3003 h22 Aluminum Plate

Production Standard: ASTM B209, AMS-QQ-A-250/2 Strict Control of Tolerances

What is 3003 H22?

3003 H22 is the specific temper designation for the 3003 aluminum alloy. The temper designation "H22" indicates that the aluminum has been strain-hardened and then partially annealed to obtain specific properties.

H: This letter indicates that the aluminum has been strain-hardened, also known as cold working. Strain hardening involves deforming a material, usually by rolling or other mechanical processes, to increase its strength and hardness.

22: The number after "H" represents the specific grade of strain hardening. In the case of H22, it indicates that the aluminum has been strain-hardened to a quarter hardness temper. This means that the material is moderately hardened, but not used to its full potential. The H22 temper achieves a lower level of hardness and strength than higher temper designations such as H32 or H34.

3003 aluminum alloy itself is a non-heat treatable alloy, mainly composed of aluminum, manganese, and a small amount of other elements. It is known for its good formability, corrosion resistance, and moderate strength. H22 tempering further improves its strength and hardness to a certain extent while maintaining its formability.

3003 H22 aluminum is typically used in applications requiring moderate strength and good formability, such as roofing, siding, and general sheet metal work. Its properties make it suitable for applications requiring bending, forming, and fabrication while maintaining a certain level of strength and corrosion resistance.

3003-h22 Aluminum Plate Properties

- Strength and Hardness: 3003-H22 is a strain-hardening (cold-worked) alloy. The "H22" temper designation indicates that it has been strain-hardened and subsequently stabilized. This tempered condition provides moderate strength and hardness, making it suitable for a variety of applications.

- Weldability: 3003-H22 aluminum has good weldability. It can be easily welded using various methods including MIG welding, TIG welding, and resistance welding. Proper welding techniques and filler materials compatible with this alloy are recommended to achieve high-quality welds.

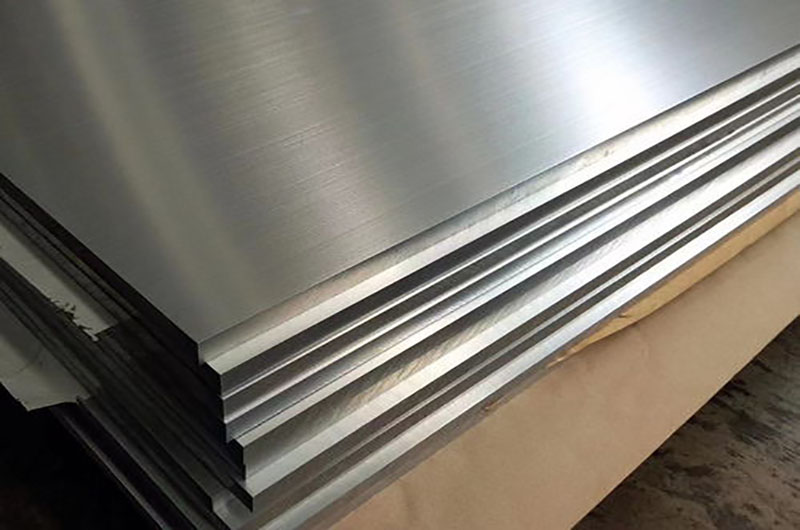

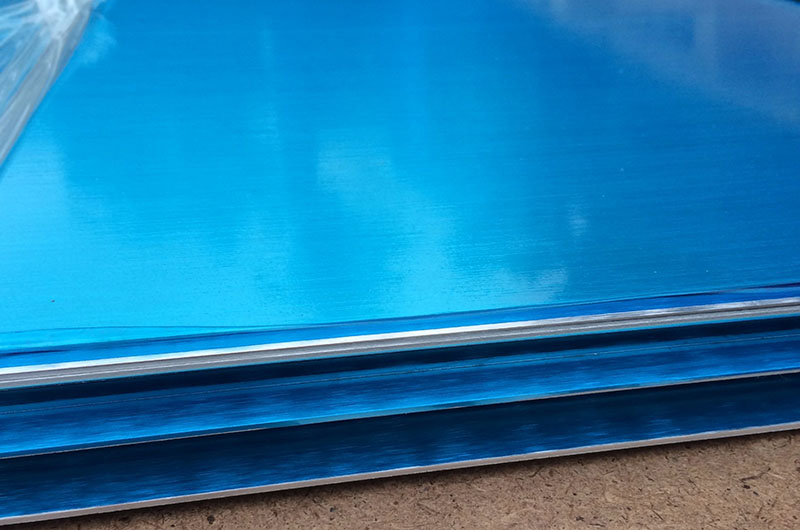

- Surface Finish: The surface finish of 3003-H22 aluminum will vary depending on the manufacturing process and any subsequent treatments. It can have a satin finish and is usually smooth but may have slight blemishes. If a specific surface finish is required, other processes such as polishing or anodizing can be applied.

