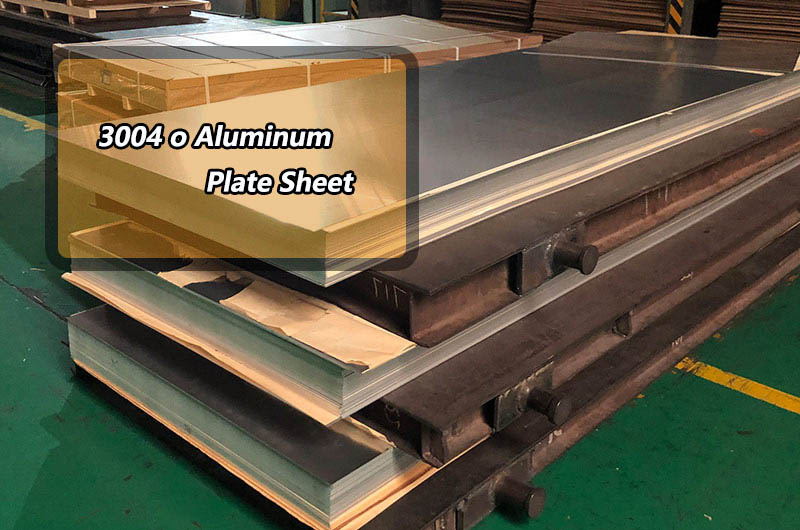

3004 o Aluminum Plate Sheet

Stable Performance Competitive Prices

3004 O aluminum plate refers to the 3004 aluminum alloy in the annealed (O) tempered state. The "O" temper designation indicates that the aluminum has been fully annealed, resulting in a soft and fully stress-relieved condition.

3004-O aluminum is 3004 aluminum in the annealed condition. It has the lowest strength and highest ductility compared to other variants of 3004 aluminum.

Aluminum alloy 3004 is commonly used in applications requiring moderate strength and good formability, such as beverage cans, automotive parts, and building materials. Its combination of properties makes it suitable for a wide range of industrial and commercial uses.

Eq to 3004: UNS A93004, ISO AlMn1Mg1, Aluminium 3004-O, AA3004-O, Al3004-O

3004 o The common application forms in aluminum life are Sheet, Foil, and Strip.

3004 o Aluminum Foil

- 3004 O recycled aluminum container foil

- 3004 aluminum foil for aluminum alloy wine cap

- 3004 O aluminum foil for single cavity lunch box

3004 o Aluminum Plate Sheet

- Lamp material 3004-O aluminum plate

- 3004 deep-drawn aluminum plate for transformer shell

3004 O Aluminum Plate Sheet Features

- Softness: 3004 O aluminum plate is highly ductile and easy to form due to its soft tempered condition. They can be bent, shaped, and manipulated without cracking or breaking.

- Ductility: O tempering gives aluminum plate excellent ductility, allowing it to be stretched and elongated without tearing.

- Surface Finish: 3004 O aluminum plate usually has a smooth and shiny surface finish.

- Corrosion resistance: 3004 aluminum alloy, including O temper, has good corrosion resistance and is suitable for a variety of indoor and less demanding outdoor applications.

- Conductivity: Aluminum has excellent conductivity, and the 3004 O aluminum plate can be used in electrical applications that require conductivity.

3004 O Aluminum Plate Sheet Specifications

- Width: The width of a 3004 O aluminum plate sheet may vary by manufacturer and application requirements. Common widths range from 1000 mm to 2000 mm (39.37 inches to 78.74 inches) and wider.

- Length: Similar to width, 3004 O aluminum plate sheets can vary in length. Typical lengths range from 2000 mm to 6000 mm (78.74 inches to 236.22 inches) or can be customized to meet specific project needs.

- Typical Sizes: Commonly used 3004 O aluminum plate sizes are 4ft x 8ft (1219mm x 2438mm) and 4ft x 10ft (1219mm x 3048mm). However, other sizes are also available, depending on the manufacturer.

- Common Thicknesses: Common thicknesses for the 3004 O aluminum plate range from 1.0mm (0.039 inches) to 6.35mm (0.25 inches). However, thicker sheets can be produced upon specific request.

3004 O Aluminum Sheet Plate Processing Performance

- 1. Good formability, particularly in thicker gauges.

- 2. Excellent resistance to corrosion, making it suitable for various environments.

- 3. Welding: Can be welded using various methods such as MIG, TIG, and resistance welding.

- 4. Machinability: Fair to good machinability; proper tooling and machining techniques are necessary.

