3003 O Aluminum Plate Sheet

Production Standard: ASTM B209, AMS-QQ-A-250/2 Stable Performance

What Does 3003-O Mean?

3003 is the alloy designation for this aluminum material, indicating its chemical composition.

O stands for annealed. In the O-temper condition, aluminum is fully annealed, which means it is in its softest state with the lowest strength but the highest ductility and formability.

The aluminum plate designated 3003 is an alloy plate mainly made of aluminum and a small amount of manganese. The number 3003 refers to the specific alloy composition, indicating that it contains approximately 98% aluminum and 1% manganese. This alloy is known for its excellent corrosion resistance, formability, and weldability, making it a popular choice in a variety of applications.

The "O" in the 3003O aluminum plate indicates that the plate has been annealed to improve ductility and reduce internal stress. Annealing involves heating a sheet of aluminum and then gradually cooling it, making it softer and easier to work with.

What Are the Key Properties of the 3003-O Aluminum Plate?

- 3003-O aluminum has excellent formability, making it easy to bend, shape, and form without cracking.

- It has good corrosion resistance, particularly in mildly corrosive environments.

- It is not heat-treatable, meaning it cannot be strengthened through heat-treatment processes.

Mechanical Property Limits

| Specified Thickness(in) | Tensile Strength - KSI | Elongationin 2 inches % | |||

|---|---|---|---|---|---|

| Ultimate | Yield | ||||

| Min | Max | Min | Max | ||

| 0.006 - 0.007 | 14 | 19 | 5 | - | 14 |

| 0.008 - 0.012 | 14 | 19 | 5 | - | 18 |

| 0.013 - 0.031 | 14 | 19 | 5 | - | 20 |

| 0.032 - 0.050 | 14 | 19 | 5 | - | 23 |

| 0.051 - 0.249 | 14 | 19 | 5 | - | 25 |

Chemical Composition Limits

| Si Silicon | Fe Iron | Cu Copper | Mn Manganese | Mg Magnesium | Cr Chromium | Ni Nickel | Zn Zinc | Ti Titanium | Others Each | Total | Total Aluminum Min |

| 0.6 | 0.7 | 0.05 - 0.2 | 1.0 - 1.50 | - | - | - | 0.1 | - | 0.05 | 0.15 | Remainder |

Can a 3003-O Aluminum Plate Be Anodized?

Yes, 3003-O aluminum can be anodized. Anodizing is a surface treatment process that can improve the material's corrosion resistance and appearance. However, the formability of the O temper can be affected by the anodizing process, so it's essential to consider the specific requirements of your project.

What Are the Limitations of the 3003-O Aluminum Plate?

While 3003-O aluminum offers excellent formability, it has lower mechanical strength compared to other tempers of 3003 aluminum. It may not be suitable for applications requiring high strength.

How Does 3003-O Compare to Other Tempers of 3003 Aluminum Plate?

3003-O is the softest temper of 3003 aluminum, offering the highest formability but the lowest strength. Other tempers, such as H14 and H22, provide increased strength at the expense of some formability.

Aluminum 3003 O Data Sheet

3003 o Aluminum Plate Performance

- Excellent formability

- High corrosion resistance

- Medium intensity

3003 O Aluminum Plate Mechanical Behavior

The mechanical properties of the 3003 O aluminum plate include relatively low tensile strength, high elongation, and good formability.

- Tensile Strength: Typically between 13, 000 psi (90 MPa) and 23, 000 psi (160 MPa).

- Yield Strength: Approximately 5, 000 psi (35 MPa) to 16, 000 psi (110 MPa).

- Elongation: Typically in the range of 30% to 40% or more. This means it can deform significantly before fracturing.

- Modulus of Elasticity: Approx. 10, 000 ksi (70 GPa). This value represents the stiffness or resistance to deformation of the material under an applied load.

It should be noted that the mechanical properties of aluminum will vary slightly depending on factors such as alloy composition, manufacturing process, and heat treatment. The values provided above are typical ranges and should be used as a general reference.

3003 O Aluminum Plate Chemical Composition

The chemical composition of 3003-O aluminum sheet generally consists of approximately 96.7% aluminum, 1% manganese, 0.05% - 0.20% copper, and trace amounts of other elements.

What is a 3003 O Aluminum Plate Used for?

3003-O aluminum is used in various applications where formability and corrosion resistance are essential. Common uses include cooking utensils, heat exchangers, chemical equipment, and decorative trim.

- General sheet metal processing: used for forming, bending, shaping, and other processes in construction, automobile, packaging, and other industries.

- Heat Exchangers: Aluminum's high thermal conductivity makes it suitable for heat transfer applications in heat exchangers and cooling systems.

- Food and beverage industry: 3003-O aluminum sheet is often used in food processing equipment, cooking utensils, packaging materials, etc. due to its non-toxic properties.

- Chemical equipment: Its corrosion resistance makes it suitable for storage tanks, pipes, and components in the chemical industry.

- Reflectors and lighting fixtures: Aluminum's reflective properties make it ideal for applications such as light reflectors and lighting fixtures.

