1060 h12 Aluminum Plate Sheet

Exact Size Competitive Prices

1060-h12 aluminum refers to the aluminum alloy 1060 in the H12 temper.To achieve this temper, the metal is strain hardened to a strength approximately one-quarter between annealed (O) and fully hard (H18).

H12 Temper Condition: The H12 temper condition involves strain hardening and partial annealing. The process imparts modest strength to the material while maintaining its formability. The H12 temper is achieved by cold working the alloy followed by a low temperature annealing treatment.

1060 h12 Aluminum Plate Properties

The following are the specific features and advantages of 1060 H12 aluminum sheet compared to other tempered conditions of 1060 aluminum:

- Increased Strength: 1060 H12 aluminum sheet has higher strength compared to the annealed (O) tempered condition of 1060 aluminum. H12 Tempering involves strain hardening and partial annealing, resulting in increased strength and improved mechanical properties.

- Excellent Formability: The 1060 H12 Aluminum Sheet maintains excellent formability, making it easy to shape, bend, and form into desired configurations. This makes it suitable for applications requiring complex shapes or complex designs.

- Corrosion resistance: 1060 h12 aluminum has good corrosion resistance, making it resistant to atmospheric corrosion. It is less prone to corrosion than other alloy families such as 3xxx or 5xxx.

- High Conductivity: 1060 H12 aluminum plate maintains the high conductivity of 1060 aluminum. Widely used in electrical applications requiring good electrical conductivity, such as electrical enclosures, connectors, and terminal blocks.

- Cost-Effective: Compared to some other aluminum alloys that contain other alloying elements, the 1060 H12 Aluminum Sheet is cost-effective. Its purity and availability contribute to its affordability, making it a practical choice for a variety of applications.

- Weldability: The 1060 H12 aluminum plate has excellent weldability and can be easily connected with other aluminum parts or structures. This facilitates efficient manufacturing processes involving welding or brazing.

These specific advantages of the 1060 H12 aluminum sheet stem from its tempered condition, providing increased strength and retaining the desirable properties of 1060 aluminum such as formability, corrosion resistance, electrical conductivity, cost-effectiveness, and weldability.

Haomei Aluminum 1060 H12 Aluminum Plate

- 1. 1060 aluminum plate has high purity, significant latent heat of fusion and high light reflection coefficient.

- 2. Similar to 1050 aluminum plate, it has excellent electrical conductivity, thermal conductivity and weldability.

- 3. Meet the requirements of conventional processing methods such as stamping and drawing, and exhibit high formability.

- 4. 1060 aluminum alloy plates can be customized, including patterns, embossing, and anti-slip aluminum plates to meet different preferences and needs.

1060 h12 Aluminum Plate Yield Strength

Generally, 1060 h12 aluminum has a yield strength between 20 and 55 MPa (megapascals).

However, the yield strength of 1060 h12 aluminum can vary depending on factors such as thickness and manufacturing process.

1060 h12 Aluminum Plate Sheet Physical Properties

| Physical Properties | Density |

| Metric | & g/cc |

| English | 0.09772 lb/in³ |

| Comments | AA; Typical |

1060 h12 Aluminum Plate Sheet Mechanical Properties

| Mechanical Properties | Metric | English | Comments |

| Hardness, Brinel | 23 | 23 | AA; Typical; 500 g load; 10 mm ball |

| Tensile Strength, Ultimate | 82.7 MPa | 12000 psi | AA; Typical |

| 75.0 - 110 MPa | 10900 - 16000 psi | Sheet and plate | |

| >= 70.0 MPa @Thickness 0.254 - 12.7 mm | >= 10200 psi @Thickness 0.0100 - 0.500 in | Drawn tube | |

| Tensile Strength, Yield | >= 62.0 MPa | >= 8990 psi | Sheet and plate |

| 75.8 MPa | 11000 psi | AA; Typical | |

| >= 28.0 MPa @Thickness 0.254 - 12.7 mm | >= 4060 psi @Thickness 0.0100 - 0.500 in | Drawn tube | |

| Elongation at Break | 6.0 - 12 % | 6.0 - 12 % | Sheet and plate |

| 16 % @Thickness 1.59 mm | 16 % @Thickness 0.0625 in | AA; Typical | |

| Modulus of Elasticity | 68.9 GPa | 10000 ksi | AA; Typical; Average of tension and compression. Compression modulus is about 2% greater than tensile modulus. |

| Poissons Ratio | 0.33 | 0.33 | |

| Fatigue Strength | 27.6 MPa @# of Cycles 5.00e+8 | 4000 psi @# of Cycles 5.00e+8 | completely reversed stress; RR Moore machine/specimen |

