2011 Aluminum Alloy

Temper: t3/t6/t7/t8 Excellent Machining Performance

What is 2011 Aluminum?

Aluminum alloy 2011 is a free-machining aluminum alloy with excellent machining characteristics. It is part of the 2000 series of aluminum alloys. This alloy is often referred to as "free-cutting alloy" because of its outstanding machinability.

Alloy 2011 Aluminum Properties

1. 2011 aluminum has good processability

2011 Aluminum is known for its excellent workability, making it easy to cut, drill and machine. Small, broken chips are formed during processing, which is beneficial to chip removal and reduces tool wear.

2. 2011 t3 aluminum has good strength

2011 aluminum has good mechanical properties and is stronger than many other aluminum alloys, especially in the T3 condition. The strength of 2011 aluminum is further enhanced by heat treatment.

3. 2011 aluminum can be anodized

Aluminum 2011 can be anodized, but it may not have an anodized coating like some other alloys, primarily due to its copper content.

While 2011 offers reasonable corrosion resistance, it is not as resistant to corrosion as some other aluminum alloys. Its copper content makes it more susceptible to corrosion under certain conditions.

2011 Aluminum Typical Temper

- 2011 t3 Aluminum

- 2011 t6 Aluminum

- 2011 t8 Aluminum

- 2011 t78 Aluminum

2011 t3 Aluminum

T3 is the solid solution heat treatment and cold working state. 2011 t3 Aluminum has good machinability and medium strength. This state is usually used for parts that require both formability and strength.

2011 t6 Aluminum

T6 is solution heat treatment and artificial aging state. 2011 t6 Aluminum provides the highest strength of 2011 aluminum in its commonly used condition. T6 is typically selected for applications where strength is the primary consideration.

2011 t8 Aluminum

T8 is a solution heat treatment, cold working and artificial aging state. 2011 t8 Aluminum combines good machinability with increased strength.

2011 t78 Aluminum

T78 is a combination condition typically associated with 2011 aluminum. 2011 t78 Aluminum involves two stages of aging.

- T6 offers the highest strength, but machinability may be reduced compared to T3.

- T8 combines good machinability with higher strength.

- T78 introduces a degree of natural aging to further improve performance.

The choice depends on the balance of machinability and mechanical properties required for the specific application.

Yield Strength of 2011 Aluminum

The yield strength for aluminum alloy 2011 can vary depending on the specific temper condition.

2011-T3 Aluminum:

Yield Strength: Typically in the range of 55-70 MPa.

2011-T6 Aluminum:

Yield Strength: Typically in the range of 105-125 MPa.

The T6 temper generally provides higher yield strength, making it suitable for applications where greater strength is required, but it may have slightly reduced machinability compared to T3.

Modulus of Elasticity 2011 Aluminum

The modulus of elasticity for aluminum alloy 2011 can vary depending on the specific temper condition.

2011-T3 Aluminum:

Modulus of Elasticity (Young's Modulus): Approximately 68.9 GPa.

2011-T6 Aluminum:

Modulus of Elasticity (Young's Modulus): Approximately 68.9 GPa.

