5052 h32 Aluminum Plate Sheet

Strict Control of Tolerances Competitive Prices

5052 H32 is the specific temper designation for the 5052 aluminum alloy. The "H32" temper indicates that the material has been strain-hardened and stabilized resulting in a specific combination of strength and formability.

5052 has particularly good resistance to marine atmosphere and salt water corrosion, excellent processability, medium static strength, high fatigue strength, and it can be drawn or formed into complex shapes.

5052 H32 aluminum has added magnesium, making it much stronger than 3003 series aluminum. This grade is highly corrosion-resistant and has the best welding properties of any aluminum.

8 Reasons to Choose 5052 H32 Aluminum Plate

There are several reasons why the 5052 H32 aluminum plate is a versatile material suitable for a wide range of applications, especially those requiring corrosion resistance, moderate strength, and formability.

1. Corrosion Resistance

5052 H32 aluminum plate exhibits excellent corrosion resistance, especially in marine and saltwater environments. It resists atmospheric and seawater corrosion and is suitable for outdoor and marine applications.

2. Intensity

In its H32 temper, 5052 aluminum offers a balanced combination of strength and formability. It has medium-strength properties, making it suitable for structural applications without sacrificing workability.

3. Forming

5052 H32 aluminum plate is highly formable and can be easily bent, formed, or deep drawn without cracking. It has good cold workability and can be formed into various shapes, including rolling stamping, and deep drawing.

4. Weldability

5052 aluminum alloy has good weldability and can be easily welded using common methods such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding. It is also suitable for spot welding and brazing.

5. Processability

While 5052 aluminum is not as easy to machine as other alloys, it can still be machined with the proper techniques and tools. It tends to produce small chips and can have a sticky texture, so the use of sharp cutting tools and proper lubrication is recommended.

6. Surface Treatment

5052 H32 aluminum sheets typically have a matte surface but can be further treated through processes such as brushing or anodizing to achieve different surface appearances and enhance corrosion resistance.

7. Conductivity

Aluminum, including 5052 H32, has good electrical conductivity. It is commonly used in electrical applications where conductivity is important, such as wiring and electrical enclosures.

8. Weight

5052 H32 aluminum sheet has a relatively low density, which makes it lightweight compared to some other metals. This lightweight property is advantageous in applications where weight reduction is required, such as in the automotive and aerospace industries.

NOTE: Exact properties may vary slightly due to factors such as thickness, processing, and specific suppliers or manufacturers. It is recommended to consult the manufacturer or supplier for detailed technical information on the 5052 H32 aluminum sheet you are considering.

5052-h32 Aluminum Plate Specifications

5052 h32 Aluminum Plate Width/Length Range

- Width: Typically between 1000 mm and 1500 mm (39 inches to 59 inches).

- Length: Typically between 2000 mm and 3000 mm (79 inches to 118 inches).

Custom widths and lengths are also available.

5052 H32 Aluminum Plate Commonly Used Size

5052 h32 Aluminum Sheet is available in custom sizes to suit specific applications.

Common sizes include:

- 4 x 8 feet (1220 mm by 2440 mm

- 4 x 10 feet (1220 mm by 3050 mm)

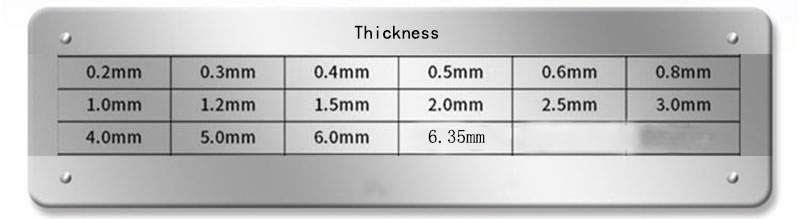

5052-h32 Aluminum Sheet Thickness

5052 H32 aluminum sheet and sheet are available in a variety of thicknesses, typically ranging from 0.2 mm (0.008 in) to 6.35 mm (0.25 in) thicker. Dimensions and availability may vary by supplier or manufacturer.

Common thicknesses include 0.5mm, 1mm, 1.5mm, 2mm, 3mm, 4mm and 5mm.

5052-h32 Aluminum Plate Thickness Tolerance

The thickness tolerance of 5052-H32 aluminum plate can vary according to manufacturing standards and the specific requirements of customers. Usually, the thickness tolerance of 5052-H32 aluminum plate is specified as a range or maximum allowable deviation.

Generally, the industry standard for aluminum plate thickness tolerance is ±10% of the nominal thickness.

For example, if the nominal thickness of the 5052-H32 aluminum plate is 1.0 mm, the thickness tolerance is ± 0.1 mm. However, it is important to note that specific tolerances may vary between different manufacturers or suppliers.