Chemical Composition of Aluminum Alloy 3004

- Aluminum (Al): Balance

- Manganese (Mn): 1.0-1.5%

- Magnesium (Mg): 0.8-1.3%

- Silicon (Si): 0.3% max

- Iron (Fe): 0.7% max

- Copper (Cu): 0.25% max

- Zinc (Zn): 0.25% max

- Titanium (Ti): 0.15% max

- Others: 0.05% each, 0.15% total max

3004 O Aluminum Sheet Plate Physical Properties

- Density: 2.68 g/cm³

- Melting Point: ~607-650°C (1125-1202°F)

- Electrical Conductivity: 26% IACS (International Annealed Copper Standard)

- Thermal Conductivity: 190 W/m-K

- Coefficient of Thermal Expansion (CTE): 23.8 µm/m°C

3004 O Aluminum Plate Sheet Mechanical Properties

- Tensile Strength (Ultimate): 145-195 MPa

- Yield Strength (0.2% Offset): 115-160 MPa

- Elongation at Break: 10-20%

- Modulus of Elasticity: 69 GPa

- Poisson's Ratio: 0.33

3004 O Aluminum Plate Sheet Thermal Properties

- Thermal Conductivity: 190 W/m-K

- Specific Heat Capacity: 0.897 J/g°C

- Thermal Expansion: 23.8 µm/m°C

Typical 3004 o Aluminum Plate

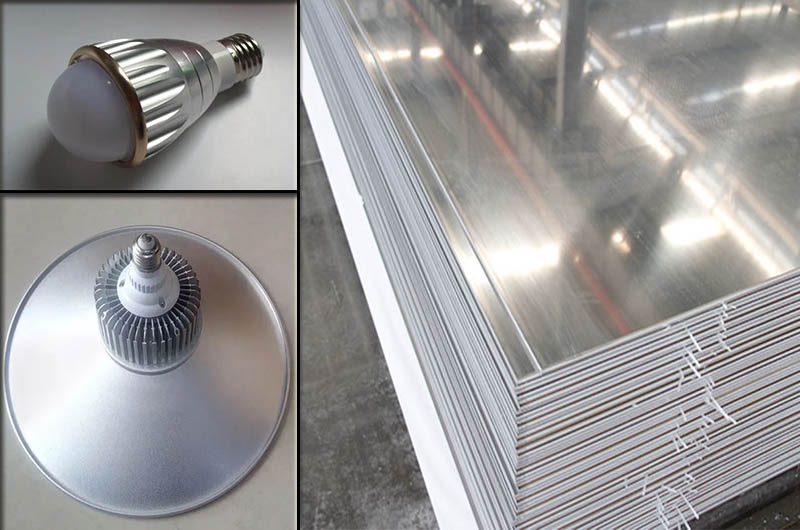

Lamp Material 3004-O Aluminum Plate

The aluminum alloy lamp head is processed and produced with 3 series aluminum magnesium manganese plate material. The common alloys are 3004-o aluminum plate and 3104-o aluminum plate. Containing manganese, it can improve the resistance to stress corrosion cracking, improve the strength of the base metal and weld, and reduce the tendency of welding cracks.

3004 aluminum plate has excellent performance for lamp head material

- It has good plasticity and is easy to process and shape.

- Excellent corrosion resistance, and strong stress corrosion cracking ability.

- A small amount of Mg is added to improve the tensile strength.

- Excellent welding performance, high recyclability, low carbon, and environmental protection.

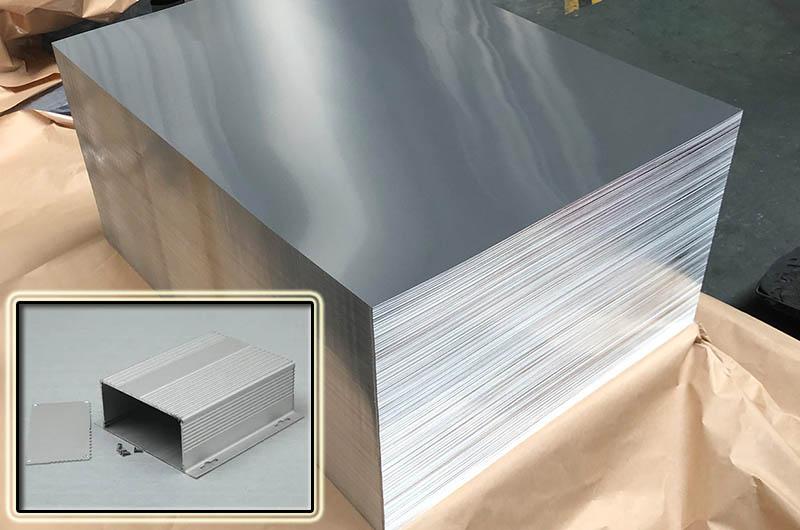

3004 Deep-drawn Aluminum Plate for Transformer Shell

The photovoltaic inverter is an indispensable equipment for photovoltaic stations. It is especially used in the field of solar photovoltaic power generation. Its biggest role is to convert the direct current generated by solar cells into alternating current energy that can be directly integrated into the grid and loaded through power electronic conversion technology.

