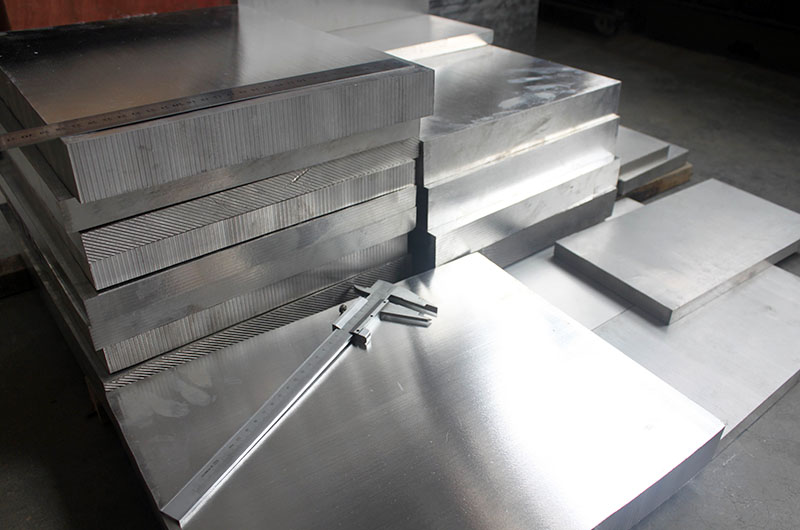

3104 o Aluminum Sheet Plate

Highest ductility Complete Specifications , Reasonable Price

Aluminum alloy lamp holders are processed and produced with 3 series aluminum magnesium manganese plate materials. The common alloy 3104-o aluminum plate is used. The aluminum alloy lamp holder material is made of 3104-o aluminum plate material and is not easy to crack when stretched and stamped. This is because the 3104 aluminum plate product contains manganese element, which can Improve the resistance to stress corrosion cracking, increase the strength of the base metal and welds, and reduce the tendency of welding cracks.

Haomei Aluminum supplies 3104 aluminum plate

- Material status F, O, H12, H14, H16H18, H19, H22, H24, H26, H28, H112, H114

- Thickness(mm)0.1-500

- Width (mm)100-2650

- Length(mm)500-16000

3104 o aluminum sheet plate characteristics

- Corrosion Resistance: 3104-O alloy has good corrosion resistance, especially when exposed to moisture and atmospheric conditions. The presence of manganese enhances its ability to resist corrosion.

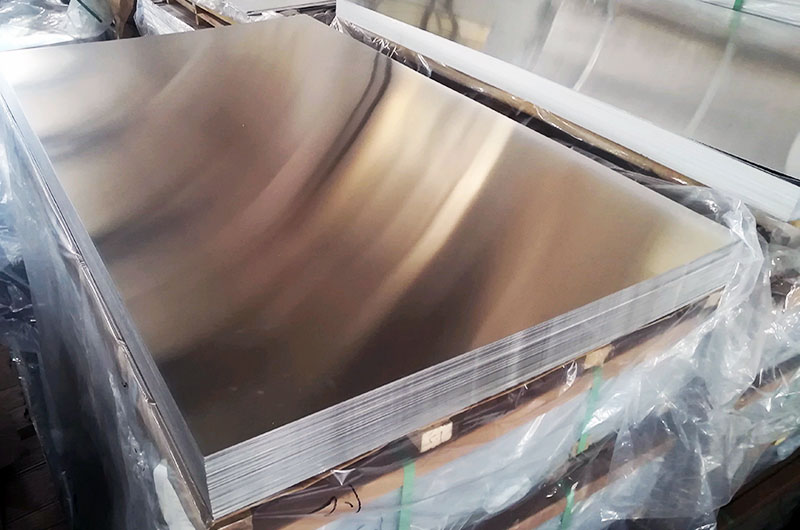

- Processability: Due to its softness, 3104-O aluminum is highly processable. It can be easily formed, stretched or spun, making it suitable for a variety of manufacturing processes.

- Surface Finish: This alloy provides a good surface finish and can be polished or coated to meet specific aesthetic or functional requirements.

3104 o Aluminum Comparison with Other Tempers of 3104 Aluminum

3104-H34 aluminum sheet plate

The H34 temper strikes a balance between strength and formability. It provides moderate tensile strength and yield strength while maintaining sufficient ductility required for the molding process. This temper is often used in applications where strength and formability are important, such as automotive body panels.

3104-H16 aluminum sheet plate

The H16 state provides a middle ground with performance between the O and H34 states. It is moderately work hardened compared to H19, providing greater strength while maintaining better formability. This makes it suitable for applications such as structural components and containers that require balanced performance.

-

3104 h19 Aluminum Plate Sheet

3104 h19 Aluminum Plate Sheet has precise specifications, good shape, high strength, easy processing, and good deep drawing performance.

-

3104 Aluminum Plate Sheet

The performance of the 3104 aluminum plate is stable, the surface is smooth, smooth, and free of defects, and the tolerance is strictly controlled to meet the standard.

Advantages and Disadvantages of 3104-O Aluminum

3104 o aluminum sheet plate advantages

- Formability: The primary advantage of 3104-O aluminum is its excellent formability. The soft temper allows it to be easily shaped into complex forms without cracking.

- Corrosion Resistance: The alloy's good resistance to corrosion makes it suitable for use in environments where exposure to moisture and other corrosive elements is a concern.

- Lightweight: As an aluminum alloy, it is inherently lightweight, which is beneficial for applications where weight reduction is important, such as in automotive and aerospace industries.

