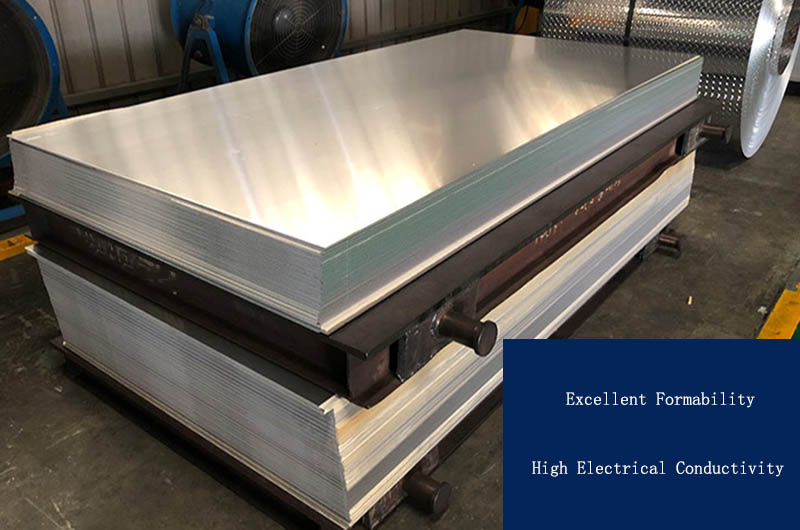

1060 h14 Aluminum Plate Sheet

Complete Specifications Stable Performance

1060 H14 aluminum plate is a special type of aluminum alloy plate.

- Alloy: The number "1060" refers to the aluminum alloy composition, consisting primarily of 99.6% pure aluminum. It is a commonly used alloy in various industries due to its excellent corrosion resistance, electrical conductivity, and thermal conductivity.

- Tempering: The "H14" tempering designation indicates the heat treatment and mechanical properties of the aluminum plate. H14 represents the strain hardened and partially annealed temper, which gives the sheet moderate strength and good formability. It is generally softer tempered than H12 or H18.

1060 h14 Aluminum Plate Thickness/Size

Aluminum plates are available in various thicknesses and sizes to suit different applications. The dimensions of the 1060 H14 aluminum sheet may vary by supplier or manufacturer.

- Common thicknesses range from 0.2mm to 6mm

- Panel dimensions may vary from 1m x 2m to 1.5m x 3m or even larger.

1060 h14 Aluminum Plate Properties

Strength: 1060 H14 aluminum has increased strength compared to the annealed (O) tempered condition of 1060 aluminum. H14 Tempering involves strain hardening and partial annealing, which increases strength and hardness.

Formability: 1060 H14 aluminum retains excellent formability, making it easy to shape, bend, and form into desired configurations. This makes it suitable for applications requiring complex shapes or complex designs.

Corrosion Resistance: Similar to other tempered conditions of 1060 Aluminum, 1060 H14 Aluminum has good corrosion resistance. It is less prone to corrosion than some other alloy families, making it suitable for a variety of indoor and outdoor applications.

Electrical Conductivity: 1060 H14 Aluminum maintains high electrical conductivity, making it suitable for electrical applications requiring good electrical conductivity, such as electrical enclosures, conductors, and bus bars.

Weldability: 1060 H14 aluminum has excellent weldability and can be easily joined to other aluminum parts or structures by welding or brazing.

1060 h14 Aluminum Plate Yield Strength

The yield strength and mechanical properties of 1060 H14 aluminum are as follows:

Yield Strength:

The yield strength of 1060 H14 aluminum is typically around 60 MPa (8, 700 psi).

1060 h14 Aluminum Plate Mechanical Properties

| Mechanical Property | Typical Value |

|---|---|

| Yield Strength | 60 MPa (8, 700 psi) |

| Tensile Strength | 110-130 MPa (16, 000-19, 000 psi) |

| Elongation at Break | 25-30% |

| Modulus of Elasticity | 69 GPa (10, 000 ksi) |

| Hardness (Brinell) | 30 HB |

NOTE: These values are general approximations and may vary slightly depending on specific manufacturing processes, heat treatments, and test methods used. In addition, mechanical properties can be affected by factors such as the thickness of the material and tempering conditions.

For the exact mechanical property values of 1060 H14 aluminum, it is recommended to refer to the material specification sheet, or test report, or consult the manufacturer or supplier, who can provide specific mechanical property data according to their production and testing process.

1060 H14 Aluminum Plate Typical Applications

NOTE: These applications are common examples and the use of 1060 H14 aluminum may vary according to specific industry requirements and customer needs.

1060 H14 Aluminum Plate For Reflector

Reflectors: 1060 H14 aluminum is often used to produce reflective materials such as reflectors or sheets for lighting fixtures, traffic signs, and solar systems.

- Specific application examples: street light reflectors.

- Other Aluminum Alloys Used: In some high-end applications, other aluminum alloys such as 3003 or 5005 may be used for strength or corrosion resistance. The specific tempering conditions for these alloys will vary depending on the application.

1060 H14 Aluminum HVAC Components

HVAC Components: Because of its formability and corrosion resistance, 1060 H14 aluminum is used in HVAC (heating, ventilation, and air conditioning) components, including ducting, heat exchanger fins, and air handling units.

- Specific application example: HVAC ductwork.

- Other aluminum alloys used: For HVAC applications other aluminum alloys such as 1100, 3003, or 5052 can be used upon specific request. Tempering conditions may vary, but commonly used tempers include H24 or H26 for strength and formability.

