3003 Aluminum Plate Sheet

Temper: H22,H24,H18,H19,O Certification: ISO 9001

What is 3003 Plate of Aluminum?

3003 aluminum is an alloy of the aluminum-manganese family that is commonly used in sheet form for a variety of applications. The "3003" designation refers to a specific alloy composition in which the main alloying element is manganese.

3003 aluminum is usually rolled and extruded, but not usually forged, and is about 10% stronger than 1100. Note that 3003 aluminum is not used for casting.

3003 Aluminum Plate Properties

- It has good formability, weldability, and corrosion resistance, and moderate strength.

- Good solderability and can be easily connected using various soldering techniques.

- Good formability, will not crack or weaken when formed and bent, suitable for molding into different structures or components.

3003 is a non-heat treatable alloy that can be cold-worked to improve its mechanical properties:

- It has high plasticity in the annealed state.

- The plasticity is still good during semi-cold work hardening.

- The plasticity is low during cold work hardening.

In the cold deformation state, 3003 aluminum alloy has a tendency of spalling corrosion. The greater the deformation, the more serious the spalling.

The specific properties and dimensions of the 3003 aluminum plate will vary depending on the manufacturing process, temperature, and thickness. Different tempers, such as H14, H16, or H18, can provide different levels of strength, hardness, and machinability to meet specific application requirements.

-

3003 h22 Aluminum Plate

3003 - H22 has good strength, high durability, easy machining, high corrosion resistance and light weight. The popular product is mainly 3003-H22 Bright Aluminum Tread Plate.

-

3003 h24 Aluminum Plate

Ensure the 3003 h24 Aluminum Plate meets the required specifications including dimensional accuracy, chemical composition, mechanical properties, and surface finish.

-

3003 h14 Aluminum Plate Sheet

3003-H14 aluminum plate has the characteristics of high strength, high durability, easy processing, strong corrosion resistance and light weight. 3003 aluminum is suitable for outdoor and harsh environment applications.

-

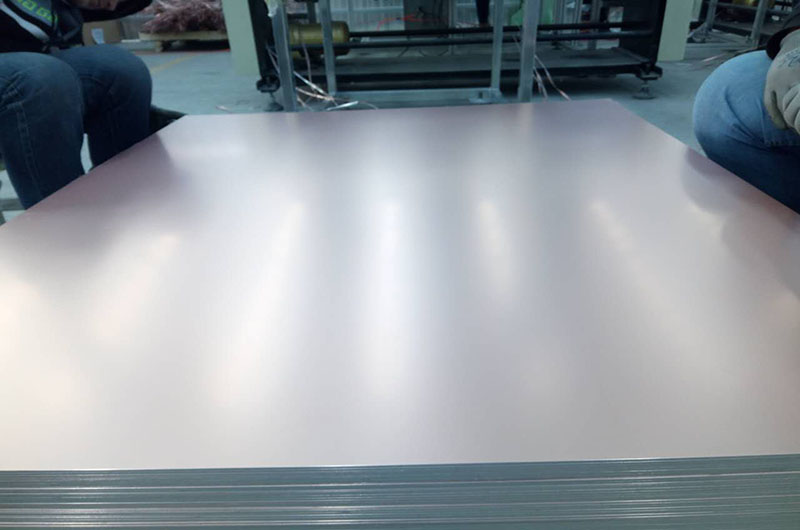

3003 O Aluminum Plate Sheet

3003 O-state aluminum plate has low hardness, and 3003 O-state aluminum plate is suitable for stamping, spinning, stretching, etc.

