1100 h18 Aluminum Plate Sheet

Strength: High Formability: Lower

1100-H18 aluminum is 1100 aluminum in the H18 temper, which is the strongest temper typically produced by strain hardening alone.

1100-H18 is the strongest tempered state among the 1100 series aluminum alloys. 1100-H18 has excellent processability, corrosion resistance, weldability, and high thermal conductivity.

1100 aluminum alloy is commercially pure aluminum with a purity of at least 99.00%. 1100 H18 aluminum refers to a special aluminum alloy belonging to the 1xxx series.

- Alloy: Aluminum alloy 1100 is composed primarily of aluminum with minor amounts of other elements. It is known for its excellent corrosion resistance, high thermal and electrical conductivity, and good machinability. This alloy is commonly used in various industries including packaging, electrical applications, and building construction.

- Temper: H18 Temper is the name used to describe the hardness of aluminum. The H18 temper indicates that the aluminum has been strain-hardened and has undergone a complete hardening process. This process involves cold working or strain hardening the material to increase its strength.

H18 tempering is usually achieved by cold rolling the aluminum alloy, which reduces its thickness and increases its hardness. This temper provides a higher level of strength than softer tempers such as H12 or H14. However, it also leads to reduced formability and increased brittleness.

1100 h18 alloy has high thermal conductivity and excellent corrosion resistance, processability and weldability. Deep drawing applications, spinning, fan blades, nameplates and metal products are typical applications.

To sum up, 1100 H18 aluminum refers to an aluminum alloy that has been strain-hardened to achieve higher hardness and strength.

Common Product Names (1100-H18)

UNS A91100, ISO Al99.0Cu, AA1100-H18, Al1100-H18

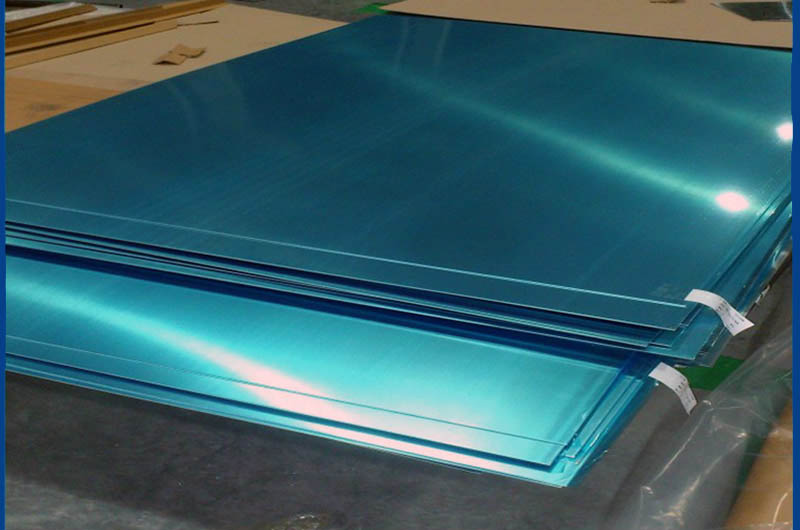

1100 H18 Aluminum Sheet Specification Information

- Alloy Number: 1100

- Temperature: H18

- Surface: Mill finish with blue PVC films

- Thickness: 1.0mm, 1.15mm, 1.20mm

- Size: 1.15mm x 1219 x 2438mm; 1.20mm x 620mm x C

- Thickness tolerance: +/- 0.02mm

- Width tolerance: +/- 2mm

1100 h18 Aluminum Plate Strength

1100 H18 aluminum is known for its high strength. The H18 temper indicates that the aluminum has undergone a complete hardening process, which increases its strength. This tempering is achieved by cold working or strain hardening the material.

1100 H18 offers higher strength properties than other tempers of 1100 aluminum such as H14 or H12 which have medium and lower strength levels respectively.

| Aluminum Temper | Strength |

|---|---|

| 1100 h14 Aluminum Plate | Moderate |

| 1100 h12 Aluminum Plate | Lower |

| 1100 h18 Aluminum Plate | High |

| 1100 O Aluminum Plate | Lower |

NOTE: Exact strength values may vary due to specific manufacturing processes, dimensions, and other factors.

1100 h18 Aluminum Plate Formability

1100 H18 aluminum is generally characterized by lower formability. The H18 temper, achieved through cold working or strain hardening, increases the strength of the material but reduces its formability. Therefore, it is more difficult to shape or deform aluminum without risk of cracking or breaking.

Compared to other tempers of 1100 aluminum such as H14 or H12, which offer good to very good formability, 1100 H18 exhibits lower formability due to its increased hardness and reduced ductility.

