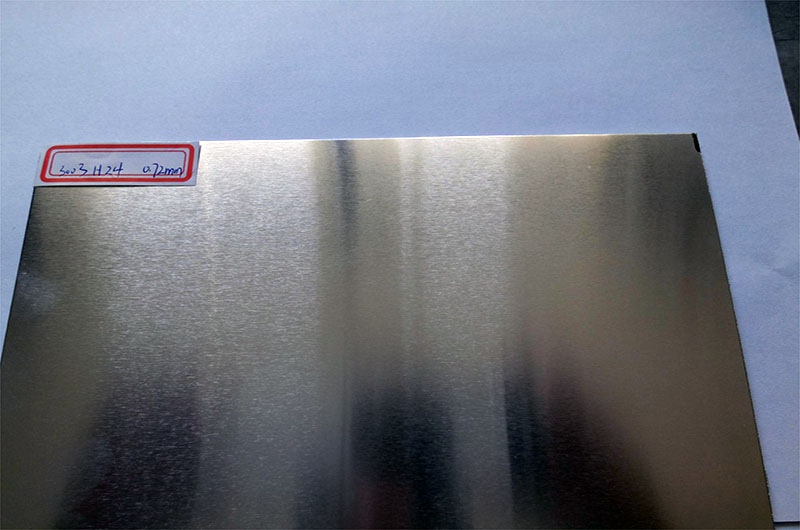

3003 h24 Aluminum Plate

Production Standard: ASTM B209, AMS-QQ-A-250/2 Dimensional Accuracy

What is H24 in Aluminum?

H24 is a specific temper designation for aluminum alloys. It indicates the tempering condition and mechanical properties of 3003 aluminum.

In the H24 temper, the letter "H" indicates that the aluminum has been strain-hardened or work-hardened. This involves plastically deforming aluminum, such as rolling or cold working, to increase its strength and hardness.

3003-H24 aluminum is 3003 aluminum in the H24 state. To achieve this state, the metal is strain hardened and then partially annealed, with a strength roughly between annealed (O) and fully hard (H28).

3003 H24 aluminum production process flow: casting-rolling-annealing-finished product packaging.

The number "24" after the "H" indicates the specific level of strain hardening and stability achieved. In the H24 temper, 3003 aluminum is strain hardened to a quarter hard temper and then stabilized. This means that the material has been moderately hardened and then subjected to a low-temperature annealing process to relieve some of the internal stress and increase its stability.

Aluminum alloys tempered with H24 generally exhibit higher strength and hardness compared to annealed or softer tempered conditions.

They may be slightly less ductile and formable than softer tempers.

The 3003 H24 temper is typically used in applications requiring a balance of strength, formability, and stability. It is frequently found in sheet metal applications including roofing, siding, and general fabrication. Additionally, it can be found in various structural components, storage tanks, and automotive components that require moderate strength and resistance to deformation.

Aluminum 3003 H24 Data Sheet

Width and Length

3003 H24 Aluminum Sheet is available in various widths and lengths and custom sizes are also available upon request.

- Common widths range from 36 inches (914mm) to 72 inches (1828mm).

- Lengths typically range from 96 inches (2438 mm) to 144 inches (3658 mm).

-

3003 Aluminum Plate Sheet

3003 aluminum has excellent processability, weldability, and corrosion resistance. Compared with 1100 aluminum, 3003 aluminum is approximately 20% stronger.

-

3003 h22 Aluminum Plate

3003 - H22 has good strength, high durability, easy machining, high corrosion resistance and light weight. The popular product is mainly 3003-H22 Bright Aluminum Tread Plate.

-

3003 h14 Aluminum Plate Sheet

3003-H14 aluminum plate has the characteristics of high strength, high durability, easy processing, strong corrosion resistance and light weight. 3003 aluminum is suitable for outdoor and harsh environment applications.

-

3003 O Aluminum Plate Sheet

3003 O-state aluminum plate has low hardness, and 3003 O-state aluminum plate is suitable for stamping, spinning, stretching, etc.

