1060 Aluminum Plate Sheet

Temper: H24/H12/H14/O Standards: ASTM B209,EN 485,GB/T 3880

What is 1060 Aluminium Grade?

The term "1060 aluminum grade" refers to an alloy in the aluminum family. In this case, 1060 is an aluminum alloy that is 99.6% pure. It belongs to the 1000 series aluminum alloy, known for its excellent corrosion resistance, high thermal and electrical conductivity, and good formability.

1060 aluminum alloy is an alloy in the forged series that is very similar to 1050 aluminum alloy. Its main difference is that the aluminum content is slightly higher at 0.1%.

The 1060 alloy is usually formed by extrusion or rolling. It is commonly used in the electrical and chemical industries due to its high conductivity, corrosion resistance and ease of processing. Compared with other important alloy metals, the mechanical strength of 1060 aluminum alloy is low. While it can be strengthened by cold working, it cannot be strengthened by heat treatment.

The number "1060" indicates the composition of the alloy.

- In the 1000 series, the first number represents the major alloying element, in this case, pure aluminum.

- The second number, in this case "0", indicates that it is a base alloy that does not contain any significant alloying elements.

- Therefore, 1060 is almost pure aluminum with very few impurities.

AL 1060 is typically used in applications requiring high electrical conductivity such as wires, bus bars, and transformer windings. It is also used in general sheet metal processing, lighting fixtures, reflectors, nameplates, and a variety of other applications where corrosion resistance and formability are an advantage.

It is worth noting that while AL 1060 is widely used, there are a variety of other aluminum alloys available, each with its own unique properties and applications.

-

1060 h24 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 h24 Aluminum Plate Sheet and has competitive prices while ensuring product quality.

-

1060 h18 Aluminum Plate Sheet

Haomei Aluminum is a quality 1060 h18 Aluminum Plate Sheet manufacturer, ensuring that its products meet industry standards and customer expectations.

-

1060 h14 Aluminum Plate Sheet

Certification & Compliance: Possessing 1060 h14 Aluminum Sheet Plate related certifications such as ISO 9001 demonstrates our commitment to our quality management system.

-

1060 h12 Aluminum Plate Sheet

Quality Control Measures: Reliable Manufacturer of 1060 h12 Aluminum Plate Sheet ensures consistent production of high-quality Aluminum Sheet Plate.

1060 Aluminum Plate Features

1060 aluminum plates are known for their high purity, versatility, formability, corrosion resistance, and electrical conductivity. These features make them well-suited for a wide range of applications across different industries.

- Corrosion Resistance: 1060 aluminum has excellent corrosion resistance, making it ideal for outdoor applications or environments with high moisture or moisture levels.

- Thermal Conductivity: 1060 aluminum has high thermal conductivity, which means it transfers heat quickly and efficiently. This makes it a popular choice for heat sinks, heat sinks, and other applications where heat transfer is important.

- Conductivity: 1060 aluminum is highly conductive, making it an excellent choice for electrical applications such as wiring and circuit boards.

- Low Strength: 1060 aluminum has low strength, which means it is not suitable for applications that require high tensile strength or resistance to deformation.

1060 Aluminum Data Plate Sheet

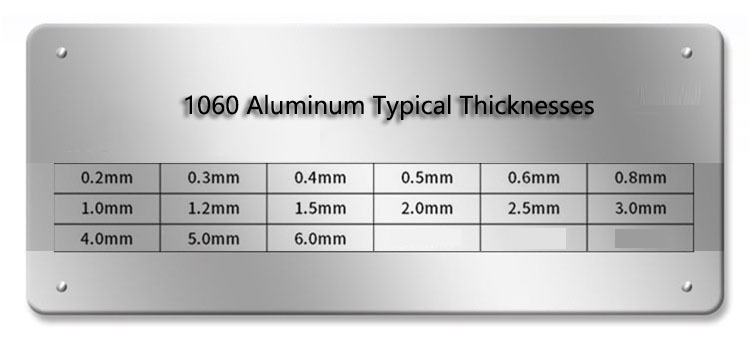

1060 Aluminum Plate Specifications

- Common Thicknesses: Typically range from 0.1 mm to 6.0 mm, depending on the application.

