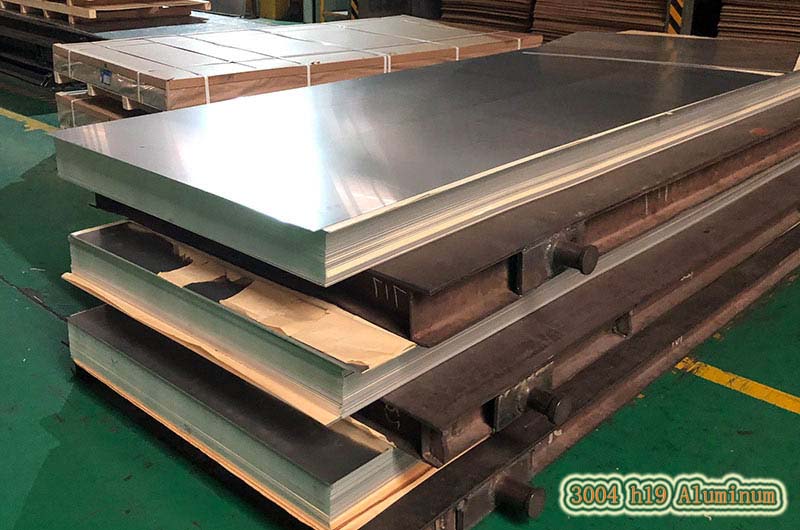

3004 h19 Aluminum Plate Sheet

Product Certification: ISO 9001 Precise Size Control

What is H19 Aluminum?

3004 H19 Aluminum refers to the 3004 alloy in the H19 temper. H19 is a strain hardening temper, which means the aluminum has been subjected to a cold working process to increase its strength.

3004-H19 Aluminum is 3004 aluminum in H19 condition. To achieve this temper, the metal is strain hardened to a strength that exceeds H18 by at least 10 MPa (or 1.5 ksi). It has the highest strength compared to other variants of 3004 aluminum.

3004 h19 Aluminum Plate Features

- Strength: 3004 H19 aluminum has higher strength than its annealed counterparts, such as H14 or H24 tempered conditions.

- Formability: Despite the strain hardening process, it maintains good formability, allowing various forming and manufacturing processes.

- Corrosion resistance: 3004 aluminum alloy, including H19 state, has excellent corrosion resistance and is suitable for outdoor applications.

- Surface Finish: The H19 temper generally has a bright, smooth surface finish.

3004 H19 Aluminum Plate Sheet Specifications

- Width: The width of the 3004 H19 aluminum plate may vary by manufacturer and application requirements. Common widths range from 1000 mm to 2000 mm (39.37 inches to 78.74 inches) and wider.

- Length: Similar to width, the 3004 H19 aluminum plate can vary in length. Typical lengths range from 2000 mm to 6000 mm (78.74 inches to 236.22 inches) or can be customized to meet specific project needs.

- Typical Sizes: Commonly used 3004 H19 aluminum plate sizes are 4ft x 8ft (1219mm x 2438mm) and 4ft x 10ft (1219mm x 3048mm). However, other sizes are also available, depending on the manufacturer.

- Common Thicknesses: Common thicknesses for 3004 H19 aluminum plate range from 1.0mm (0.039 inches) to 6.35mm (0.25 inches). However, thicker sheets can be produced upon specific request.

3004 h19 Aluminum Plate Tolerance

| Thickness | Thickness Tolerance ± | Width | Length | Width/ Length Tolerance ± |