- Recyclability: Aluminum is highly recyclable, and using 3104-O aluminum contributes to sustainable manufacturing practices.

3104 o aluminum sheet plate disadvantages

- Low Strength: The primary drawback of 3104-O aluminum is its low tensile and yield strength. This limits its use in applications requiring high structural strength.

- Wear Resistance: The soft temper makes the alloy less resistant to wear and abrasion, which can be a limitation in applications involving significant mechanical stress.

- Thermal Stability: While the alloy has good thermal conductivity, its soft temper can result in reduced thermal stability under high temperatures, affecting its mechanical properties.

Applications of 3104-O Aluminum Sheet Plate

The unique combination of properties makes 3104-O aluminum sheet plates suitable for a range of applications. Below are some of the key areas where this material is used:

3104-O Aluminum Sheet Plate for Packaging Industry

3104-O aluminum is extensively used in the packaging industry, particularly for the production of beverage cans and closures. The material's formability, combined with its good corrosion resistance, makes it ideal for creating thin-walled containers that are both lightweight and durable. The ability to withstand pressure without rupturing is crucial for maintaining the integrity of carbonated beverages.

3104-O Aluminum Sheet Plate for Automotive Industry

In the automotive industry, 3104-O aluminum is used for making various components that benefit from its lightweight and corrosion-resistant properties. Applications include heat shields, interior panels, and trim components. The material helps reduce the overall weight of vehicles, contributing to improved fuel efficiency and lower emissions.

3104-O Aluminum Sheet Plate for Building and Construction

For building and construction, 3104-O aluminum sheet plates are used in applications such as roofing, siding, and architectural panels. The alloy's ability to withstand harsh environmental conditions without corroding makes it a preferred choice for exterior applications. Additionally, its formability allows for creative architectural designs.

3104-O Aluminum Sheet Plate for HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems often use 3104-O aluminum for components like fins, coils, and heat exchangers. The material's thermal conductivity and resistance to corrosion make it effective for efficient heat transfer and long-lasting performance.

3104-O Aluminum Sheet Plate for 3C

In the consumer electronics industry, 3104-O aluminum is used for casings and structural components of devices like laptops and smartphones. The lightweight nature of the alloy, combined with its ability to be easily machined and finished, makes it ideal for sleek, durable electronic housings.

Processing Techniques for 3104-O Aluminum

Rolling

One of the primary methods for producing 3104-O aluminum sheet plates is through rolling. The process involves passing the aluminum alloy between heavy rollers under high pressure to achieve the desired thickness. The annealing process is typically conducted after rolling to achieve the O temper.

Deep Drawing 3104-O Aluminum

Drawing is a forming process used to produce hollow shapes and thin-walled containers from 3104-O aluminum. The high ductility of the O temper allows the material to be stretched and shaped without breaking, making it suitable for deep-drawing applications.

Spinning 3104-O Aluminum

Metal spinning involves rotating a disk or tube of 3104-O aluminum at high speed while pressing it against a form to shape it into axially symmetric parts. This technique is used to create complex, rounded shapes like cooking utensils and industrial components.

Stamping

Stamping is another common process used with 3104-O aluminum sheet plates. It involves cutting and shaping the material using a die and press. The process is efficient for producing large quantities of parts with consistent dimensions and quality.

3104-O Aluminum Sheet is a versatile material with unique properties that make it suitable for a wide range of applications. Its excellent formability, good corrosion resistance and lightweight properties have significant advantages in industries such as packaging, automotive, construction, HVAC and consumer electronics.

People also searched for Aluminum Plate

-

3004 Aluminum Plate Sheet

3004 aluminum is similar to 3003 aluminum, but it is stronger than 3003 alloy. 3004 aluminum also has good formability, good processability, excellent corrosion resistance and drawing characteristics.

-

3004 h19 Aluminum Plate Sheet

3004 H19 is a non-heat treatable aluminum alloy suitable for chemical and food contact applications, common ones such as beverage cans.

-

3004 h18 Aluminum Plate Sheet

3004-H18 aluminum is 3004 aluminum in the H18 state, which has higher strength, excellent formability and good corrosion resistance than 3003.

-

3004 o Aluminum Plate Sheet

3004-O aluminum is 3004 aluminum in the annealed condition. It has the lowest strength and highest ductility compared to other variants of 3004 aluminum.

-

3105 Aluminum Plate Sheet

3105 aluminum alloy is stronger than 1100 and 3003 alloys. 3105 aluminum sheet is often used in street signs, building siding and bottle caps.

-

3003 h14 Aluminum Plate Sheet

3003-H14 aluminum plate has the characteristics of high strength, high durability, easy processing, strong corrosion resistance and light weight. 3003 aluminum is suitable for outdoor and harsh environment applications.

-

3003 O Aluminum Plate Sheet

3003 O-state aluminum plate has low hardness, and 3003 O-state aluminum plate is suitable for stamping, spinning, stretching, etc.

-

3003 h24 Aluminum Plate

Ensure the 3003 h24 Aluminum Plate meets the required specifications including dimensional accuracy, chemical composition, mechanical properties, and surface finish.

-

3003 h22 Aluminum Plate

3003 - H22 has good strength, high durability, easy machining, high corrosion resistance and light weight. The popular product is mainly 3003-H22 Bright Aluminum Tread Plate.

-

3003 Aluminum Plate Sheet

3003 aluminum has excellent processability, weldability, and corrosion resistance. Compared with 1100 aluminum, 3003 aluminum is approximately 20% stronger.