What is the Typical Thickness Range for 3003-H22 Aluminum Plates?

3003-H22 aluminum plates are available in various thicknesses, with common thicknesses ranging from 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). Custom thicknesses can also be manufactured.

3003-H22 Aluminum Plate Typical Sizes

3003 H22 aluminum plates are available in a variety of standard sizes to accommodate different applications. The typical size or dimensions of these plates can vary depending on the manufacturer and the specific needs of the customer. However, here are some common standard sizes for 3003-H22 aluminum plates:

| Item | Thickness | Size | Weight per Plate |

| 3003-H22 | 0.058 inches/1.4732 mm | 48 x 96 | 29.66 lbs/13.43598 kg |

| 3003-H22 | 0.058 inches/1.4732 mm | 48 x 144 | 44.49 lbs/20.15397 kg |

| 3003-H22 | 0.072 inches/1.8288 mm | 60 x 192 | 91.71 lbs/41.54463 kg |

| 3003-H22 | 0.080 inches/2.032 mm | 48 x 96 | 40.66 lbs/18.41898 kg |

| 3003-H22 | 0.080 inches/2.032 mm | 48 x 120 | 50.82 lbs/23.02146 kg |

| 3003-H22 | 0.080 inches/2.032 mm | 48 x 144 | 60.98 lbs/27.62394 kg |

| 3003-H22 | 0.080 inches/2.032 mm | 48 x 192 | 81.31 lbs/36.83343 kg |

| 3003-H22 | 0.100 inches/2.54 mm | 48 x 96 | 50.10 lbs/22.6953 kg |

| 3003-H22 | 0.100 inches/2.54 mm | 48 x 144 | 75.15 lbs/34.04295 kg |

| 3003-H22 | 0.100 inches/2.54 mm | 48 x 192 | 100.20 lbs/45.3906 kg |

| 3003-H22 | 0.100 inches/2.54 mm | 60 x 192 | 125.25 lbs/56.73825 kg |

| 3003-H22 | 0.125 inches/3.1750 mm | 48 x 96 | 61.50 lbs/27.8595 kg |

| 3003-H22 | 0.125 inches/3.1750 mm | 48 x 144 | 92.26 lbs/41.79378 kg |

| 3003-H22 | 0.125 inches/3.1750 mm | 48 x 192 | 123.01 lbs/55.72353 kg |

| 3003-H22 | 0.125 inches/3.1750 mm | 60 x 144 | 115.32 lbs/52.23996 kg |

| 3003-H22 | 0.125 inches/3.1750 mm | 60 x 192 | 153.76 lbs/69.65328 kg |

| 3003-H22 | 0.188 inches/4.7752 mm | 48 x 96 | 90.24 lbs/40.87872 kg |

| 3003-H22 | 0.188 inches/4.7752 mm | 48 x 144 | 135.37 lbs/61.32261 kg |

| 3003-H22 | 0.188 inches/4.7752 mm | 48 x 192 | 180.49 lbs/81.76197 kg |

| 3003-H22 | 0.188 inches/4.7752 mm | 60 x 192 | 225.61 lbs/102.20133 kg |

-

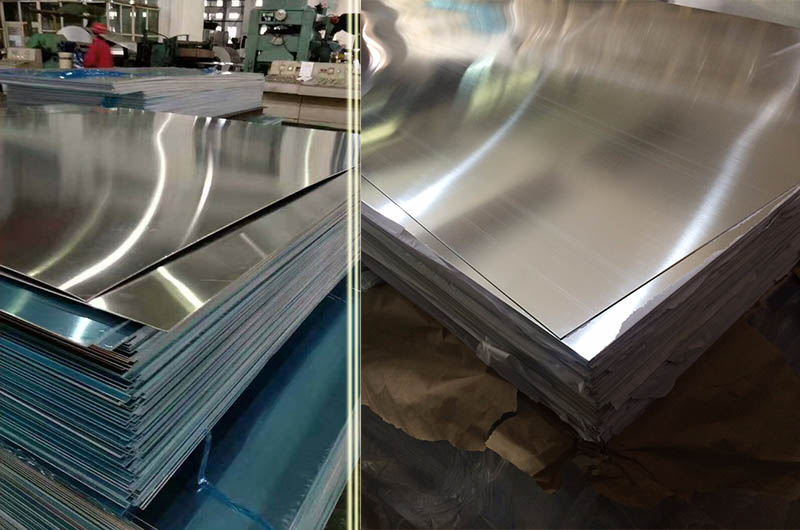

3003 Aluminum Plate Sheet

3003 aluminum has excellent processability, weldability, and corrosion resistance. Compared with 1100 aluminum, 3003 aluminum is approximately 20% stronger.

-

3003 h24 Aluminum Plate

Ensure the 3003 h24 Aluminum Plate meets the required specifications including dimensional accuracy, chemical composition, mechanical properties, and surface finish.

-

3003 h14 Aluminum Plate Sheet

3003-H14 aluminum plate has the characteristics of high strength, high durability, easy processing, strong corrosion resistance and light weight. 3003 aluminum is suitable for outdoor and harsh environment applications.

-

3003 O Aluminum Plate Sheet

3003 O-state aluminum plate has low hardness, and 3003 O-state aluminum plate is suitable for stamping, spinning, stretching, etc.

When is the 3003 H22 Aluminum Plate the Best Choice?

3003 H22 Aluminum Sheet is a specific alloy and state of aluminum that has certain properties that make it suitable for a variety of applications. The following are some situations and corresponding application examples where a 3003 H22 aluminum plate may be the best choice:

1. Corrosion Resistance