| 0.032" 3004 h19 Aluminum Plate Sheet | 0.003 | 12" | 12" | 0.125 |

| 0.032" 3004 h19 Aluminum Plate Sheet | 0.003 | 12" | 24" | 0.125 |

| 0.032" 3004 h19 Aluminum Plate Sheet | 0.003 | 24" | 24" | 0.125 |

| 0.032" 3004 h19 Aluminum Plate Sheet | 0.003 | 24" | 48" | 0.125 |

| 0.040" 3004 h19 Aluminum Plate Sheet | 0.0035 | 12" | 12" | 0.125 |

| 0.040" 3004 h19 Aluminum Plate Sheet | 0.0035 | 12" | 24" | 0.125 |

| 0.040" 3004 h19 Aluminum Plate Sheet | 0.0035 | 24" | 24" | 0.125 |

| 0.040" 3004 h19 Aluminum Plate Sheet | 0.0035 | 24" | 48" | 0.125 |

| 0.050" 3004 h19 Aluminum Plate Sheet | 0.0035 | 12" | 12" | 0.125 |

| 0.050" 3004 h19 Aluminum Plate Sheet | 0.0035 | 12" | 24" | 0.125 |

| 0.050" 3004 h19 Aluminum Plate Sheet | 0.0035 | 24" | 24" | 0.125 |

| 0.050" 3004 h19 Aluminum Plate Sheet | 0.0035 | 24" | 48" | 0.125 |

| 0.080" 3004 h19 Aluminum Plate Sheet | 0.0045 | 12" | 12" | 0.125 |

| 0.080" 3004 h19 Aluminum Plate Sheet | 0.0045 | 12" | 24" | 0.125 |

| 0.080" 3004 h19 Aluminum Plate Sheet | 0.0045 | 24" | 24" | 0.125 |

| 0.080" 3004 h19 Aluminum Plate Sheet | 0.0045 | 24" | 48" | 0.125 |

| 0.080" 3004 h19 Aluminum Plate Sheet | 0.0045 | 48" | 96" | 0.125 |

| 0.080" 3004 h19 Aluminum Plate Sheet | 0.0045 | 48" | 120" | 0.125 |

| 0.080" 3004 h19 Aluminum Plate Sheet | 0.0045 | 48" | 144" | 0.125 |

| 0.100" 3004 h19 Aluminum Plate Sheet | 0.0055 | 48" | 96" | 0.125 |

| 0.100" 3004 h19 Aluminum Plate Sheet | 0.0055 | 48" | 120" | 0.125 |

| 0.100" 3004 h19 Aluminum Plate Sheet | 0.0055 | 48" | 144" | 0.125 |

| 0.125" 3004 h19 Aluminum Plate Sheet | 0.0055 | 12" | 12" | 0.125 |

| 0.125" 3004 h19 Aluminum Plate Sheet | 0.0055 | 12" | 24" | 0.125 |

| 0.125" 3004 h19 Aluminum Plate Sheet | 0.0055 | 24" | 24" | 0.125 |

| 0.125" 3004 h19 Aluminum Plate Sheet | 0.0055 | 24" | 48" | 0.125 |

| 0.160" 3004 h19 Aluminum Plate Sheet | 0.009 | 48" | 96" | 0.125 |

| 0.160" 3004 h19 Aluminum Plate Sheet | 0.009 | 48" | 120" | 0.125 |

| 0.250" 3004 h19 Aluminum Plate Sheet | 0.014 | 48" | 96" | 0.312 |

| 0.250" 3004 h19 Aluminum Plate Sheet | 0.014 | 48" | 120" | 0.312 |

| 0.375" 3004 h19 Aluminum Plate Sheet | 0.023 | 48" | 120" | 0.312 |

| 0.500" 3004 h19 Aluminum Plate Sheet | 0.023 | 48" | 96" | 0.312 |

3004 H19 Aluminum Plate Sheet Mechanical Properties

- Tensile Strength: 290 MPa - 330 MPa (42, 000 psi - 48, 000 psi)

- Yield Strength: 230 MPa - 280 MPa (33, 000 psi - 40, 000 psi)

- Elongation: 2% - 5%

- Hardness (Brinell): 70 - 90 HB

It should be noted that the specific dimensions, dimensions, and mechanical properties of the 3004 H19 aluminum sheet will vary slightly depending on the manufacturer and the specific production process. Therefore, it is advisable to consult the manufacturer or supplier regarding the specifications of the 3004 H19 aluminum sheet required for your application.

Aluminum 3004 h19 Applications

- Beverage cans: 3004 H19 aluminum is often used in the production of beverage cans, especially cans. The H19 condition provides the necessary strength and formability for efficient filling operations.