Mechanical Property Limits

| Temper | Specified Thickness(in) | Tensile Strength - KSI | Elongationin 2 inches % | |||

| Ultimate | Yield | |||||

| Min | Max | Min | Max | |||

| H12 | 0.017 - 0.019 | 17 | 23 | 12 | - | 3 |

| H12 | 0.020 - 0.031 | 17 | 23 | 12 | - | 4 |

| H12 | 0.032 - 0.050 | 17 | 23 | 12 | - | 5 |

| H12 | 0.051 - 0.113 | 17 | 23 | 12 | - | 6 |

| H12 | 0.114 - 0.161 | 17 | 23 | 12 | - | 7 |

| H12 | 0.162 - 0.249 | 17 | 23 | 12 | - | 8 |

| H14 | 0.009 - 0.012 | 20 | 26 | 17 | - | 1 |

| H14 | 0.013 - 0.019 | 20 | 26 | 17 | - | 2 |

| H14 | 0.020 - 0.031 | 20 | 26 | 17 | - | 3 |

| H14 | 0.032 - 0.050 | 20 | 26 | 17 | - | 4 |

| H14 | 0.051 - 0.113 | 20 | 26 | 17 | - | 5 |

| H14 | 0.114 - 0.161 | 20 | 26 | 17 | - | 6 |

| H14 | 0.162 - 0.249 | 20 | 26 | 17 | - | 7 |

| H16 | 0.006 - 0.019 | 24 | 30 | 21 | - | 1 |

| H16 | 0.020 - 0.031 | 24 | 30 | 21 | - | 2 |

| H16 | 0.032 - 0.050 | 24 | 30 | 21 | - | 3 |

| H16 | 0.051 - 0.162 | 24 | 30 | 21 | - | 4 |

| H18 | 0.006 - 0.019 | 27 | - | 24 | - | 1 |

| H18 | 0.020 - 0.031 | 27 | - | 24 | - | 2 |

| H18 | 0.032 - 0.050 | 27 | - | 24 | - | 3 |

| H18 | 0.051 - 0.128 | 27 | - | 24 | - | 4 |

| H19 | 0.006 - 0.063 | 29 | - | - | - | 1 |

| O | 0.006 - 0.007 | 14 | 19 | 5 | - | 14 |

| O | 0.008 - 0.012 | 14 | 19 | 5 | - | 18 |

| O | 0.013 - 0.031 | 14 | 19 | 5 | - | 20 |

| O | 0.032 - 0.050 | 14 | 19 | 5 | - | 23 |

| O | 0.051 - 0.249 | 14 | 19 | 5 | - | 25 |

Chemical Composition Limits

| Si Silicon | Fe Iron | Cu Copper | Mn Manganese | Mg Magnesium | Cr Chromium | Ni Nickel | Zn Zinc | Ti Titanium | Others Each | Total | Total Aluminum Min |

| 0.6 | 0.7 | 0.05 - 0.2 | 1.0 - 1.50 | - | - | - | 0.1 | - | 0.05 | 0.15 | Remainder |

