1070 Aluminum Plate Sheet

Conductivity: About 63% IACS Stable Performance

What is 1070 Aluminum Grade?

1070 aluminum plate contains 99.7% Al, which is the alloy plate with the highest Al content among the 1xxx series of industrial aluminum. Therefore, 1070 aluminum alloy retains the excellent properties of pure aluminum itself, suitable extension processing, good thermal conductivity, high corrosion resistance, etc. In addition, by adding a small amount of alloying elements, the mechanical properties of 1070 aluminum plates are slightly enhanced.

Since 1070 aluminum does not contain other technical elements, the production process is single and the price is relatively cheap. It is currently the most commonly used series in conventional industries.

1070 is an aluminum grade that belongs to the 1000 series of aluminum alloys. Aluminum grades are designated by a four-digit number system developed by the Aluminum Institute. Each digit in the number represents a specific property or characteristic of the alloy.

Take 1070 aluminum grade as an example:

- The first number "1" means pure aluminum alloy with a minimum aluminum content of 99.00%.

- The second digit "0" indicates that it is part of the 1000 series, which includes pure aluminum alloys with excellent formability and high thermal and electrical conductivity.

- The last two digits "70" do not have any specific meaning and are used for identification purposes within the 1000 series.

1070 aluminum has relatively low strength compared to other aluminum alloys, so it is not typically used in applications requiring high structural integrity or load-carrying capacity.

In addition to aluminum, 1070 aluminum alloy also contains a small amount of impurity elements. These impurity elements are mainly iron, silicon, manganese and copper. Iron is the main impurity element, usually less than 0.25%. The presence of iron will reduce the strength and plasticity of aluminum alloys, but can improve the material's corrosion resistance.

- Silicon content is usually less than 0.20%. The presence of silicon can increase the strength and hardness of aluminum alloys.

- The manganese content is usually less than 0.03%. The presence of manganese can improve the corrosion resistance of aluminum alloys.

- Copper content is usually less than 0.04%. The presence of copper can improve the strength and plasticity of aluminum alloys.

1070 aluminum is known for its high electrical and thermal conductivity, good formability, and high reflectivity. It is commonly used in applications where these properties are required, such as electrical components, radiators, reflectors, and certain types of cookware.

What are the Properties of the 1070 Aluminum Plate?

The following are the 1070 aluminum alloy properties:

- 1070 Aluminum Plate has excellent conductivity which makes it suitable for electrical and electronic applications.

- 1060 aluminum has good thermal conductivity for efficient heat transfer in applications such as heat sinks.

- 1070 aluminum plate has good atmospheric corrosion resistance and is suitable for outdoor applications.

- Light weight, under the same volume, 1070 aluminum plate is lighter than steel, iron, and copper.

- Excellent corrosion resistance, 1070 aluminum plate has excellent resistance to atmospheric and water corrosion as well as most acids and organic compounds.

- 1070 aluminum plate is a non-heat-treatable alloy that is cooled and processed to increase its strength. The cutting performance is poor, but contact welding, gas welding, etc. are acceptable.

1070 Aluminum Sheet Specifications

| Aluminum alloy | 1070 Aluminum sheet |

|---|---|

| Temper | O, H12, H14, H16 H18, H19, H22, H24 H26, H28, H112, etc. |

| Thickness (mm) | 0.1-500 |

| Width (mm) | 20-2650 |

| Length (mm) | 500-16000 |

| Application examples | Heat sink, battery charging stations, anti-corrosion and heat preservation materials, wire armor, etc. |

Equivalent 1070 Aluminum Alloy Name

A1070, 1070a, aa1070, 1070aa, al1070, al1070a, a 1070, aa 1070, jis a1070p, al1070 class, aw1070, en1070 grade etc.

1070 Aluminum Alloy Performance Advantages

1. 1070 aluminum plate is industrial pure aluminum with low density, high plasticity and corrosion resistance.

2. Excellent electrical and thermal conductivity.

3. Gas welding, argon arc welding and spot welding can be performed.

4. Less impurities, which improves the continuity and corrosion resistance of the oxide film on the aluminum surface.

5. Corrosion-resistant, suitable for contact welding and gas welding.

6. It cannot be strengthened by heat treatment. Strength can be increased by cold deformation. The only form of heat treatment is annealing.

