1100 h12 Aluminum Plate Sheet

ASTM B209/AMS 4001 Complete Specifications

What Material is 1100 H12?

1100 H12 refers to an aluminum alloy with the designation 1100 and the temper designation H12. Let's break down what these designations mean:

1100 h12 aluminum is an aluminum alloy that belongs to the 1000 series of aluminum grades. "1100" indicates the purity of the aluminum as it is 99% aluminum. "H12" refers to the hardness of aluminum, which represents the hardness and machinability of the material.

The h12 temper is a strain hardening (cold worked) temper, which means that the aluminum plate or sheet has undergone a strain hardening process to increase its strength. This state provides moderate strength and good formability, making it suitable for a wide range of applications.

1100: This is an aluminum alloy, and the number 1100 specifically refers to the Aluminum Association's classification system. In this system, the first digit (1 in this case) represents the major alloying element, which is pure aluminum (99.00% minimum aluminum content). So, 1100 is essentially pure aluminum.

H12: The "H12" designation represents the temper or hardness of the aluminum. In the temper designation, the "H" stands for "strain-hardened, " and the number "12" indicates the specific level of hardness. H12 is a designation indicating that the aluminum has undergone a certain amount of strain hardening to achieve its properties.

In the case of 1100 H12 aluminum, it is a strain-hardened pure aluminum alloy with a specific level of hardness. This type of aluminum is known for its excellent corrosion resistance, high electrical conductivity, and good workability. It is often used in applications where these properties are desirable, such as in electrical conductors, heat exchangers, and various forms of sheet metal work. However, it is not as strong as some other aluminum alloys and may not be suitable for high-stress applications.

1100-h12 Aluminum Plate Properties

1100-H12 aluminum plate offers a balance between strength and formability, making it suitable for a range of applications across different industries. Its excellent corrosion resistance and weldability further enhance its versatility in various fabrication projects.

| Property | 1100-H12 | 1100-O (Annealed) | 1100-H14 |

|---|---|---|---|

| Temper | H12 | O (Annealed) | H14 |

| Strength | Moderate | Low | Higher |

| Formability | Good | Excellent | Good |

| Corrosion Resistance | Excellent | Excellent | Excellent |

| Weldability | Easily Weldable | Easily Weldable | Easily Weldable |

| Applications | General sheet metal, | Deep-drawn parts, | General sheet metal, |

| HVAC components, | cookware, | HVAC components, | |

| structural and | intricate forming, | structural and | |

| non-structural | various applications | non-structural |

-

1100 Aluminum Plate Sheet

Compared with 1100 aluminum and 1050A, other process properties of type 1100 are basically similar. Typically, Type 1100 aluminum is used in applications that require good formability, high corrosion resistance, but not high strength.

-

1100 h14 Aluminum Plate Sheet

1100-H14 Aluminum Sheet Manufacturer Products have a smooth, uniform appearance, strictly controlled tolerances, and stable performance.

-

1100 h18 Aluminum Plate Sheet

1100 h18 Aluminum This temper provides a higher level of strength than softer tempers such as H12 or H14.

-

1100 h12 Aluminum Plate Sheet

1100 h12 Aluminum offers moderate strength and good formability making it suitable for a wide range of applications.

Common Size of 1100 h12 Aluminum Plate

- Width: Typically between 36 inches (914 mm) and 72 inches (1829 mm)

- Length: Typically between 96 inches (2438 mm) and 144 inches (3658 mm)

- Thickness: Typically available in thicknesses ranging from 0.016" (0.4mm) to 0.25" (6.35mm)

| Product | Inches (in) | Millimeters (mm) |

|---|---|---|

| 1100 h12 Aluminum Plate | 0.032 | 0.813 |

| 1100 h12 Aluminum Plate | 0.04 | 1.016 |

| 1100 h12 Aluminum Plate | 0.05 | 1.27 |

| 1100 h12 Aluminum Plate | 0.063 | 1.6 |

| 1100 h12 Aluminum Plate | 0.08 | 2.03 |

| 1100 h12 Aluminum Plate | 0.09 | 2.29 |

| 1100 h12 Aluminum Plate | 0.125 | 3.18 |

| 1100 h12 Aluminum Plate | 0.16 | 4.06 |

| 1100 h12 Aluminum Plate | 0.19 | 4.83 |

| 1100 h12 Aluminum Plate | 0.25 | 6.35 |

- ASTM B209: Standard Specification for Aluminum and Aluminum Alloy Sheet and Plate