Aluminum 3003 Data Sheet

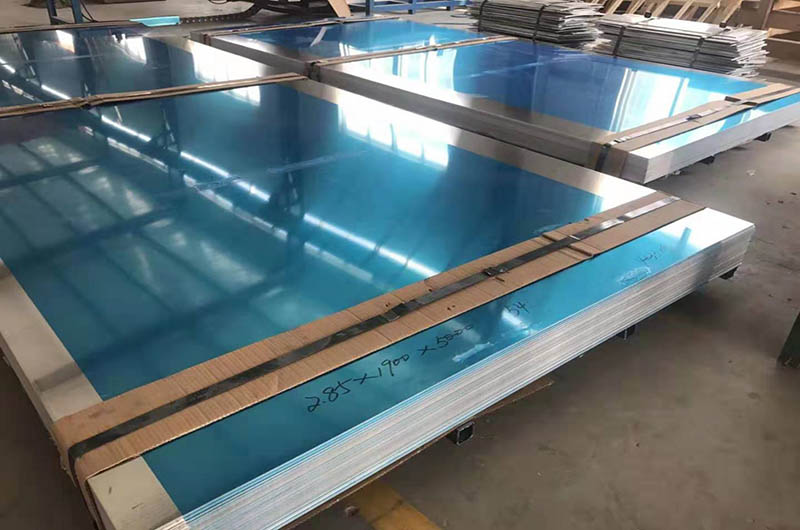

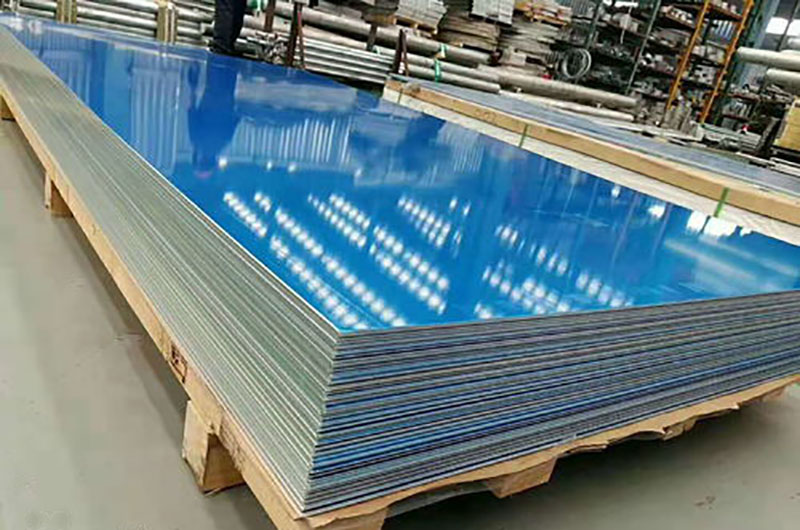

3003 Aluminum Plate Specifications

- Temper: H22, H24, H18, H19, O

- Width: Typically 1, 000 mm to 2, 500 mm (39.37 inches to 98.43 inches).

- Length: Typically 2, 000 mm to 6, 000 mm (78.74 inches to 236.22 inches).

- Typical Dimensions: Thickness range 0.2 mm to 6 mm (0.0079 in. to 0.2362 in.).

- Standards: ISO standard 6361 and the ASTM standards B209, B210, B211, B221, B483, B491, and B547.

- Certified: ISO 9001, ISO 14001

- Equivalent to 3003 Aluminum: AA3003, AlMn1Cu, 3.0517, A93003.

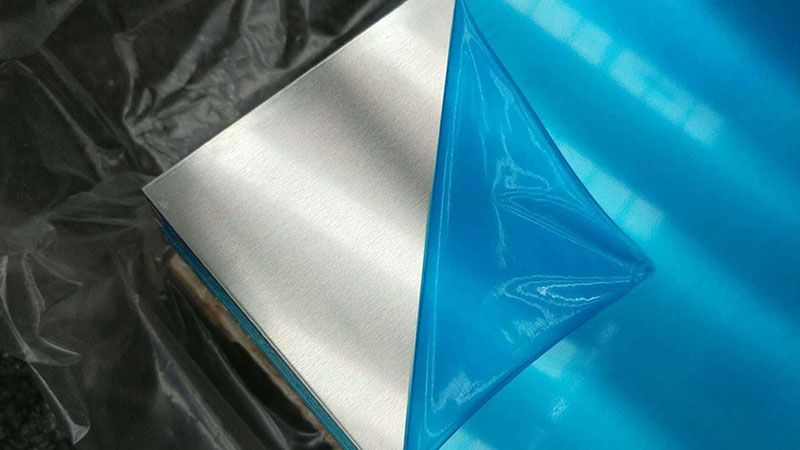

- Surface Treatment: Polished, Anodized, Painted or Coated

Note: Because the color is uneven after anodizing, anodizing is generally not performed.

