5005 Aluminum Plate Sheet

Temper: H32/H34/H14 High Quality and Stable Performance

What is Aluminum Grades 5005?

Aluminum grade 5005 is a non-heat treatable aluminum alloy. It belongs to the 5xxx series of aluminum alloys known for excellent corrosion resistance, good formability, and moderate strength.

5005 aluminum alloy is similar to 3003 alloy and has medium strength and good corrosion resistance. 5005 aluminum alloy is used as conductors, cookware, instrument panels, shells and architectural decoration parts. The anodized film is brighter than the oxide film on the 3003 alloy and is consistent with the color tone of the 6063 alloy.

5005 aluminum is a medium-strength aluminum alloy with a small amount of magnesium as the main alloying element. It has good formability and can be used in applications requiring bending, spinning, drawing, stamping and roll forming. It is commonly used in applications requiring an anodized surface treatment.

Main Features of 5005 Aluminum Plate

- Corrosion Resistance: 5005 Aluminum has excellent resistance to atmospheric corrosion, making it suitable for outdoor applications and environments frequently exposed to moisture or salt water.

- Formability: This alloy has good formability and can be subjected to various manufacturing processes such as bending, stamping, and deep drawing. It can be easily molded into different shapes without visible cracking or deformation.

- Weldability: 5005 aluminum has good weldability and can be easily joined using a variety of welding techniques, including MIG welding, TIG welding, and resistance welding.

- Anodizing Potential: Aluminum 5005 has a high-quality anodizing finish potential, making it a popular choice for applications requiring an aesthetic or protective anodized coating.

Aluminum Alloy 5005 Specifications

5005 Aluminum Plate Commonly Used Temper

- H32: Strain-hardened and stable state, providing good formability and moderate strength.

- H34: Strain-hardened and partially annealed temper, providing higher strength and improved corrosion resistance.

- Other statuses such as H111, H112, H114, or H116 are also available on specific request.

-

5005 h32 Aluminum Plate Sheet

5005-H32 aluminum is 5005 aluminum in the H32 condition. To achieve this state, the metal is strain-hardened and then stabilized to about one-fourth the strength between annealed (O) and fully hard (H38).

-

5005 h34 Aluminum Plate Sheet

5005 H34 aluminum has stable properties, it can stabilize mechanical properties and eliminate residual internal stress, and generally improves ductility.

5005 Aluminum Plate Width

Typically available in a range of widths including standard widths of 36", 48", 60" or 72" (914mm, 1219mm, 1524mm, or 1829mm).

Custom widths are also available upon request.

5005 Aluminum Plate Length

Usually available in standard lengths of 96" or 120" (2438mm or 3048mm).

Custom lengths are also available upon request.

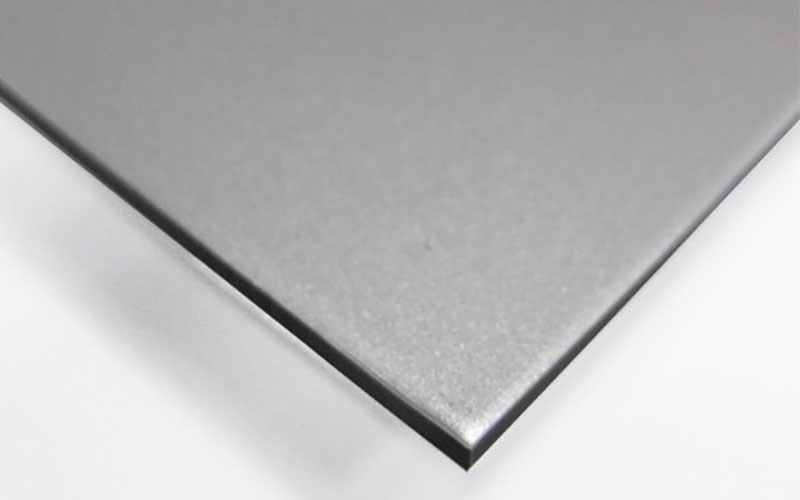

5005 Aluminum Plate Thickness

Common thicknesses range from 0.016" to 0.250" (0.4mm to 6.35mm).

5005 aluminum plate is available in a variety of common thicknesses to suit a variety of applications. 5005 aluminum sheet thickness typically varies from very thin sheets to thicker sheets. Here are some common thicknesses of 5005 aluminum sheets:

- Thin sheet: As thin as 0.2 millimeters (mm) or less. Thin sheets are often used in applications where low weight and flexibility are important, such as the manufacture of lightweight signs or nameplates.