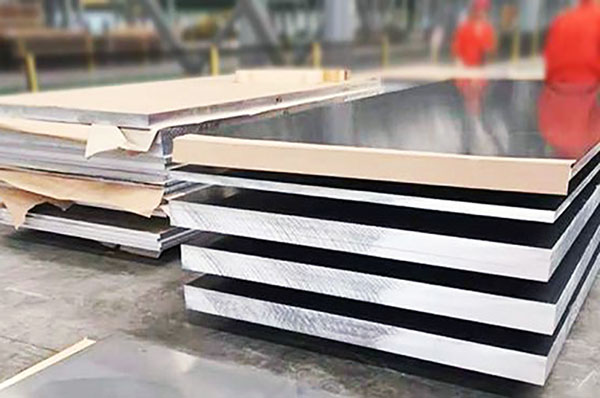

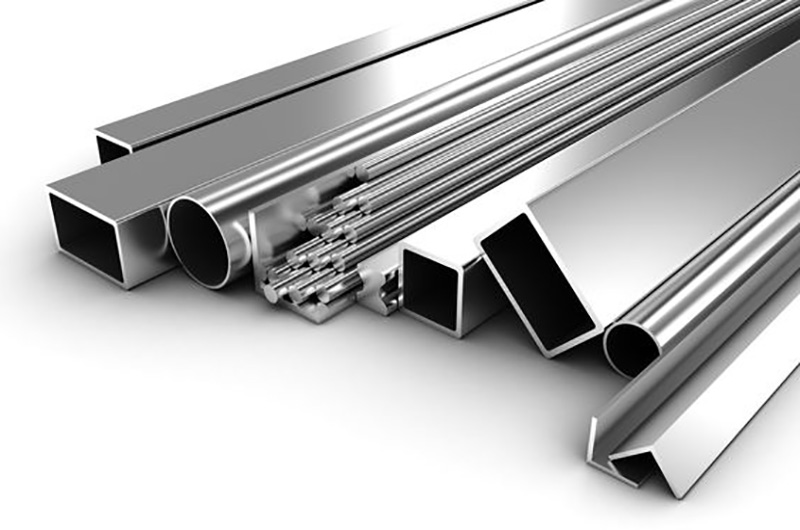

2011 Aluminum Product Forms

- 2011 Aluminum Wire

- 2011 Aluminum Frame

- 2011 Aluminum Bar

- 2011 Aluminum Rod

- 2011 Aluminum Profile

2011 Aluminum Wire

2011 aluminum wire is commonly used in applications requiring good machinability and high strength. It is widely used in various industries including manufacturing, automotive and aerospace for applications such as fasteners, connectors and electrical components.

2011 Aluminum Frame

Aluminum alloy 2011 frames are used in various industries including automotive and machinery. These frames can provide lightweight structural support and are valued for their workability.

2011 Aluminum Bar

2011 Aluminum Bar is typically used in machining applications where the alloy's excellent machinability is critical. They can be turned, drilled, milled and otherwise processed to create precision components for a range of industries.

2011 Aluminum Rod

2011 Aluminum Rod is used to manufacture precision components in a variety of applications. They are frequently found in the production of fasteners, couplings and connectors, as well as in the automotive and mechanical sectors.

2011 Aluminum Profile

Aluminum profiles made from 2011 alloy can be used in a variety of structural and industrial applications. These profiles can be machined into specific shapes and used in components and structures where machinability is important.

Of all these product forms, aluminum alloy 2011 was chosen for its excellent machinability properties, making it a valuable material for applications requiring precision machining and complex component production.

2011 Specific applications for aluminum will depend on the properties required, including machinability and strength, as well as the requirements of the industry or application.

2011 Aluminum Composition

| Element | Typical Percentage |

|---|---|

| Aluminum (Al) | 91.5% - 95.0% |

| Copper (Cu) | 5.0% - 6.0% |

| Bismuth (Bi) | 0.20% - 0.60% |

| Lead (Pb) | 0.20% - 0.60% |

| Iron (Fe) | ≤ 0.70% |

| Silicon (Si) | ≤ 0.40% |

| Other Elements | Trace amounts |

Typical 2011 Aluminum Uses

- 2011 Aluminum Grip

- 2011 Aluminum Alloy Wire for Rivets

- 2011 T3 T6 Aerospace Aluminum Bar Rod

2011 Aluminum Grip

2011 aluminum is a suitable material for manufacturing grips, particularly for applications where a combination of strength, machinability, and light weight is important. Grips are often found in various tools, equipment, and machinery.

2011 Aluminum Alloy Wire for Rivets

Aluminum alloy 2011 is a good choice for manufacturing wire used in rivets. Its excellent machinability allows for the production of precise wire forms that can be easily formed into rivets. Rivets made from 2011 aluminum are used in a wide range of applications, including construction, automotive, and aerospace.

2011 T3 T6 Aerospace Aluminum Bar Rod

The T3 and T6 temper conditions of aluminum alloy 2011 are relevant in aerospace applications. Bars and rods made from 2011 aluminum in these tempers provide the necessary balance of machinability and strength for aerospace components. These components can include fasteners, fittings, and other precision parts used in the aerospace industry.

