1060 h24 Aluminum Plate Sheet

Standards: ASTM B209, EN 485, GB/T 3880 Stable Performance

What is 1060 H24 in Aluminium?

1060 H24 aluminum plate is a special type of aluminum alloy sheet made of 99.6% pure aluminum (alloy 1060) and undergoes a specific tempering process called H24.

The designation "1060" refers to the aluminum alloy composition, which is mainly composed of 99.6% aluminum and small amounts of other elements. It is a commercially pure aluminum alloy with excellent corrosion resistance, high electrical conductivity, and good thermal conductivity. Due to its high purity, 1060 aluminum is relatively soft and less strong than alloy aluminum sheets.

The tempering designation "H24" indicates the specific tempering process that the aluminum sheet goes through. The H24 temper is a work-hardened and partially annealed temper, achieved by cold rolling and annealing. This tempering process increases the strength and hardness of the aluminum sheet while retaining some formability.

1060 h24 Aluminum Plate Properties

1060 H24 aluminum refers to aluminum alloys in the 1000 series, specifically 1060 alloy, in the H24 temper. Following are some properties and applications of 1060 H24 Aluminum:

- Compared to other tempers of 1060 alloy, 1060 H24 has moderate strength, making it suitable for applications where high strength is not required.

- 1060 H24 temper maintains good formability allowing a wide variety of forming, bending, and fabrication processes.

- 1060 aluminum has excellent corrosion resistance, including resistance to atmospheric corrosion.

- 1060 H24 tempers generally provide a smooth surface finish suitable for a variety of applications.

1060 h24 Aluminum Plate Mechanical Properties

| Property | Typical Value |

|---|---|

| Yield Strength | 60 MPa (8, 700 psi) |

| Tensile Strength | 70-105 MPa (10, 000-15, 200 psi) |

| Elongation | 25-30% |

| Hardness (HB) | 35-45 |

1060 H24 Aluminum Plate Typical Applications

1060 H24 Aluminum Plate is commonly used in a variety of applications where a lightweight, corrosion-resistant, and formable material is required. Some common uses include:

| Application | Description |

|---|---|

| Roofing and cladding | Used for roof coverings, flashing, and decorative purposes due to its corrosion resistance and malleability. |

| Reflectors | Suitable for reflectors in lighting fixtures, solar panels, and decorative mirrors due to its high reflectivity. |

| Signage and advertising | Used for signage boards, nameplates, and advertising applications due to ease of fabrication and corrosion resistance. |

| Chemical industry | Utilized in chemical tanks and storage containers due to its high corrosion resistance. |

| Food processing equipment | Used in the manufacture of food processing equipment and storage containers due to its corrosion resistance. |

| Heat sinks | Often employed in heat sink applications due to its excellent thermal conductivity. |

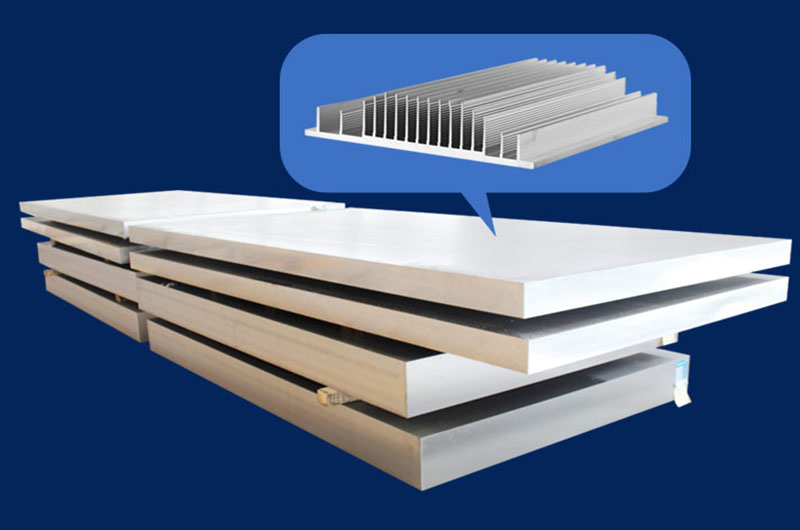

1060 h24 Aluminum Plate for Heat Sink

Radiators generally use materials with high thermal conductivity. 1060 h24 aluminum coil is a commonly used one. It belongs to the pure aluminum series. It has good thermal conductivity, low density, and is not easy to oxidize (dense alumina will be produced after surface oxidation to prevent further oxidation), can meet the needs of heat dissipation, coupled with lightweight, easy processing, and affordable price, so most heat sinks are now made of aluminum or aluminum alloy.

- Commonly used heat sink materials are copper and aluminum, both of which have their own advantages and disadvantages.

- Copper has good thermal conductivity, but it is more expensive, difficult to process, too heavy, has a small heat capacity, and is easy to oxidize.

- Relatively speaking, the 1060 aluminum coil has good thermal conductivity, and low density, is lightweight, easy processing, and low cost.

- All things considered, it is a good choice to use 1060 h24 aluminum to make the radiator.

1060 h24 Aluminum for Bottle Cap Material

The aluminum anti-theft bottle cap material can be precisely processed by 1060h24 stamped aluminum plate material, which is used for the packaging of wine, beverages (with or without gas), and medicine and health care products, and can meet special requirements such as high-temperature cooking and sterilization.