| Shear Modulus | 26.0 GPa | 3770 ksi | Calculated |

| Shear Strength | 55.2 MPa | 8000 psi | AA; Typical |

1060 h12 Aluminum Plate Sheet Electrical Properties

| Electrical Properties | Electrical Resistivity |

| Metric | 0.00000280 ohm-cm |

| English | 0.00000280 ohm-cm |

Aluminium 1060-H12 Thermal Properties

| Thermal Properties | Metric | English | Comments |

| Heat of Fusion | 390 J/g | 168 BTU/lb | |

| CTE, linear | 21.8 µm/m-°C @Temperature -50.0 - 20.0 °C | 12.1 µin/in-°F @Temperature -58.0 - 68.0 °F | |

| 23.6 µm/m-°C @Temperature 20.0 - 100 °C | 13.1 µin/in-°F @Temperature 68.0 - 212 °F | AA; Typical; average over range | |

| 24.5 µm/m-°C @Temperature 20.0 - 200 °C | 13.6 µin/in-°F @Temperature 68.0 - 392 °F | ||

| 25.5 µm/m-°C @Temperature 20.0 - 300 °C | 14.2 µin/in-°F @Temperature 68.0 - 572 °F | ||

| Specific Heat Capacity | 0.900 J/g-°C | 0.215 BTU/lb-°F | |

| Thermal Conductivity | 230 W/m-K | 1600 BTU-in/hr-ft²-°F | |

| Melting Point | 646.1 - 657.2 °C | 1195 - 1215 °F | AA; Typical range based on typical composition for wrought products >= 1/4 in. thickness |

| Solidus | 646.1 °C | 1195 °F | AA; Typical |

| Liquidus | 657.2 °C | 1215 °F | AA; Typical |

Aluminium 1060-H12 Processing Properties

| Processing Properties | Annealing Temperature |

| Metric | 343 °C |

| English | 650 °F |

1060 H12 Aluminum Plate Thickness Deviation

The thickness deviation of the 1060 H12 aluminum sheet will vary according to the manufacturing process, specific requirements, and standards. However, in general, the thickness deviation of a 1060 H12 aluminum sheet is usually specified within a certain tolerance range.

The standard tolerance of the thickness deviation of the aluminum plate is usually expressed as a percentage of the nominal thickness. For the 1060 H12 aluminum sheet, the thickness deviation tolerance can be between ±5% and ±10%, depending on the specific application and customer requirements.

It should be noted that actual thickness deviation tolerances for specific 1060 H12 aluminum sheets should be determined in accordance with applicable standards, specifications, and agreements between the manufacturer and the customer. It is recommended to consult the relevant standards or communicate directly with the supplier or manufacturer for accurate information on the thickness deviation tolerances for specific 1060 H12 aluminum sheets.

1060 Aluminum Plate Chemical Composition

1060 aluminum is a pure aluminum alloy with a minimum aluminum content of 99.60%. It is known for its high conductivity and good corrosion resistance.

| Element | Maximum Content (%) |

|---|---|

| Aluminium | 99.6 |

| Copper | 0.05 |

| Iron | 0.35 |

| Magnesium | 0.03 |

| Manganese | 0.03 |

| Silicon | 0.25 |

| Titanium | 0.03 |

| Vanadium | 0.05 |

| Zinc | 0.05 |

1060 H12 Aluminum Plate Typical Applications

The properties of 1060 h12 aluminum make it particularly suitable for applications where formability, moderate strength, and good corrosion resistance are a priority.

1060 H12 aluminum sheet is used in various industries and fields because of its special properties. Such as electrical enclosures, signage and advertising panels, building and construction, heat exchanger fins, automotive parts, food and beverage packaging, etc.

1060 H12 Aluminum for Cans and Packaging

- Application: Beverage Cans, Food Cans, Packaging Containers

- Application Parts: Can Body, Can End

- Other Aluminum Cans and Packaging Aluminum: 3004 Aluminum (H19 Status) for Can Ends, 5052 Aluminum (H19 Status) for Easy Open Ends

1060 H12 Aluminum for Heat Exchanger Fins

- Applications: Fins for Heat Exchangers in HVAC systems, Radiators

- Application Parts: Heat Exchanger Fins

- Other Heat Exchanger Fin Aluminum Alloys: 1100 Aluminum (H14 Condition), 3003 Aluminum (H14 Condition)

