1050 h24 Aluminum Plate Sheet

Stable Performance Competitive Price

What is Aluminum Alloy Plate 1050 H24?

Aluminum 1050 H24 refers to the aluminum alloy 1050 in the H24 temper. This temper designation signifies that the aluminum has been strain-hardened (cold-worked) and partially annealed to achieve the desired mechanical properties.

- Aluminum alloy: The alloy designation "1050" indicates that the main alloying element in this aluminum sheet is pure aluminum (99.5% minimum purity). It is a commercially pure aluminum alloy with excellent corrosion resistance and good formability.

- H24 Temper: The "H24" temper designation indicates the specific heat treatment and mechanical properties of the aluminum alloy sheet. In the H24 temper, the aluminum alloy is strain hardened (cold worked) and then partially annealed. This tempering provides a balance between strength gain and formability retention.

1050 H24 aluminum refers to H24 tempered 1050 aluminum alloy, that is, the work-hardened 1050 aluminum is incompletely annealed to obtain 1/2 hardness. At the same time, the strength of the obtained aluminum 1050 h24 is approximately between that of annealed (O) and fully hard (H28). Essentially, 1050 aluminum alloy is a typical 1 series pure aluminum with an Al content of 99.5%.

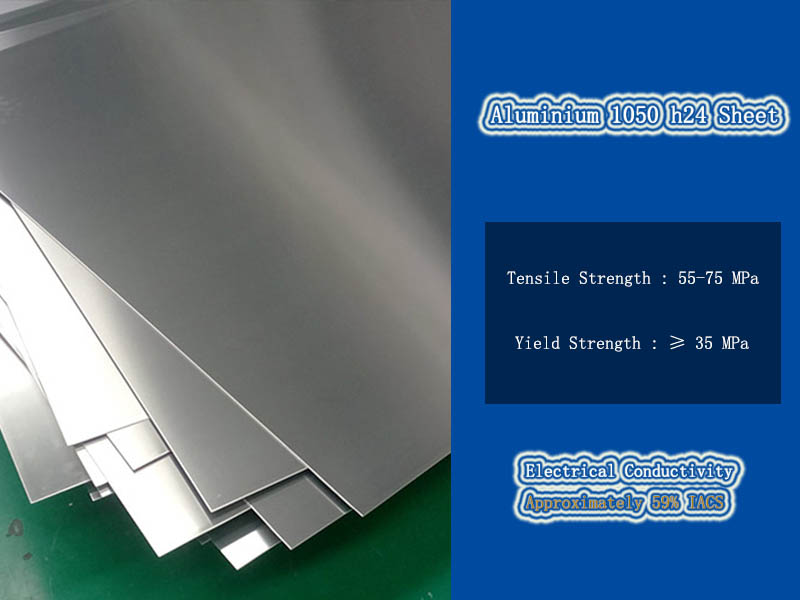

1050 h24 Aluminum Plate Properties

- 1. 1050 H24 aluminum alloy retains the silvery white luster and light texture of pure aluminum.

- 2. Excellent weldability, ductility, smooth finish, reflective properties, corrosion resistance, conductivity, etc.

- 3. 1050 aluminum plate has high plasticity and strong corrosion resistance.

- 4. Surface anodized 1050 h24 aluminum sheet coil has a stunning appearance. It also has high corrosion resistance and reflectivity.

- 5. Aluminum 1050 H24 has excellent weldability, such as gas welding, arc welding, brazing, weldability, resistance welding, etc.

- 6. 1050 aluminum has lower strength.

Aluminum 1050 H24 Data Sheet

Following are some key properties of Aluminum 1050 H24 Sheet/Sheet:

1050 h24 Aluminum Plate Sheet Mechanical Parameters

The tensile strength of 1050 H24 aluminum is 95-125MPa, and the conditional yield strength is greater than 75MPa.

