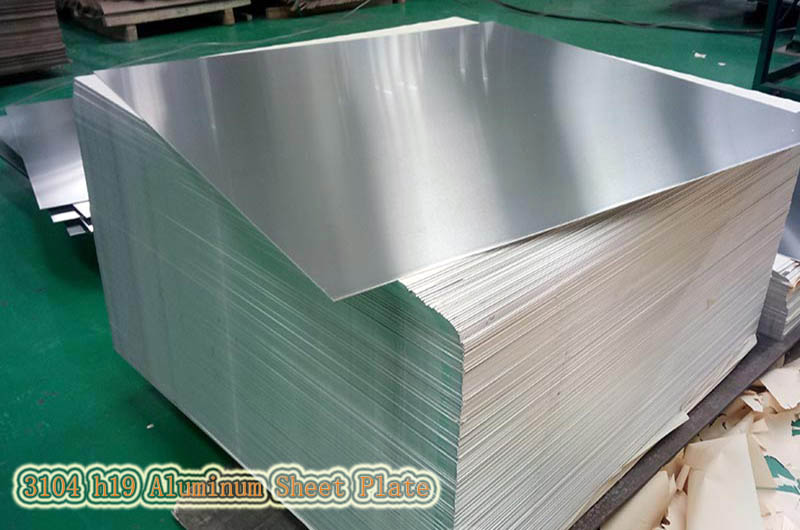

3104 h19 Aluminum Plate Sheet

High Dimensional Accuracy High Flatness

3104-H19 aluminum plate is a special tempered state of 3104 aluminum alloy. Here are the details:

- Status: 3104-H19 Aluminum Sheet/Sheet is usually supplied in flat or plank form.

- Temper: H19 indicates a tempered condition characterized by a high degree of strain hardening without subsequent annealing. It undergoes a cold working or strain-hardening process to increase its strength and hardness.

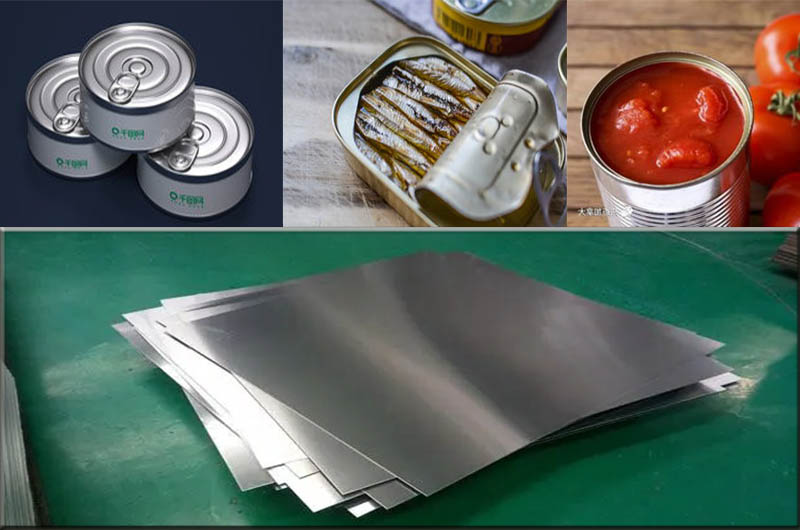

The can lid material can be made of 3104-H19 aluminum sheet. 3104 h19 Aluminum Sheet is suitable for all cans except sparkling beverages, such as canned pet food, canned beef, canned fruit, rice pudding, etc.

Aluminum 3104 H19 Data Sheet

3104 H19 Aluminum Plate Specifications

- Width: 1000mm - 2000mm (39" to 79").

- Length: 2000mm - 6000mm (79" to 236") standard lengths.

- Thickness: 0.2mm - 6mm (0.008" to 0.24"), 3104-H19 Aluminum Sheet/Plate is available in a variety of thicknesses which may vary by supplier and manufacturing capability.

Common Thicknesses of 3104 H19 Aluminum Plate

| Aluminum Plate | Common Thickness (mm) | Common Thickness (inches) |

|---|---|---|

| 3104 H19 Aluminum Plate | 0.5 mm | 0.020 inches |

| 3104 H19 Aluminum Plate | 1.0 mm | 0.039 inches |

| 3104 H19 Aluminum Plate | 1.5 mm | 0.059 inches |

| 3104 H19 Aluminum Plate | 2.0 mm | 0.079 inches |

| 3104 H19 Aluminum Plate | 3.0 mm | 0.118 inches |

| 3104 H19 Aluminum Plate | 4.0 mm and above | 0.157 inches and above |

3104 H19 Aluminum Plate Standards

- ASTM B209: Standard Specification for Aluminum and Aluminum Alloy Sheet and Plate

- EN 485: Aluminum and aluminum alloys - Plate, strip, and plate

3104 H19 Aluminum Plate Mechanical Behavior

- Tensile Strength: The tensile strength of 3104-H19 aluminum sheet/plate is typically about 185 MPa (26, 900 psi).