3003 Aluminum Plate Thickness

The thickness of the 3003 aluminum plate will vary depending on the specific application and manufacturing specifications. However, common thicknesses for 3003 aluminum plates are typically between 0.025 inches (0.63 mm) and 0.125 inches (3.18 mm). It is important to note that aluminum sheet is available in a variety of thicknesses and the exact thickness required should be determined based on the intended use and structural requirements of the application.

Common Thicknesses of 3000 Aluminum Sheets

| Thickness (Inches) Product | Thickness (Millimeters) |

| .032" 3003 Aluminum Sheet | 0.813 |

| .040" 3003 Aluminum Sheet | 1.016 |

| .050" 3003 Aluminum Sheet | 1.27 |

| .063" 3003 Aluminum Sheet | 1.6 |

| .080" 3003 Aluminum Sheet | 2.032 |

| .090" 3003 Aluminum Sheet | 2.286 |

| .125" 3003 Aluminum Sheet | 3.175 |

| 0.020" 3003 Aluminum Sheet | 0.508 |

| 0.025" 3003 Aluminum Sheet | 0.635 |

| 0.032" 3003 Aluminum Sheet | 0.813 |

| 0.040" 3003 Aluminum Sheet | 1.016 |

| 0.050" 3003 Aluminum Sheet | 1.27 |

| 0.063" 3003 Aluminum Sheet | 1.6 |

| 0.080" 3003 Aluminum Sheet | 2.032 |

| 0.090" 3003 Aluminum Sheet | 2.286 |

| 0.100" 3003 Aluminum Sheet | 2.54 |

| 0.125" 3003 Aluminum Sheet | 3.175 |

3003 Aluminum Plate Mechanical Behavior

The mechanical properties of the 3003 aluminum plate may vary depending on the temper (condition) of the material. The following are approximate values for the O (annealed) state:

- Tensile Strength: 125 MPa

- Yield Strength: 115 MPa

- Elongation: 20%

3003 Aluminum Plate Chemical Composition

- Aluminum (Al): 98.6%

- Manganese (Mn): 1.2-1.8%

- Copper (Cu): 0.05-0.20%

- Other elements: less than 0.3% (each)

- Impurities: less than 0.15%

Please note that specifications and attributes provided are general and may vary by specific manufacturer and product model. It is always recommended to refer to the manufacturer's data sheet or technical specification for accurate information.

3003 Aluminum Plate Chemical Properties

The chemical properties of 3003 aluminum alloy are determined by its composition. 3003 aluminum is a non-heat-treatable alloy primarily composed of aluminum (Al) with small additions of manganese (Mn) and traces of other elements. Here are the key chemical properties of 3003 aluminum:

1. Corrosion Resistance

3003 aluminum offers good corrosion resistance, especially in mild to moderately aggressive environments. Its corrosion resistance makes it suitable for applications exposed to moisture and various atmospheric conditions.

The corrosion resistance of the 3003 aluminum plate is very good, close to the corrosion resistance of industrial pure aluminum. It has good corrosion resistance to the atmosphere, fresh water, seawater, food, organic acids, gasoline, neutral inorganic salt water solutions, etc., and has good corrosion resistance in dilute acids. Corrosion resistance is also very good.

2. Oxidation

Aluminum naturally forms a protective oxide layer on its surface when exposed to air, which provides additional corrosion resistance.

3. Reactivity

Aluminum is generally considered chemically stable. It reacts with strong acids, such as hydrochloric acid (HCl) and sulfuric acid (H2SO4), releasing hydrogen gas. However, the surface oxide layer can provide some protection against such reactions.

4. Melting Point

3003 aluminum has a melting point of approximately 660.3°C (1220.5°F). This property is important for casting and processing the alloy.

5. Heat Resistance

3003 aluminum retains its mechanical properties at elevated temperatures, which is beneficial for applications requiring heat resistance.

6. Electrical Conductivity

Aluminum is an excellent conductor of electricity, and 3003 aluminum retains this property. It is used in electrical and electronic applications.

