5005 h34 Aluminum Plate Sheet

Strictly Control Product Quality Competitive Price

5005 H34 aluminum plate is another variation of 5005 aluminum alloy. H34 refers to the tempered designation, indicating that the aluminum plate has been strain-hardened and partially annealed to achieve a specific level of hardness and mechanical properties.

5005-H34 aluminum is 5005 aluminum in H34 condition. To achieve this state, the metal is strain-hardened and then stabilized to a strength approximately halfway between annealed (O) and fully hard (H38).

Specifications for 5005 H34 Aluminum Plate

- Common Thicknesses: 5005 H34 aluminum plate is available in a variety of thicknesses, typically ranging from 0.2mm to 6.35mm (0.008" to 0.25").

- Common Sizes and Width/Length Range: 5005 H34 Aluminum Plate is available in standard sizes or can be custom cut to meet specific requirements. Plate width and length may vary by supplier or manufacturer.

- Surface Treatment: The 5005 H34 Aluminum Plate can be given various surface treatments to enhance its appearance and provide additional protection against corrosion. Common finishes include satin finish (natural aluminum finish), anodizing, powder coating, and painting.

Al 5005 h34 Mechanical Properties

5005 H34 aluminum plate has moderate strength and excellent formability. The typical mechanical properties of 5005 H34 are as follows:

- Tensile strength: 145 - 185 MPa

- Yield strength: 115 - 155 MPa

- Elongation: 5 - 15%

- Hardness (Brinell): 47 - 59 HB

5005 h34 Aluminum Plate Chemical Composition

Alloy composition: The 5005 H34 aluminum plate is mainly composed of aluminum (Al) as the main element, and contains a small amount of other alloying elements. Typical compositional ranges are as follows:

- Aluminum (Al): 96.8 - 98.8%

- Magnesium (Mg): 0.5 - 1.1%

- Iron (Fe): 0.0 - 0.3%

- Silicon (Si): 0.0 - 0.3%

- Copper (Cu): 0.0 - 0.2%

- Zinc (Zn): 0.0 - 0.25%

- Manganese (Mn): 0.0 - 0.2%

- Other (each): 0.0 - 0.05%

- Other (total): 0.0 - 0.15%

5052 h34 Aluminum Plate Applications

Applications: 5005 H34 Aluminum Plate is used in a wide variety of industries and uses, including:

- Building - roofing, cladding corrugated sheet

- Signage, road signs name plates

- Food chemical equipment

- Furniture

- Anodised Parts

- HVAC Equipment

- Packaging

- Pipe and Tube

- Can Bodies

- Architecture and Construction Projects

- Roof and Siding

- Cladding and Façades

- Signage and Display

- Auto parts and panels

- General sheet metal processing

- Electrical enclosure

- Packaging Materials

- Decorative elements

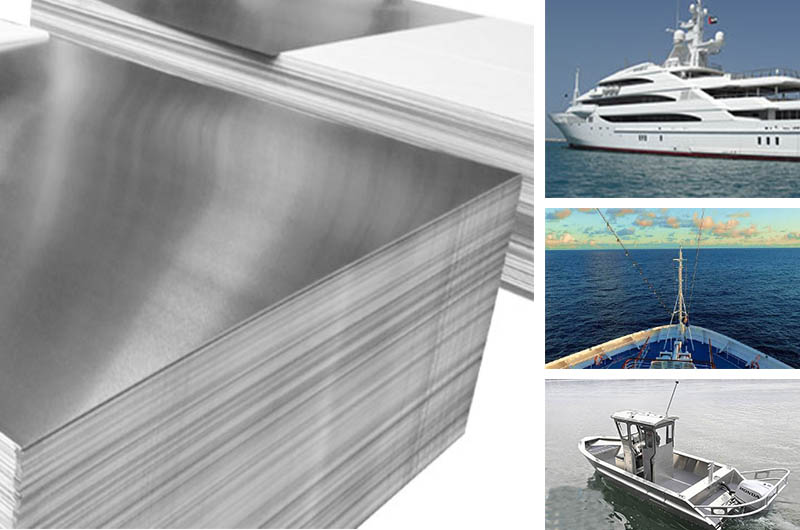

5005 H34 + 5052-H32

- Applications: Marine Industry

- Uses: hulls, ship components, fuel tanks, and other ship structures

- 5005 H34 for non-structural marine components, interior panels, and trim

- 5052-H32 for structural elements such as hulls, bulkheads, and superstructures

5005 H34 + 6063-T5

- Applications: Architecture and Construction Projects

- Uses: window frames, door frames, curtain walls, and other building profiles

- 5005 H34 for non-structural building elements, wall cladding, and decorative elements;

- 6063-T5 for structural elements such as window and door frames, curtain walls, and load-bearing extrusions

5005 H34 + 5754-H22

- Applications: Automotive Industry

- Uses: Automotive panels, fuel tanks, chassis components and body structures

- 5005 H34 is used for automotive non-structural parts, interior parts, and decorative parts;

- 5754-H22 is suitable for structural components such as automotive body panels, fuel tanks, and chassis components

5005 H34 + 3003-H14

- Applications: HVAC and Roofing

- Uses: HVAC ducts, heat exchangers, and roofing panels

- 5005 H34 for nonstructural HVAC components, ductwork, and non-loadbearing roof elements;

- 3003-H14 for structural elements such as heat exchangers, roof panels, and flashings

5005 H34 + 7075-T6

- Applications: Aerospace and Defense

- Uses: Aerospace structures, aircraft spars, fuselage frames and missile components

- 5005 H34 for nonstructural aerospace components, interior panels, and trims;

- 7075-T6 for structural elements including spars, fuselage frames, helicopter rotor blades, and missile components

Notice:

The use of these alloys in combination with 5005 H34 aluminum may vary depending on specific design requirements, performance specifications, and industry standards. The above-mentioned alloys are generally used in the respective applications to achieve the desired properties and performances.

