plate.

-

1060 h14 Aluminum Plate Sheet

Certification & Compliance: Possessing 1060 h14 Aluminum Sheet Plate related certifications such as ISO 9001 demonstrates our commitment to our quality management system.

-

1060 h18 Aluminum Plate Sheet

Haomei Aluminum is a quality 1060 h18 Aluminum Plate Sheet manufacturer, ensuring that its products meet industry standards and customer expectations.

-

1060 h24 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 h24 Aluminum Plate Sheet and has competitive prices while ensuring product quality.

-

1070 Aluminum Plate Sheet

1070 aluminum plate has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but its strength is low.

-

1100 Aluminum Plate Sheet

Compared with 1100 aluminum and 1050A, other process properties of type 1100 are basically similar. Typically, Type 1100 aluminum is used in applications that require good formability, high corrosion resistance, but not high strength.

-

1100 h12 Aluminum Plate Sheet

1100 h12 Aluminum offers moderate strength and good formability making it suitable for a wide range of applications.

-

1100 h14 Aluminum Plate Sheet

1100-H14 Aluminum Sheet Manufacturer Products have a smooth, uniform appearance, strictly controlled tolerances, and stable performance.

-

1100 h18 Aluminum Plate Sheet

1100 h18 Aluminum This temper provides a higher level of strength than softer tempers such as H12 or H14.

-

1350 Aluminum Alloy

1350 Aluminum is a soft and highly ductile alloy used primarily in electrical applications where high electrical conductivity and low electrical resistance are critical.

1050 Aluminum Plate Sheet Typical Size

| Product | Width (in) | Length (in) |

| H14/H24 PVC 0.080" Aluminum 1050 Sheet | 12" | 24" |

| H14/H24 PVC 0.100" Aluminum 1050 Sheet | 24" | 48" |

| H14/H24 PVC 0.125" Aluminum 1050 Sheet | 48" | 144" |

| H14/H24 PVC 0.160" Aluminum 1050 Sheet | 12" | 24" |

| H14/H24 PVC 0.190" Aluminum 1050 Sheet | 24" | 48" |

| H14/H24 PVC 0.250" Aluminum 1050 Plate | 48" | 144" |

| H14/H24 PVC 0.313" Aluminum 1050 Plate | 12" | 24" |

| H14/H24 PVC 0.375" Aluminum 1050 Plate | 24" | 48" |

| H14/H24 PVC 0.500" Aluminum 1050 Plate | 48" | 144" |

| H14/H24 PVC 0.625" Aluminum 1050 Plate | 12" | 24" |

| H14/H24 PVC 0.750" Aluminum 1050 Plate | 24" | 48" |

| 0.080" 1050 H14/H24 Aluminum Sheet | 48" | 144" |

| 0.100" 1050 H14/H24 Aluminum Sheet | 12" | 24" |

| 0.125" 1050 H14/H24 Aluminum Sheet | 24" | 48" |

| 0.160" 1050 H14/H24 Aluminum Sheet | 48" | 144" |

| 0.190" 1050 H14/H24 Aluminum Sheet | 12" | 24" |

| 0.250" 1050 H14/H24 Aluminum Plate | 24" | 48" |

| 0.313" 1050 H14/H24 Aluminum Plate | 48" | 144" |

| 0.375" 1050 H14/H24 Aluminum Plate | 12" | 24" |

| 0.500" 1050 H14/H24 Aluminum Plate | 24" | 48" |

| 0.625" 1050 H14/H24 Aluminum Plate | 48" | 144" |

| 0.750" 1050 H14/H24 Aluminum Plate | 12" | 24" |