1060 h18 Aluminum Plate Sheet

Stable Performance Competitive Prices

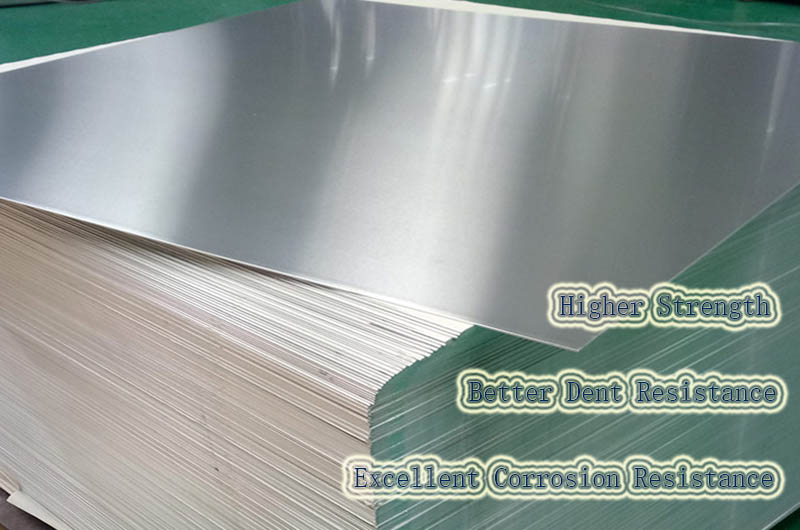

1060 H18 aluminum plate is another variation of 1060 aluminum alloy with different tempering characteristics.

- Alloy: Similar to 1060 H14, "1060" refers to the aluminum alloy composition, consisting of 99.6% pure aluminum. It has excellent corrosion resistance and electrical and thermal conductivity.

- Temper: The "H18" temper designation indicates different heat treatment and mechanical properties compared to H14. H18 indicates the fully hard condition obtained by strain hardening. It offers the highest strength in the H1x temper range but may have reduced formability compared to H14.

When is the 1060 H18 Aluminum Plate the Best Choice?

The selection of a 1060 aluminum plate with a specific temper condition (H18, H14, or H24) depends on the performance requirements of the application.

- 1060 H18 aluminum offering the highest strength.

- 1060 H14 aluminum provides a balance between strength and formability.

- 1060 H24 aluminum is a good choice for applications requiring moderate strength and formability.

| Property | 1060 H18 | 1060 H14 | 1060 H24 |

|---|---|---|---|

| Temper | H18 | H14 | H24 |

| Strength | Highest | Moderate | Moderate |

| Formability | Moderate | Good | Good |

| Corrosion Resistance | Good | Good | Good |

| Weldability | Easily Weldable | Easily Weldable | Easily Weldable |

| Applications | High-strength | Balanced | Moderate strength |

| with less | strength and good | with good |

1060 h18 Aluminum Plate Mechanical Properties

| Property | Typical Value |

|---|---|

| Yield Strength | 80 MPa (11, 600 psi) |

| Tensile Strength | 110-140 MPa (16, 000-20, 000 psi) |

| Elongation | 2-3% |

| Hardness (HB) | 35-45 |

1060 H18 Aluminum Plate Typical Applications

The specific properties and benefits of the 1060 H18 aluminum sheet make it suitable for certain applications, especially those requiring higher strength, hardness, dent resistance, and good corrosion resistance. However, due to its completely hard condition, it may be less suitable for applications requiring extensive forming or deep drawing.

1060 H18 Aluminum is Used in Electronics and Electrical

- Applications of 1060 H18: In electronic and electrical applications, 1060 H18 aluminum sheets can be used for busbars, heat sinks, electrical conductors, and components in electronic equipment.

- Other Aluminum Alloys: In addition to 1060 H18, other aluminum alloys commonly used in electronic and electrical applications include 1100, 3003, and 6061. These alloys may be available in different tempers such as H12, H14, and T6, depending on the specific requirements of the application.

