2024 t851 Aluminum Plate Sheet

Precise Dimensional Tolerances Quality Meets Industry Standards

What is the 2024 T851 Aluminum Plate?

Al 2024 T851 refers to a specific type of aluminum alloy. 2024 Aluminum is a high-strength alloy with copper as the main alloying element. The "T851" designation indicates that the alloy has been solution heat treated, quenched, and then artificially aged to achieve its maximum strength and toughness.

2024-T851 Aluminum is 2024 aluminum in T851 condition. To achieve this tempering effect, the metal needs to be solution heat treated, stress relieved, and then artificially aged.

2024-T851 aluminum is commonly used in aerospace, automotive, mechanical and industrial applications. 2024 is one of the strongest aluminum alloys, but is slightly less corrosion resistant.

2024 T851 aluminum is commonly used in aerospace and military applications, such as the construction of aircraft structural components, due to its excellent strength-to-weight ratio and fatigue resistance. It can also be used in high-stress applications such as automotive and mechanical parts.

2024 t851 Aluminum Plate Sizes

2024 T851 aluminum is available in a variety of sheet sizes, thicknesses, and widths. The exact sizes available depend on the supplier and application requirements.

Common Size of 2024 T851 Aluminum Plate

- Thickness: 0.25" to 6"

- Width: up to 96"

- Length: up to 288"

| Thickness (in) | Size (in) |

| 1/2" 2024 t851 Aluminum Plate | 48" x 96" |

| 3/4" 2024 t851 Aluminum Plate | 48" x 96" |

| 7/8" 2024 t851 Aluminum Plate | 48" x 96" |

| 1" 2024 t851 Aluminum Plate | 48" x 96" |

| 1-1/8" 2024 t851 Aluminum Plate | 48" x 96" |

| 1-1/4" 2024 t851 Aluminum Plate | 48" x 96" |

| 1-3/8" 2024 t851 Aluminum Plate | 48" x 96" |

| 1-1/2" 2024 t851 Aluminum Plate | 48" x 96" |

| 1-3/4" 2024 t851 Aluminum Plate | 48" x 96" |

| 2" 2024 t851 Aluminum Plate | 48" x 96" |

| 2-1/4" 2024 t851 Aluminum Plate | 48" x 96" |

| 2-1/2" 2024 t851 Aluminum Plate | 48" x 96" |

These are common sizes only and the availability of specific sizes may vary by supplier. It is best to check directly with the supplier for their exact size offerings.

2024 T851 Aluminum Plate Standards

- AMS 4041

- ASTM B209

- QQ-A-250/4

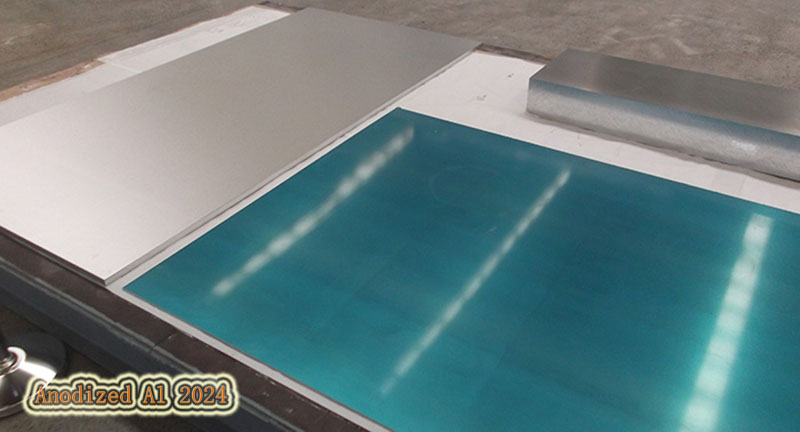

2024 T851 Aluminum Plate Surface Treatments

- Anodized: Anodized can improve the corrosion resistance and durability of aluminum 2024 T851. Anodized aluminum has a hard, protective layer that can be dyed to a variety of colors.

- Painted: Aluminum 2024 T851 can be painted or coated with a variety of coatings to improve its appearance or provide additional protection.

- Polished: Aluminum 2024 T851 can be polished to a high shine for decorative purposes.

2024 T851 Aluminum Plate Certifications

- 2024 T851 Aluminum Sheet is available in a variety of standards including AMS 4041 and ASTM B209, ISO 9001, and more.

- A mill test report (MTR) is also available from the manufacturer or supplier, which provides details on the chemical composition, mechanical properties, and other quality specifications of the aluminum sheet.

- 2024 t851 aluminum sheet suppliers may also offer certifications such as ISO 9001, which show that the manufacturing process meets certain quality standards.