7. Weldability

3003 aluminum is easily weldable using various methods, including TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding. Proper welding techniques and filler materials should be used for quality welds.

8. Machinability

The machinability of 3003 aluminum is generally good, allowing for various machining processes. However, it may become more challenging as the alloy is work-hardened.

9. Solubility

The solubility of alloying elements in 3003 aluminum varies with temperature and composition. This understanding is important when performing heat treatments or alloy modifications.

These chemical properties collectively contribute to the versatility and utility of 3003 aluminum in various applications, including sheet metal fabrication, cooking utensils, food packaging, and more.

3003 Aluminum Sheet Stock

| Description | Temper | Thickness(IN) | Width(IN) | Length(IN) |

| ASTM B209 .0200" 3003 H14 Alminum Sheet | H14 | 0.02 | 36 | 96 IN |

| ASTM B209 .0250" 3003 H14 Alminum Sheet | H14 | 0.025 | 48 | 120 IN |

| ASTM B209 .0320" 3003 H154 Alminum Stucco | H154 | 0.032 | 48 | 120 IN |

| ASTM B209 .0320" 3003 H154 Alminum Stucco | H154 | 0.032 | 48 | 144 IN |

| ASTM B209 .0320" 3003 H154 Alminum Sheet | H154 | 0.032 | 48 | CTO |

| ASTM B209 .0320" 3003 H14 Alminum Sheet | H14 | 0.032 | 36 | 120 IN |

| ASTM B209 .0320" 3003 H14 Alminum Sheet | H14 | 0.032 | 48 | 120 IN |

| ASTM B209 .0320" 3003 H14 Alminum Sheet | H14 | 0.032 | 48 | 144 IN |

| ASTM B209 .0400" 3003 H14 Alminum Sheet | H14 | 0.04 | 48 | 120 IN |

| ASTM B209 .0400" 3003 H14 Alminum Sheet | H14 | 0.04 | 48 | 144 IN |

| ASTM B209 .0400" 3003 H14 Alminum Sheet | H14 | 0.04 | 48 | 120 |

| AMS4006 ASTM B209 .0400" 3003 O Alminum Sheet | O | 0.04 | 48 | 144 |

| ASTM B209 .0500" 3003 H14 Alminum Sheet | H14 | 0.05 | 48 | 96 IN |

| AMS4006 ASTM B209 .0500" 3003 O Alminum Sheet | O | 0.05 | 48 | 144 IN |

| ASTM B209 .0500" 3003 H14 Alminum Sheet | H14 | 0.05 | 48 | 120 IN |

| ASTM B209 .0500" 3003 H14 Alminum Sheet | H14 | 0.05 | 60 | 144 IN |

| ASTM B209 .0500" 3003 H14 Alminum Sheet | H14 | 0.05 | 60 | 120 IN |

| AMS4006 ASTM B209 .0630" 3003 O Alminum Sheet | O | 0.063 | 48 | 144 IN |

| ASTM B209 .0630" 3003 H14 Alminum Sheet | H14 | 0.063 | 48 | 120 IN |

| ASTM B209 .0630" 3003 H14 Alminum Sheet | H14 | 0.063 | 48 | 96 IN |

| ASTM B209 .0630" 3003 H14 Alminum Sheet | H14 | 0.063 | 48 | 144 IN |

| ASTM B209 .0630" 3003 H14 Alminum Sheet | H14 | 0.063 | 60 | 120 IN |

| ASTM B209 .0800" 3003 H14 Alminum Sheet | H14 | 0.08 | 36 | 96 IN |

| ASTM B209 .0800" 3003 H14 Alminum Sheet | H14 | 0.08 | 48 | 120 IN |

| ASTM B209 .0800" 3003 H14 Alminum Sheet | H14 | 0.08 | 48 | 96 IN |

| ASTM B209 .0800" 3003 H14 Alminum Sheet | H14 | 0.08 | 48 | 144 IN |