Specific applications, dimensions, and availability may vary by supplier or manufacturer. It is always advisable to consult the supplier or refer to their product specifications for accurate information on the 5005 H34 Aluminum Plate.

5005 h34 Aluminum Plate vs 5005 h32 Aluminum Plate

The main difference between 5005 H34 and 5005 H32 aluminum sheets is their tempering characteristics and resulting mechanical properties. Here is a comparison of 5005 H34 and 5005 H32 aluminum sheets:

1. Temper Designation

- 5005 H34: The "H34" temper indicates a strain-hardened and partially annealed temper. It undergoes a controlled cooling process after work hardening, resulting in a medium-hard material.

- 5005 H32: The "H32" temper also represents the strain hardened state, but is harder than H34. It undergoes more extensive work hardening and more severe strain hardening.

2. Mechanical Properties

Tensile Strength

- 5005 H34: Typically in the range of 145 to 185 MPa.

- 5005 H32: Typically in the range of 155 to 195 MPa. H32 has higher tensile strength compared to H34.

Yield Strength

- 5005 H34: Typically in the range of 115 to 155 MPa.

- 5005 H32: Typically in the range of 125 to 165 MPa. H32 has a higher yield strength compared to H34.

Elongation

- 5005 H34: Typically between 5% and 15%.

- 5005 H32: Typically between 1% and 12%. H34 generally exhibits higher elongation compared to H32.

Hardness (Brinell)

- 5005 H34: Usually between 47 and 59 HB.

- 5005 H32: Usually between 52 and 63 HB. Compared with H34, H32 has a higher hardness.

3. Usage and Applications

Both 5005 H34 and 5005 H32 aluminum sheets are used in similar applications including construction projects, roofing, cladding, signage, automotive parts, sheet metal fabrication, and more. The choice between the two depends on the specific requirements of the application, taking into account factors such as required strength, formability, and hardness.

NOTE: The specific mechanical properties, thickness, dimensions, and availability of these aluminum sheets may vary by supplier or manufacturer. It is recommended to consult the supplier or refer to their product specifications for accurate information on 5005 H34 and 5005 H32 aluminum plates.

-

5005 Aluminum Plate Sheet

5005 aluminum is a medium-strength aluminum alloy with a small amount of magnesium as the main alloying element. It has good formability and is often used in applications requiring anodized surface treatments.

-

5005 h32 Aluminum Plate Sheet

5005-H32 aluminum is 5005 aluminum in the H32 condition. To achieve this state, the metal is strain-hardened and then stabilized to about one-fourth the strength between annealed (O) and fully hard (H38).

People also searched for Aluminum Plate

-

5052 Aluminum Plate Sheet

5052 aluminum plate is mainly composed of magnesium and chromium. It has good processability, medium static strength, high fatigue strength, and good weldability. The fatigue strength of 5052 aluminum alloy is higher than most aluminum alloys.

-

5052 h32 Aluminum Plate Sheet

5052 H32 aluminum plate has higher fatigue strength than most alloys, 5052H32 aluminum plate has excellent corrosion resistance, especially in marine applications, and has excellent machinability.

-

5052 h34 Aluminum Plate Sheet

5052 h34 aluminum plate has enhanced corrosion resistance, workability, strength, good formability and weldability.

-

5052 h38 Aluminum Plate Sheet

5052-H38 aluminum is 5052 aluminum in H38 condition. This is the strongest state usually produced by strain hardening and stabilization. It is closely related to H18.

-

3003 Aluminum Plate Sheet

3003 aluminum has excellent processability, weldability, and corrosion resistance. Compared with 1100 aluminum, 3003 aluminum is approximately 20% stronger.

-

3003 h22 Aluminum Plate

3003 - H22 has good strength, high durability, easy machining, high corrosion resistance and light weight. The popular product is mainly 3003-H22 Bright Aluminum Tread Plate.

-

3003 h24 Aluminum Plate

Ensure the 3003 h24 Aluminum Plate meets the required specifications including dimensional accuracy, chemical composition, mechanical properties, and surface finish.

-

3003 O Aluminum Plate Sheet

3003 O-state aluminum plate has low hardness, and 3003 O-state aluminum plate is suitable for stamping, spinning, stretching, etc.

-

3003 h14 Aluminum Plate Sheet

3003-H14 aluminum plate has the characteristics of high strength, high durability, easy processing, strong corrosion resistance and light weight. 3003 aluminum is suitable for outdoor and harsh environment applications.