- 0.5 mm to 3 mm: This range includes medium-thickness sheets suitable for a variety of applications including building components, trim, and automotive panels.

- 4mm to 6mm: These thicker sheets are typically used in applications that require greater structural integrity, such as building exteriors, marine components, or structural panels.

- 7mm and above: For heavy-duty applications where increased strength and durability are required, sheets with thicknesses of 7mm and above are available. These may be used in construction, heavy machinery, or specialized industrial equipment.

It's worth noting that the availability of specific thicknesses may vary depending on the supplier or manufacturer. When selecting the thickness of your 5005 aluminum sheet, consider the specific requirements of your project, including structural and mechanical needs and weight limitations. If you require a non-standard thickness, custom milling or fabrication is also an option.

Thinner or thicker options are available according to specific needs.

| Property | Description |

|---|---|

| Surface Treatment Type | anodized, painted, or coated |

| Product Certification | ASTM , EN |

Equivalent to 5005

- UNS A95005

- AA5005

- AlMg1

- EN AW-5005

- ISO AlMg1

- H16 alloy

5005 Aluminum Mechanical Properties

| Alloy and Temper | Thickness mm | Tensile Strength | Elongation (% min in 50mm) | ||||

| Over | Up to | Ultimate | Yield | ||||

| Min | Max | Min | Max | ||||

| 5005-O | 1.2 | 6.3 | 105 | 145 | 35 | – | 21 |

| 5005-H14 | 1.2 | 6.3 | 145 | 185 | 115 | – | 3 |

| 5005-H34 | 1.2 | 6.3 | 140 | 180 | 105 | – | 5 |

| 5052-H32 | 0.63 | 50 | 215 | 265 | 160 | – | 5-11 |

| 5052-H38 | 0.63 | 3.20 | 270 | – | 220 | – | 4 |

5005 properties by temper

| Alloy | Form | Temper | Tensile Strength | Yield Strength | Elongation |

| 5005 | Sheet | H12 | 20 | 19 | 10 |

| 5005 | Sheet | H14 | 23 | 22 | 6 |

| 5005 | Sheet | H16 | 26 | 25 | 5 |

| 5005 | Sheet | H18 | 29 | 28 | 4 |

| 5005 | Sheet | H32 | 20 | 17 | 11 |

| 5005 | Sheet | H34 | 23 | 20 | 8 |

| 5005 | Sheet | H36 | 26 | 24 | 6 |

| 5005 | Sheet | H38 | 29 | 27 | 5 |

5005 Aluminum Plate Chemical Composition

- Aluminum (Al): 95.7% to 97.7%

- Magnesium (Mg): 0.50% to 1.10%

- Iron (Fe): 0.0% to 0.70%

- Silicon (Si): 0.0% to 0.25%

- Copper (Cu): 0.0% to 0.20%

- Manganese (Mn): 0.0% to 0.20%

- Zinc (Zn): 0.0% to 0.20%

- Other elements: 0.0% to 0.05% each, less than 0.15% in total.

5005 aluminum alloy is not typically used for casting but is instead cold-worked to achieve moderate to high strength. This alloy can achieve good mechanical properties, including strength and hardness, after cold working.

5005 Aluminum Plate Advantages and Disadvantages

The 5005 aluminum grade is the weakest alloy among non-heat treatable aluminums. However, it can be hardened by cold work, is ideal for decorative anodizing, and has good weldability.

5005 is not used for casting, it can obtain medium to high strength through cold working, and has relatively high welding strength compared with other aluminum alloy series. Hardness H116 and H321 available for fresh and salt water.

5005 Aluminum Plate Cold Processing

1. Advantages of cold working of 5005 aluminum plate

Cold working includes rolling, drawing, cold drawing, bending, and other processes, which can be used to improve the strength, hardness, and other mechanical properties of 5005 aluminum alloy.

Cold working can change the shape, size, and thickness of aluminum sheets to make them suitable for a variety of applications.

2. Mechanical properties

5005 aluminum alloy can achieve moderate to high strength after cold working, depending on the degree of processing.

Cold working can also increase the hardness and tensile strength of aluminum sheets, making them more suitable for applications requiring higher strength.

3. Cold working method of 5005 aluminum plate

Cold working can be carried out by rolling, drawing, deep drawing, bending, etc. Different processes will produce different effects.

The appropriate method and degree of cold working needs to be selected based on specific project needs.

4. Precautions for cold processing of 5005 aluminum plate

Cold working may cause the aluminum plate to become brittle, so the temperature and degree of deformation during processing need to be carefully controlled to avoid unnecessary damage.