7. Long service life, low cost and high recycling value.

Mechanical Properties Of 1070 Aluminum Alloy at Different Temper

| Alloy and Temper | Thickness(mm) | tensile strength(Mpa) | Elongation(%) | |

| National standard | Internal control | |||

| 1070 O Aluminum | >0.2-0.3 | 55-95 | 55-95 | ≥15 |

| 1070 O Aluminum | >0.3-0.5 | ≥20 | ||

| 1070 O Aluminum | >0.5-0.8 | ≥25 | ||

| 1070 O Aluminum | >0.8-1.3 | ≥30 | ||

| 1070 O Aluminum | >1.3-4.5 | ≥35 | ||

| 1070 H22 Aluminum | >0.2-0.5 | 10-100 | 100-125 | ≥12 |

| 1070 H22 Aluminum | >0.5-1.0 | ≥15 | ||

| 1070 H22 Aluminum | >1.0-4.5 | ≥18 | ||

| 1070 H24 Aluminum | >0.2-0.5 | 85-120 | 120-150 | ≥6 |

| 1070 H24 Aluminum | >0.5-1.0 | ≥8 | ||

| 1070 H24 Aluminum | >1.0-4.5 | ≥10 | ||

| 1070 H26 Aluminum | >0.2-0.5 | 110-155 | 140-170 | ≥2 |

| 1070 H26 Aluminum | >0.5-1.0 | ≥4 | ||

| 1070 H26 Aluminum | >1.0-4.5 | ≥6 | ||

| 1070 H18 Aluminum | >0.2-0.5 | ≥120 | ≥170 | ≥2 |

| 1070 H18 Aluminum | >0.5-1.0 | ≥3 | ||

| 1070 H18 Aluminum | >1.0-5.5 | ≥4 | ||

Chemical Composition of 1070 Aluminum Sheet

| Element | Content (%) |

|---|---|

| Aluminum | ≥ 99.7 |

| Iron | ≤ 0.25 |

| Silicon | ≤ 0.20 |

| Zinc | ≤ 0.040 |

| Vanadium | ≤ 0.050 |

| Copper | ≤ 0.040 |

| Titanium | ≤ 0.030 |

| Magnesium | ≤ 0.030 |

| Manganese | ≤ 0.030 |

| Other Elements | ≤ 0.030 |

1070 Aluminum Data Plate Sheet

Aluminum 1070 Thermal Conductivity

1070 aluminum alloy has a high thermal conductivity, which is one of its distinctive features. Aluminum 1070 has an approximate thermal conductivity of approximately 229 W/m K (133 BTU/(hr ft °F)).

Aluminum alloys, including 1070, are known for their excellent thermal conductivity. This makes them suitable for applications requiring efficient heat transfer, such as heat sinks, cooling systems, and electrical conductors.

It is important to note that thermal conductivity may vary slightly due to factors such as alloy composition, temperature, and manufacturing process. Therefore, reference to manufacturer specifications or test data is recommended for exact thermal conductivity values in specific applications.

Surface Treatment Types

Surface treatments for 1070 aluminum can include:

- Anodized: An electrochemical process that forms a protective oxide layer on the surface, providing improved corrosion resistance and the ability to apply various colors.

- Coating: Application of coatings such as PVDF (Polyvinylidene fluoride) or polyester for enhanced weather resistance, aesthetics, and protection against UV rays.

- Polishing: The surface of 1070 aluminum can be polished to achieve high reflectivity or smoothness, depending on the application.

Product Certifications

Common Certifications for 1070 Aluminum Products May Include Iso (International Organization for Standardization) Certification, Rohs (RESTRICTION of Hazardous Substancanc ES) Compliance, and Industry-Specific Certifications Depending on the Application, Such As Electrical Certifications for Electrical Components.

Equivalent to 1070 Aluminum Alloy

Some common aliases or trade names associated with 1070 aluminum include:

- AA1070

- EN AW-1070A

- Al99.7

What is the Conductivity of 1070 Aluminum?

The electrical conductivity of 1070 aluminum alloy is typically about 63% of the International Annealed Copper Standard (IACS). IACS is a measurement scale representing the electrical conductivity of pure annealed copper, with a specified value of 100%. Therefore, the electrical conductivity of 1070 aluminum alloy is about 63% of that of pure copper.

It is worth noting that the conductivity will vary depending on factors such as impurities, alloying elements, and the specific processing of the aluminum. The values mentioned here are an approximate average and the actual conductivity of specific 1070 aluminum samples may vary slightly.

What is 1070 Aluminum Used for?

Aluminum 1070 for Electrical

1070 aluminum sheet is widely used in electrical wiring, bus bars, transformer windings, and electronic components due to its high electrical conductivity.

- Condition: 1070 aluminum sheets for electrical applications are usually in the annealed (O) condition, which means they are completely soft and have excellent formability.

- Surface treatment: In some cases, the surface of the aluminum sheet may be treated with a thin layer of insulating material or coating to improve electrical insulation properties.