- Packaging: This tempered state of 3004 aluminum is also used in other packaging applications such as aerosol cans, food containers, and cosmetic packaging.

- Roof and Siding: Due to its increased strength, the 3004 H19 Aluminum plate can be used in roofing and siding applications, providing a durable and corrosion-resistant solution.

- Heat Exchangers: The combination of strength and formability makes 3004 H19 suitable for use in heat exchanger components where efficient heat transfer is critical.

Can Lid (Bottom) Material 3104-H19 Aluminum Plate

With the increase in personalized demand in the market, there is also an increasing demand for can packaging. The more commonly used can lid material is the 3104-H19 aluminum plate.

- Status: h19

- Thickness: 0.208-0.360mm

- Width: 800-1730mm

- Performance: excellent corrosion resistance, lightweight, high cleanliness, energy saving and environmental protection, high recycling rate.

3004 h19 Honeycomb Aluminum Foil

The aluminum honeycomb core is made of multiple layers of aluminum foil bonded, laminated, and then stretched and expanded into a regular hexagonal honeycomb core. 3004 h19 aluminum foil is a commonly used honeycomb aluminum foil base material.

3004 h19 aluminum foil has good anti-rust properties, and its strength is much higher than that of 1100 aluminum foil. The finished product is not easy to deform. The product is cleanly degreased, has high strength, and has a flat shape.

It is to be noted that the exact dimensions, dimensions, and production standards of 3004 H19 Aluminum may vary by manufacturer and customer requirements. Consultation with the supplier or manufacturer is recommended for accurate information and availability for your specific project needs.

Production Process of 3004 H19 Aluminum Plate

- Alloy preparation: The first step is to prepare 3004 aluminum alloy. This involves melting primary aluminum and adding alloying elements such as manganese (Mn) and magnesium (Mg) to achieve the desired chemical composition. The alloy is carefully controlled to meet specific quality and performance requirements.

- Casting: The molten 3004 aluminum alloy is cast into large slabs or billets using continuous casting or traditional ingot casting methods. This process helps solidify the aluminum into a manageable form for subsequent processing.

- Homogenization: The slab or slab is then homogenized to improve the microstructure of the alloy and relieve internal stresses. This step involves heating the metal to a specific temperature for a period of time to ensure an even distribution of alloying elements.

- Hot Rolling: Passing a homogenized billet or slab of aluminum through a series of rolling mills to reduce thickness and form a coil or plate. The metal is heated to the proper temperature to increase its ductility, and then continuously rolled to achieve the desired thickness.

- Annealing: After hot rolling, the aluminum sheet is annealed to relieve any residual stress and improve its mechanical properties. The sheet is heated to a specific temperature for a certain period of time, followed by controlled cooling. This process helps to improve the formability and stability of the aluminum sheet.

- Cold Rolling: The annealed aluminum sheet is then cold rolled to further reduce its thickness and improve the surface finish. The process involves passing the sheet through a series of cold rolling mills while applying pressure. Cold rolling also improves the mechanical properties and dimensional accuracy of the sheet.

- Final annealing: After cold rolling, aluminum plates may be subjected to a final annealing treatment to achieve the desired temper, such as H19. The sheet is heated and then rapidly quenched to set the mechanical properties specific to the H19 temper, including strength and formability.

- Finishing operations: Trimming, leveling, and cutting the aluminum sheet to size. They may have surface treatments such as cleaning, degreasing, and/or coating to enhance their appearance and corrosion resistance.

- Quality control: Throughout the production process, various quality control measures are implemented to ensure that the 3004 H19 aluminum sheet meets the specified requirements. This includes testing the chemical composition, mechanical properties, surface quality, and dimensions of the panels.

NOTE: The exact details of the production process may vary depending on the manufacturer, equipment used, and customer requirements. The steps above outline a typical production process for a 3004 H19 aluminum sheet.