| ASTM B209 .0800" 3003 H14 Alminum Sheet | H14 | 0.08 | 60 | 120 IN |

| ASTM B209 .0800" 3003 H14 Alminum Sheet | H14 | 0.08 | 60 | 96 IN |

| ASTM B209 .0900" 3003 H14 Alminum Sheet | H14 | 0.09 | 48 | 120 IN |

| ASTM B209 .0900" 3003 H14 Alminum Sheet | H14 | 0.09 | 48 | 144 IN |

| ASTM B209 .0900" 3003 O Alminum Sheet | O | 0.09 | 48 | 144 IN |

| ASTM B209 .0900" 3003 H14 Alminum Sheet | H14 | 0.09 | 60 | 120 IN |

| ASTM B209 .0900" 3003 H14 Alminum Sheet | H14 | 0.09 | 48 | 96 IN |

| ASTM B209 .0900" 3003 H14 Alminum Sheet | H14 | 0.09 | 60 | 96 IN |

| ASTM B209 .1000" 3003 H14 Alminum Sheet | H14 | 0.1 | 36 | 96 IN |

| ASTM B209 .1000" 3003 H14 Alminum Sheet | H14 | 0.1 | 48 | 144 IN |

| ASTM B209 .1000" 3003 H14 Alminum Sheet | H14 | 0.1 | 48 | 120 IN |

| ASTM B209 .1250" 3003 H14 Alminum Sheet | H14 | 0.125 | 36 | 120 IN |

| ASTM B209 .1250" 3003 H14 Alminum Sheet | H14 | 0.125 | 48 | 144 IN |

| ASTM B209 .1250" 3003 H14 Alminum Sheet | H14 | 0.125 | 60 | 144 IN |

| ASTM B209 .1250" 3003 H14 Alminum Sheet | H14 | 0.125 | 48 | 96 IN |

| ASTM B209 .1250" 3003 H14 Alminum Sheet | H14 | 0.125 | 60 | 120 IN |

| ASTM B209 .1250" 3003 H14 Alminum Sheet | H14 | 0.125 | 48 | 120 IN |

| ASTM B209 .1900" 3003 H14 Alminum Sheet | H14 | 0.19 | 48 | 120 IN |

| ASTM B209 .1900" 3003 H14 Alminum Sheet | H14 | 0.19 | 48 | 144 IN |

| ASTM B209 .1900" 3003 H14 Alminum Sheet | H14 | 0.19 | 60 | 144 IN |

| ASTM B209 .190" 3003 H14 Alminum Sheet | H14 | 0.19 | 60 | 120 IN |

| ASTM B209 .1900" 3003 H14 Alminum Sheet | H14 | 0.19 | 48 | 96 IN |

| ASTM B209 .2490" 3003 H14 Alminum Sheet | H14 | 0.249 | 48 | 144 IN |

| ASTM B209 .2490" 3003 H14 Alminum Sheet | H14 | 0.249 | 48 | 120 IN |

Typical 3003 Aluminum Sheet Plate

3003 H14 Aluminum Plate

- Common Applications: Roofing, siding, chemical equipment, sheet metal fabrication, general manufacturing.

- Specifications: H14 refers to the temper of aluminum, indicating that it has been strain-hardened and partially annealed. The hardness is between H12 and H18, with good formability.

-

Advantage:

- Good formability: The H14 temper makes the sheet easy to bend, shape, and form.

- Corrosion resistance: 3003 aluminum has excellent atmospheric corrosion resistance in the H14 state.

- High Strength: While not as strong as some other aluminum alloys, it has moderate strength suitable for many applications.

3003 O Aluminum Plate

- Common Applications: Cookware, Packaging, General Sheet Metal, Signage.

- Specifications: O stands for annealed, meaning the aluminum has been fully annealed to soften for enhanced formability.

-

Advantage:

- Excellent Formability: The fully annealed condition of 3003 O aluminum makes it easy to form and form, making it suitable for complex designs.