1050 h24 Aluminum Plate Physical Properties

| Physical Property | Value |

|---|---|

| Density | Approximately 2.7 g/cm³ |

| Melting Range | 640 to 660°C |

| Thermal Conductivity | 229 W/m·K |

| Electrical Conductivity | Approximately 59% IACS |

1050 H24 Aluminum Plate Thickness Deviation

Thickness tolerances for 1050 H24 aluminum plates may vary depending on the manufacturing process and the specific standard followed.

| Aluminum Plate | Specified Thickness (mm) | Allowable Deviation Range (mm) |

|---|---|---|

| 1050 H24 Aluminum Plate | 1 | ±0.05 to ±0.1 |

| 1050 H24 Aluminum Plate | 2 | ±0.1 to ±0.2 |

| 1050 H24 Aluminum Plate | 5 | ±0.25 to ±0.5 |

| 1050 H24 Aluminum Plate | 10 | ±0.5 to ±1 |

| 1050 H24 Aluminum Plate | 20 | ±1 to ±2 |

| 1050 H24 Aluminum Plate | 50 | ±2.5 to ±5 |

| 1050 H24 Aluminum Plate | 100 | ±5 to ±10 |

NOTE: These values are general guidelines and specific tolerances may vary depending on specific requirements, standards, and agreement between buyer and seller. It is recommended to consult the manufacturer or supplier for accurate information on thickness deviation tolerances for 1050 H24 aluminum sheets.

1050 h24 Aluminum Plate Surface Treatment

The surface finish of 1050 H24 Aluminum Sheet/Sheet may vary by manufacturer or supplier. It may have a satin finish, which is a smooth and shiny finish that does not require any additional treatment or coating. Other surface treatments such as anodizing or painting can be applied according to specific requirements.

NOTE: Exact dimensions, thicknesses, and certifications for 1050 H24 aluminum sheets/sheets may vary by manufacturer or supplier. It is recommended to consult them for accurate information and to ensure that they meet your specific project requirements.

Aluminum 1050 h24 Plate Typical Applications

Due to its moderate strength and good formability, it is suitable for applications requiring both strength and processability.

1050 H24 Aluminum Sheet/Sheet is used in a variety of industries including construction, automotive, signage, and general manufacturing.

It can be used for roofing, cladding, building panels, structural components, and more.

1050 H24 aluminum can be used in a variety of applications including architectural, automotive, signage, and roofing. Here's a breakdown of its use in each application:

Aluminum 1050 H24 for Construction

- 1050 H24 aluminum in construction can be used for roofing, cladding, facades, and structural components.

- Its lightweight, corrosion resistance and good formability make it suitable for applications requiring durability and aesthetics.

- It can be used in the construction of residential, commercial, and industrial buildings.

1050 Automotive Aluminum Plate

- 1050 H24 aluminum is used in the automotive industry for components such as body panels, trim, and interior trim.

- Its lightweight properties help improve fuel efficiency and reduce the overall weight of the vehicle.

- The corrosion resistance and formability of 1050 H24 aluminum make it suitable for a variety of automotive manufacturing processes.

Aluminum 1050 h24 for Signage

- 1050 H24 aluminum is commonly used in the sign industry for both outdoor and indoor signage.

- Its excellent corrosion resistance and ability to withstand harsh weather conditions make it ideal for outdoor signage.

- The formability of 1050 H24 aluminum allows for the creation of a variety of sign shapes and designs.

1050 Aluminum Roofing Sheet

- 1050 H24 aluminum can be used in roofing applications such as shingles or shingles.

- Its corrosion resistance, lightweight, and durability make it a popular choice for roofing on residential and commercial buildings.

- The 1050 H24 aluminum roof provides durable protection from the elements.

Food grade aluminum alloy plate 1050 H24 for cookware

Because 1050 aluminum has excellent electrical conductivity, second only to copper, but copper is prone to rust. Further process steps require deep drawing or spinning. Both DC and CC sheets are suitable as cookware materials, and the former has better molding properties.

1050 H24 aluminum plate for air duct

Ducts must be flexible, flexible and durable. 1050 aluminum metal fully meets such requirements, especially its oxide film acts as a protective layer inside the plate.

The hardness of 1050 H24 aluminum plate is not strong, which limits its application in areas with low strength requirements, such as clock plates, cookware, labels, decorations, reflective panels, etc.

Specific application examples are as follows:

- 1. PS aluminum CTP printing plate, used for printing offset printing, signs, billboards, and nameplates.