- AMS 4001: Aluminum Alloy Sheet and Plate, 0.12Cu (1100-H12)

Common Product Names (1100-H12)

- Aluminium 1100-H12

- UNS A91100

- ISO Al99.0Cu

- NF A45 (France)

- CSA 990C (Canada)

- AA1100-H12

- Al1100-H12

1100 h12 Aluminum Plate Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 16 ksi |

| Yield Strength | 10 ksi |

| Elongation | 35% |

| Hardness (HB) | 23 |

1100 h12 Aluminum Plate Sheet Mechanical Property Limits

| alloy and temper | specified | tensil strength - ksi | elongation | |||

| thickness | ultimate | yield | in 2 inches % | |||

| inches | min | max | min | max | ||

| 1100-H12 | 0.017-0.019 | 14 | 19 | 11 | - | 3 |

| 1100-H12 | 0.020-0.031 | 14 | 19 | 11 | - | 4 |

| 1100-H12 | 0.032-0.050 | 14 | 19 | 11 | - | 6 |

| 1100-H12 | 0.051-0.113 | 14 | 19 | 11 | - | 8 |

| 1100-H12 | 0.114-0.499 | 14 | 19 | 11 | - | 9 |

| 1100-H12 | 0.500-2.000 | 14 | 19 | 11 | - | 12 |

1100 h12 Aluminum Plate Weight

The weight of an aluminum plate, including an aluminum alloy like 1100-H12, can vary depending on its dimensions (length, width, and thickness). To calculate the weight of an aluminum plate, you can use the following formula:

Weight (in pounds) = Length (inches) x Width (inches) x Thickness (inches) x Density of Aluminum (in pounds per cubic inch)

For aluminum 1100-H12, the density is approximately 0.098 pounds per cubic inch (lb/in³).

If you have the dimensions of the plate, you can plug them into the formula to calculate the weight. For example, if you have a plate that is 24 inches in length, 12 inches in width, and 0.25 inches in thickness:

Weight = 24 inches x 12 inches x 0.25 inches x 0.098 lb/in³ = 70.56 pounds

So, an 1100-H12 aluminum plate with these dimensions would weigh approximately 70.56 pounds.

1100 h12 Aluminum Plate Chemical Composition

| Element | Composition |

|---|---|

| Aluminum | 99.0% min |

| Silicon | 0.95% max |

| Iron | 0.05% max |

| Copper | 0.05% max |

| Manganese | 0.05% max |

| Zinc | 0.10% max |

| Titanium | 0.05% max |

| Others | Each 0.05% max, Total 0.15% max |

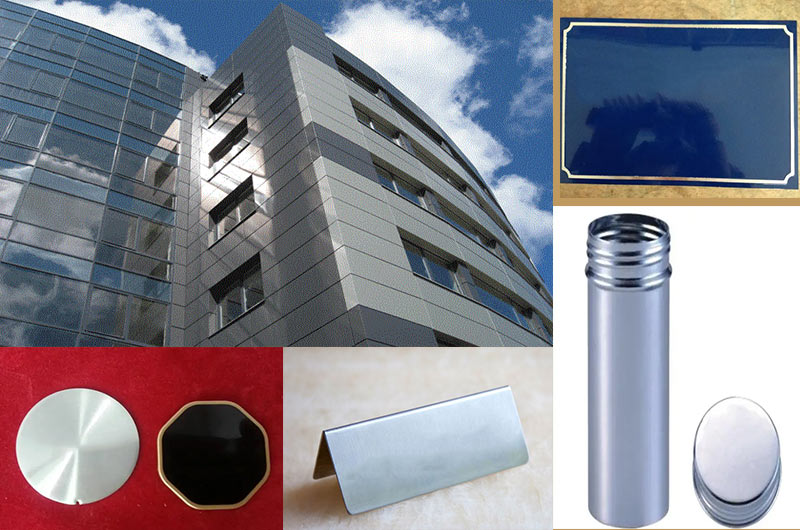

Typical Application 1100 h12 Aluminum Plate

Aluminum alloy 1100 h12 is typically used for general sheet metal fabrication such as construction, signage, electrical panels, and chemical equipment. It is also used in packaging, heat exchangers, reflectors, and various other applications where lightweight and corrosion resistance are important.