When selecting the hardness of aluminum, it is important to consider the specific requirements of your application. If high formability is a key factor, you may want to explore other tempers such as H14 or H12 which offer better formability at the expense of some strength.

| Aluminum Temper | Formability |

|---|---|

| 1100 h14 Aluminum Plate | Good |

| 1100 h12 Aluminum Plate | Very Good |

| 1100 h18 Aluminum Plate | Lower |

| 1100 O Aluminum Plate | Excellent |

-

1100 Aluminum Plate Sheet

Compared with 1100 aluminum and 1050A, other process properties of type 1100 are basically similar. Typically, Type 1100 aluminum is used in applications that require good formability, high corrosion resistance, but not high strength.

-

1100 h12 Aluminum Plate Sheet

1100 h12 Aluminum offers moderate strength and good formability making it suitable for a wide range of applications.

-

1100 h14 Aluminum Plate Sheet

1100-H14 Aluminum Sheet Manufacturer Products have a smooth, uniform appearance, strictly controlled tolerances, and stable performance.

1100 h18 Aluminum Plate Hardness

The Brinell hardness of 1100 H18 aluminum falls within the range of approximately 32 to 47 HB. However, the Brinell hardness of 1100 H18 aluminum will vary depending on factors such as processing conditions and alloy impurities.

1100 h18 Aluminum Plate Elongation

The elongation of 1100 H18 aluminum is its ability to stretch or deform before breaking under tensile stress. Elongation, usually expressed as a percentage, indicates the amount of permanent deformation a material can withstand without breaking.

1100 H18 aluminum is in the fully hardened state and tends to have lower elongation compared to the softer state. However, the specific elongation value will vary depending on the material thickness, test method, processing conditions, and other factors.

As a general guideline, the elongation of 1100 H18 aluminum is usually in the range of 2% to 4%. This means that the material can deform between 2% and 4% of its original length before reaching its breaking point.

| alloy and temper | specified thickness/inches | elongation in 2 inches % |

|---|---|---|

| 1100-H18 | 0.006-0.019 | 1 |

| 1100-H18 | 0.020-0.031 | 2 |

| 1100-H18 | 0.032-0.050 | 3 |

| 1100-H18 | 0.051-0.128 | 4 |

NOTE: The lower elongation of 1100 H18 aluminum is a trade-off for its higher strength. The reduced ductility and elongation make it less suitable for applications requiring extensive forming or bending, where higher elongation or more ductile alloys may be preferred.

1100 h18 Aluminum Physical Properties

| Param | Value |

|---|---|

| Density | 0.1 lb/in3 |

| Ultimate Tensile Strength | 24 ksi |

| Yield Tensile Strength | 22 ksi |

| Fatigue Strength | 9 ksi |

| Shear Strength | 13 ksi |

| Shear Modulus | 3, 700 ksi |

| Hardness Rockwell | Brinell | N/A | 44 |

| Elongation at Break Percentage | 1-4% |

| Modulus of Elasticity | 10, 000 ksi |

| Poisson's Ratio | 0.33 |

| Machinability Percentage | 30% |

| Melting Point | 1, 190-1, 215 °F |

| Specific Heat | 2.2 x 10^-1 BTU/lb-°F |

| Thermal Conductivity | 1, 560 BTU-in/hr-ft^2-°F |

| Electrical Conductivity | 57% IACS |

1100 h18 Aluminum Plate Sheet Chemical Composition

| Alloy | 1100 |

| Si | 0.95 |

| Fe | |

| Cu | 0.05-0.2 |

| Mn | 0.05 |

| Mg | - |

| Cr | - |

| Ni | - |

| Zn | 0.1 |

| Ti | - |

| Al | 99 |

1100 h18 Aluminum Plate Applications

1100 h18 aluminum is often used in deep drawing applications, spinning, fan blades, nameplates and metal products are typical applications, aluminum gaskets are generally made of 1100-H18 or 1145-H19.

1100 h18 Aluminum Electrical Industry

- Aluminum alloys used with 1100 H18: Typically, 1050 or 1350 aluminum alloys are used with 1100 H18.

- State of matching alloys: matching alloys are often in a soft or annealed state (O temper).

- Applications: 1100 H18 is often used in electrical components such as transformer windings, while companion alloys such as 1050 or 1350 are used in other parts of electrical systems.

Heat Exchangers

- Aluminum alloys used with 1100 H18: In heat exchangers, 1100 H18 aluminum can be used as a layer in a composite or in combination with other alloys such as 3003 or 5052.

- Condition of Matched Alloy: Depending on the specific design and requirements of the heat exchanger, the matched alloy may be in various tempers.

- Application: 1100 H18 aluminum can be used for structural parts or high strength parts of heat exchangers, and matching alloys are used for other parts such as tubes, fins, or plates.

