1050 h14 Aluminum Plate Sheet

Rich Production Experience Quality Assurance

What is 1050A H14 Grade Aluminum?

What is Aluminum Grade 1050 H14?

These are the 2 most frequently asked questions about 1050 h14 Aluminum, today we will know about 1050 h14 Aluminum.

1050A H14 grade aluminum and aluminum grade 1050H14 refer to the same aluminum alloy, which is 1050 aluminum in the H14 temper condition.

Aluminum grade 1050 is a commercially pure aluminum alloy with excellent formability, high corrosion resistance, and good electrical and thermal conductivity. It is commonly used in various industries and applications where these characteristics are required.

The "H14" temper designation indicates that the aluminum has been strain-hardened, which increases strength and hardness. The H14 temper is achieved by a cold working process followed by partial annealing. This tempered condition provides a balance between strength and formability, making it suitable for applications requiring moderate strength and good formability.

Overall, 1050H14 aluminum is a versatile material that is used in a variety of industries including construction, electrical, automotive, and general manufacturing. It is commonly used in sheet form for applications such as roofing, signage, reflectors, and general metalworking.

What is the Thickness Range Available for 1050 H14 Aluminum Plates?

The thickness of 1050 H14 aluminum plates can vary depending on the supplier and manufacturer. Common thicknesses range from 0.2 mm (8 mils) to 10 millimeters.

1050 H14 Aluminum Plates Typical Thicknesses

| Product | Thickness (mm) | Thickness (mils) |

|---|---|---|

| 1050 H14 Aluminum Plate | 0.2 | 8 |

| 1050 H14 Aluminum Plate | 0.3 | 12 |

| 1050 H14 Aluminum Plate | 0.5 | 20 |

| 1050 H14 Aluminum Plate | 0.8 | 32 |

| 1050 H14 Aluminum Plate | 1 | 40 |

| 1050 H14 Aluminum Plate | 1.2 | 48 |

| 1050 H14 Aluminum Plate | 1.5 | 60 |

| 1050 H14 Aluminum Plate | 2 | 80 |

| 1050 H14 Aluminum Plate | 2.5 | 100 |

| 1050 H14 Aluminum Plate | 3 | 120 |

| 1050 H14 Aluminum Plate | 4 | 160 |

| 1050 H14 Aluminum Plate | 5 | 200 |

| 1050 H14 Aluminum Plate | 6 | 240 |

| 1050 H14 Aluminum Plate | 8 | 320 |

| 1050 H14 Aluminum Plate | 10 | 400 |

What are the Dimensions of 1050 H14 Aluminum Plates?

The dimensions of 1050 H14 aluminum plates can vary widely, depending on the specific requirements of the application. Standard sizes are typically available, but custom sizes can also be ordered from manufacturers.

1050 H14 Aluminum Plates Typical Sizes

| Product | Size (mm) | Size (inches) |

|---|---|---|

| 1050 H14 Aluminum Plate | 1000 mm x 2000 mm | 39.37 inches x 78.74 inches |

| 1050 H14 Aluminum Plate | 1220 mm x 2440 mm | 48.03 inches x 96.06 inches |

| 1050 H14 Aluminum Plate | 1500 mm x 3000 mm | 59.06 inches x 118.11 inches |

| 1050 H14 Aluminum Plate | 2000 mm x 4000 mm | 78.74 inches x 157.48 inches |

| 1050 H14 Aluminum Plate | 2000 mm x 6000 mm | 78.74 inches x 236.22 inches |

| 1050 H14 Aluminum Plate | 4 feet x 8 feet | 48 inches x 96 inches |

| 1050 H14 Aluminum Plate | 4 feet x 10 feet | 48 inches x 120 inches |

| 1050 H14 Aluminum Plate | 5 feet x 10 feet | 60 inches x 120 inches |

It is important to note that the specific benefits of the 1050 H14 aluminum sheet may vary depending on the application and project requirements. It is recommended to consult the manufacturer or supplier on how the 1050 H14 aluminum sheet can best meet your specific needs.

1050 H14 Aluminum Plate Properties

1050 H14 aluminum is known for its excellent corrosion resistance, high thermal conductivity, and good formability. It has a relatively low strength compared to some other aluminum alloys, making it suitable for applications that don't require high mechanical strength.

1050 H14 Aluminum Plate Mechanical Properties

| Property | 1050 Aluminum H14 |

|---|---|

| Tensile Strength (MPa) | 95-125 |

| Yield Strength (MPa) | 85-105 |

| Elongation (%) | 12-18 |

1050 H14 Aluminum Plate Physical Properties

| Property | Value |

|---|---|

| Density (g/cm³) | 2.71 |

| Melting Point (°C) | 660 |

| Electrical Conductivity (% IACS) | 59 |

| Thermal Conductivity (W/m·K) | 230 |

| Coefficient of Thermal Expansion (K^(-1)) | 23.5 x 10^(-6) |

Weldability

1050 H14 aluminum can be welded using various welding techniques such as TIG (tungsten inert gas) welding and MIG (metal inert gas) welding. It is important to use proper welding procedures and filler materials to obtain a good-quality weld.