2024 t851 Aluminum Plate Data Sheet

Mechanical Properties of 2024 T851 Aluminum Plate

| Property | Value |

|---|---|

| Ultimate Tensile Strength | 78 ksi (537 MPa) |

| Yield Strength | 56 ksi (386 MPa) |

| Elongation | 10% |

| Modulus of Elasticity | 10.6 x 10^6 psi (73 GPa) |

| Shear Strength | 47 ksi (324 MPa) |

Physical Properties of 2024 T851 Aluminum Plate

| Property | Value |

|---|---|

| Density | 0.101 lb/in^3 (2.80 g/cm^3) |

| Thermal Conductivity | 94 Btu/(hr·ft·°F) (163 W/(m·K)) |

| Coefficient of Thermal Expansion | 13.1 µin/in-°F (23.6 µm/m-°C) |

| Melting Range | 935-1180°F (502-638°C) |

These values are provided as general guidelines and specific properties of 2024 T851 Aluminum may vary depending on the manufacturing process, product form, and other factors. It is always important to refer to the data sheets provided by the manufacturer for the specific alloy and product form being used.

Chemical Composition of 2024 T851 Aluminum Plate

| Element | Percentage |

|---|---|

| Aluminum (Al) | 90.7% |

| Copper (Cu) | 4.5% |

| Magnesium (Mg) | 1.5% |

| Manganese (Mn) | 0.7% |

| Silicon (Si) | 0.5% |

| Iron (Fe) | 0.5% |

| Zinc (Zn) | 0.25% |

| Titanium (Ti) | 0.15% |

| Chromium (Cr) | 0.1% |

| Other | 0.15% max |

2024 t851 Aluminum Plate Typical Applications

-

2024 t851 Aerospace Aluminum Plate

Due to its high strength-to-weight ratio and excellent fatigue resistance, 2024 T851 aluminum is widely used in aircraft structures, wings, and fuselages in the aerospace industry.

-

2024 t851 Marine Aluminum Plate

The corrosion resistance of aluminum 2024 T851 makes it a popular choice for marine applications such as hulls and superstructures.

-

Al 2024 t851 Automotive

Al 2024 T851 is used in the automotive industry for components that require high strength, such as engine components, suspension components, and wheels.

-

2024 t851 Defense Aluminum Plate

The high strength and durability of 2024 T851 aluminum make it a popular choice for military vehicles and equipment, such as armored personnel carriers and tanks.

-

Industrial Equipment

The excellent corrosion resistance and strength of 2024 T851 aluminum make it suitable for industrial applications such as pressure vessels, structural supports, and machine parts.

-

Sports Equipment

The high strength and lightweight properties of 2024 T851 aluminum make it a popular choice for sports equipment such as bicycle frames, tennis racquets, and baseball bats.

These are just a few examples of the many applications for 2024 T851 aluminum. Its strength, corrosion resistance, and lightweight properties make it a versatile material for many different industries and applications.

2024-t851 aluminum alloy plate production process flow

- Casting: The aluminum alloy raw material is melted, usually in a furnace.

- Uniform heating: The molten aluminum alloy liquid is heated evenly to ensure uniform composition.

- Sawing: A uniformly heated liquid aluminum alloy is cast into the preliminary shape of the sheet.

- Surface milling: Mill the sawn aluminum alloy plate to ensure a smooth and flat surface.

- Heating: The aluminum alloy plate is heated again to prepare for the subsequent hot rolling process.

- Hot rolling: The heated aluminum alloy plate is plastically deformed through a hot rolling mill to achieve the required plate thickness and shape.

- Quenching: Rapidly cooling the hot-rolled aluminum alloy sheet to change its internal crystal structure and increase hardness and strength.

- Stretching: The quenched aluminum alloy sheet is stretched to further improve its strength and plasticity.

- Aging: Aging treatment is performed on the stretched aluminum alloy sheet to stabilize its crystal structure and improve its corrosion resistance.

- Sawing: The aged aluminum alloy sheet is trimmed to final dimensions as required.

- Finished product inspection: Conduct various quality inspections on the final 2024 t851 aluminum alloy plate to ensure compliance with relevant standards and customer requirements.

2024 T851 Aluminum Alloy Plate Aging Process

The 2024 alloy thick plate has been quenched, pre-stretched, aged, etc. It can significantly reduce the quenching residual stress and increase the alloy strength, and can obtain excellent comprehensive properties.

- As the aging temperature increases and the aging time prolongs, the strength and hardness of the plate gradually increase, and then gradually decrease after reaching the peak value.

- As the aging temperature increases, the elongation of the plate gradually decreases as the aging time increases.

- As the aging temperature increases and the aging time increases, the electrical conductivity of the plate gradually increases.

- The optimal aging system for the 2024-T851 aluminum alloy thick plate is: aging temperature (1905) C aging time 12 hours. The above process system can be realized under the existing production conditions. The mechanics of the 2024-T851 aluminum alloy thick plate produced according to this system Performance and other indicators comply with the ASTM B209M-95 standard and reach the test target value. The surface of the plate is flat and the color is uniform, which can meet the user's requirements.