For large or complex cold working projects, it is best to consult with a professional processing manufacturer or engineer to ensure the required mechanical performance and quality standards are achieved.

5005 aluminum plate can be cold worked to obtain the required mechanical properties, making it a suitable choice for a variety of applications. Before cold working, the appropriate processing method should be carefully planned and selected based on specific needs.

How does the 5005 Aluminum Plate Compare to other Aluminum Alloys?

1. Comparison between 5005 aluminum alloy and 3003 aluminum alloy

5005 aluminum plate is equivalent to 3003 aluminum alloy in terms of strength but has a brighter and more beautiful-looking anodized film.

5005 has good weldability and processability, making it a preferred choice for manufacturing.

Compared with 3003, 5005 has better corrosion resistance.

2. Comparison between 5005 aluminum alloy and 5052 aluminum alloy

Both 5005 and 5052 aluminum alloys have moderate strength, but 5052 aluminum alloy is generally stronger than 5005 aluminum alloy.

5005 has a brighter anodized film that harmonizes with the color tone of the 6063 alloy.

Although people sometimes use 5052 instead of 5005, 5052 may be more prone to color variations and other defects.

3. Anodizing treatment

The anodized film for 5005 alloys is brighter. Anodizing can improve the surface hardness, corrosion resistance, and appearance of aluminum alloys.

It should be noted that the anodized films of different alloys may have different characteristics, including color and appearance. Therefore, suitable alloy selection is crucial to achieve the desired appearance.

4. The need for beautiful surfaces

If you require a beautiful and consistent result on the surface, it is recommended not to attempt anodizing aluminum alloys such as 3003, 3105, etc., as they may suffer from defects such as structural streaks, haze, blemishes, and color changes.

The final selection should be based on specific project needs, performance requirements, and appearance requirements.

Typical 5005 Aluminum Plate

5005 h34 Aluminum Plate

- Condition: H34 (strain hardened and partially annealed)

- Mechanical properties: Higher strength and higher corrosion resistance compared to H32 temper.

- Common Applications: Marine applications requiring increased strength and corrosion resistance, building components, roofing, and general sheet metal applications.

5005 h32 Aluminum Plate

- Condition: H32 (strain hardened and stabilized)

- Mechanical properties: good formability, moderate strength.

- Common Applications: General sheet metal applications, building components, roofs, signage, and facades.

Aluminum Plate 5005 h14

- Condition: H14 (strain hardening only)

- Mechanical properties: moderate strength, good formability.

- Common Applications: Sheet Metal Fabrication, General Purpose Applications, Building Facades, and Building Components.

5005 Anodized Aluminum Plate

Anodized aluminum plate is usually available in various tempers including H32 and H34.

- Surface treatment: Anodized to provide a protective and decorative oxide layer on the surface.

- Common Applications: Architectural elements, decorative panels, signage, consumer electronics, and other applications requiring durable, corrosion-resistant, and aesthetically pleasing surfaces.

It is important to note that the specific properties and applications of the 5005 aluminum grade may vary due to factors such as thickness, surface treatment, and specific manufacturing processes. Consultation with the supplier or an industry professional is recommended for details and suitability for specific applications.

What is Aluminum 5005 Used for?

Architecture and Construction

Because of its corrosion resistance and formability, aluminum 5005 is commonly used in architectural applications, including building facades, roofs, gutters, and siding.

- Condition: H14, H34, or H114 Typically used in building and construction applications. These tempers provide a good balance of formability and strength.

-

Alloy Combinations: In some cases, aluminum grade 5005 can be combined with other alloys such as 6061 or 6063 for structural components requiring higher strength or special properties.

- 5005: Roofing panels, wall cladding, or decorative architectural elements requiring corrosion resistance and formability.

- 6061: Beams, columns, braces, or other load-bearing members require high strength and durability.

Transportation

5005 Aluminum alloy is used in the automotive industry for panels, trims, and parts requiring corrosion resistance and formability.

- Tempers: H32 or H34 tempers are often used in the transportation industry as they offer a good combination of strength, formability, and resistance to vibration or shock.

-

Alloy Combinations: Aluminum grade 5005 can be combined with other alloys such as 5052 or 6061 for specific automotive or transportation applications requiring higher strength, such as panels or structural components.

- 5005: Body panels, trim, or interior components where corrosion resistance and formability are important.

- 5052: Structural elements such as chassis, frames, or reinforcements require higher strength and impact resistance.

Electrical Equipment

5005 aluminum is suitable for electrical enclosures and cabinets due to its corrosion resistance and ease of fabrication.

- Status: H34 or H114 status is typically used in electrical equipment applications. These tempers provide good formability and moderate strength.