1070 Aluminum for Heat sinks

The good thermal conductivity of 1070 aluminum makes it suitable for heat sinks in electronic equipment, LED lighting, and power modules.

- Tempers: Heat sink applications may require various tempers of 1070 aluminum, including annealed (O) for ease of fabrication or hardened (H) for increased strength.

- Surface treatment: The surface of 1070 aluminum heat sinks is usually treated with anodizing or thermal interface material to improve heat dissipation and corrosion resistance.

1070 Aluminum for Reflectors

Aluminum's high reflectivity makes 1070 aluminum plates ideal for reflectors in lighting fixtures, solar panels, and decorative mirrors.

- Condition: Depending on the manufacturing process and requirements, reflectors made of 1070 aluminum can be in the annealed (O) condition or a more special condition.

- Surface treatment: The surface of the reflector is usually polished to achieve high reflectivity. Additionally, a protective coating or anodization can be applied to increase durability and resistance to environmental elements.

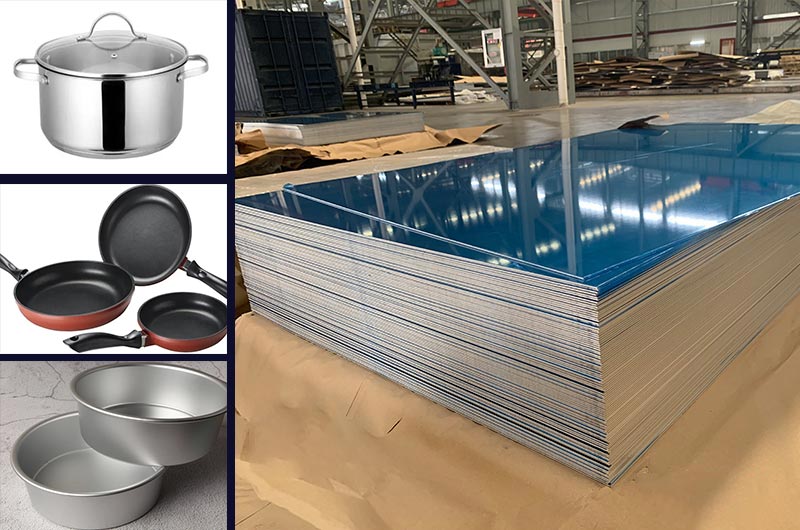

1070 Cookware Aluminum Plate

1070 aluminum is commonly used in the production of cookware and kitchenware due to its good formability and corrosion resistance.

- Condition: Depending on the manufacturing process and requirements, reflectors made of 1070 aluminum can be in the annealed (O) condition or a more special condition.

- Surface treatment: The surface of the reflector is usually polished to achieve high reflectivity. Additionally, a protective coating or anodization can be applied to increase durability and resistance to environmental elements.

Chemical and Food Processing

The corrosion resistance of the 1070 aluminum plate makes it suitable for chemical tanks, food processing equipment and storage containers.

- Conditions: 1070 aluminum plates or sheets used in chemical and food processing applications can be in various conditions including annealed (O) or hardened (H), depending on the specific requirements of the equipment.

- Surface treatment: The surface of aluminum may be treated such as passivation or application of corrosion-resistant coatings to enhance chemical resistance and ensure food safety.

Roofing and Cladding

Due to its corrosion resistance and formability, the sheet is used in construction for roofing, flashing, and decorative purposes.

The Roof

- Condition: 1070 aluminum for roofing is usually in the annealed (O) condition because it is easier to fabricate and install.

- Surface treatment: The surface of aluminum roofing panels can be treated with various treatments, such as coating or painting, to improve weather resistance, durability, and aesthetics. Coatings such as PVDF (polyvinylidene fluoride) or polyester are often used to provide enhanced UV and corrosion protection.

Cladding

- Condition: Similarly, 1070 aluminum cladding is usually in the annealed (O) condition for better formability and ease of installation.

- Surface treatment: The surface of the aluminum veneer can be treated by anodizing or powder coating. Anodizing forms a protective oxide layer on the surface, enhancing corrosion resistance and allowing color customization. Powder coating provides a durable and decorative finish, available in a variety of color options.

It is important to note that for roofing and cladding applications, high-strength aluminum alloys such as the 3xxx, 5xxx, or 6xxx series are more commonly used due to their superior mechanical properties and better weather resistance. These alloys provide a balance of strength, formability, and corrosion resistance, making them suitable for such demanding applications.

Specific uses and applications may vary depending on thickness, size and project specific requirements. Also, for precise advice and specifications, it is advisable to consult a metal supplier or engineer familiar with your application requirements.

