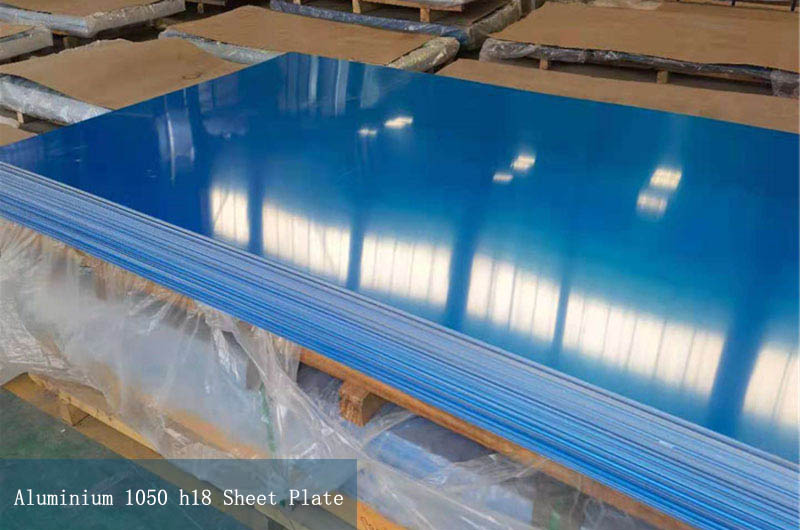

1050 h18 Aluminum Plate Sheet

Competitive Price Rich Production Experience

Aluminum alloy 1050 H18 refers to a special aluminum alloy in the state of H18. Here is a breakdown of the components of this name:

- Aluminum Alloys: The alloy designation "1050" indicates that the aluminum sheet or sheet contains pure aluminum (99.5% minimum purity) as the major alloying element. It is a commercially pure aluminum alloy with excellent corrosion resistance and good formability.

- H18 Temper: The "H18" temper designation indicates specific heat treatment and mechanical properties of aluminum alloy sheets or plates. In the H18 temper, the aluminum alloy is strain hardened (cold worked) and then fully annealed. This tempering provides the alloy with maximum strength and hardness.

1050 h18 Aluminum Plate Advantages

1050 H18 aluminum plate offers several advantages over other tempered conditions of 1050 aluminum. Here are some advantages:

- Higher Strength: Compared to softer tempered conditions like H14 or O, 1050 H18 aluminum sheet has higher strength due to the cold work hardening process. This increased strength provides improved structural integrity and resistance to deformation.

- Increased hardness: H18 tempering involves a higher degree of strain hardening, resulting in increased hardness of the aluminum sheet. This hardness provides better wear resistance and durability, making it suitable for applications where the material may be subjected to mechanical stress or friction.

- Improved Formability: Although the 1050 H18 aluminum plate has higher strength and hardness, it still maintains good formability. It can be easily shaped, bent, and formed without cracking or breaking, making it suitable for applications requiring complex shapes or designs.

- Better Surface Finish: H18 tempers often involve additional surface preparation processes such as cold rolling and annealing, resulting in a smoother and more uniform surface finish. This improved surface quality enhances the appearance and aesthetics of the aluminum sheet.

- Improved Corrosion Resistance: H18 tempering does not significantly affect the corrosion resistance of 1050 aluminum. Therefore, the 1050 H18 aluminum plate retains the excellent corrosion resistance of the base alloy. Resistant to atmospheric corrosion and able to withstand exposure to a variety of environmental conditions.

- Suitable for precision manufacturing: The high strength and hardness of the 1050 H18 aluminum plate make it very suitable for precision manufacturing processes such as machining, drilling, and cutting. It can be precisely formed and machined to meet tight dimensional tolerances.

It is important to note that the specific benefits of the 1050 H18 aluminum sheet may vary depending on the application and project requirements. It is recommended to consult with the manufacturer or supplier on how the 1050 H18 aluminum sheet can best meet your specific needs.