-

Alloy Combination: Grade 5005 aluminum is often used alone in electrical enclosures and cabinets. However, in some cases, it may be combined with other alloys such as 5052 or 6061 to meet specific requirements for electrical conductivity, strength, or thermal management.

- 5005: Body panels, trim, or interior components where corrosion resistance and formability are important.

- 5052: Structural elements such as chassis, frames, or reinforcements require higher strength and impact resistance.

Signage and Displays

It is widely used for signage, display panels, and nameplates due to its excellent surface finish and anodizing potential.

- Tempers: H32 or H34 tempers are commonly used in signage and display applications and offer a good balance of formability and strength.

- Alloy Combination: Grade 5005 aluminum is commonly used as a stand-alone alloy for signage and display applications. The focus is on achieving a high-quality surface finish through anodizing or other surface treatments.

- 5005: Signage panels, display panels, or nameplates that benefit from corrosion resistance, formability, and high-quality finishes.

General Sheet Metal Manufacturing

Aluminum 5005 is used in a variety of sheet metal applications such as panels, cabinets, and assemblies where a combination of formability, corrosion resistance, and moderate strength is required.

- Tempers: H14 or H34 tempers are commonly used in general sheet metal fabrication. These tempers provide good formability and moderate strength.

- Alloy Combinations: Aluminum grade 5005 can be used alone or in combination with other alloys according to the specific requirements of the fabrication project.

It is important to note that the specific properties and applications of the 5005 aluminum grade may vary depending on factors such as temper, thickness, and manufacturing process. It is recommended to consult the supplier or an industry professional for detailed specifications and suitability for your particular application.

What is the difference between 5005 and 5052 Aluminum?

1. Chemical Composition

- 5005 Aluminum: It is an aluminum-magnesium alloy with a nominal magnesium content of about 0.8%. It also contains small amounts of other elements such as iron, silicon, and copper.

- 5052 aluminum: It is an aluminum-magnesium alloy with a high magnesium content of about 2.5%. Likewise, it contains trace amounts of other elements such as iron, silicon, and copper.

2. Mechanical Properties

- 5005 aluminum: moderate strength, good formability. It has a lower tensile strength than 5052, typically between 145 MPa and 195 MPa (21, 000 psi and 28, 000 psi).

- 5052 Aluminum: Has higher strength and improved mechanical properties. It exhibits higher tensile strength, ranging from 215 MPa to 305 MPa (31, 000 psi to 44, 000 psi), stronger than 5005.

3. Corrosion Resistance

Both alloys have excellent corrosion resistance due to the presence of magnesium, which provides a protective oxide layer on the surface.

However, compared to 5005, 5052 aluminum is slightly more resistant to corrosion in harsh environments or when exposed to salt water.

4. Applications

- 5005 Aluminum: Commonly used in general sheet metal applications, building facades, roofs, and other building components. For applications requiring moderate strength, formability, and corrosion resistance.

- 5052 Aluminum: Widely used in marine applications such as hulls and components due to its higher corrosion resistance. It is also used in structural components in the transportation industry, panels, and automotive body parts where higher strength is required.

How to Choose 5005 Aluminum Plates?

Selecting the appropriate condition for 5005 aluminum sheeting depends on the specific requirements of your project, including factors such as strength, formability, corrosion resistance, and intended application. The following step-by-step guide can help you make the right choice:

1. Understand your application requirements

Start by clearly defining the performance characteristics required for your project. Consider factors such as mechanical strength, formability, corrosion resistance, and any other special requirements.

2. Determine Strength Needs

Evaluate the strength required for your application. Different tempers provide varying degrees of strength.

- If your project requires high strength, you may be tempted to use a harder material like H34, H36, or H38.

- For applications where strength is less important, a softer state such as H32 or O may be appropriate.

3. Evaluate formability requirements

Consider the level of formability required for your project.

- Softer states such as O and H32 are highly formable and suitable where complex shapes or extensive bending are required.

- Harder temper states such as H34 and H38 reduce formability but increase strength.

4. Evaluate corrosion resistance

Determine the level of corrosion resistance required for your application. 5005 aluminum is known for its good corrosion resistance, but certain states, such as H116 and H111, can provide higher corrosion resistance, making it suitable for use in marine or harsh environments.

5. Consider surface finish

Certain states, such as O and H32, are preferred for applications that require anodizing or coating to enhance surface appearance and protection. The ability to achieve a bright anodized surface may also be a consideration.

6. Evaluate cost considerations

Different states may have different costs associated with manufacturing and processing. Consider your budget constraints and balance them with your performance requirements.