- Common Widths: Usually available in widths from 20 mm to 2600 mm, depending on production capacity and specific requirements.

1060 Aluminum Plate Typical Temper

| Typical Temper | Description |

|---|---|

| 1060 O Aluminum Plate | Fully annealed, soft condition |

| 1060 H12 Aluminum Plate | Strain-hardened, 1/4 hard condition |

| 1060 H14 Aluminum Plate | Strain-hardened, half-hard condition |

| 1060 H16 Aluminum Plate | Strain-hardened, 3/4 hard condition |

| 1060 H18 Aluminum Plate | Strain-hardened, full hard condition |

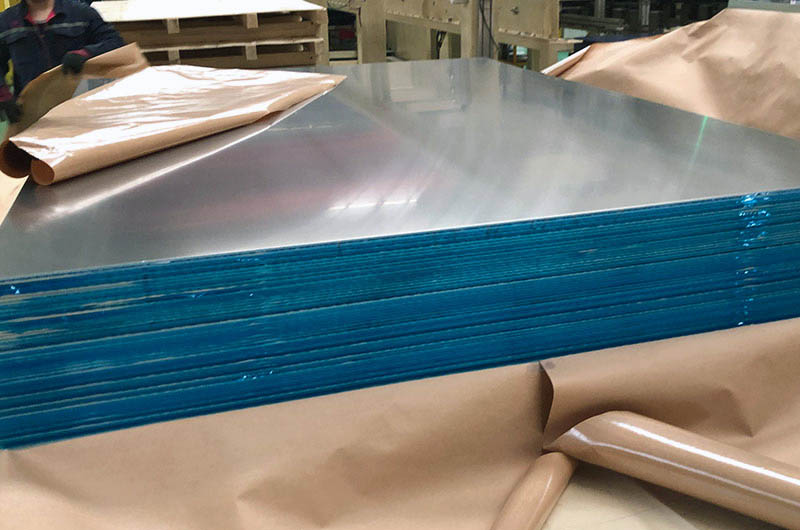

1060 Aluminum Plate Surface Treatment Types

- Mill finish: Untreated surface with a slight roughness.

- Anodized: The aluminum surface is coated with an anodized layer, providing improved corrosion resistance, durability, and decorative options.

- Powder-coated: A dry powder coating is applied to the surface and then cured to create a durable and decorative finish.

- Polished: The surface is mechanically polished to achieve a smooth, reflective finish.

Product Certifications

The specific certifications may vary depending on the manufacturer and the intended application. Common certifications for 1060 aluminum include ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System).

1060 Aluminum Plate Production Standards

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- EN 485: Aluminium and aluminium alloys - Sheet, strip, and plate

- GB/T 3880: Wrought Aluminium and Aluminium Alloy Plates, Sheets, and Strips for General Engineering

Equivalent of 1060 Aluminum

- AA 1060

- UNS A91060

- Al99.6 (European designation)

- A1N99.6 (Germany)

- A1060 (ISO)

- 1.0254 (EN)

Equivalent alloy name: a1060, 1060a, aa1060, 1060aa, al1060, al1060a, a 1060, aa 1060, jis a1060p, al1060 class, aw1060, en1060 grade etc.

Please note that while these specifications and details are generally accurate, it is always advisable to consult specific manufacturers or suppliers for the most up-to-date and precise information regarding 1060 aluminum alloy.

Thermal Conductivity of 1060 Aluminum Plate

1060 alloy aluminum has a high thermal conductivity, with a typical value of about 209W/m·K at room temperature. This high thermal conductivity makes it suitable for applications requiring efficient heat transfer, such as radiators and heat exchangers.