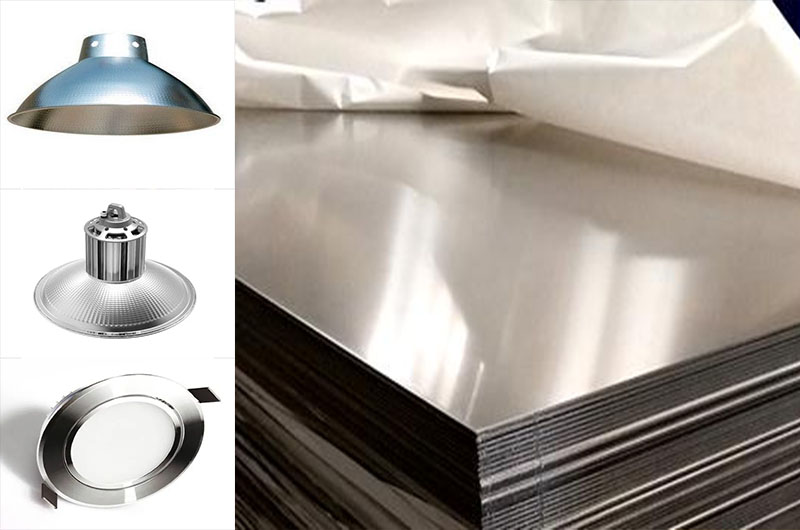

1060 H18 Aluminum Reflector And Lighting

- Application of 1060 H18: In terms of reflectors and lighting, due to its high reflectivity, the 1060 H18 aluminum sheet is used for reflectors, lamps, lampshades, and other lighting components.

- Other Aluminum Alloys: Other aluminum alloys commonly used in this application include 1050, 1070, and 3004. These alloys may also be in different tempers such as H16 or H24.

1060 H18 Aluminum Plate Decorative Applications

- Applications of 1060 H18: In decorative applications, the 1060 H18 aluminum sheet can be used for architectural trim, wall panels, trim, and other decorative elements.

- Other Aluminum Alloys: Other aluminum alloys commonly used for decorative purposes include 3003 and 5052. These alloys may be in different tempers, such as H14 or H32, depending on the desired properties and design requirements.

1060 H18 Aluminum Packaging

- Applications of 1060 H18: The corrosion resistance and formability of 1060 H18 aluminum sheet make it ideal for food and beverage packaging, 1060 H18 aluminum sheet is commonly used in food and beverage packaging, including cans, foils, and containers.

- Other Aluminum Alloys: Other aluminum alloys used in packaging applications include 3004 and 8011. These alloys may be in different tempers such as H19 or H24 to ensure strength and formability for packaging purposes.

1060 H18 Aluminum Chemical Industry

- Applications of 1060 H18: In the chemical industry, 1060 H18 aluminum sheets can be used for storage tanks, pipes, and other equipment that require corrosion resistance and chemical inertness.

- Other Aluminum Alloys: Other aluminum alloys commonly used in the chemical industry include 5052, 5083, and 6061. These alloys may be available in different tempers such as H32, H34, or T6, depending on the specific requirements of the chemical application.

Note: While the 1060 H18 aluminum sheet is suitable for these applications, other aluminum alloys and quenched and tempered materials can also be used depending on specific needs and requirements. The choice of aluminum alloy and quenched and tempered depends on strength, corrosion resistance, formability, and other application-specific considerations.

High-quality 1060 h18 Aluminum Plate Supplier

Haomei Aluminum is a premium 1060 Aluminum Sheet manufacturer, ensuring that its products meet industry standards and customer expectations. Here are the reasons to choose us:

- Expertise and Experience: We have extensive expertise and experience in the production of aluminum sheets. In-depth knowledge of the aluminum industry including alloy composition, temper specification, production process, and quality control measures.

- Quality Control Measures: Reliable manufacturers have robust quality control measures in place to ensure consistent production of high-quality aluminum sheets. This includes rigorous inspection procedures, adherence to industry standards and codes, and thorough testing of finished products.

- State-of-the-Art Manufacturing Facility: Has a state-of-the-art manufacturing facility equipped with modern equipment and technology. This ensures an efficient production process, precise dimensional control, and the ability to meet various customer requirements.

- Certification and Compliance: Having relevant certifications, such as ISO 9001, demonstrates our commitment to our quality management system.

- Material Traceability: Manufacturers have a robust system in place to track and trace the raw materials used to produce 1060 aluminum sheets. The quality, origin, and compliance of the materials are ensured.