3003 h24 Aluminum Plate Properties

3003 h24 Aluminum Plate General

| Property | Temperature | Value |

| Density | 23.0 °C | 2.73 g/cm³ |

3003 h24 Aluminum Plate Dimension

| Property | Value |

| Thickness | 0.2 - 1 mm |

3003 h24 Aluminum Plate Mechanical

| Property | Temperature | Value |

| Bending angle 180° | 23.0 °C | 1 °/t |

| Bending angle 90° | 23.0 °C | 0.5 °/t |

| Elastic modulus | 23.0 °C | 69 GPa |

| Elongation A50 | 23.0 °C | 4 % |

| Hardness, HBW | 23.0 °C | 37 - 45 [-] |

| Shear modulus | 23.0 °C | 26 GPa |

| Tensile strength | 23.0 °C | 120 - 185 MPa |

| Yield strength | 23.0 °C | 80 MPa |

3003 h24 Aluminum Plate Thermal

| Property | Temperature | Value | Comment |

| Coefficient of thermal expansion | 100.0 °C | 2.3E-5 1/K | 20-100°C |

| Thermal conductivity | 23.0 °C | 176 W/(m·K) |

3003 h24 Aluminum Plate Electrical

| Property | Temperature | Value |

| Electrical resistivity | 23.0 °C | 3.4E-8 Ω·m |

3003 h24 Aluminum Plate Chemical properties

| Property | Value |

| Copper | 0.05 - 0.2 % |

| Iron | 0.7 % |

| Manganese | 1 - 1.5 % |

| Silicon | 0.6 % |

| Zinc | 0.1 % |

3003 h24 Aluminum Plate Technological properties

| Property | Value |

| Anodizing | Good |

| Brazing | Excellent |

| Corrosion properties | Very Good |

| Welding | Very Good |

| Workability | Very Good |

What is the 3003 H24 Aluminum Plate Used for?

Haomei Aluminum's 3003 aluminum plates are mainly hot-rolled plates and can be customized to produce thicknesses of 0.1-500mm, widths of 100-2650mm, and lengths of 500-16000mm. It can produce ultra-wide and ultra-thick aluminum plates, which are widely used in bus skins, silos, and antennas. Pot materials, wide curtain wall panels, wide roof panels, etc.

Common forms of 3003 H24 aluminum

- 3003 h24 Aluminum Plate

- 3003 h24 Aluminum Coil

- 3003 h24 Aluminum Foil

These different forms of 3003 H24 aluminum may vary in thickness, width, and length, and specific specifications and uses will be based on project needs.

3003 h24 Lunch Box Aluminum Foil

3003 H24 aluminum foil is a commonly used raw material for lunch boxes. The 3003 lunch box aluminum foil produced by Haomei Aluminum has a clean surface, no oil stains, bright lines, and other inclusions. It has a high elongation rate, is safe and hygienic, and is favored by users.

The surface of 3003 H24 aluminum foil has an oxide layer. Its performance is very stable and harmless to the human body. The aluminum foil lunch box not only meets the hygienic standards for food containers but the product can be heated directly without fear of danger, giving people a fast-paced life. It brings great convenience.

Aluminum Honeycomb Panel Material 3003 h24 Aluminum Plate

3003 H24 aluminum plate is a suitable choice for the skin (outer layer) of aluminum honeycomb panels. The H24 temper provides a good balance of strength and formability, which is important for the structural integrity of the panels and their ability to bond well to the honeycomb core.

Applications: Aluminum honeycomb panels are widely used in various industries such as aerospace, construction, and transportation due to their lightweight, high strength, and stiffness properties. They are commonly used in aircraft interiors, building exteriors, and transport vehicle components such as interior siding on trains and buses.

3003 h24 Aluminum Plate Coil for Thermal Insulation

Performance advantages of 3003 h24 aluminum coils for thermal insulation

- 1. Has excellent anti-rust properties;

- 2. Good surface flatness, strong plasticity, and pressure resistance;

- 3. Good processability, excellent high-temperature corrosion resistance, good electrical conductivity, and weldability.

3003 H24 Aluminum Coil for Car Fenders

Car fenders can be made of 3003-h24 aluminum coil material. Aluminum has good mechanical properties, its density is only 1/3 of steel, and its machining performance is 4.5 times higher than iron. Car fenders made of aluminum coils do not increase The car's own weight, while also well preventing damage to the car;

The oxide film formed on the surface of 3003-h24 aluminum prevents the fenders from rusting, and the aluminum is oxidized and colored into various colors to ensure the beauty of the car fenders.

3003 h24 Aluminum Plate Curtain Wall Aluminum Plate Base Material

Aluminum curtain walls usually use 1.5-3.0mm aluminum alloy plates, model 3003 aluminum plates, H24 status. Its structure mainly consists of embedded plates, panels, reinforcement ribs, and corner codes.

4 major advantages of using 3003 h24 aluminum plate as curtain wall substrate

- 1. Lightweight, high strength, and corrosion resistance

- 2. Features of good craftsmanship

- 3. Easy to clean and maintain

- 4. Easy and quick installation

3003 H24 Tread Aluminum Plate

3003 H24 tread aluminum plate is an aluminum-manganese alloy with slightly higher strength than ordinary aluminum alloy patterned plate.

3003 H24 tread aluminum plate has certain anti-rust properties, but its hardness and corrosion resistance are not as good as those of 5-series tread plates. Therefore, this product is used in areas with less stringent anti-rust requirements, such as truck models and cold storage floors.

3003 h24 Aluminum Plate for Power Battery Shell

3003 H24 aluminum plate can also be used in power battery housing applications. The H24 temper provides moderate strength and formability, making it useful for manufacturing battery casings.

Application: A 3003 h24 power battery housing aluminum sheet is used to produce battery housings for electric vehicles (EVs) and other energy storage applications. These plates play a vital role in protecting the battery cells and providing thermal management for the battery.

3003 h24 Stamped Aluminum Plate

3003-h24 aluminum plate has good stamping performance and is widely used in some metal shell fields.

The 3003 H24 alloy aluminum plate produced by Haomei Aluminum has good formability and is mainly used for deep drawing materials. The 3003 H24 aluminum plate is used to make stamped parts, models, shells, etc. It has many advantages such as good surface quality, good plasticity, and pressure resistance.