- Yield Strength: Yield strength is approximately 165 MPa (24, 000 psi).

- Elongation: Elongation at break is typically between 8% and 12%.

These values are approximate and may vary depending on the specific manufacturing process and thickness of the board/sheet.

3104 H19 Aluminum Plate Certified

- ISO 9001: This certification ensures that a manufacturer has implemented a quality management system and meets specified quality standards.

- ISO 14001: This certification demonstrates that a manufacturer has implemented an environmental management system and follows environmentally sustainable practices.

Other product certifications may vary by manufacturer and customer requirements. Examples might include certifications related to specific industries, safety standards, or customer-specific requirements.

NOTE: Specifications, size options, production standards, and product certifications may vary by manufacturer, region, and application-specific requirements. For accurate information and availability, it is recommended to consult an aluminum supplier or a manufacturer specializing in 3104-H19 aluminum plates.

When is the 3104 H19 Aluminum Plate the Best Choice?

1. Cost-Effective

Compared to some other aluminum alloys, 3104 H19 can be a cost-effective option, making it appealing for applications where budget constraints are a concern.

2. Strength and Stiffness

While not as strong as some other aluminum alloys, 3104 H19 still offers sufficient strength and stiffness for applications where moderate mechanical properties are required. This can include automotive components, brackets, and panels.

3. Food and Beverage Packaging

This alloy is commonly used in the manufacturing of food and beverage cans due to its corrosion resistance and formability. It meets the requirements for maintaining the freshness and safety of the contents.

4. Corrosion Resistance

3104 H19 aluminum plate offers good corrosion resistance, making it suitable for applications where exposure to moisture, chemicals, or corrosive environments is a concern. This can include outdoor structures, marine components, or chemical processing equipment.

5. Formability

3104 aluminum alloy is known for its excellent formability, which means it can be easily shaped, bent, and formed without cracking or losing its structural integrity. It's often used in the manufacture of cans, containers, and various formed parts.

6. Weldability

3104 H19 can be welded using common methods such as MIG and TIG welding. If your project involves welding aluminum components, this alloy may be a suitable choice.

7. Heat Exchangers

In some cases, the 3104 H19 aluminum plate may be used in the construction of heat exchangers due to its corrosion resistance and heat transfer properties.

It's important to note that the suitability of the 3104 H19 aluminum plate for your specific application will also depend on factors such as the required thickness, size, and shape of the components, as well as any regulatory or industry standards that must be met.

3104 H19 Aluminum Plate Sheet Applications

3104-H19 Aluminum Sheet/Plate is commonly used in applications requiring high strength and formability. Some examples include beverage cans, can ends, and other packaging applications.

Can Lid Material 3104-H19 Aluminum Plate

Aluminum cans are lightweight, easy to open, and easy to recycle, and are quickly loved by the public and have developed rapidly in a short period of time.

The can is composed of a can lid, can bottom, can body, and pull ring. It supplies 3104-h19 aluminum plate, 5052-h19 aluminum plate, and pull ring material for 5182-h19 aluminum plate. It has excellent quality and stable performance.

Can Body

- Alloy: 3104-H19, 3004

- These alloys provide a good balance of strength, formability, and corrosion resistance, making them suitable for forming tank bodies.

Alloy selection may depend on specific requirements such as tank size, application, and regional preference.

Can Lid (End)

- Alloy: 5052, 5182

- These alloys have excellent strength and corrosion resistance, making them suitable for can ends.

Alloy selection may vary based on factors such as tank size, pressure requirements, and specific customer preferences.

Pull Ring

- Alloy: 5182 or 5052

- The pull ring is the ring used to open the can.

Alloys used for can ends are typically used for tabs due to their strength and formability requirements.

It is important to note that specific alloy selection may vary by manufacturer, region, and size. Also, alloy selection may vary for specific applications or special requirements.

Can Lid Material 3104-h19 Aluminum Plate Specifications

- Thickness: 0.208-0.360mm

- Width: 800-1730mm

Performance Characteristics of 3104-h19 Aluminum Plate for Can Lid Material

- 3104 aluminum alloy has high strength and excellent elongation.

- Has good deep drawing performance and corrosion resistance.

- It has good processing performance, can be welded, and has excellent forming performance.

- Small density, lightweight, high recyclable value, widely used in food cans, lids, and bottom materials.

Food Can Lid Material 3104-H19 Aluminum Plate

Canned food is a special form of food preservation, usually made of metal sheet, glass, plastic, cardboard, or a combination of some of the above materials into a sealable container, used to preserve food can extend its shelf life, easy to carry, transport, and storage.

3104-h19 aluminum plate, 5182 aluminum plate, 5052 aluminum plate, etc. can be used for metal can lids to meet various performance requirements of food containers.