Aluminum alloy photovoltaic inverter casings usually use 1060 aluminum sheets, 1070 aluminum sheets, 3004 aluminum sheets, 5052 aluminum sheets, etc. In comparison, 3004 aluminum sheets have outstanding performance advantages and are more suitable for use as photovoltaic inverter casings.

Tensile strength 5052 >3004 >1060/1070

Since the hardness of 3004 alloy is higher than that of 1070 in the same state, it can replace the first series and reduce the thickness of the shell, thereby reducing product procurement costs.

- 3004 alloy has fine lines and is easy to make stamping products, and 3004 alloy is an anti-rust aluminum product with good oxidation resistance.

- The 3004 alloys can also replace the 5052 alloys under the condition of the same or close performance, which has a price advantage.

3004 Aluminum Plate Applications

- General Forming and Fabrication: A 3004 O Aluminum plate is commonly used for general forming and fabrication purposes such as producing complex shapes, brackets, and other components that require easy forming.

- Roof and Siding: The softness and ease of formability of the 3004 O aluminum plate make it suitable for roof and siding applications requiring gentle curves or contours.

- Heat Shields: The malleability of 3004 O aluminum plate allows it to be used in applications requiring heat shields or panels, such as automotive or industrial environments.

- Insulating Jacketing: The excellent ductility of the 3004 O Aluminum plate allows it to be easily wrapped around pipes or used as insulating jacketing material in HVAC systems.

- Reflectors: The reflective properties of aluminum combined with the formability of 3004 O aluminum plate make it suitable for applications requiring reflective surfaces such as light fixtures or signage.

It should be noted that the specific dimensions, dimensions, and production standards of 3004O aluminum sheets may vary depending on manufacturer and customer requirements. Consultation with the supplier or manufacturer is recommended for accurate information and availability for your specific project needs.

3004-O Aluminum Plate Manufacturer

Haomei Aluminum has strict factory quality standards. Many products can be customized. The after-sales service is relatively complete, the production is arranged quickly, and the delivery is timely. If you want to know more and more specific product information and preferential quotations, please feel free to consult online.

-

3004 Aluminum Plate Sheet

3004 aluminum is similar to 3003 aluminum, but it is stronger than 3003 alloy. 3004 aluminum also has good formability, good processability, excellent corrosion resistance and drawing characteristics.

-

3004 h19 Aluminum Plate Sheet

3004 H19 is a non-heat treatable aluminum alloy suitable for chemical and food contact applications, common ones such as beverage cans.

-

3004 h18 Aluminum Plate Sheet

3004-H18 aluminum is 3004 aluminum in the H18 state, which has higher strength, excellent formability and good corrosion resistance than 3003.

People also searched for Aluminum Plate

-

3003 Aluminum Plate Sheet

3003 aluminum has excellent processability, weldability, and corrosion resistance. Compared with 1100 aluminum, 3003 aluminum is approximately 20% stronger.

-

3003 h22 Aluminum Plate

3003 - H22 has good strength, high durability, easy machining, high corrosion resistance and light weight. The popular product is mainly 3003-H22 Bright Aluminum Tread Plate.

-

3003 h24 Aluminum Plate

Ensure the 3003 h24 Aluminum Plate meets the required specifications including dimensional accuracy, chemical composition, mechanical properties, and surface finish.

-

3003 O Aluminum Plate Sheet

3003 O-state aluminum plate has low hardness, and 3003 O-state aluminum plate is suitable for stamping, spinning, stretching, etc.

-

3003 h14 Aluminum Plate Sheet

3003-H14 aluminum plate has the characteristics of high strength, high durability, easy processing, strong corrosion resistance and light weight. 3003 aluminum is suitable for outdoor and harsh environment applications.

-

3104 Aluminum Plate Sheet

The performance of the 3104 aluminum plate is stable, the surface is smooth, smooth, and free of defects, and the tolerance is strictly controlled to meet the standard.

-

3104 h19 Aluminum Plate Sheet

3104 h19 Aluminum Plate Sheet has precise specifications, good shape, high strength, easy processing, and good deep drawing performance.

-

3105 Aluminum Plate Sheet

3105 aluminum alloy is stronger than 1100 and 3003 alloys. 3105 aluminum sheet is often used in street signs, building siding and bottle caps.