2011 Aluminum`s superior machinability is a key factor, allowing the production of complex, precision-machined parts. The choice of temper (T3, T6, etc.) depends on the specific requirements of the application, balancing processability and mechanical properties. In addition, it is important to ensure that materials comply with relevant industry standards and safety regulations, especially in aerospace applications.

2011 Aluminum Equivalent

2011 Aluminum alloy is a unique alloy with specific properties, notably excellent machinability due to its composition of copper, bismuth and lead. No identical alloy exists with the same combination of elements and properties, especially with regard to machinability.

However, if you are looking for an aluminum alloy with some similar properties, you might consider the following:

- Aluminum Alloy 6262: This alloy contains high levels of copper and manganese and has good machinability. It is used for parts that require machining, such as fittings and connectors.

- Aluminum Alloy 2024: Although its machinability is not as good as 2011, 2024 is known for its strength and is used in aerospace and structural applications.

- Aluminum Alloy 7075: This alloy is known for its high strength and good machinability, making it suitable for applications in aerospace, automotive and industrial sectors.

It is important to note that each alloy has its own unique properties and is selected based on the specific requirements of the application. The closest "equivalent" will depend on the specific properties and workability requirements you are looking for in your project.

AA 2011 Aluminum

There is no significant difference between "2011 aluminum" and "AA 2011 aluminum." In both cases, they refer to the same aluminum alloy, and "AA 2011 aluminum" is a more specific and standardized way of designating the alloy.

AA 2011 Aluminum: The "AA" prefix indicates that the aluminum alloy follows the Aluminum Association's standardized alloy designation system, which is commonly used in North America.

"AA 2011 aluminum" is the formal and standardized way of specifying the alloy, ensuring consistency and clarity in the identification of the material.

Anodizing 2011 Aluminum

Anodizing is a surface treatment process commonly used on aluminum and its alloys to enhance corrosion resistance, improve appearance, and provide a variety of other benefits.

Due to the presence of copper and other elements in 2011 aluminum alloys, anodizing 2011 aluminum can be more challenging than other aluminum alloys. Anodizing may not produce the same results as pure aluminum alloys.

What is the difference between 6061 and 2011 Aluminum?

2011 aluminum vs 6061

Aluminum alloys 6061 and 2011 are two distinct materials with significant differences in composition, properties, and applications. Here's a comparison between the two:

- 6061 Aluminum: Heat-treatable, and different temper conditions (T6, T651, etc.) can be applied to achieve various strength levels.

- 2011 Aluminum: Typically not heat-treatable. The alloy properties remain relatively consistent.

Composition

| Element | Aluminum 6061 | Aluminum 2011 |

|---|---|---|

| Aluminum (Al) | Approx. 97.9% | Approx. 91.5% - 95.0% |

| Magnesium (Mg) | 1.0% - 1.5% | Trace amounts |

| Silicon (Si) | 0.4% - 0.8% | Trace amounts |

| Copper (Cu) | 0.15% - 0.4% | Approx. 5.0% - 6.0% |

| Chromium (Cr) | 0.04% - 0.35% | Trace amounts |

| Bismuth (Bi) | Trace amounts | Approx. 0.20% - 0.60% |

| Lead (Pb) | Trace amounts | Approx. 0.20% - 0.60% |

| Heat-Treatable | Yes | No |

Properties

| Property | Aluminum 6061 | Aluminum 2011 |

|---|---|---|

| Strength | Good | Lower |

| Corrosion Resistance | Decent | Moderate |

| Machinability | Moderate | Excellent |

Applications

| Application | Aluminum 6061 | Aluminum 2011 |

|---|---|---|

| Structural Components | Yes | Less common |

| Automotive Parts | Yes | Less common |

| General-Purpose Machining | Yes | Preferred choice for machining |

| Fasteners | Less common | Common |

| Connectors | Less common | Common |

In conclusion, while both aluminum alloys have their advantages, they are used in different ways due to their unique properties. 6061 aluminum is versatile and is often chosen when a balance of strength, corrosion resistance and workability is required.

2011 Aluminum is sought after for its exceptional machinability and is often used in applications where precision machining is a primary concern.

The choice between the two depends on the specific requirements of your project or application.