1050 H18 Aluminum Plate Properties

H18 temper has the following characteristics:

1050 h18 Aluminum Plate Mechanical Properties

| Mechanical Property | Typical Value |

|---|---|

| Tensile Strength | 125-150 MPa |

| Yield Strength | ≥ 115 MPa |

| Elongation | ≥ 2% |

1050 h18 Aluminum Plate Thermal Properties

| Thermal Property | Typical Value |

|---|---|

| Thermal Conductivity | 229 W/m·K |

| Melting Range | 640-660°C |

Note: These values are approximate and may vary due to factors such as impurities and specific manufacturing processes. In addition, thermal performance can also be affected by factors such as temperature gradient, heat treatment, and sample size.

For precise and detailed thermal performance data for aluminum alloy 1050 H18, it is recommended to consult the manufacturer or supplier. They can give you the most accurate information based on their material specifications and test results.

1050 h18 Aluminum Plate Electrical Properties

| Electrical Property | Typical Value |

|---|---|

| Electrical Conductivity | Approximately 59% IACS |

|

Note: Aluminum alloy 1050 H18 has lower conductivity than copper, But still has good electrical conductivity in many applications. |

|

1050 h18 Aluminum Plate Surface Treatment

The surface finish of 1050 H18 aluminum alloy sheet may vary by manufacturer or supplier. It may have a satin finish, which is a smooth and shiny finish that does not require any additional treatment or coating. Other surface treatments such as anodizing or painting can be applied according to specific requirements.

1050 Aluminum Plate Composition

| Element | Composition Range |

|---|---|

| Aluminum (Al) | 99.5 - 100% |

| Iron (Fe) | 0 - 0.4% |

| Silicon (Si) | 0 - 0.25% |

| Manganese (Mn) | 0 - 0.050% |

| Zinc (Zn) | 0 - 0.050% |

| Copper (Cu) | 0 - 0.050% |

| Magnesium (Mg) | 0 - 0.050% |

| Vanadium (V) | 0 - 0.050% |

| Titanium (Ti) | 0 - 0.030% |

1050 H18 Aluminum Plate Typical Applications

Aluminum alloy sheet or plate 1050 H18 is commonly used in a variety of industries including construction, automotive, electrical, and general manufacturing.

It is suitable for applications such as roofing, cladding, electrical enclosures, decorative panels, and more.

The H18 temper provides high strength and hardness making it suitable for applications requiring structural integrity and durability.

- Electrical Conductor: 1050 H18 aluminum sheet is often used in electrical applications where good electrical conductivity is required. It is used in the manufacture of busbars, electrical connectors, and conductive components in various electrical systems.

-

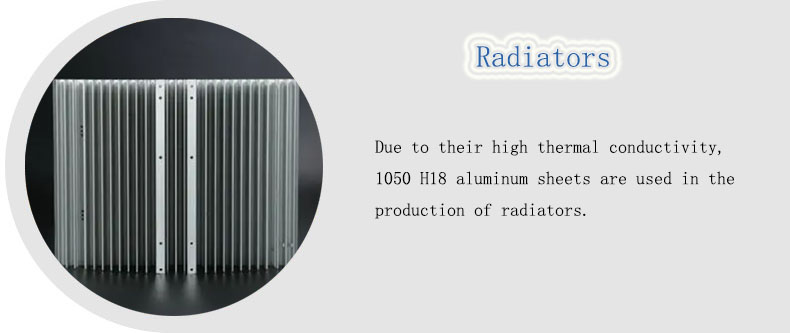

Radiators: Due to their high thermal conductivity, 1050 H18 aluminum sheets are used in the production of radiators. Heat sinks help dissipate the heat generated by electronic components, ensuring their optimum performance and longevity.

- Reflective Sheeting: The high reflectivity of the 1050 H18 aluminum sheet makes it suitable for applications that require a reflective surface, such as solar panels, lighting fixtures, and reflectors.

- Architectural Applications: 1050 H18 Aluminum Sheet is used for architectural decorative purposes such as wall cladding, ceilings, and decorative trim. Its lightweight and corrosion-resistant properties make it ideal for enhancing the aesthetics of buildings.