- Customization ability: ability to provide customized solutions to meet specific customer requirements. This includes offering a range of thicknesses, sizes, and surface finishes, as well as the ability to meet special requirements for alloys, tempers, and additional machining.

By considering these factors, you can choose Haomei Aluminum to provide a reliable product, meet your specific requirements, and provide excellent customer support.

1060 h18 Aluminum Plate vs1060 h14 Aluminum vs 1060 h12 Aluminum

1. Strength

- 1060 H18: Highest strength among the three tempers due to its fully hard condition achieved through strain hardening.

- 1060 H14: Moderate strength, striking a balance between strength and formability.

- 1060 H12: Lowest strength, offering high formability but less overall strength compared to H18 and H14.

2. Formability

- 1060 H18: Less formable due to its fully hard condition, requiring more specialized techniques for shaping and bending.

- 1060 H14: Good formability, allowing for easier shaping, bending, and fabrication.

- 1060 H12: Excellent formability, making it easy to shape, bend, and fabricate without cracking or damaging the material.

3. Surface Finish

- 1060 H18: Typically provides a smoother and more uniform surface finish.

- 1060 H14: Offers a reasonably smooth surface finish.

- 1060 H12: Provides a smooth surface finish suitable for various applications.

4. Applications

- 1060 H18: Often used in structural applications that require higher strength, dent resistance, and load-bearing capacity.

- 1060 H14: Commonly used in electrical components, signage, roofing, and general-purpose applications where a balance between strength and formability is required.

- 1060 H12: Used in general fabrication, light-duty applications, and projects where ease of forming is critical.

-

1060 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 Aluminum Plate Sheet. Has rich expertise and experience in the production of aluminum plates.

-

1060 h12 Aluminum Plate Sheet

Quality Control Measures: Reliable Manufacturer of 1060 h12 Aluminum Plate Sheet ensures consistent production of high-quality Aluminum Sheet Plate.

-

1060 h14 Aluminum Plate Sheet

Certification & Compliance: Possessing 1060 h14 Aluminum Sheet Plate related certifications such as ISO 9001 demonstrates our commitment to our quality management system.

-

1060 h24 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 h24 Aluminum Plate Sheet and has competitive prices while ensuring product quality.

By comparing these characteristics, you can determine the most suitable temperature based on the specific requirements of your application, such as the desired strength, formability, and surface finish.

People also searched for Aluminum Plate

-

1050 Aluminum Plate Sheet

Haomei Aluminum has a sound quality control process to ensure consistent and reliable quality of 1050 aluminum sheets. This includes rigorous inspection and testing procedures at all stages of production to meet or exceed industry standards.

-

1050 h18 Aluminum Plate Sheet

Purchase high-quality raw materials, ensure the use of pure aluminum, and strictly control the alloy composition. This helps to guarantee the desired properties and performance of the 1050 h18 aluminum plate.

-

1050 h14 Aluminum Plate Sheet

Competitive Price: Haomei Aluminum offers competitive prices for 1050 h14 Aluminum Sheet Plates while guaranteeing high quality.

-

1050 h24 Aluminum Plate Sheet

Production Capacity: With advanced production facilities and equipment, the Aluminum 1050 h24 Sheet Plate produced is an aluminum plate with precise dimensions, a smooth surface, and consistent thickness. Capable of meeting different customer requirements, including custom sizes and specifications.

-

1070 Aluminum Plate Sheet

1070 aluminum plate has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but its strength is low.

-

1100 Aluminum Plate Sheet

Compared with 1100 aluminum and 1050A, other process properties of type 1100 are basically similar. Typically, Type 1100 aluminum is used in applications that require good formability, high corrosion resistance, but not high strength.

-

1100 h12 Aluminum Plate Sheet

1100 h12 Aluminum offers moderate strength and good formability making it suitable for a wide range of applications.

-

1100 h14 Aluminum Plate Sheet

1100-H14 Aluminum Sheet Manufacturer Products have a smooth, uniform appearance, strictly controlled tolerances, and stable performance.

-

1100 h18 Aluminum Plate Sheet

1100 h18 Aluminum This temper provides a higher level of strength than softer tempers such as H12 or H14.