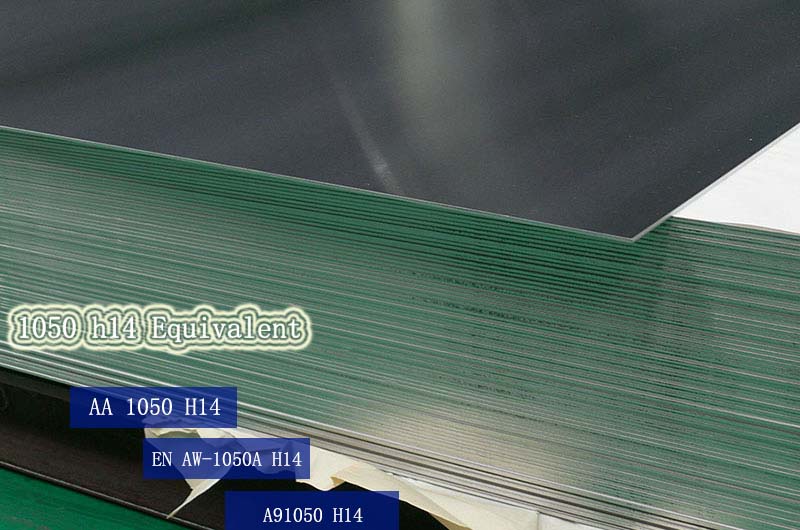

1050 h14 Equivalent

Equivalent grades for 1050 H14 aluminum alloy may vary by country and reference standard. However, some commonly used equivalents include:

- AA 1050 H14: This is the designation used in the Aluminum Association (AA) system widely used in North America.

- EN AW-1050A H14: This is the equivalent designation used in European standards EN 573-3 and EN 485-2.

- A91050 H14: This is the equivalent designation used in the International Organization for Standardization (ISO) standard ISO 209-1.

While these equivalents are commonly used, there may be slight variations in chemical composition, mechanical properties, or temper designations between standards. Therefore, it is advisable to consult relevant codes or standards to ensure the selection of the correct material for a particular application.

What are the Common Applications of 1050 H14 Aluminum Plate?

This alloy is often used in applications that require good corrosion resistance and moderate strength. Common applications include roofing, cladding, chemical equipment, reflectors, nameplates, and other decorative uses.

Aluminum Sheet Alloy 1050a h14/h24

Aluminum alloy 1050A, a variant of aluminum alloy 1050, is a commercially pure aluminum alloy with excellent formability and high corrosion resistance. The "A" in 1050A indicates a slight change in chemical composition from 1050, usually with the addition of small amounts of copper (0.1% to 0.5%) to improve its strength and hardness.

In tempered condition, both H14 and H24 offer 1050A. Here is a brief description of each temper condition:

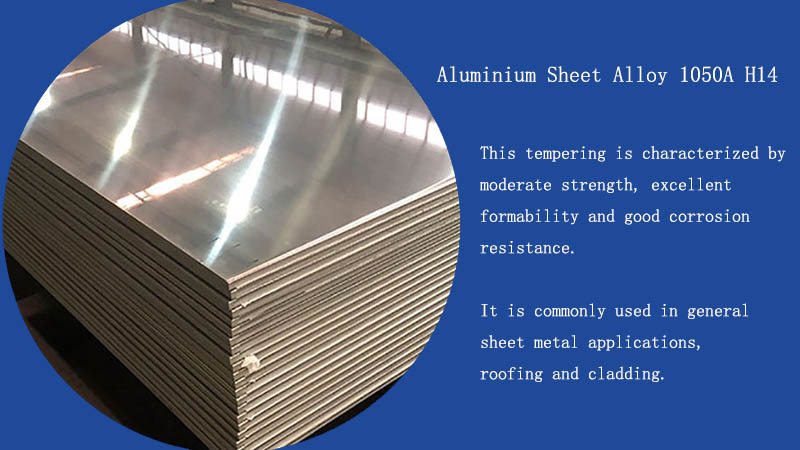

Aluminum Sheet Alloy 1050A H14

In the H14 temper, aluminum is strain-hardened and partially annealed to increase its strength while maintaining good formability. This tempering is characterized by moderate strength, excellent formability, and good corrosion resistance. It is commonly used in general sheet metal applications, roofing, and cladding.

Aluminum Sheet Alloy 1050A H24

Compared to H14, the H24 temper involves a more extensive annealing process, resulting in increased hardness and strength. It offers higher mechanical properties than H14 while maintaining good formability. 1050A H24 is typically used in applications requiring higher strength such as automotive panels, building facades, and structural components.