In addition to general thickness tolerances, customers may have stricter requirements or specifications to meet. These requirements can be communicated to the manufacturer or supplier to ensure that the required thickness tolerances are achieved.

5052-h32 Aluminum Plate Weight

The weight of a 5052-H32 aluminum plate can be calculated using its dimensions (length, width, and thickness) and the density of the aluminum. Aluminum has a density of approximately 2.7 grams per cubic centimeter (g/cm³) or 2700 kilograms per cubic meter (kg/m³).

To calculate the weight of the 5052-H32 aluminum plate, use the following formula:

Weight (kg) = Length (m) x Width (m) x Thickness (m) x Density (kg/m3)

If you prefer weight in a different unit, you can convert it accordingly. For example, to get the weight in pounds (lbs), you would multiply the weight in kilograms by 2.20462.

NOTE: This calculation is an estimate and actual weight may vary slightly due to manufacturing tolerances and variations in alloy composition.

Aluminum Alloy 5052 h32 Surface Treatment Type

5052 H32 aluminum sheet may have a variety of finishes including:

- Polished: The board has a raw, untreated surface.

- Brushed Finish: The finish is brushed for a textured look.

- Anodized: The plate undergoes an electrochemical process to form a protective oxide layer and acquire a specific color or enhanced corrosion resistance.

Aluminum alloy 5052 H32 can undergo various types of surface treatments to enhance its appearance, corrosion resistance, and other properties. Some common surface treatment types for 5052 H32 aluminum include:

1. Natural Finish

This is the untreated surface of the aluminum sheet, which is often referred to as a "mill finish" or "as-machined" finish. It has a matte appearance and does not undergo any additional surface treatment.

2. 5052 H32 Anodized Aluminum Plate

Anodizing is an electrochemical process that forms a protective oxide layer on the surface of the aluminum. It enhances corrosion resistance, improves durability, and provides a range of color options. Anodized 5052 H32 aluminum is often used in architectural and decorative applications.

3. 5052 H32 Powder Coated Aluminum Plate

Powder coating involves applying a dry powder paint onto the aluminum surface and then curing it in an oven. It provides a durable, uniform, and attractive finish that is available in various colors and textures. Powder-coated 5052 H32 aluminum is commonly used in applications where a specific color or finish is desired.

4. 5052 H32 Painted Aluminum Plate

Aluminum can be painted with various types of coatings, including epoxy, polyester, or acrylic paints. Painting provides both decorative and protective properties, allowing for customization of color and appearance. Painted 5052 H32 aluminum is used in a wide range of applications, including signage and automotive parts.

5. 5052 H32 Brushed Finish Aluminum Plate

Brushing the aluminum surface creates a directional pattern of fine lines or "brush strokes." This finish can provide a unique and aesthetically pleasing appearance while preserving the natural aluminum color.

6. Chemical Conversion Coating

Chemical conversion coatings, such as chromate conversion coatings or Alodine treatments, can be applied to the aluminum surface to enhance corrosion resistance and promote adhesion for subsequent painting or bonding processes.

7. 5052 H32 Embossed Aluminum Plate:

Embossing involves creating raised or recessed patterns on the aluminum surface. This technique can be used for decorative or functional purposes, such as adding texture or improving grip on certain applications.

8. Laminating

Laminating involves bonding a layer of protective material, such as a film or plastic, to the aluminum surface. This can provide additional protection against abrasion, UV radiation, or chemicals.

The choice of surface treatment for 5052 H32 aluminum depends on the specific application's requirements, including aesthetics, corrosion resistance, durability, and functionality. Different surface treatments offer various benefits, and the selection should consider the intended use and environmental conditions to ensure optimal performance and appearance.

Aluminum 5052-h32 Data Sheet

General Properties

- Density: 2.68 g/cm³ or 168 lb/ft³

- Melting Range: 607-649°C or 1125-1200°F

Aluminum 5052 h32 Mechanical Properties (Typical Values)

- Tensile Strength: 210-260 MPa (30, 000-37, 000 psi)

- Yield Strength: 150-230 MPa (22, 000-33, 000 psi)

- Elongation: 12-20%

- Hardness (Brinell): 60-70 HB

- Thermal Properties

- Thermal Expansion: 23.8 μm/m-°C or 13.2 μin/in-°F

- Thermal Conductivity: 138-157 W/m-K or 95.6-108 BTU-in/hr-ft²-°F

- Electrical Conductivity

- Electrical Conductivity (% IACS): 33-39

Aluminum 5052 h32 Chemical Composition (percentage by weight)

| Element | Composition Range (%) |

|---|---|

| Aluminum | 95.7 - 97.7 |

| Magnesium | 2.2 - 2.8 |

| Chromium | 0.15 - 0.35 |

| Manganese | 0.1 |

| Iron | 0.4 |

| Zinc | 0.1 |

| Copper | 0.1 |

These values are approximate and may vary based on specific production and testing methods.