- Aluminum coil thickness: 0.2-0.5mm

- Tensile strength MPa: >95

Aluminum coil material performance: easy to stretch, stable performance, smooth and delicate surface, aluminum box aluminum cover made of 1060 aluminum foil material

The aluminum anti-theft cap made of 1060 h24 aluminum plate has a simple structure, strong adaptability, and good sealing effect.

1060 H24 Alloy Aluminum Plate for Ventilation Duct

The use of ventilation ducts can be said to be ubiquitous, whether in office spaces or some public buildings, there are ventilation ducts installed. At present, most of the ventilation ducts on the market are made of aluminum alloy plates, and the 1060 h24 aluminum plate has a better use effect.

- Thickness: 0.1-500mm

- Width: 100-2650mm

- Length: 500-1600mm

1060 H24 Stamped Aluminum Plate

1060 aluminum plate is a commonly used stamping material. It has good elongation and tensile strength, meets the conventional stamping and tensile requirements, has high formability, and is not easy to crack or wrinkle.

1060 H24 stamped aluminum plate is suitable for busbar, power battery soft connection, aluminum-plastic plate, lighting material, metal stamping parts, etc.

1060-O Aluminum Plate and 1060-H24 Aluminum Plate

| Property | 1060-O Aluminum Plate | 1060-H24 Aluminum Plate |

|---|---|---|

| Strength | Low | Moderate |

| Formability | Excellent | Good |

| Ductility | High | Moderate |

| Hardness (HB) | Relatively low | Higher than O condition |

| Typical Use | Deep drawing, forming | Roofing, cladding, panels |

-

1060 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 Aluminum Plate Sheet. Has rich expertise and experience in the production of aluminum plates.

-

1060 h14 Aluminum Plate Sheet

Certification & Compliance: Possessing 1060 h14 Aluminum Sheet Plate related certifications such as ISO 9001 demonstrates our commitment to our quality management system.

-

1060 h12 Aluminum Plate Sheet

Quality Control Measures: Reliable Manufacturer of 1060 h12 Aluminum Plate Sheet ensures consistent production of high-quality Aluminum Sheet Plate.

-

1060 h18 Aluminum Plate Sheet

Haomei Aluminum is a quality 1060 h18 Aluminum Plate Sheet manufacturer, ensuring that its products meet industry standards and customer expectations.

1060-O Aluminum Plate

- 1060-O aluminum plate refers to the annealed state of 1060 aluminum alloy.

- The "O" mark stands for annealing, which means that the aluminum sheet has been fully annealed to eliminate internal stress and improve its formability.

- In this case, the aluminum sheet is soft and low in strength but exhibits excellent ductility and workability.

1060-H24 Aluminum Plate

- 1060-H24 aluminum plate is a special tempering treatment of 1060 aluminum alloy. The "H24" designation indicates a work-hardened and partially annealed condition, achieved by cold rolling and annealing.

- This tempering process increases the strength and hardness of the aluminum sheet while retaining some formability.

- Compared with the annealed (O) condition, the H24 aluminum plate has moderate strength and improved mechanical properties.

1. In Terms of Production Technology

- 1060 H24 is in a state of incomplete annealing after work hardening.

- The O-state aluminum plate is formed by crystallization after complete annealing.

2. In Terms of Physical Properties

- The H24 state aluminum plate is harder than the O state.

- O-state aluminum plates are softer.

The hardness of the 1060 H24 state is greater than the 1060 O aluminum plate.

3. In Terms of Scope of Use

- 1060 H24 is relatively hard and can be drawn, sheared, and bent. It is generally used in curtain walls, mechanical processing, and other industries.

- Because the O-state aluminum plate is relatively soft, it is easy to bend and draw. It is mainly used in decoration, packaging, and other industries.

People also searched for Aluminum Plate

-

1070 Aluminum Plate Sheet

1070 aluminum plate has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but its strength is low.

-

1100 Aluminum Plate Sheet

Compared with 1100 aluminum and 1050A, other process properties of type 1100 are basically similar. Typically, Type 1100 aluminum is used in applications that require good formability, high corrosion resistance, but not high strength.

-

1100 h12 Aluminum Plate Sheet

1100 h12 Aluminum offers moderate strength and good formability making it suitable for a wide range of applications.

-

1100 h14 Aluminum Plate Sheet

1100-H14 Aluminum Sheet Manufacturer Products have a smooth, uniform appearance, strictly controlled tolerances, and stable performance.

-

1100 h18 Aluminum Plate Sheet

1100 h18 Aluminum This temper provides a higher level of strength than softer tempers such as H12 or H14.

-

1050 Aluminum Plate Sheet

Haomei Aluminum has a sound quality control process to ensure consistent and reliable quality of 1050 aluminum sheets. This includes rigorous inspection and testing procedures at all stages of production to meet or exceed industry standards.

-

1050 h18 Aluminum Plate Sheet

Purchase high-quality raw materials, ensure the use of pure aluminum, and strictly control the alloy composition. This helps to guarantee the desired properties and performance of the 1050 h18 aluminum plate.

-

1050 h14 Aluminum Plate Sheet

Competitive Price: Haomei Aluminum offers competitive prices for 1050 h14 Aluminum Sheet Plates while guaranteeing high quality.

-

1050 h24 Aluminum Plate Sheet

Production Capacity: With advanced production facilities and equipment, the Aluminum 1050 h24 Sheet Plate produced is an aluminum plate with precise dimensions, a smooth surface, and consistent thickness. Capable of meeting different customer requirements, including custom sizes and specifications.