Your choice of Temper can significantly affect your project's performance and functionality, so take the time to make an informed decision based on your specific needs.

How should the 5005 Aluminum Plate be Stored and Handled?

To prevent corrosion and damage, the 5005 aluminum plate should be stored in a dry, well-ventilated area away from moisture and direct sunlight. Handle the plates with care to avoid surface scratches or dents during transportation and handling.

5005 Aluminum Sheet Plate Thickness Tolerance

| Thickness | Thickness Tolerance | Width | Length |

| 0.063" 5005 Aluminum Sheet | +/-.003 | 2" | 24" |

| 0.063" 5005 Aluminum Sheet | +/ -.003 | 4" | 24" |

| 0.063" 5005 Aluminum Sheet | +/ -.003 | 6" | 6" |

| 0.063" 5005 Aluminum Sheet | +/-.003 | 6" | 12" |

| 0.063" 5005 Aluminum Sheet | +/ -.003 | 6" | 24" |

| 0.063" 5005 Aluminum Sheet | +/ -.003 | 12" | 12" |

| 0.063" 5005 Aluminum Sheet | +/-.003 | 12" | 24" |

| 0.063" 5005 Aluminum Sheet | +/-.003 | 24" | 24" |

| 0.063" 5005 Aluminum Sheet | +/-.003 | 24" | 48" |

| 0.090" 5005 Aluminum Sheet | +/ -.005 | 2" | 24" |

| 0.090" 5005 Aluminum Sheet | +/ -.005 | 4" | 24" |

| 0.090" 5005 Aluminum Sheet | +/-.005 | 6" | 6" |

| 0.090" 5005 Aluminum Sheet | +/ -.005 | 6" | 12" |

| 0.090" 5005 Aluminum Sheet | +/ -.005 | 6" | 24" |

| 0.090" 5005 Aluminum Sheet | +/ -.0045 | 12" | 12" |

| 0.090" 5005 Aluminum Sheet | +/ -.0045 | 12" | 24" |

| 0.090" 5005 Aluminum Sheet | +/-.0045 | 24" | 24" |

| 0.090" 5005 Aluminum Sheet | +/-.0045 | 24" | 48" |

| 0.090" 5005 Aluminum Sheet | +/-.0045 | 48" | 96" |

| 0.090" 5005 Aluminum Sheet | +/-.0045 | 48" | 144" |

| 0.125" 5005 Aluminum Sheet | +/ -.006 | 2" | 24" |

| 0.125" 5005 Aluminum Sheet | +/ -.006 | 4" | 24" |

| 0.125" 5005 Aluminum Sheet | +/-.006 | 6" | 6" |

| 0.125" 5005 Aluminum Sheet | +/ -.006 | 6" | 12" |

| 0.125" 5005 Aluminum Sheet | +/ -.006 | 6" | 24" |

| 0.125" 5005 Aluminum Sheet | +/-.0055 | 12" | 12" |

| 0.125" 5005 Aluminum Sheet | +/-.0055 | 12" | 24" |

| 0.125" 5005 Aluminum Sheet | +/-.0055 | 24" | 24" |

| 0.125" 5005 Aluminum Sheet | +/-.0055 | 24" | 48" |

| 0.125" 5005 Aluminum Sheet | +/-.0055 | 48" | 96" |

| 0.125" 5005 Aluminum Sheet | +/-.0055 | 48" | 120" |

| 0.125" 5005 Aluminum Sheet | +/-.0055 | 48" | 144" |

| 0.190" 5005 Aluminum Sheet | +/-.009 | 2" | 24" |

| 0.190" 5005 Aluminum Sheet | +/-.009 | 4" | 24" |

| 0.190" 5005 Aluminum Sheet | +/-.009 | 6" | 6" |

| 0.190" 5005 Aluminum Sheet | +/-.009 | 6" | 12" |

| 0.190" 5005 Aluminum Sheet | +/-.009 | 6" | 24" |

| 0.190" 5005 Aluminum Sheet | +/-.009 | 12" | 12" |

| 0.190" 5005 Aluminum Sheet | +/-.009 | 12" | 24" |

| 0.190" 5005 Aluminum Sheet | +/-.009 | 24" | 24" |

| 0.190" 5005 Aluminum Sheet | +/-.009 | 24" | 48" |

| 0.250" 5005 Aluminum Plate | +/-.014 | 2" | 24" |

| 0.250" 5005 Aluminum Plate | +/-.014 | 4" | 24" |

| 0.250" 5005 Aluminum Plate | +/-.014 | 6" | 6" |

| 0.250" 5005 Aluminum Plate | +/-.014 | 6" | 12" |

| 0.250" 5005 Aluminum Plate | +/-.014 | 6" | 24" |

| 0.250" 5005 Aluminum Plate | +/-.014 | 12" | 12" |

| 0.250" 5005 Aluminum Plate | +/-.014 | 12" | 24" |

| 0.250" 5005 Aluminum Plate | +/-.014 | 24" | 24" |

| 0.250" 5005 Aluminum Plate | +/-.014 | 24" | 48" |

| 0.250" 5005 Aluminum Plate | +/-.014 | 48" | 144" |

| 0.375" 5005 Aluminum Plate | +/-.017 | 2" | 24" |

| 0.375" 5005 Aluminum Plate | +/-.017 | 4" | 24" |

| 0.375" 5005 Aluminum Plate | +/-.017 | 6" | 6" |

| 0.375" 5005 Aluminum Plate | +/-.017 | 6" | 12" |

| 0.375" 5005 Aluminum Plate | +/-.017 | 6" | 24" |

| 0.375" 5005 Aluminum Plate | +/-.017 | 12" | 12" |

| 0.375" 5005 Aluminum Plate | +/-.017 | 12" | 24" |

| 0.375" 5005 Aluminum Plate | +/-.017 | 24" | 24" |

| 0.375" 5005 Aluminum Plate | +/-.017 | 24" | 48" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 2" | 24" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 4" | 24" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 6" | 6" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 6" | 12" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 6" | 24" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 12" | 12" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 12" | 24" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 24" | 24" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 24" | 48" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 2" | 24" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 4" | 24" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 6" | 6" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 6" | 12" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 6" | 24" |