3003 aluminum alloy is known for its excellent corrosion resistance. This makes it a good choice for applications where exposure to moisture, chemicals, or other corrosive elements is a consideration. H22 tempering further enhances its corrosion resistance.

Applications: Food and beverage containers, such as cans, are resistant to acid and salt substances, 3003 H22 Aluminum is essential to prevent corrosion and contamination.

2. Formability

The 3003 H22 condition means that the aluminum plate has been strain-hardened and partially annealed. This provides good formability, allowing it to be easily shaped and formed into a variety of designs without cracking or breaking. This makes it ideal for processes such as bending, rolling, and deep drawing.

Applications: Roofing and cladding materials for the construction industry, the ability to easily shape aluminum into a variety of profiles and shapes is critical to achieving different building designs.

3. Weldability

3003 aluminum is also highly weldable, making it suitable for applications that require welding or joining. It can be easily welded using a variety of methods, including MIG and TIG welding.

Applications: Heat exchangers in HVAC (heating, ventilation, and air conditioning) systems. The plates and fins of heat exchangers often need to be welded, and 3003 H22 aluminum is suitable for this purpose.

4. Cost-effectiveness

Compared to some other aluminum alloys, 3003 aluminum is relatively affordable, making it a cost-effective choice for projects with budget constraints in mind.

Applications: Household cooking utensils such as cooking pots and pans. The affordability and corrosion resistance of 3003 h22 aluminum makes it a practical choice for these consumer products.

5. Not Heat Treatable

3003 Aluminum is a non-heat treatable alloy. This means that it cannot be further strengthened by heat treatment processes such as solution heat treatment and quenching. However, the H22 temper provides a good balance of strength and formability for many applications without the need for additional heat treatment.

Applications: Automotive body panels and parts. The 3003 H22 temper provides a balance of strength and formability without the need for additional heat treatment, making it suitable for bodybuilding.

3003 H22 aluminum plate is a general-purpose material suitable for applications requiring corrosion resistance, formability, weldability, and moderate strength. Its affordability and wide availability also make it a practical choice for many projects where these characteristics are important. However, it is important to consider the specific requirements of your project and consult with Haomei Aluminum to determine if 3003 H22 Aluminum is the best choice for your application.

Aluminum 3003 H22 Data Sheet

3003 H22 aluminum plate generally complies with industry standards such as ASTM B209 or AMS-QQ-A-250/2. These standards specify the chemical composition, mechanical properties, dimensional tolerances, and other requirements of materials.

3003 H22 Aluminum is the specific temper designation for the 3003 aluminum alloy. It indicates the strain hardened and partially annealed state. Alloy 3003 itself is a non-heat treatable aluminum alloy known for its good formability, corrosion resistance, and moderate strength.