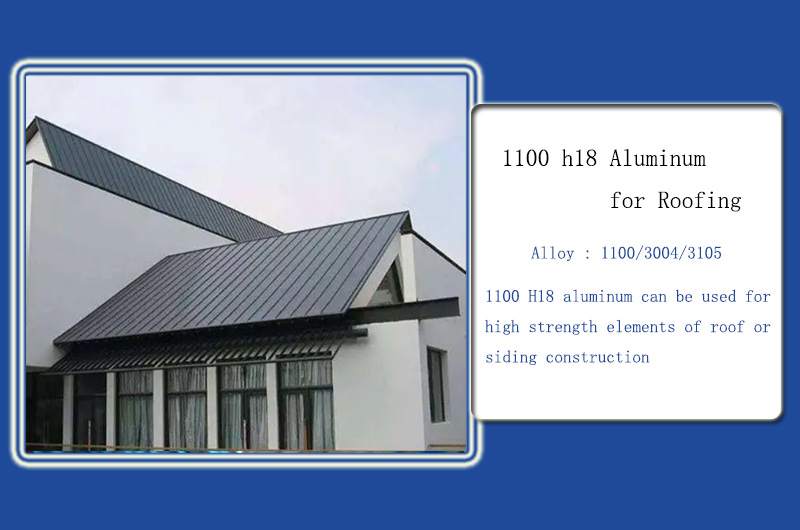

1100 h18 Aluminum Plate for Roofing and Siding

- Aluminum alloys used with 1100 H18: Typically, 3004 or 3105 aluminum alloys are used with 1100 H18 for roofing and siding applications.

- Condition of Matching Alloys: Depending on the specific requirements of the roof or siding system, matching alloys may be in various tempers.

- Applications: 1100 H18 aluminum can be used for high-strength elements of roof or siding construction while matching alloys such as 3004 or 3105 are used for panels, panels, or other components.

1100 h18 Packaging Aluminum

- Aluminum alloys used with 1100 H18: For packaging applications, 3004 or 5182 aluminum alloys are often used with 1100 H18.

- Condition of Matched Alloys: Matched alloys are usually in a specific temper suitable for forming or machining packaging components.

- Applications: 1100 H18 Aluminum is used for high strength components of packaging such as cans or closures, while companion alloys such as 3004 or 5182 are used for can bodies or can body stock.

1100-h18 Aluminum-plastic Composite Panel

Aluminum-plastic composite panel, referred to as aluminum-plastic panel, is a new type of building decoration material, which is composed of multiple layers of materials. The upper and lower layers are high-purity aluminum alloy plates, often using 1100-h18 aluminum plates.

Advantages of 1080 h18 aluminum-plastic composite panel

- 1. Good weather resistance, high strength, and easy maintenance.

- 2. It has good plasticity, and impact resistance, can reduce the load on buildings, and has good earthquake resistance.

- 3. It has excellent processability, thermal insulation, sound insulation, and fire resistance.

- 4. Good flatness, lightweight, and convenient construction.

1080 h18 aluminum-plastic composite panels are widely used in building exterior walls, curtain walls, indoor walls, ceilings, advertising signs, and other fields.

1100 H18 aluminum plate for PCB drilling

1100 H18 aluminum plate for PCB drilling is an entry-level drilling material for printed circuit boards, which to a certain extent meets the requirements for conventional PCB drilling. The thermal conductivity of aluminum sheet 1100 H18 is much greater than that of epoxy resin and phenolic resin, which can better dissipate heat for the drill bit.

Specific alloy selection and application may vary based on factors such as industry standards, design specifications, and customer requirements. It is always advisable to consult specific industry guides or consult an expert for the most accurate and up-to-date information on alloy selection and application suitability.

Haomei Aluminum is an experienced 1100 aluminum plate manufacturer in China, which can produce various 1000 series aluminum plates, including 1050 aluminum plate, 1100 aluminum plate, 1200 aluminum plate and 1060 aluminum plate.

Our 1100 h18 aluminum plate customers mainly come from Bangladesh, Kenya, Ghana, Bolivia, the United States, Togo, the Middle East, Central Asia, Algeria, the Philippines, etc. The products are well recognized by customers and the price is competitive.

People also searched for Aluminum Plate

-

1070 Aluminum Plate Sheet

1070 aluminum plate has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but its strength is low.

-

1060 Aluminum Plate Sheet

Haomei Aluminum strictly controls the quality of the 1060 Aluminum Plate Sheet. Has rich expertise and experience in the production of aluminum plates.

-

1050 Aluminum Plate Sheet

Haomei Aluminum has a sound quality control process to ensure consistent and reliable quality of 1050 aluminum sheets. This includes rigorous inspection and testing procedures at all stages of production to meet or exceed industry standards.

-

1050 h18 Aluminum Plate Sheet

Purchase high-quality raw materials, ensure the use of pure aluminum, and strictly control the alloy composition. This helps to guarantee the desired properties and performance of the 1050 h18 aluminum plate.

-

1060 h18 Aluminum Plate Sheet

Haomei Aluminum is a quality 1060 h18 Aluminum Plate Sheet manufacturer, ensuring that its products meet industry standards and customer expectations.