| 0.500" 5005 Aluminum Plate | +/-.023 | 12" | 12" |

| 0.750" 5005 Aluminum Plate | +/-.031 | 12" | 24" |

| 0.750" 5005 Aluminum Plate | +/-.031 | 24" | 24" |

| 0.750" 5005 Aluminum Plate | +/-.031 | 24" | 48" |

| 1.00" 5005 Aluminum Plate | +/-.039 | 2" | 24" |

| 1.00" 5005 Aluminum Plate | +/-.039 | 4" | 24" |

| 1.00" 5005 Aluminum Plate | +/-.039 | 6" | 6" |

| 1.00" 5005 Aluminum Plate | +/-.039 | 6" | 12" |

| 1.00" 5005 Aluminum Plate | +/-.039 | 6" | 24" |

| 1.00" 5005 Aluminum Plate | +/-.039 | 12" | 12" |

| 1.00" 5005 Aluminum Plate | +/-.039 | 12" | 24" |

| 1.00" 5005 Aluminum Plate | +/-.039 | 24" | 24" |

| 1.00" 5005 Aluminum Plate | +/-.039 | 24" | 48" |

5005 Aluminum Sheet Plate Stock List

| Product | Size (ft.) |

| 1/32" 5005 Aluminum Sheet | 1 X 1 ft. |

| 1/32" 5005 H32 Aluminum Sheet | 1 X 2 ft. |

| 1/32" 5005 Aluminum Sheet | 1 X 3 ft. |

| 1/32" 5005 H14 Aluminum Sheet | 1 X 4 ft. |

| 1/32" 5005 Aluminum Sheet | 2 X 2 ft. |

| 1/32" 5005 H18 Aluminum Sheet | 2 X 3 ft. |

| 1/32" 5005 Aluminum Sheet | 2 X 4 ft. |

| 1/32" 5005 Aluminum Sheet | 3 X 3 ft. |

| 1/32" 5005 H34 Aluminum Sheet | 3 X 4 ft. |

| 1/32" 5005 Aluminum Sheet | 4 X 4 ft. |

| 1/32" 5005 Aluminum Sheet | 4 X 10 ft. |

| 0.040" 5005 H24 Aluminum Sheet | 1 X 1 ft. |

| 0.040" 5005 Aluminum Sheet | 1 X 2 ft. |

| 0.040" 5005 H32 Aluminum Sheet | 1 X 3 ft. |

| 0.040" 5005 Aluminum Sheet | 1 X 4 ft. |

| 0.040" 5005 H18 Aluminum Sheet | 2 X 2 ft. |

| 0.040" 5005 Aluminum Sheet | 2 X 3 ft. |

| 0.040" 5005 H14 Aluminum Sheet | 2 X 4 ft. |

| 0.040" 5005 Aluminum Sheet | 3 X 3 ft. |

| 0.040" 5005 H38 Aluminum Sheet | 3 X 4 ft. |

| 0.040" 5005 Aluminum Sheet | 4 X 4 ft. |

| 0.040" 5005 H38 Aluminum Sheet | 4 X 10 ft. |

| 0.050" 5005 Aluminum Sheet | 1 X 1 ft. |

| 0.050" 5005 Aluminum Sheet | 1 X 2 ft. |

| 0.050" 5005 H32 Aluminum Sheet | 1 X 3 ft. |

| 0.050" 5005 Aluminum Sheet | 1 X 4 ft. |

| 0.050" 5005 Aluminum Sheet | 2 X 2 ft. |

| 0.050" 5005 H34 Aluminum Sheet | 2 X 3 ft. |

| 0.050" 5005 Aluminum Sheet | 2 X 4 ft. |

| 0.050" 5005 Aluminum Sheet | 3 X 3 ft. |

| 0.050" 5005 H14 Aluminum Sheet | 3 X 4 ft. |

| 0.050" 5005 Aluminum Sheet | 4 X 4 ft. |

| 0.050" 5005 H18 Aluminum Sheet | 4 X 10 ft. |

| 1/16" 5005 Aluminum Sheet | 1 X 1 ft. |

| 1/16" 5005 Aluminum Sheet | 1 X 2 ft. |

| 1/16" 5005 Aluminum Sheet | 1 X 3 ft. |

| 1/16" 5005 H32 Aluminum Sheet | 1 X 4 ft. |

| 1/16" 5005 Aluminum Sheet | 2 X 2 ft. |

| 1/16" 5005 H34 Aluminum Sheet | 2 X 3 ft. |