- Solderability: The softness of O temper makes it highly weldable, allowing easy joining of parts.

- Good Corrosion Resistance: 3003 aluminum in the annealed condition has good corrosion resistance.

3003 H22 Aluminum Plate

- Common applications: automotive panels, storage tanks, trailers, chemical equipment.

- Specification: H22 indicates that the aluminum has been strain-hardened and partially annealed, resulting in a stable temper with a specified hardness.

-

Advantage:

- High Strength: Compared to the O state, the H22 state provides higher strength, making it suitable for applications requiring higher structural integrity.

- Excellent Corrosion Resistance: 3003 Aluminum in the H22 state has excellent corrosion resistance making it suitable for outdoor or harsh environments.

- Good solderability: The H22 state maintains good solderability for easy fabrication and connection.

3003 Aluminum Checker Plate

The surface of the 3003 aluminum plate has a checkerboard pattern, which is both beautiful and non-slip. It is commonly used for decorative purposes, wall cladding, truck tool boxes, and trailer fenders. 3003 alloy has good corrosion resistance and weldability.

3003 Aluminum Sheet Metal

3003 aluminum plate is a kind of flat aluminum with various thicknesses. It is used in a wide range of applications including signage, cabinetry, plumbing, and general manufacturing. Alloy 3003 has good formability, corrosion resistance, and moderate strength.

3003 Aluminum Plate for Heat Exchanger

3003 aluminum plate is designed for heat exchanger applications. 3003 aluminum plate for heat exchanger has excellent thermal conductivity and corrosion resistance, suitable for HVAC systems, radiators, condenser fins, and evaporator coils. Alloy 3003 was chosen for its high heat transfer efficiency and machinability.

What is 3003 Aluminum Used for?

3003 aluminum sheet is usually used for general sheet metal processing, including building facades, roofs, kitchen utensils, heat exchangers, and storage tanks. The alloy's corrosion resistance makes it suitable for outdoor applications exposed to moisture and other environmental factors.

| Application | Description |

|---|---|

| Roofing and siding | Provides corrosion-resistant protection for residential and commercial buildings |

| Food and beverage packaging | Used in the production of cans for food and beverage products |

| Heat exchangers | Employed in air conditioning, refrigeration, and automotive cooling systems |

| Chemical equipment | Suitable for tanks, pipes, and fittings in corrosive chemical processing |

| Cooking utensils | Used for pots, pans, and baking sheets with excellent heat distribution properties |

| General sheet metal work | Ideal for fabrication and welding in automotive, construction, and signage industries |

| HVAC systems | Commonly used in ductwork, air handlers, and heat exchanger components in HVAC systems |

| Application | 3003 Aluminum Temper |

|---|---|

| Roofing, Siding, Architectural Components | 3003 H14 Aluminum Plate |

| Food and Beverage Cans | 3003 H16/H18 Aluminum Plate |

| Heat Exchanger Fins | 3003 H24 Aluminum Plate |

| Storage Tanks | 3003 H24 Aluminum Plate |

| General Sheet Metal Work | 3003 H24 Aluminum Plate |

| Cookware | 3003 H22 Aluminum Plate |

| Electrical Wiring | 3003 O Aluminum Plate |

| Reflectors | Varies |

| Chemical Equipment | Varies |

| Packaging Foils | Varies |

3003 Aluminum Plate Heat Treatment Process

3003 aluminum is a non-heat-treatable alloy, which means it cannot be significantly strengthened through heat treatment processes like precipitation hardening. Instead, it is typically used in its as-annealed or cold-worked condition. However, some heat treatments may be used for stress relief or annealing for formability purposes. Here are some common heat treatment processes for 3003 aluminum:

Annealing

Heat the 3003 aluminum plate to a temperature between 390°C and 430°C (734°F to 806°F).