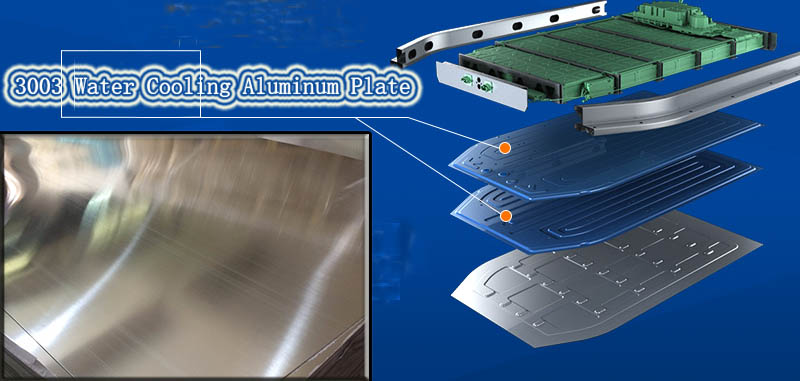

New Energy 3003 o Automobile Water Cooling Aluminum Plate

The new energy vehicle power battery generates a lot of heat during the working process. Excessive temperature will have a great impact on the reliability, life, and performance of the battery cell. Therefore, it is necessary to adopt an effective way to dissipate heat.

3003 o Automotive water-cooled aluminum plate, as one of the key components in the battery pack liquid cooling system, transfers the excess heat generated by the battery operation.

Using 3003 aluminum alloy and 4343/4045 composite materials, it has the advantages of compact structure, high heat dissipation efficiency, and high corrosion resistance, and is widely used in new energy vehicles.

3003-O Aluminum Plate for Cookware and Tableware

The 3003-O aluminum plate belongs to the AL-Mn alloy, and the O state is an annealed state. In this state, it has good tensile properties and is a good raw material for making tableware and kitchen utensils.

3003-o aluminum plate is used for pot lining because the aluminum lining is easy to process and shape, the surface is smooth and clean, and the mechanical properties are good. Not easy to corrode. Aluminum conducts heat evenly, is easy to shape, and is more beautiful. It can be compounded with other metals or alloys. It is the main material for mid-range cookware.

3003-o Aluminum Plate for Battery Case

3003 O stretched aluminum sheet is a 3-series alloy product with good deep drawing and tensile properties. It is widely used in electronic product casings. The thickness is mostly 0.4mm. It can be produced according to the specific needs of customers.

3003 o deep-drawing aluminum plate has good formability and is mainly used in deep-drawing materials. 3003 aluminum alloy plate has many advantages such as good surface, good plasticity, and pressure resistance for stamping parts, models, tanks, shells, etc.

The power battery casing made of 3003 aluminum plate can reduce the weight of the battery, increase the capacity density of the battery, make the battery work stably, indirectly reduce the weight of the vehicle, and increase the battery life.

FAQ about 3003-O Aluminum Plates

1. Can 3003-O Aluminum Be Used for Food Contact Applications?

Yes, 3003-O aluminum is commonly used for food contact applications due to its corrosion resistance and formability. It is often used for cooking utensils, food containers, and beverage cans.

2. Is 3003-O Aluminum Recyclable?

Yes, aluminum is highly recyclable, and 3003-O aluminum is no exception. Recycling aluminum helps conserve natural resources and reduce energy consumption.

3. Is 3003-O Aluminum Plate Weldable?

Yes, 3003-O aluminum is weldable using various welding methods, such as MIG and TIG welding. It is often used in applications requiring welding, such as the fabrication of heat exchangers and automotive components.

-

3003 Aluminum Plate Sheet

3003 aluminum has excellent processability, weldability, and corrosion resistance. Compared with 1100 aluminum, 3003 aluminum is approximately 20% stronger.

-

3003 h22 Aluminum Plate

3003 - H22 has good strength, high durability, easy machining, high corrosion resistance and light weight. The popular product is mainly 3003-H22 Bright Aluminum Tread Plate.

-

3003 h24 Aluminum Plate

Ensure the 3003 h24 Aluminum Plate meets the required specifications including dimensional accuracy, chemical composition, mechanical properties, and surface finish.

-

3003 h14 Aluminum Plate Sheet

3003-H14 aluminum plate has the characteristics of high strength, high durability, easy processing, strong corrosion resistance and light weight. 3003 aluminum is suitable for outdoor and harsh environment applications.

People also searched for Aluminum Plate

-

3004 Aluminum Plate Sheet

3004 aluminum is similar to 3003 aluminum, but it is stronger than 3003 alloy. 3004 aluminum also has good formability, good processability, excellent corrosion resistance and drawing characteristics.

-

3004 h19 Aluminum Plate Sheet

3004 H19 is a non-heat treatable aluminum alloy suitable for chemical and food contact applications, common ones such as beverage cans.

-

3004 h18 Aluminum Plate Sheet

3004-H18 aluminum is 3004 aluminum in the H18 state, which has higher strength, excellent formability and good corrosion resistance than 3003.

-

3004 o Aluminum Plate Sheet

3004-O aluminum is 3004 aluminum in the annealed condition. It has the lowest strength and highest ductility compared to other variants of 3004 aluminum.

-

3104 Aluminum Plate Sheet

The performance of the 3104 aluminum plate is stable, the surface is smooth, smooth, and free of defects, and the tolerance is strictly controlled to meet the standard.

-

3104 h19 Aluminum Plate Sheet

3104 h19 Aluminum Plate Sheet has precise specifications, good shape, high strength, easy processing, and good deep drawing performance.

-

3105 Aluminum Plate Sheet

3105 aluminum alloy is stronger than 1100 and 3003 alloys. 3105 aluminum sheet is often used in street signs, building siding and bottle caps.