- 2. Building exterior decoration, such as aluminum-plastic panels (ACP), etc.

- 3. Daily necessities, lighting fixtures, lamps, fan blades.

- 4. Heat sinks, heat exchangers, chemical containers, chemical and brewing industries, electronics, baffles, stamping parts, etc.

Note: Specific dimensions, thickness, and design considerations may vary according to the requirements of each application. It is always advisable to consult the manufacturer or supplier for accurate information on the use of 1050 H24 aluminum in these specific applications.

Packaging/Transportation Precautions for 1050 Aluminum Plate

Packaging and shipping of 1050 H24 aluminum sheets is essential to guarantee its protection and safe delivery. Here are some common practices for packaging and shipping:

1050 H24 Aluminum Plate Packaging

- Protective Packaging: Aluminum panels are often wrapped in a protective material such as plastic film or paper to prevent scratches, scuffs, and other surface damage during handling and shipping.

- Wooden Skids or Pallets: Wrapped panels are usually stacked on wooden skids or pallets to provide stability and ease of handling. Skids or pallets also help protect the board from direct contact with the ground or other surfaces.

- Securing and Fastening: Boards can be secured and secured using straps, straps, or stretch film to prevent shifting or shifting during transport.

1050 H24 Aluminum Plate Transportation

- Truck or container: 1050 H24 aluminum sheet is usually shipped by truck or container. These vehicles protect from the elements and ensure safe transportation.

- Handling and Loading: Proper handling techniques should be followed to avoid excessive bending or deformation of the sheet. Forklifts or cranes are often used to safely load and unload panels.

- Stacking and positioning: When stacking boards, attention should be paid to the even distribution of weight to prevent excessive pressure on the bottom board. Spacers or protective layers can be used between the plates to avoid metal-to-metal contact.

-

1050 Aluminum Plate Sheet

Haomei Aluminum has a sound quality control process to ensure consistent and reliable quality of 1050 aluminum sheets. This includes rigorous inspection and testing procedures at all stages of production to meet or exceed industry standards.

-

1050 h14 Aluminum Plate Sheet

Competitive Price: Haomei Aluminum offers competitive prices for 1050 h14 Aluminum Sheet Plates while guaranteeing high quality.

-

1050 h18 Aluminum Plate Sheet

Purchase high-quality raw materials, ensure the use of pure aluminum, and strictly control the alloy composition. This helps to guarantee the desired properties and performance of the 1050 h18 aluminum plate.

People also searched for Aluminum Plate

-

1060 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 Aluminum Plate Sheet. Has rich expertise and experience in the production of aluminum plates.

-

1060 h12 Aluminum Plate Sheet

Quality Control Measures: Reliable Manufacturer of 1060 h12 Aluminum Plate Sheet ensures consistent production of high-quality Aluminum Sheet Plate.

-

1060 h14 Aluminum Plate Sheet

Certification & Compliance: Possessing 1060 h14 Aluminum Sheet Plate related certifications such as ISO 9001 demonstrates our commitment to our quality management system.

-

1060 h18 Aluminum Plate Sheet

Haomei Aluminum is a quality 1060 h18 Aluminum Plate Sheet manufacturer, ensuring that its products meet industry standards and customer expectations.

-

1060 h24 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 h24 Aluminum Plate Sheet and has competitive prices while ensuring product quality.

-

1070 Aluminum Plate Sheet

1070 aluminum plate has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but its strength is low.

-

1100 Aluminum Plate Sheet

Compared with 1100 aluminum and 1050A, other process properties of type 1100 are basically similar. Typically, Type 1100 aluminum is used in applications that require good formability, high corrosion resistance, but not high strength.

-

1100 h12 Aluminum Plate Sheet

1100 h12 Aluminum offers moderate strength and good formability making it suitable for a wide range of applications.

-

1100 h14 Aluminum Plate Sheet

1100-H14 Aluminum Sheet Manufacturer Products have a smooth, uniform appearance, strictly controlled tolerances, and stable performance.

-

1100 h18 Aluminum Plate Sheet

1100 h18 Aluminum This temper provides a higher level of strength than softer tempers such as H12 or H14.