| 1/16" 5005 Aluminum Sheet | 2 X 4 ft. |

| 1/16" 5005 H32 Aluminum Sheet | 3 X 3 ft. |

| 1/16" 5005 Aluminum Sheet | 3 X 4 ft. |

| 1/16" 5005 Aluminum Sheet | 4 X 4 ft. |

| 1/16" 5005 Aluminum Sheet | 4 X 10 ft. |

| 0.080" 5005 Aluminum Sheet | 1 X 1 ft. |

| 0.080" 5005 Aluminum Sheet | 1 X 2 ft. |

| 0.080" 5005 Aluminum Sheet | 1 X 3 ft. |

| 0.080" 5005 Aluminum Sheet | 1 X 4 ft. |

| 0.080" 5005 Aluminum Sheet | 2 X 2 ft. |

| 0.080" 5005 Aluminum Sheet | 2 X 3 ft. |

| 0.080" 5005 H34 Aluminum Sheet | 2 X 4 ft. |

| 0.080" 5005 Aluminum Sheet | 3 X 3 ft. |

| 0.080" 5005 H34 Aluminum Sheet | 3 X 4 ft. |

| 0.080" 5005 Aluminum Sheet | 4 X 4 ft. |

| 0.080" 5005 Aluminum Sheet | 4 X 10 ft. |

| 0.090" 5005 Aluminum Sheet | 1 X 1 ft. |

| 0.090" 5005 Aluminum Sheet | 1 X 2 ft. |

| 0.090" 5005 H34 Aluminum Sheet | 1 X 3 ft. |

| 0.090" 5005 Aluminum Sheet | 1 X 4 ft. |

| 0.090" 5005 Aluminum Sheet | 2 X 2 ft. |

| 0.090" 5005 H32 Aluminum Sheet | 2 X 3 ft. |

| 0.090" 5005 Aluminum Sheet | 2 X 4 ft. |

| 0.090" 5005 H32 Aluminum Sheet | 3 X 3 ft. |

| 0.090" 5005 Aluminum Sheet | 3 X 4 ft. |

| 0.090" 5005 Aluminum Sheet | 4 X 4 ft. |

| 0.090" 5005 Aluminum Sheet | 4 X 10 ft. |

| 1/8" 5005 H18 Aluminum Sheet | 1 X 1 ft. |

| 1/8" 5005 Aluminum Sheet | 1 X 2 ft. |

| 1/8" 5005 Aluminum Sheet | 1 X 3 ft. |

| 1/8" 5005 H38 Aluminum Sheet | 1 X 4 ft. |

| 1/8" 5005 Aluminum Sheet | 2 X 2 ft. |

| 1/8" 5005 H38 Aluminum Sheet | 2 X 3 ft. |

| 1/8" 5005 Aluminum Sheet | 2 X 4 ft. |

| 1/8" 5005 H38 Aluminum Sheet | 3 X 3 ft. |

| 1/8" 5005 Aluminum Sheet | 3 X 4 ft. |

| 1/8" 5005 Aluminum Sheet | 4 X 4 ft. |

| 1/8" 5005 H14 Aluminum Sheet | 4 X 10 ft. |

| 1/4" 5005 Aluminum Plate | 1 X 1 ft. |

| 1/4" 5005 H14 Aluminum Plate | 1 X 2 ft. |

| 1/4" 5005 Aluminum Plate | 1 X 3 ft. |

| 1/4" 5005 H14 Aluminum Plate | 1 X 4 ft. |

| 1/4" 5005 Aluminum Plate | 2 X 2 ft. |

| 1/4" 5005 H14 Aluminum Plate | 2 X 3 ft. |

| 1/4" 5005 Aluminum Plate | 2 X 4 ft. |

| 1/4" 5005 Aluminum Plate | 3 X 3 ft. |

| 1/4" 5005 H18 Aluminum Plate | 3 X 4 ft. |

| 1/4" 5005 H18 Aluminum Plate | 4 X 4 ft. |

| 1/4" 5005 Aluminum Plate | 4 X 10 ft. |

| 1/2" 5005 Aluminum Plate | 1 X 1 ft. |

| 1/2" 5005 Aluminum Plate | 1 X 2 ft. |

| 1/2" 5005 Aluminum Plate | 1 X 3 ft. |

| 1/2" 5005 Aluminum Plate | 1 X 4 ft. |

| 1/2" 5005 Aluminum Plate | 2 X 2 ft. |

| 1/2" 5005 Aluminum Plate | 2 X 3 ft. |

| 1/2" 5005 Aluminum Plate | 2 X 4 ft. |

| 1/2" 5005 Aluminum Plate | 3 X 3 ft. |