The 3104 aluminum plate for food cans is a deformed aluminum alloy with high tensile strength, high elongation, and good deep drawing performance. It is suitable for thinning, and stretching, and is light-weight to reduce material consumption.

Food cans and lids have strict requirements on the materials and processes. Haomei Aluminum strictly controls each process to make the product have appropriate strength and formability.

3104 h19 Aluminum Plate vs 3004 h19 Aluminum Plate

Alloy Composition

- 3104-H19 aluminum plate: The alloy composition is mainly composed of aluminum, manganese, and magnesium. It is designed for high-strength applications.

- 3004-H19 aluminum plate: The alloy composition includes aluminum, manganese, and a small amount of magnesium. It is also known for its high strength and formability.

Mechanical Behavior

- 3104-H19 Aluminum Plate: It has a high tensile strength, typically about 185 MPa (26, 900 psi), and a yield strength of about 165 MPa (24, 000 psi). Elongation at break is typically between 8% and 12%.

- 3004-H19 Aluminum Plate: It also offers high tensile and yield strength values comparable to 3104-H19. The specific mechanical properties are similar but may vary slightly depending on the manufacturing process and the specific thickness of the plate.

Application

- 3104-H19 Aluminum Plate: Commonly used in applications requiring high strength and formability, such as beverage cans, can ends, and other packaging applications.

- 3004-H19 Aluminum Plate: It is also used in similar applications to 3104-H19, including beverage cans, can ends, and packaging applications requiring high strength and formability.

Alloy Specification

While both alloys, 3104 and 3004, are known for their high strength and formability, they may have slightly different composition and performance characteristics. These differences may be due to changes in alloy chemistry and processing parameters.

Note: The specific properties and applications of aluminum sheets may vary depending on factors such as thickness, manufacturing process, and customer requirements. Consultation with aluminum suppliers or manufacturers is recommended for accurate information on the suitability of these alloys for specific applications.

3104 h19 Aluminum Sheet Plate Supplier

3104 aluminum plate is a popular product of Haomei Aluminum in the market. According to the feedback from cooperative users, this 3104 deep-drawing aluminum plate has stable and reliable performance, exquisite workmanship, excellent shape, plate surface, control thickness, mechanical properties and other aspects. , has good formability and strength, so the usage rate in the market is getting higher and higher.

The product quality of Haomei Aluminum is guaranteed, the after-sales service is perfect, and the products are all directly ex-factory prices, which are more competitive than other merchants.

-

3104 Aluminum Plate Sheet

The performance of the 3104 aluminum plate is stable, the surface is smooth, smooth, and free of defects, and the tolerance is strictly controlled to meet the standard.

-

3104 o Aluminum Sheet Plate

3104-O aluminum is 3104 aluminum in the annealed condition. It has the lowest strength and highest ductility compared to other variants of 3104 aluminum.

People also searched for Aluminum Plate

-

3105 Aluminum Plate Sheet

3105 aluminum alloy is stronger than 1100 and 3003 alloys. 3105 aluminum sheet is often used in street signs, building siding and bottle caps.

-

3004 Aluminum Plate Sheet

3004 aluminum is similar to 3003 aluminum, but it is stronger than 3003 alloy. 3004 aluminum also has good formability, good processability, excellent corrosion resistance and drawing characteristics.

-

3004 h19 Aluminum Plate Sheet

3004 H19 is a non-heat treatable aluminum alloy suitable for chemical and food contact applications, common ones such as beverage cans.

-

3004 h18 Aluminum Plate Sheet

3004-H18 aluminum is 3004 aluminum in the H18 state, which has higher strength, excellent formability and good corrosion resistance than 3003.

-

3004 o Aluminum Plate Sheet

3004-O aluminum is 3004 aluminum in the annealed condition. It has the lowest strength and highest ductility compared to other variants of 3004 aluminum.

-

3003 h14 Aluminum Plate Sheet

3003-H14 aluminum plate has the characteristics of high strength, high durability, easy processing, strong corrosion resistance and light weight. 3003 aluminum is suitable for outdoor and harsh environment applications.

-

3003 O Aluminum Plate Sheet

3003 O-state aluminum plate has low hardness, and 3003 O-state aluminum plate is suitable for stamping, spinning, stretching, etc.

-

3003 h24 Aluminum Plate

Ensure the 3003 h24 Aluminum Plate meets the required specifications including dimensional accuracy, chemical composition, mechanical properties, and surface finish.

-

3003 h22 Aluminum Plate

3003 - H22 has good strength, high durability, easy machining, high corrosion resistance and light weight. The popular product is mainly 3003-H22 Bright Aluminum Tread Plate.

-

3003 Aluminum Plate Sheet

3003 aluminum has excellent processability, weldability, and corrosion resistance. Compared with 1100 aluminum, 3003 aluminum is approximately 20% stronger.