Some typical applications for 1100 h12 aluminum plates include:

- Roofing and Cladding: 1100 h12 aluminum is commonly used in roofing and cladding applications due to its lightweight, corrosion resistance, and ease of installation. It protects from the elements while maintaining its aesthetics.

- Insulation Panels: 1100 h12 aluminum's excellent formability and workability make it suitable for building insulation panels. These panels provide thermal and acoustic insulation while being lightweight and durable.

- Chemical and Food Processing Equipment: 1100 h12 aluminum is used in chemical and food processing equipment such as storage tanks, piping systems, and food containers. Its corrosion resistance and low reactivity with substances make it ideal for these applications.

- Heat Exchangers: The high thermal conductivity of 1100 h12 aluminum makes it the material of choice for heat exchangers. These devices efficiently transfer heat in a variety of industries, including HVAC, refrigeration, and automotive.

- Reflectors: Aluminum alloy 1100 h12 is commonly used for reflectors in lighting fixtures, solar panels, and other applications requiring high reflectivity. Its smooth surface and excellent light reflection properties make it an ideal choice.

- Nameplates and Signs: Due to its ability to be easily formed and engraved, 1100 h12 aluminum is used for nameplates, labels, and signs. Its corrosion resistance ensures long-lasting visibility in various environments.

- Electrical Enclosures: The combination of electrical conductivity and corrosion resistance makes 1100 h12 aluminum suitable for use in electrical enclosures and cabinets. It provides a lightweight and durable solution for protecting electrical components.

- Marine Applications: 1100 h12 aluminum is used in the marine industry for hulls, pontoons, and other structures. Its saltwater resistance and light weight make it popular in this field.

These are some of the typical applications for 1100 h12 aluminum sheet or sheet, but its versatility allows it to be used in a variety of other industries and applications where light weight, corrosion resistance, and formability are required.

People also searched for Aluminum Plate

-

1050 Aluminum Plate Sheet

Haomei Aluminum has a sound quality control process to ensure consistent and reliable quality of 1050 aluminum sheets. This includes rigorous inspection and testing procedures at all stages of production to meet or exceed industry standards.

-

1060 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 Aluminum Plate Sheet. Has rich expertise and experience in the production of aluminum plates.

-

1070 Aluminum Plate Sheet

1070 aluminum plate has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but its strength is low.

-

1060 h12 Aluminum Plate Sheet

Quality Control Measures: Reliable Manufacturer of 1060 h12 Aluminum Plate Sheet ensures consistent production of high-quality Aluminum Sheet Plate.

-

1060 h14 Aluminum Plate Sheet

Certification & Compliance: Possessing 1060 h14 Aluminum Sheet Plate related certifications such as ISO 9001 demonstrates our commitment to our quality management system.

-

1060 h18 Aluminum Plate Sheet

Haomei Aluminum is a quality 1060 h18 Aluminum Plate Sheet manufacturer, ensuring that its products meet industry standards and customer expectations.

-

1060 h24 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 h24 Aluminum Plate Sheet and has competitive prices while ensuring product quality.

-

1050 h18 Aluminum Plate Sheet

Purchase high-quality raw materials, ensure the use of pure aluminum, and strictly control the alloy composition. This helps to guarantee the desired properties and performance of the 1050 h18 aluminum plate.

-

1050 h14 Aluminum Plate Sheet

Competitive Price: Haomei Aluminum offers competitive prices for 1050 h14 Aluminum Sheet Plates while guaranteeing high quality.

-

1050 h24 Aluminum Plate Sheet

Production Capacity: With advanced production facilities and equipment, the Aluminum 1050 h24 Sheet Plate produced is an aluminum plate with precise dimensions, a smooth surface, and consistent thickness. Capable of meeting different customer requirements, including custom sizes and specifications.