Mechanical Properties of 1060 Aluminum Sheet

| Alloy Temper | Specified | Tensile | Yield | Elongation(%) |

| Thickness(in.) | strength(ksi) | strength(ksi) | ||

| 1060-O(annealed) | 0.006-0.019 | 8.0-14.0 | 2.5 | Min15 |

| 0.020-0.050 | Min22 | |||

| 0.051-3.000 | Min25 | |||

| 1060-H12/1060-H22 | 0.017-0.050 | 11.0-16.0 | 9 | Min6 |

| 0.051-2.000 | Min12 | |||

| 1060-H14/1060-H24 | 0.006-0.019 | 12.0-17.0 | 10 | Min1 |

| 0.020-0.050 | Min5 | |||

| 0.051-1.000 | Min10 | |||

| 1060-H16/1060-H26 | 0.006-0.019 | 14.0-19.0 | 11 | Min1 |

| 0.020-0.050 | Min4 | |||

| 0.051-0.162 | Min5 | |||

| 1060-H18/1060-H28 | 0.006-0.019 | Min16.0 | Min12.0 | Min1 |

| 0.020-0.050 | Min3 | |||

| 0.051-0.128 | Min4 | |||

| 1060-H112 | 0.250-0.499 | Min11.0 | Min7.0 | Min10 |

| 0.500-1.000 | Min10.0 | Min5.0 | Min20 | |

| 1.001-3.000 | Min9.0 | Min4.0 | Min25 |

Modulus of Elasticity of 1060 Aluminum

The modulus of elasticity of 1060 alloy aluminum, also known as Young's modulus, is approximately 69 GPa. This property describes the stiffness and resistance to deformation of a material under an applied load.

1060 Aluminum Plate Chemical Composition

| Element | Composition Range (%) |

|---|---|

| Aluminum (Al) | 99.6 min |

| Silicon (Si) | 0.25 max |

| Iron (Fe) | 0.35 max |

| Copper (Cu) | 0.05 max |

| Manganese (Mn) | 0.03 max |

| Magnesium (Mg) | 0.03 max |

| Zinc (Zn) | 0.05 max |

| Titanium (Ti) | 0.03 max |

| Others | Each 0.05 max, Total 0.15 max |

Typical Al 1060

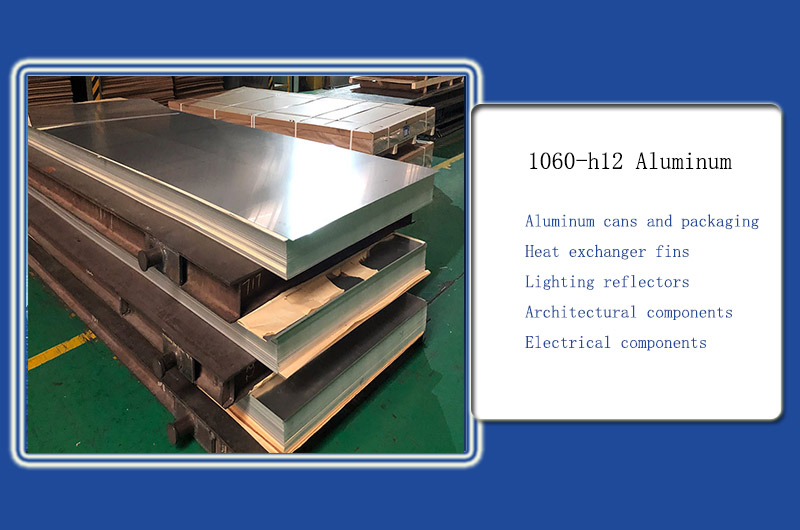

1060-h12 Aluminum Plate

1060 h12 aluminum is the aluminum alloy 1060 in the H12 temper. H12 Temper is the designation that indicates that the material has been strain-hardened and partially annealed. It has moderate strength and good formability.

Some common applications include:

- Aluminum cans and packaging

- Heat exchanger fins

- Lighting reflectors

- Architectural components

- Electrical components

1060 h24 Aluminum Plate

1060 h24 aluminum refers to the aluminum alloy 1060 in the H24 temper. The H24 temper indicates that the material has been strain-hardened and then partially annealed to a low level. It has a higher strength than H12 and is suitable for applications requiring higher structural integrity.

Common applications include:

- Roofing and siding

- Automotive parts, such as panels and trim

- Decorative trim and accents

- Chemical equipment

- Heat sinks

1060 h14 Aluminum Plate

1060-h14 aluminum refers to aluminum alloy 1060 in the H14 temper. The H14 temper indicates that the material has undergone strain hardening followed by a more extensive annealing process. It offers a balance between strength and formability and is typically used in applications requiring moderate strength and good processability.