3003 h24 Aluminum Plate VS 5052 h24 Aluminum Plate

1. From the Chemical Composition

- 3003 h24 aluminum plate is an aluminum-manganese alloy, and the main alloying element is manganese.

- 5052 h24 aluminum plate is an aluminum-magnesium alloy, and the main alloy element is magnesium.

The aluminum content of the 3003 aluminum plate is slightly higher than that of the 5052 aluminum plate.

2. From the Mechanical Properties

The tensile strength of 5052 H24 is much higher than that of 3003H24 aluminum plate

- The tensile strength of 3003 H24 aluminum plate is 145-195Rm/MPa

- The tensile strength of the 5052 H24 aluminum plate is as high as 230-280Rm/MPa

The performance of the 5052 aluminum plate is significantly better than that of the 3003 aluminum plate.

- The extension strength of 3003 H24 aluminum plate is 115Rm/MPa

- The elongation strength of the 5052 H24 aluminum plate is 150Rm/MPa.

3. From the Common Specifications

3003 aluminum plates are mainly thin plates, and thick plates are not widely used.

In addition to thin plates, 5052 aluminum plates are also widely used in thick plates.

4. From the Scope of Application

3003 aluminum plates are mainly used in humid environments, such as product packaging, refrigerators, air conditioners, cold storage, ventilation ducts, etc.

5052 aluminum plate is commonly used in electrical casings, transportation vehicles, pressure vessels, etc. It is a common material for manufacturing automobiles and aircraft fuel tanks and oil pipes.

5. From the Price of Aluminum Plates

The price of the 3003 h24 aluminum plate is slightly higher than that of the pure aluminum plate, and the price of the 5052 h24 aluminum plate is significantly higher than that of the 3003 aluminum plate.

Depending on the specifications and thickness, the price of a ton of 5052 aluminum plates is about 2, 000-3, 000 yuan higher than the price of a ton of 3003 aluminum plates.

What is the Difference between 3003 H14 and 3003 H24?

The main differences between 3003 H14 and 3003 H24 are their condition names and the mechanical properties resulting from these different states. Here's a breakdown of these differences:

1. Temper Name

- 3003 H14: The "H14" temper designation indicates that the aluminum alloy has undergone a strain hardening process followed by a partial annealing process. This state is characterized by a hardness of 1/2 and a relatively high level of work hardening, making it somewhat stiff and less formable than the H24 state.

- 3003 H24: On the other hand, the "H24" temper designation indicates that the aluminum alloy has undergone a strain hardening process followed by a more substantial annealing process. The H24 temper is characterized by being closer to fully annealed, resulting in improved formability and reduced stiffness compared to H14.

2. Mechanical Properties

- 3003 H14: This state is harder than H24. It has higher tensile and yield strengths but lower elongation (meaning less ductility) than H24. H14 is often chosen when higher mechanical strength is required at the expense of some formability.

- 3003 H24: Compared with H14, the H24 state has better formability and ductility. It is less hard and has lower tensile and yield strengths, but is easier to shape and will not break.

3. Application

- 3003 H14: H14 is typically used in applications where moderate strength and stiffness are required and formability is not important. Common applications include roofing materials, automotive components, and some structural components.

- 3003 H24: Choose H24 when improved formability and ease of manufacturing are more important than high mechanical strength. It is commonly used in applications such as food and beverage containers, heat exchangers, and other components that require complex shapes.

The main differences between 3003 H14 and 3003 H24 are their mechanical properties and formability. H14 is harder and has higher strength but poor formability, while H24 is softer and has better formability but lower strength. The choice between the two depends on the specific requirements of the application and the desired balance between strength and formability.

People also searched for Aluminum Plate

-

3004 Aluminum Plate Sheet

3004 aluminum is similar to 3003 aluminum, but it is stronger than 3003 alloy. 3004 aluminum also has good formability, good processability, excellent corrosion resistance and drawing characteristics.

-

3004 h19 Aluminum Plate Sheet

3004 H19 is a non-heat treatable aluminum alloy suitable for chemical and food contact applications, common ones such as beverage cans.

-

3004 h18 Aluminum Plate Sheet

3004-H18 aluminum is 3004 aluminum in the H18 state, which has higher strength, excellent formability and good corrosion resistance than 3003.

-

3004 o Aluminum Plate Sheet

3004-O aluminum is 3004 aluminum in the annealed condition. It has the lowest strength and highest ductility compared to other variants of 3004 aluminum.

-

3104 Aluminum Plate Sheet

The performance of the 3104 aluminum plate is stable, the surface is smooth, smooth, and free of defects, and the tolerance is strictly controlled to meet the standard.

-

3104 h19 Aluminum Plate Sheet

3104 h19 Aluminum Plate Sheet has precise specifications, good shape, high strength, easy processing, and good deep drawing performance.

-

3105 Aluminum Plate Sheet

3105 aluminum alloy is stronger than 1100 and 3003 alloys. 3105 aluminum sheet is often used in street signs, building siding and bottle caps.