3004 h19 Aluminum Plate Supplier

Haomei Aluminum is an experienced supplier of aluminum sheets, strictly controlling the production process during the production process, including strict inspection, testing, and monitoring of chemical composition, mechanical properties, dimensions, surface finish, and other related parameters.

- Manufacturing Standards: Adherence to recognized manufacturing standards such as ASTM (American Society for Testing and Materials) or EN (European Norms) ensures that production processes follow established guidelines. Compliance with standards helps maintain the consistent quality and performance of aluminum panels.

- Surface finish: The surface of the 3004 H19 aluminum plate is smooth and flat.

- Dimensional Accuracy: Precise dimensional control ensures the plate meets specified thickness, width, and length tolerances for ease of use and compatibility with intended applications.

- Mechanical Properties: The 3004 H19 Aluminum Plate has reliable and consistent mechanical properties including appropriate values for tensile strength, yield strength, elongation, and hardness to ensure that the sheet will withstand the expected loads and provide the required formability.

- Product certification: Product certifications, such as ISO 9001 (quality management systems) or industry-specific certifications, provide quality assurance and adherence to recognized standards.

Haomei Aluminum manufactures high-quality 3004 H19 Aluminum Plate for a wide range of application requirements while ensuring consistent performance and customer satisfaction.

-

3004 Aluminum Plate Sheet

3004 aluminum is similar to 3003 aluminum, but it is stronger than 3003 alloy. 3004 aluminum also has good formability, good processability, excellent corrosion resistance and drawing characteristics.

-

3004 h18 Aluminum Plate Sheet

3004-H18 aluminum is 3004 aluminum in the H18 state, which has higher strength, excellent formability and good corrosion resistance than 3003.

-

3004 o Aluminum Plate Sheet

3004-O aluminum is 3004 aluminum in the annealed condition. It has the lowest strength and highest ductility compared to other variants of 3004 aluminum.

People Also Searched about 3004 h19 Aluminum

- 3004 H19 Aluminum Coil Strip for Can Body

- What is H19 aluminum?

- What is 3004 aluminum used for?

- What is aluminum grade en aw 3004?

- How strong is 3004 aluminum?

- 3004 aluminum alloy

- 3004 aluminum

- 3004 aluminum properties

- 3004 aluminum sheet

- aluminum 3004 vs 6061

- aluminum 3004 properties

- 3004 aluminum alloy composition

- aluminum alloy 3004 melting point

- aluminum alloy al 3004 price

- al 5182

- al 5182 melting point

- aluminum 3104 properties

People also searched for Aluminum Plate

-

3003 Aluminum Plate Sheet

3003 aluminum has excellent processability, weldability, and corrosion resistance. Compared with 1100 aluminum, 3003 aluminum is approximately 20% stronger.

-

3003 h22 Aluminum Plate

3003 - H22 has good strength, high durability, easy machining, high corrosion resistance and light weight. The popular product is mainly 3003-H22 Bright Aluminum Tread Plate.

-

3003 h24 Aluminum Plate

Ensure the 3003 h24 Aluminum Plate meets the required specifications including dimensional accuracy, chemical composition, mechanical properties, and surface finish.

-

3003 O Aluminum Plate Sheet

3003 O-state aluminum plate has low hardness, and 3003 O-state aluminum plate is suitable for stamping, spinning, stretching, etc.

-

3003 h14 Aluminum Plate Sheet

3003-H14 aluminum plate has the characteristics of high strength, high durability, easy processing, strong corrosion resistance and light weight. 3003 aluminum is suitable for outdoor and harsh environment applications.

-

3104 Aluminum Plate Sheet

The performance of the 3104 aluminum plate is stable, the surface is smooth, smooth, and free of defects, and the tolerance is strictly controlled to meet the standard.

-

3104 h19 Aluminum Plate Sheet

3104 h19 Aluminum Plate Sheet has precise specifications, good shape, high strength, easy processing, and good deep drawing performance.

-

3105 Aluminum Plate Sheet

3105 aluminum alloy is stronger than 1100 and 3003 alloys. 3105 aluminum sheet is often used in street signs, building siding and bottle caps.