Common uses include:

- Signage and nameplates

- Food and beverage containers

- Heat exchangers

- HVAC components

- Electrical conductors

1060-0 Aluminum Plate

1060-0 aluminum refers to the aluminum alloy 1060 in the annealed or soft state. The "0" designation indicates that the material has been fully annealed, making it very soft and easy to form. It lacks the strength of strain-hardening alloys, but has excellent machinability, making it suitable for applications where ductility is critical.

Common applications include:

- Kitchenware and utensils

- Foil and packaging material

- HVAC ductwork

- Chemical storage tanks

- Reflective mirrors

1060 Extruded Aluminum

1060 Extruded Aluminum refers to 1060 alloy aluminum processed by extrusion manufacturing method. Extrusion involves forcing an alloy through a die to form a specific shape or profile. This process enhances the material's mechanical properties and allows for the creation of complex cross-sectional designs. Extruded aluminum is commonly used in architectural, automotive, and general engineering applications requiring strength and structural integrity.

Common applications include:

- Window and door frames

- Structural components in buildings

- Heat sinks and heat transfer profiles

- Conveyor systems

- Automotive structural parts

What is the 1060 Aluminum Plate Used for?

1060 alloy aluminum is valued for its high electrical and thermal conductivity, excellent formability, and relatively good corrosion resistance. Its properties make it suitable for a wide range of applications in the electrical, automotive, construction, and general manufacturing industries.

| Application | Description |

|---|---|

| Electrical Conductors | Power transmission lines, busbars, electrical wiring, transformer windings |

| Heat Exchangers | Fins, tubes, and plates for efficient heat transfer |

| Reflectors and Lighting | Reflectors for fluorescent lights, LED luminaires |

| Kitchenware and Utensils | Pots, pans, cooking utensils, food storage containers |

| Packaging and Foil | Packaging materials, foil for food and beverage industry |

| Signage and Nameplates | Road signs, building signage, industrial labels |

| Roofing and Siding | Roofing sheets, siding for buildings |

| Automotive Trim and Parts | Trim, decorative accents, structural components |

| Chemical Equipment | Tanks and equipment for non-corrosive substances |

| General Engineering Applications | Machinery components, equipment, structures |

1050 vs. 1060 Aluminum Plate

1050 and 1060 aluminum are both commonly used alloys, but they have some differences in terms of their alloy composition, mechanical properties, and applications. Here's a comparison between 1050 and 1060 aluminum:

Alloy Composition

- 1050 Aluminum: It is a pure aluminum alloy with a minimum aluminum content of 99.50%. It is the most commercially pure aluminum alloy and has excellent corrosion resistance.

- 1060 Aluminum: It is also a pure aluminum alloy with a minimum aluminum content of 99.60%. Like 1050, it has good corrosion resistance and high electrical conductivity.

Mechanical Properties

- 1050 Aluminum: It is a soft alloy with relatively low strength. It has a tensile strength of about 55 MPa and a yield strength of around 21 MPa. It is known for its excellent formability and ductility.

- 1060 Aluminum: It is slightly stronger than 1050 aluminum. It has a tensile strength ranging from 55 to 110 MPa and a yield strength between 21 and 83 MPa. It also exhibits good formability and ductility.

Applications

- 1050 Aluminum: Due to its high electrical conductivity and excellent corrosion resistance, 1050 aluminum is commonly used in electrical applications such as conductors, transformer windings, and busbars. It is also used for reflective signage, chemical equipment, and general sheet metal work.

- 1060 Aluminum: With similar properties to 1050, 1060 aluminum is also used in electrical applications and general sheet metal work. It finds use in applications such as heat exchanger fins, reflectors, kitchenware, packaging, and general engineering components.

Weldability

Both 1050 and 1060 aluminum alloys have good weldability. They can be easily welded using various methods such as gas tungsten arc welding (GTAW/TIG), gas metal arc welding (GMAW/MIG), and resistance spot welding (RSW).