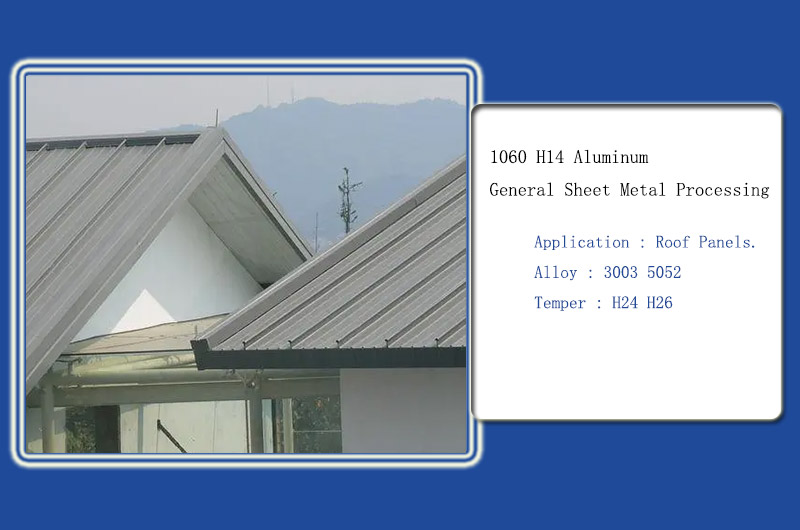

1060 H14 Aluminum General Sheet Metal Processing

General Sheet Metal Fabrication: 1060 H14 Aluminum is suitable for general sheet metal applications such as roofing, siding, gutters, and moldings, where its formability, corrosion resistance, and cost-effectiveness provide advantages.

- Specific application example: Roof panels.

- Other Aluminum Alloys Used: Depending on specific application requirements, other aluminum alloys such as 3003 or 5052 can be used. Tempering conditions can vary, commonly used tempers include H24 or H26 for strength and corrosion resistance.

1060 H14 Aluminum Food And Beverage Packaging

Food and Beverage Packaging: Some food and beverage packaging applications can use 1060 H14 aluminum because of its formability, corrosion resistance, and compliance with food grade requirements.

- Specific application: cans, containers, or lids.

- Other aluminum alloys used: For food and beverage packaging, aluminum alloys such as 3004 or 5052 can be used. A common tempering condition for canning is H19, which provides high strength and formability.

1060 H14 Aluminum Electronic Enclosure

Electronic Enclosures: The combination of electrical conductivity and formability makes 1060 H14 aluminum suitable for electronic enclosures, such as those for electronic devices and equipment.

- Specific application examples: laptop or computer housings.

- Other aluminum alloys used: Other aluminum alloys such as 6061 or 5052 can be used in electronic housings that require greater strength or better heat dissipation. Tempering conditions can vary depending on the specific requirements of the enclosure, but commonly used tempers include T6 or H32.

NOTE: The choice of aluminum alloy and its tempering conditions may vary depending on factors such as specific application requirements, desired properties, and availability. It is recommended to consult the manufacturer or supplier for exact alloy and temper recommendations based on specific application needs.

-

1060 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 Aluminum Plate Sheet. Has rich expertise and experience in the production of aluminum plates.

-

1060 h24 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 h24 Aluminum Plate Sheet and has competitive prices while ensuring product quality.

-

1060 h18 Aluminum Plate Sheet

Haomei Aluminum is a quality 1060 h18 Aluminum Plate Sheet manufacturer, ensuring that its products meet industry standards and customer expectations.

-

1060 h12 Aluminum Plate Sheet

Quality Control Measures: Reliable Manufacturer of 1060 h12 Aluminum Plate Sheet ensures consistent production of high-quality Aluminum Sheet Plate.

People also searched for Aluminum Plate

-

1050 Aluminum Plate Sheet

Haomei Aluminum has a sound quality control process to ensure consistent and reliable quality of 1050 aluminum sheets. This includes rigorous inspection and testing procedures at all stages of production to meet or exceed industry standards.

-

1050 h18 Aluminum Plate Sheet

Purchase high-quality raw materials, ensure the use of pure aluminum, and strictly control the alloy composition. This helps to guarantee the desired properties and performance of the 1050 h18 aluminum plate.

-

1050 h14 Aluminum Plate Sheet

Competitive Price: Haomei Aluminum offers competitive prices for 1050 h14 Aluminum Sheet Plates while guaranteeing high quality.

-

1050 h24 Aluminum Plate Sheet

Production Capacity: With advanced production facilities and equipment, the Aluminum 1050 h24 Sheet Plate produced is an aluminum plate with precise dimensions, a smooth surface, and consistent thickness. Capable of meeting different customer requirements, including custom sizes and specifications.

-

1070 Aluminum Plate Sheet

1070 aluminum plate has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but its strength is low.

-

1100 Aluminum Plate Sheet

Compared with 1100 aluminum and 1050A, other process properties of type 1100 are basically similar. Typically, Type 1100 aluminum is used in applications that require good formability, high corrosion resistance, but not high strength.

-

1100 h12 Aluminum Plate Sheet

1100 h12 Aluminum offers moderate strength and good formability making it suitable for a wide range of applications.

-

1100 h14 Aluminum Plate Sheet

1100-H14 Aluminum Sheet Manufacturer Products have a smooth, uniform appearance, strictly controlled tolerances, and stable performance.

-

1100 h18 Aluminum Plate Sheet

1100 h18 Aluminum This temper provides a higher level of strength than softer tempers such as H12 or H14.