The exact specifications, dimensions, certifications, and mechanical properties of 3003 H22 Aluminum Sheet may vary between different suppliers or manufacturers. It is therefore advisable to consult the specific data sheets provided by the manufacturer or to contact them directly for accurate and up-to-date information on the product.

3003 h22 Aluminum Plate Mechanical Properties

- Tensile Strength: Typically between approximately 16, 000 psi (110 MPa) and 24, 000 psi (165 MPa).

- Yield Strength: Typically between approximately 8, 000 psi (55 MPa) and 21, 000 psi (145 MPa).

- Elongation: Typically around 15% to 25%.

- Hardness: Varies by tempering process.

3003 H12 Aluminum Plate Thermal Properties

Thermal properties of 3003-H12 aluminum alloy refer to how the material responds to changes in temperature. These properties are important to consider in applications where temperature variations are a factor. Here are some key thermal properties of 3003-H12 aluminum plate:

| Property | Value and Units |

|---|---|

| Thermal Conductivity | 125 - 230 W/m·K |

| Coefficient of Thermal Expansion | 23.6 x 10^-6/°C (13.1 x 10^-6/°F) |

| Melting Point | 660.3 °C (Centigrade) |

| Specific Heat Capacity | 0.90 J/g·°C |

| Thermal Diffusivity | High |

| Thermal Resistance | Low |

It's important to note that the specific thermal properties of 3003-H12 aluminum can vary slightly depending on factors such as alloy composition, temper, and processing conditions.

3003 h12 Aluminum Plate Electrical Properties

The electrical properties of 3003-H12 aluminum alloy are important when considering its use in electrical and electronic applications. While aluminum is a good conductor of electricity, the specific electrical properties can vary based on factors such as alloy composition and processing. Here are some general electrical properties of 3003-H12 aluminum plate:

| Property | Value/Description |

|---|---|

| Electrical Conductivity | Approximately 61% of IACS (35 to 62 MS/m) |

| Resistivity | Approximately 0.0281 ohm-mm |

| Dielectric Constant | Close to 1.0 |

| Frequency Response | Varies with frequency |

| Contact Resistance | Depends on surface treatment and contact design |

| EMI Shielding | Effective for electromagnetic interference (EMI) shielding |

It's important to note that the electrical properties of 3003-H12 aluminum can be influenced by factors such as alloy purity, processing conditions, and surface treatment. These properties make aluminum suitable for a wide range of electrical and electronic applications, including wiring, busbars, heat sinks, and components for the electronics industry. However, in high-current and high-frequency applications, other alloys with even higher electrical conductivity may be preferred.

3003 Aluminum Plate Chemical Composition

The chemical composition of 3003 H22 aluminum sheet generally includes about 96.7% aluminum, 1% manganese, 0.05% - 0.20% copper, and trace amounts of other elements.

What is the 3003 H22 Aluminum Plate Used for?

3003 H22 Aluminum is commonly used in a variety of applications requiring a combination of formability, corrosion resistance, and moderate strength. Some common uses for 3003 H22 aluminum include:

- Roof and Siding: 3003 H22 aluminum is commonly used in roofing and siding applications in the construction industry. Its formability, corrosion resistance, and moderate strength make it suitable for these exterior applications.

- Gutters and Downspouts: The corrosion resistance and formability of 3003 H22 aluminum make it an ideal material for gutters and downspouts. It is commonly used in residential and commercial buildings for effective stormwater management.

- Food and Beverage Packaging: Due to its non-toxic properties and good formability, 3003 H22 aluminum is used to make food and beverage packaging. It can be found in cans, lids, and other food containers.

- Chemical Equipment: The corrosion resistance of 3003 H22 aluminum makes it suitable for a variety of chemical equipment applications. It is commonly used in tanks, pipes, and assemblies in the chemical industry.

- Heat Exchangers: 3003 H22 Aluminum's excellent thermal conductivity makes it a popular choice for heat exchangers. It is commonly used in air conditioning systems, radiators, and evaporator coils.

- General Sheet Metal Fabrication: The formability and workability of 3003 H22 aluminum make it ideal for general sheet metal fabrication. It is used to produce panels, ductwork, cabinets, and other sheet metal components.

- Signage and Decorative Applications: The combination of formability and aesthetic appeal of 3003 H22 aluminum makes it a popular choice for signage, decorative trim, and architectural elements.

- Heat Shields and Reflectors: Aluminum's reflective properties make 3003 H22 Aluminum an excellent choice for heat shields and reflectors in a variety of applications, including lighting fixtures and solar panels.