1060 H12 Aluminum Plate for Lighting Reflector

- Applications: Reflectors for Lighting Equipment, Lamps

- Application Parts: Reflector

- Other lighting reflector aluminum alloys: 1100 aluminum (H18 condition), 3003 aluminum (H18 condition)

1060 H12 Aluminum for Building Components

- Application: Decoration, Decorative Elements in Architectural Projects

- Application Parts: Architectural Decoration, Decoration

- Other building components Aluminum alloys: 3003 aluminum (H14 temper), 6061 aluminum (T6 temper)

1060 H12 Aluminum for Electrical Components

- Applications: Electrical Enclosures, Connectors, Terminals

- Application Parts: Electrical Enclosure

- Aluminum Alloys for Other Electrical Components: 1100 Aluminum (H12 Condition), 5052 Aluminum (H32 Condition)

General Sheet Metal Processing

- Applications: Sheet Metal Fabrication, Panels, Enclosures

- Application Parts: Electrical Enclosures, Connectors, Terminals

- 1060 h12 aluminum: Electrical Enclosure

- Other aluminum alloys: 1100 aluminum (H12 temper), 5052 aluminum (H32 temper)

In these applications, 1060 h12 aluminum is widely used because of its desirable properties including formability, moderate strength, and corrosion resistance. However, it is important to note that the specific choice of aluminum alloy and temper may vary based on factors such as application requirements, industry standards, and design considerations.

1060 aluminum plate Other applications

- Battery pack soft connection

- bus interior

- car parts

- Aluminum plastic panel

- signage

- lighting fixtures

- wide curtain wall

- Bus luggage rack/floor/pattern board

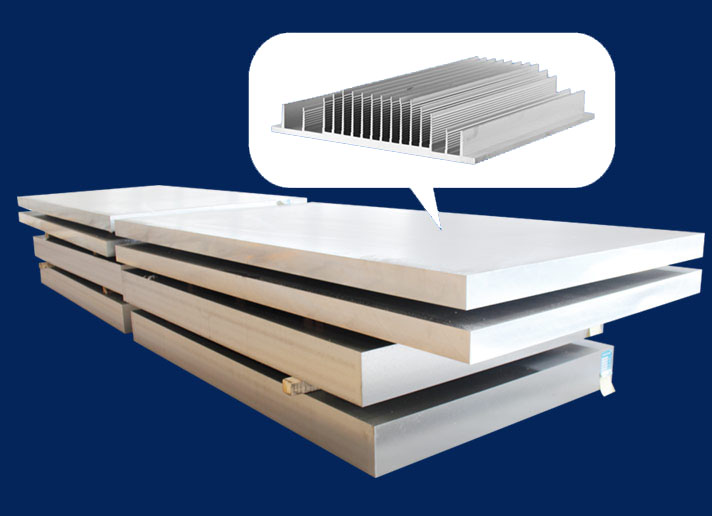

1060 medium thick aluminum plate application

- Aluminum busbar

- car radiator

- New energy vehicle charging pile

- Mold, etc.

1060 aluminum foil roll application

- Aluminum foil gasket

- food packaging

- Electronic tags

- Aluminum foil for automotive heat shields

- battery foil

- Battery soft connection

- battery label

- Battery explosion-proof valve, etc.

1060-O Aluminum Applications

- car heat shield

- Electronic tags

- Flexible battery connection

- battery label

- Aluminum foil for battery explosion-proof valve, etc.

- Aluminium 1060-H12; UNS A91060; AA1060-H12; Al1060-H12

Haomei Aluminum specializes in the R&D and production of hot-rolled 1060 aluminum plates. 1060 aluminum plate is famous for its high elongation, tensile strength, excellent electrical conductivity and excellent formability, meeting the requirements of traditional processing methods such as stamping and drawing. Haomei Aluminum's extra-wide and extra-thick 1060 aluminum plates are stress-relieved to ensure minimal deformation when cutting. Available in widths up to 2650mm and thicknesses up to 500mm, they offer unparalleled versatility for a variety of applications.

-

1060 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 Aluminum Plate Sheet. Has rich expertise and experience in the production of aluminum plates.

-

1060 h24 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 h24 Aluminum Plate Sheet and has competitive prices while ensuring product quality.

-

1060 h18 Aluminum Plate Sheet

Haomei Aluminum is a quality 1060 h18 Aluminum Plate Sheet manufacturer, ensuring that its products meet industry standards and customer expectations.

-

1060 h14 Aluminum Plate Sheet

Certification & Compliance: Possessing 1060 h14 Aluminum Sheet Plate related certifications such as ISO 9001 demonstrates our commitment to our quality management system.