-

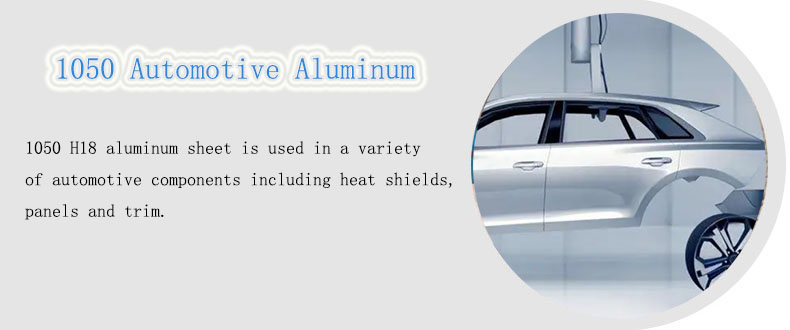

Automotive Components: 1050 H18 aluminum sheet is used in a variety of automotive components including heat shields, panels, and trim. Its lightweight properties help improve fuel efficiency and reduce the overall weight of the vehicle.

- Packaging material: 1050 H18 aluminum sheet is often used in the production of packaging materials, such as aluminum cans, bottle caps, food containers, etc. Its corrosion resistance and ability to maintain the freshness of packaged products make it suitable for the food and beverage industry.

- Industrial Applications: 1050 H18 Aluminum Sheet can be used in a variety of industrial applications such as chemical processing equipment, storage tanks, and manufacturing machinery components. Its corrosion resistance and formability make it suitable for diverse industrial environments.

It should be noted that the specific application of the 1050 H18 aluminum sheet can vary according to the requirements and specifications of the project. These examples give us a glimpse into the potential applications of 1050 H18 aluminum sheets in different industries.

NOTE: The exact size, thickness, and certification of 1050 H18 aluminum alloy sheet or plate may vary by manufacturer or supplier. It is recommended to consult them for accurate information and to ensure that they meet your specific project requirements.

-

1050 Aluminum Plate Sheet

Haomei Aluminum has a sound quality control process to ensure consistent and reliable quality of 1050 aluminum sheets. This includes rigorous inspection and testing procedures at all stages of production to meet or exceed industry standards.

-

1050 h24 Aluminum Plate Sheet

Production Capacity: With advanced production facilities and equipment, the Aluminum 1050 h24 Sheet Plate produced is an aluminum plate with precise dimensions, a smooth surface, and consistent thickness. Capable of meeting different customer requirements, including custom sizes and specifications.

-

1050 h14 Aluminum Plate Sheet

Competitive Price: Haomei Aluminum offers competitive prices for 1050 h14 Aluminum Sheet Plates while guaranteeing high quality.

People also searched for Aluminum Plate

-

1060 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 Aluminum Plate Sheet. Has rich expertise and experience in the production of aluminum plates.

-

1060 h12 Aluminum Plate Sheet

Quality Control Measures: Reliable Manufacturer of 1060 h12 Aluminum Plate Sheet ensures consistent production of high-quality Aluminum Sheet Plate.

-

1060 h14 Aluminum Plate Sheet

Certification & Compliance: Possessing 1060 h14 Aluminum Sheet Plate related certifications such as ISO 9001 demonstrates our commitment to our quality management system.

-

1060 h18 Aluminum Plate Sheet

Haomei Aluminum is a quality 1060 h18 Aluminum Plate Sheet manufacturer, ensuring that its products meet industry standards and customer expectations.

-

1060 h24 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 h24 Aluminum Plate Sheet and has competitive prices while ensuring product quality.

-

1070 Aluminum Plate Sheet

1070 aluminum plate has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but its strength is low.

-

1100 Aluminum Plate Sheet

Compared with 1100 aluminum and 1050A, other process properties of type 1100 are basically similar. Typically, Type 1100 aluminum is used in applications that require good formability, high corrosion resistance, but not high strength.

-

1100 h12 Aluminum Plate Sheet

1100 h12 Aluminum offers moderate strength and good formability making it suitable for a wide range of applications.

-

1100 h14 Aluminum Plate Sheet

1100-H14 Aluminum Sheet Manufacturer Products have a smooth, uniform appearance, strictly controlled tolerances, and stable performance.

-

1100 h18 Aluminum Plate Sheet

1100 h18 Aluminum This temper provides a higher level of strength than softer tempers such as H12 or H14.