Al 2024 t851 Plate vs Al 2024 t3 Plate vs Al 2024 t4 Plate

-

2024 T4 Aluminum Plate Sheet

2024 T4 aluminum has a high strength-to-weight ratio and good fatigue resistance, making it a popular choice for aerospace and structural applications. It also has good machinability and weldability, although it is not as corrosion resistant as some other aluminum alloys.

-

2024 T3 Aluminum Plate Sheet

2024 T351 aviation aluminum plate is a high-strength aviation aluminum alloy material. T351 has large surface and internal residual stress and good explosion impact resistance. 2024 t351 is one of the aviation aluminum alloys. It is widely used in skins, bulkheads and structural parts that need to withstand high cyclic loads on various aircraft.

-

2024 Aluminum Plate Sheet

2024 aluminum is a prominent hard aluminum alloy in the aluminum-copper-magnesium series. 2024 aluminum plates are famous for their high strength and excellent fatigue resistance, as well as their ability to be easily processed and welded.

2024 T851, 2024 T3 and 2024 T4 are all 2024 series aluminum alloys, but due to different manufacturing and heat treatment processes, their tempering or mechanical properties are different. Here are some key differences between 2024 T851, 2024 T3 and 2024 T4 aluminum panels:

2024 T851 Aluminum Plate

The alloy is solution heat treated and stress relieved, then artificially aged to the T851 temper. This process gives the aluminum sheet high strength and excellent resistance to fatigue and stress corrosion cracking.

T851 tempering is achieved through a special aging process, giving the material the highest strength and hardness in the 2024 series.

2024 T851 is typically used in applications requiring high strength, fatigue, and corrosion resistance, such as aerospace, defense, and industrial equipment.

| Mechanical Property | Value |

|---|---|

| Tensile strength | 530 MPa (77, 000 psi) |

| Yield strength | 470 MPa (68, 000 psi) |

| Elongation | 10% |

| Modulus of elasticity | 73.1 GPa (10.6 Msi) |

| Shear strength | 310 MPa (45, 000 psi) |

| Fatigue strength | 210 MPa (30, 000 psi) |

2024 T3 Aluminum Plate

The alloy is solution heat treated and cold worked, then naturally aged to the T3 temper. This process imparts good strength and ductility to the aluminum sheet, as well as moderate resistance to fatigue and stress corrosion cracking.

T3 Tempering is achieved through a natural aging process that allows the material to age slowly over time and achieve its desired properties.

2024 T3 is typically used in applications requiring good strength and ductility, such as aircraft skins, fuselage frames, and spars.

| Mechanical Property | Value |

|---|---|

| Tensile strength | 450 MPa (65, 000 psi) |

| Yield strength | 325 MPa (47, 000 psi) |

| Elongation | 12% |

| Modulus of elasticity | 73.1 GPa (10.6 Msi) |

| Shear strength | 283 MPa (41, 000 psi) |

| Fatigue strength | 120 MPa (17, 000 psi) |

2024 T4 Aluminum Plate

The alloy is solution heat treated and naturally aged to the T4 temper. This process makes the aluminum plate have moderate strength and good formability, as well as good resistance to fatigue and stress corrosion cracking.

The T4 temper is achieved through a natural aging process which allows the material to age slowly over time and achieve its desired properties.

2024 T4 is typically used in applications requiring good formability and moderate strength, such as aircraft parts, wheels, and gears.

| Mechanical Property | Value |

|---|---|

| Tensile strength | 470 MPa (68, 000 psi) |

| Yield strength | 325 MPa (47, 000 psi) |

| Elongation | 20% |

| Modulus of elasticity | 73.1 GPa (10.6 Msi) |

| Shear strength | 283 MPa (41, 000 psi) |

| Fatigue strength | 120 MPa (17, 000 psi) |

2024 T851, 2024 T3 and 2024 T4 aluminum sheets are available in different tempers for different applications based on their strength, ductility, formability, and resistance to fatigue and stress corrosion cracking.

People also searched for Aluminum Plate

-

2014 Aluminum Plate Sheet

2014 Aluminum Alloy is a popular aluminum alloy, especially in the aerospace industry, where 2014 T6 Aluminum is often preferred when maximum strength is required.

-

2017 Aluminum Plate Sheet

2017 aluminum plate is a heat-treatable forged aluminum product with good strength, ductility and good workability.

-

2219 Aluminum Plate Sheet

2219 aluminum alloy is a high-strength alloy, high temperature resistant and good cutting processing and good mechanical properties. 2219 aluminum plates are in line with AMS QQ-A-250/30. Common TEMPER includes T31, T81, O, etc.

-

2618 Aluminum Plate

2618 aluminum is a high-strength aluminum alloy primarily used in applications requiring excellent mechanical properties, especially in high temperature and high stress environments.

-

2011 Aluminum Alloy

Aluminum alloy 2011 is a free-machining aluminum alloy with excellent machining characteristics. It is part of the 2000 series of aluminum alloys.