Overall, the main difference between 1050 and 1060 aluminum lies in their mechanical properties. 1060 aluminum has slightly higher strength compared to 1050, but both alloys offer excellent formability, corrosion resistance, and electrical conductivity. The choice between the two depends on the specific requirements of the application and the desired strength level.

People also searched for Aluminum Plate

-

1070 Aluminum Plate Sheet

1070 aluminum plate has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but its strength is low.

-

1100 Aluminum Plate Sheet

Compared with 1100 aluminum and 1050A, other process properties of type 1100 are basically similar. Typically, Type 1100 aluminum is used in applications that require good formability, high corrosion resistance, but not high strength.

-

1100 h12 Aluminum Plate Sheet

1100 h12 Aluminum offers moderate strength and good formability making it suitable for a wide range of applications.

-

1100 h14 Aluminum Plate Sheet

1100-H14 Aluminum Sheet Manufacturer Products have a smooth, uniform appearance, strictly controlled tolerances, and stable performance.

-

1100 h18 Aluminum Plate Sheet

1100 h18 Aluminum This temper provides a higher level of strength than softer tempers such as H12 or H14.

-

1050 Aluminum Plate Sheet

Haomei Aluminum has a sound quality control process to ensure consistent and reliable quality of 1050 aluminum sheets. This includes rigorous inspection and testing procedures at all stages of production to meet or exceed industry standards.

-

1050 h18 Aluminum Plate Sheet

Purchase high-quality raw materials, ensure the use of pure aluminum, and strictly control the alloy composition. This helps to guarantee the desired properties and performance of the 1050 h18 aluminum plate.

-

1050 h14 Aluminum Plate Sheet

Competitive Price: Haomei Aluminum offers competitive prices for 1050 h14 Aluminum Sheet Plates while guaranteeing high quality.

-

1050 h24 Aluminum Plate Sheet

Production Capacity: With advanced production facilities and equipment, the Aluminum 1050 h24 Sheet Plate produced is an aluminum plate with precise dimensions, a smooth surface, and consistent thickness. Capable of meeting different customer requirements, including custom sizes and specifications.

-

1350 Aluminum Alloy

1350 Aluminum is a soft and highly ductile alloy used primarily in electrical applications where high electrical conductivity and low electrical resistance are critical.

What is the difference between the 1060 and 6061 Aluminum Plates?

Alloy Composition

- 1060 Aluminum: It is a pure aluminum alloy with a minimum aluminum content of 99.60%. It has excellent corrosion resistance and high electrical conductivity.

- 6061 Aluminum: It is an aluminum-magnesium-silicon alloy with varying compositions. The typical composition includes around 97.9% aluminum, 1% magnesium, and 0.6% silicon. It offers good strength and excellent machinability.

Mechanical Properties

- 1060 Aluminum: It is a soft alloy with relatively low strength. It has a tensile strength of about 55 MPa (MegaPascals) and a yield strength of around 21 MPa. It is known for its excellent formability and ductility.

- 6061 Aluminum: It is a structural alloy with higher strength compared to 1060. It has a tensile strength ranging from 276 to 310 MPa and a yield strength between 241 and 276 MPa. It also exhibits good toughness and excellent corrosion resistance.

Applications

- 1060 Aluminum: Due to its high electrical conductivity and formability, 1060 aluminum is commonly used in electrical applications like wiring, busbars, and transformer windings. It is also used for heat exchanger fins, reflectors, kitchenware, packaging, and general engineering applications where lightweight and corrosion resistance are important.

- 6061 Aluminum: It is widely used in structural applications that require higher strength, such as aircraft and marine components, automotive parts, bicycle frames, construction materials, and machine parts. It is also suitable for heat sinks, architectural extrusions, and general machining operations.

Machinability

- 1060 Aluminum: It has excellent machinability and can be easily formed, bent, and stamped. It is suitable for operations like drilling, turning, milling, and welding.

- 6061 Aluminum: Although it is more challenging to machine compared to 1060, it still offers good machinability. It can be shaped using various machining processes, including milling, drilling, turning, and tapping.

Overall, the choice between 1060 and 6061 aluminum depends on the specific requirements of the application. 1060 is favored for its electrical conductivity, formability, and corrosion resistance, while 6061 offers higher strength and is suitable for structural and high-strength applications.