1070 Hot Rolled Aluminum Plate Heat Treatment Process

1. Complete annealing: heating to 390~430℃; depending on the effective thickness of the material, the holding time is 30~120min; cooling in the furnace to 300℃ at a speed of 30~50℃/h, and then air cooling

2. Rapid annealing: heating at 350~370℃; depending on the effective thickness of the material, the holding time is 30~120min; air or water cooling

3. Quenching and aging: quenching at 500~510℃, air cooling; artificial aging at 95~105℃, 3h, air cooling; natural aging at room temperature for 120h

The following products may interest you

1070 Aluminum Plate Related Searches

- aluminium 1070 polished plate

- aluminium 1070 plates supplier

- 1070 aluminium plate equivalent grades

- 1070 aluminium alloy plate weight chart

- aluminium alloy 1070 h18 plate

- 1070 aluminium plate weight chart

- aluminium 1070 plates stockist

- aluminium 1070 plate size

- aluminium 1070 roofing plate

- aluminium 1070 plates

- 1070 aluminum expanded plate

- aluminium 1070 hot rolled plate

- aluminium 1070-o plate

- aluminium 1070 plate price

- aluminium 1070 h24 plates

- aluminium alloy 1070 cold rolled plate

- 1070 aluminium plate thickness

- asme sb209 aluminium 1070 h19 plate

- aluminium 1070 astm b209 plate

- aluminium 1070 extrusions plate

- aluminium 1070 embossed plate

- 1070 h24 aluminium alloy plate

Haomei Aluminum has decades of experience in aluminum plate production and is able to produce and supply high-quality 1070 aluminum plates in different sizes and states, including O (annealed), H12, H14, H16, H18, H26, etc. In addition, other 1xxx series aluminum plates are available for inquiry, including 1050, 1060, 1100, 1035, etc.

People also searched for Aluminum Plate

-

1100 Aluminum Plate Sheet

Compared with 1100 aluminum and 1050A, other process properties of type 1100 are basically similar. Typically, Type 1100 aluminum is used in applications that require good formability, high corrosion resistance, but not high strength.

-

1060 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 Aluminum Plate Sheet. Has rich expertise and experience in the production of aluminum plates.

-

1050 Aluminum Plate Sheet

Haomei Aluminum has a sound quality control process to ensure consistent and reliable quality of 1050 aluminum sheets. This includes rigorous inspection and testing procedures at all stages of production to meet or exceed industry standards.

-

1050 h18 Aluminum Plate Sheet

Purchase high-quality raw materials, ensure the use of pure aluminum, and strictly control the alloy composition. This helps to guarantee the desired properties and performance of the 1050 h18 aluminum plate.

-

1050 h14 Aluminum Plate Sheet

Competitive Price: Haomei Aluminum offers competitive prices for 1050 h14 Aluminum Sheet Plates while guaranteeing high quality.

-

1050 h24 Aluminum Plate Sheet

Production Capacity: With advanced production facilities and equipment, the Aluminum 1050 h24 Sheet Plate produced is an aluminum plate with precise dimensions, a smooth surface, and consistent thickness. Capable of meeting different customer requirements, including custom sizes and specifications.

-

1060 h12 Aluminum Plate Sheet

Quality Control Measures: Reliable Manufacturer of 1060 h12 Aluminum Plate Sheet ensures consistent production of high-quality Aluminum Sheet Plate.

-

1060 h14 Aluminum Plate Sheet

Certification & Compliance: Possessing 1060 h14 Aluminum Sheet Plate related certifications such as ISO 9001 demonstrates our commitment to our quality management system.

-

1060 h18 Aluminum Plate Sheet

Haomei Aluminum is a quality 1060 h18 Aluminum Plate Sheet manufacturer, ensuring that its products meet industry standards and customer expectations.

-

1060 h24 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 h24 Aluminum Plate Sheet and has competitive prices while ensuring product quality.

-

1100 h12 Aluminum Plate Sheet

1100 h12 Aluminum offers moderate strength and good formability making it suitable for a wide range of applications.

-

1100 h14 Aluminum Plate Sheet

1100-H14 Aluminum Sheet Manufacturer Products have a smooth, uniform appearance, strictly controlled tolerances, and stable performance.

-

1100 h18 Aluminum Plate Sheet

1100 h18 Aluminum This temper provides a higher level of strength than softer tempers such as H12 or H14.

-

1350 Aluminum Alloy

1350 Aluminum is a soft and highly ductile alloy used primarily in electrical applications where high electrical conductivity and low electrical resistance are critical.