- Bus Body: The formability and corrosion resistance of 3003 H22 aluminum make it suitable for the manufacture of bus bodies. It is used to build panels, roofs, and other parts of the bus.

These are just a few examples of the wide range of applications for 3003 H22 Aluminum. Its versatility and good performance make it a popular choice for industries requiring a combination of corrosion resistance, formability, and moderate strength.

How is a 3003-H12 Aluminum Plate Typically Processed and Formed?

3003-H22 aluminum plate is typically processed and formed using methods such as cutting, bending, stamping, deep drawing, welding, machining, assembly, and finishing, depending on the specific application and manufacturing requirements.

- Cutting: The first step in processing the 3003-H22 aluminum plate is often cutting it to the desired size and shape. Common cutting methods include shearing, sawing, or using a CNC cutting machine. The choice of method depends on the precision and complexity of the cut required.

- Bending and Forming: The 3003-H22 aluminum plate is highly malleable, making it suitable for bending and forming operations. It can be shaped into various forms, including angles, channels, curves, and complex geometries. Bending and forming can be accomplished using press brakes, roll-forming machines, or other specialized equipment.

- Deep Drawing: Deep drawing is a process used to create complex, three-dimensional shapes from flat sheets of metal. 3003-H22 aluminum is well-suited for deep drawing applications, making it suitable for products like cookware, automotive parts, and containers.

- Stamping: Stamping involves using a die and press to cut or shape the aluminum plate. It's commonly used in the production of intricate parts, such as automotive components and electrical connectors.

- Welding: 3003-H22 aluminum can be welded using various methods, including TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding. Proper welding techniques and filler materials should be used to ensure high-quality welds.

- Machining: Machining operations, such as milling, drilling, and turning, can be performed on 3003-H22 aluminum to create precise shapes and holes. It's important to use sharp tools and proper coolant to achieve clean and accurate cuts.

- Assembly: Aluminum parts can be assembled using methods such as riveting, bolting, or adhesive bonding. The choice of assembly method depends on the specific application and structural requirements.

- Finishing: After processing and forming, 3003-H22 aluminum parts may undergo finishing processes such as surface cleaning, deburring, and, in some cases, surface treatments like anodizing or painting to enhance appearance and durability.

What is the Difference Between 3003-H22 and 3003-H12 Aluminum?

The "H22" and "H12" designations indicate different temper conditions.

- "H22" is strain-hardened and partially annealed.

- "H12" is more extensively strain-hardened and slightly more rigid.

The choice between them depends on the desired mechanical properties of the application.

Does 3003-H22 Aluminum Require any Special Surface Treatment for Corrosion Resistance?

While 3003 aluminum has good inherent corrosion resistance, for some applications, additional surface treatments like anodizing or painting may be applied to enhance protection against corrosion.

Can 3003-H22 Aluminum be Used in Outdoor Applications?

Yes, 3003-H22 aluminum has good corrosion resistance and can be used in outdoor applications. However, the longevity of its appearance and performance may benefit from appropriate surface treatments or coatings, depending on the specific environmental conditions.

People also searched for Aluminum Plate

-

3004 Aluminum Plate Sheet

3004 aluminum is similar to 3003 aluminum, but it is stronger than 3003 alloy. 3004 aluminum also has good formability, good processability, excellent corrosion resistance and drawing characteristics.

-

3004 h19 Aluminum Plate Sheet

3004 H19 is a non-heat treatable aluminum alloy suitable for chemical and food contact applications, common ones such as beverage cans.

-

3004 h18 Aluminum Plate Sheet

3004-H18 aluminum is 3004 aluminum in the H18 state, which has higher strength, excellent formability and good corrosion resistance than 3003.

-

3004 o Aluminum Plate Sheet

3004-O aluminum is 3004 aluminum in the annealed condition. It has the lowest strength and highest ductility compared to other variants of 3004 aluminum.

-

3104 Aluminum Plate Sheet

The performance of the 3104 aluminum plate is stable, the surface is smooth, smooth, and free of defects, and the tolerance is strictly controlled to meet the standard.

-

3104 h19 Aluminum Plate Sheet

3104 h19 Aluminum Plate Sheet has precise specifications, good shape, high strength, easy processing, and good deep drawing performance.

-

3105 Aluminum Plate Sheet

3105 aluminum alloy is stronger than 1100 and 3003 alloys. 3105 aluminum sheet is often used in street signs, building siding and bottle caps.