1050A H14 and H24 are used in a wide variety of industries including construction, transportation, electrical, and general manufacturing where lightweight, corrosion-resistant, and formable aluminum sheet is required. The specific choice between H14 and H24 depends on the specific application requirements and desired mechanical properties.

-

1050 Aluminum Plate Sheet

Haomei Aluminum has a sound quality control process to ensure consistent and reliable quality of 1050 aluminum sheets. This includes rigorous inspection and testing procedures at all stages of production to meet or exceed industry standards.

-

1050 h24 Aluminum Plate Sheet

Production Capacity: With advanced production facilities and equipment, the Aluminum 1050 h24 Sheet Plate produced is an aluminum plate with precise dimensions, a smooth surface, and consistent thickness. Capable of meeting different customer requirements, including custom sizes and specifications.

-

1050 h18 Aluminum Plate Sheet

Purchase high-quality raw materials, ensure the use of pure aluminum, and strictly control the alloy composition. This helps to guarantee the desired properties and performance of the 1050 h18 aluminum plate.

1050 h14 Aluminum Sheet Plate Supplier

Haomei Aluminum is a high-quality 1050 aluminum plate supplier, the following are the reasons why you choose us:

- Expertise and Experience: The manufacturer has extensive knowledge and experience in producing and supplying aluminum sheets. Gain an in-depth understanding of the properties, specifications, and applications of 1050 Aluminum.

- Quality Control: Manufacturers have robust quality control processes in place to ensure consistent and reliable product quality. This includes rigorous inspection and testing procedures at all stages of production to meet or exceed industry standards.

- Material selection: Purchasing high-quality raw materials, ensuring the use of pure aluminum and strictly controlling the alloy composition. This helps to guarantee the desired properties and performance of the 1050 aluminum sheet.

- Production capacity: The production enterprise has advanced production facilities and equipment to produce aluminum plates with precise dimensions, smooth surfaces, and consistent thickness. Capable of meeting different customer requirements, including custom sizes and specifications.

- Certifications and Standards: Includes quality management certifications such as ISO 9001 and certifications related to environmental sustainability.

- Competitive Prices: While quality is of paramount importance, it offers competitive prices for its products while maintaining high quality.

How is 1050 H14 Aluminum Plate Typically Processed or Fabricated?

1050 H14 aluminum can be cut, formed, and machined using standard metalworking techniques. It's commonly processed using shearing, bending, stamping, and drilling equipment.

Is Surface Finish Important for 1050 H14 Aluminum Plates?

Surface finish can be important depending on the application. For decorative or reflective applications, a polished or coated surface may be desirable. In contrast, some industrial applications may not require a highly finished surface.

What are the Advantages of using 1050 H14 aluminum in construction?

1050 H14 aluminum's advantages in construction include its lightweight nature, corrosion resistance, and ease of fabrication. It's often used for roofing, cladding, and architectural elements.

What are the Limitations of 1050 H14 Aluminum Plates?

One limitation is its relatively low mechanical strength compared to other aluminum alloys. It's not suitable for applications requiring high strength or where the material will be subject to heavy loads.

People also searched for Aluminum Plate

-

1060 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 Aluminum Plate Sheet. Has rich expertise and experience in the production of aluminum plates.

-

1060 h12 Aluminum Plate Sheet

Quality Control Measures: Reliable Manufacturer of 1060 h12 Aluminum Plate Sheet ensures consistent production of high-quality Aluminum Sheet Plate.

-

1060 h14 Aluminum Plate Sheet

Certification & Compliance: Possessing 1060 h14 Aluminum Sheet Plate related certifications such as ISO 9001 demonstrates our commitment to our quality management system.

-

1060 h18 Aluminum Plate Sheet

Haomei Aluminum is a quality 1060 h18 Aluminum Plate Sheet manufacturer, ensuring that its products meet industry standards and customer expectations.

-

1060 h24 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 h24 Aluminum Plate Sheet and has competitive prices while ensuring product quality.

-

1070 Aluminum Plate Sheet

1070 aluminum plate has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but its strength is low.

-

1100 Aluminum Plate Sheet

Compared with 1100 aluminum and 1050A, other process properties of type 1100 are basically similar. Typically, Type 1100 aluminum is used in applications that require good formability, high corrosion resistance, but not high strength.

-

1100 h12 Aluminum Plate Sheet

1100 h12 Aluminum offers moderate strength and good formability making it suitable for a wide range of applications.

-

1100 h14 Aluminum Plate Sheet

1100-H14 Aluminum Sheet Manufacturer Products have a smooth, uniform appearance, strictly controlled tolerances, and stable performance.

-

1100 h18 Aluminum Plate Sheet

1100 h18 Aluminum This temper provides a higher level of strength than softer tempers such as H12 or H14.