| 1/2" 5005 Aluminum Plate | 3 X 4 ft. |

| 1/2" 5005 Aluminum Plate | 4 X 4 ft. |

| 1/2" 5005 Aluminum Plate | 4 X 10 ft. |

| 3/4" 5005 Aluminum Plate | 1 X 1 ft. |

| 3/4" 5005 Aluminum Plate | 1 X 2 ft. |

| 3/4" 5005 Aluminum Plate | 1 X 3 ft. |

| 3/4" 5005 Aluminum Plate | 1 X 4 ft. |

| 3/4" 5005 Aluminum Plate | 2 X 2 ft. |

| 3/4" 5005 Aluminum Plate | 2 X 3 ft. |

| 3/4" 5005 Aluminum Plate | 2 X 4 ft. |

| 3/4" 5005 Aluminum Plate | 3 X 3 ft. |

| 3/4" 5005 Aluminum Plate | 3 X 4 ft. |

| 3/4" 5005 Aluminum Plate | 4 X 4 ft. |

| 3/4" 5005 Aluminum Plate | 4 X 10 ft. |

People also searched for Aluminum Plate

-

5052 Aluminum Plate Sheet

5052 aluminum plate is mainly composed of magnesium and chromium. It has good processability, medium static strength, high fatigue strength, and good weldability. The fatigue strength of 5052 aluminum alloy is higher than most aluminum alloys.

-

5052 h32 Aluminum Plate Sheet

5052 H32 aluminum plate has higher fatigue strength than most alloys, 5052H32 aluminum plate has excellent corrosion resistance, especially in marine applications, and has excellent machinability.

-

5052 h34 Aluminum Plate Sheet

5052 h34 aluminum plate has enhanced corrosion resistance, workability, strength, good formability and weldability.

-

5052 h38 Aluminum Plate Sheet

5052-H38 aluminum is 5052 aluminum in H38 condition. This is the strongest state usually produced by strain hardening and stabilization. It is closely related to H18.

-

3003 Aluminum Plate Sheet

3003 aluminum has excellent processability, weldability, and corrosion resistance. Compared with 1100 aluminum, 3003 aluminum is approximately 20% stronger.

-

3003 h22 Aluminum Plate

3003 - H22 has good strength, high durability, easy machining, high corrosion resistance and light weight. The popular product is mainly 3003-H22 Bright Aluminum Tread Plate.

-

3003 h24 Aluminum Plate

Ensure the 3003 h24 Aluminum Plate meets the required specifications including dimensional accuracy, chemical composition, mechanical properties, and surface finish.

-

3003 O Aluminum Plate Sheet

3003 O-state aluminum plate has low hardness, and 3003 O-state aluminum plate is suitable for stamping, spinning, stretching, etc.

-

3003 h14 Aluminum Plate Sheet

3003-H14 aluminum plate has the characteristics of high strength, high durability, easy processing, strong corrosion resistance and light weight. 3003 aluminum is suitable for outdoor and harsh environment applications.