Hold the material at this temperature for a specific time, which can vary depending on the thickness of the material (approximately 30 to 120 minutes).

Gradually cool the material down to 300°C (572°F) at a rate of 30 to 50°C per hour (54 to 90°F per hour).

After reaching 300°C, you can allow it to air-cool.

Rapid Annealing

Heat the 3003 aluminum plate to a temperature between 350°C and 370°C (662°F to 698°F).

Hold the material at this temperature for a specific time, which can vary depending on the thickness (approximately 30 to 120 minutes).

After the hold time, you can either air-cool it or quench it in water.

It's important to note that these heat treatments for 3003 aluminum are primarily used for stress relief or to enhance formability, but they won't significantly change the alloy's mechanical properties or strength since 3003 is a non-heat-treatable alloy. The choice between slow annealing and rapid annealing may depend on the specific requirements of your application.

3003 vs. 5052 Aluminum Plate

Both 3003 and 5052 are commonly used aluminum alloy grades, often in sheet form for a variety of applications. Here is a comparison between 3003 and 5052 aluminum sheets:

Element

Both 3003 and 5052 aluminum alloys belong to the 5xxx series of aluminum alloys. However, their ingredients are slightly different.

- 3003 aluminum alloy contains about 1.2% manganese, making it more corrosion-resistant than pure aluminum. It is typically used for general-purpose applications requiring moderate strength and good formability.

- 5052 aluminum alloy contains about 2.5% magnesium and a small amount of chromium, making it more corrosion resistant and stronger than 3003. Commonly used in marine environments, sheet metal fabrication, and structural applications for higher strength and better resistance to saltwater corrosion.

Strength and Mechanical Properties

Compared with 3003, 5052 aluminum alloy has higher strength and better mechanical properties. It has a higher tensile and yield strength, making it more suitable for structural applications requiring greater strength and durability.

Formability: Both alloys have good formability characteristics, but 3003 is generally considered to be more formable than 5052. This makes 3003 aluminum plates a better choice for applications that require complex forming or bending, such as food packaging, heat exchangers, and roofing.

Corrosion Resistance

5052 aluminum alloy has better saltwater corrosion resistance. This makes it the first choice for marine applications such as hulls and components exposed to seawater.

Weldability

Both 3003 and 5052 aluminum alloys have excellent weldability. They can be welded easily using a variety of methods, including MIG and TIG welding, with proper precautions.

The specific requirements of the application will determine which alloy is most suitable. Consider factors such as strength, corrosion resistance, formability, and intended use to make an informed choice between 3003 and 5052 aluminum plates.

People also searched for Aluminum Plate

-

3004 Aluminum Plate Sheet

3004 aluminum is similar to 3003 aluminum, but it is stronger than 3003 alloy. 3004 aluminum also has good formability, good processability, excellent corrosion resistance and drawing characteristics.

-

3004 h19 Aluminum Plate Sheet

3004 H19 is a non-heat treatable aluminum alloy suitable for chemical and food contact applications, common ones such as beverage cans.

-

3004 h18 Aluminum Plate Sheet

3004-H18 aluminum is 3004 aluminum in the H18 state, which has higher strength, excellent formability and good corrosion resistance than 3003.

-

3004 o Aluminum Plate Sheet

3004-O aluminum is 3004 aluminum in the annealed condition. It has the lowest strength and highest ductility compared to other variants of 3004 aluminum.

-

3104 Aluminum Plate Sheet

The performance of the 3104 aluminum plate is stable, the surface is smooth, smooth, and free of defects, and the tolerance is strictly controlled to meet the standard.

-

3104 h19 Aluminum Plate Sheet

3104 h19 Aluminum Plate Sheet has precise specifications, good shape, high strength, easy processing, and good deep drawing performance.

-

3105 Aluminum Plate Sheet

3105 aluminum alloy is stronger than 1100 and 3003 alloys. 3105 aluminum sheet is often used in street signs, building siding and bottle caps.