When purchasing a 5052 H32 aluminum plate, it is important to consider your specific requirements such as dimensions, tolerances, surface finish, and any other machining needs. It is recommended to consult a reputable supplier or manufacturer who can provide detailed information and assist you in selecting the appropriate product for your application.

5052 h32 Aluminum Plate Processing

5052 is the strongest of the more common non-heat treatable grades and has higher fatigue strength than most aluminum alloys. It is a lightweight material that is typically processed to end-user specifications.

5052 h32 Aluminum Plate Applications

5052 H32 aluminum plate is ideally suited to most machining techniques and interior and exterior applications where strength is required over 3003 series aluminum.

Uses include truck and trailer parts, aircraft fuel tank parts, boat hulls, ladders, railings, tool boxes, kitchen equipment, decorative trim, sign blanks, storm shutters, refrigerator liners and panels, and more.

- 5052 h32 Marine Aluminum: 5052 H32 aluminum plate is commonly used in the construction of various marine components and structures such as boat hulls, decks, railings, and fittings. Its corrosion resistance and durability make it suitable for prolonged exposure ure to saltwater and harsh marine environments.

- Alu 5052 h32 for Automotive Parts: The automotive industry utilizes 5052 H32 aluminum plates for various parts, including body panels, chassis components, heat shields, and engine parts. Its lightweight nature contributes to fuel efficiency and helps reduce overall vehicle weight.

- 5052 h32 Al Transportation Equipment: 5052 H32 aluminum plate is employed in the manufacturing of transportation equipment such as trailers, truck bodies, and railcar components. Its high strength and corrosion resistance are beneficial for withstand demanding transportation conditions.

- Architectural Applications: The architectural industry utilizes 5052 H32 aluminum plates for a wide range of applications, including roofing, siding, façades, and decorative elements. Its aesthetic appeal, corrosion resistance, and ease of forming make it popular in architectural designs.

- Sheet Metal Work: 5052 H32 aluminum plate is widely used in various sheet metal fabrication applications. It can be easily cut, formed, and welded, making it suitable for a broad range of projects, including HVAC components, electrical enclosures, and general sheet metal work.

- Alloy 5052 h32 for Fuel Tanks: Due to its excellent corrosion resistance, the 5052 H32 aluminum plate is commonly used for manufacturing fuel tanks in the automotive, marine, and aviation industries. It helps ensure the integrity and safety of fuel storage.

- 5052 h32 Sheet for Cooking Utensils: The food industry utilizes 5052 H32 aluminum plates for the production of cooking utensils such as pots, pans, and baking sheets. It offers good heat conductivity, lightweight construction, and corrosion resistance, making it suitable for food preparation and cooking applications.

Factors Affecting the Price of 5052 H32 Aluminum Plate

The price of a 5052 H32 aluminum plate can be affected by a variety of factors, including external market conditions and internal product-specific attributes. The following are some key factors that affect the price of the 5052 H32 aluminum plate:

1. Aluminum Market Price

The main driver of 5052 H32 aluminum plate prices is the overall price of aluminum in the global market. Aluminum is a commodity and its price is subject to market fluctuations based on factors such as supply and demand, economic conditions, geopolitical events, and production levels. When aluminum prices are high, the cost of 5052H32 aluminum plates tends to rise.

2. Alloy and Tempering

Different aluminum alloys and tempering conditions have different costs. 5052 H32 is a specific alloy and temper combination that may be priced differently than other aluminum alloys and tempers due to differences in raw material costs and production processes.

3. Thickness and Size

The thickness and size of the aluminum plate have a great impact on its price. Thicker and larger sheets generally cost more because they require more raw materials and involve additional processing.

4. Quantity and Order Volume

Bulk or larger quantity orders usually receive a price discount compared to small or single-piece orders. Manufacturers may offer lower prices for bulk purchases.

5. Surface Finish and Treatment

If the 5052 H32 aluminum plate has additional surface treatments or finishes, such as anodizing, painting, or special coatings, it may affect the price. These treatments increase manufacturing costs.

6. Market Demand

Fluctuations in market demand for aluminum products (including 5052 H32 aluminum plates) will affect pricing. An increase in demand may cause prices to rise, while a decrease in demand may cause prices to fall.

7. Currency Exchange Rate

Because aluminum is traded globally, currency exchange rates can affect the price of imported aluminum products. Exchange rate changes may cause price fluctuations.

8. Customization and Processing

Customizing aluminum panels to specific sizes, shapes or processing requirements can increase costs. Complex or specialized processing may also increase the price.

9. Quality and Certifications

Higher quality standards, certifications, and compliance with industry specifications may result in increased production and testing costs, which may affect prices.

10. Regulatory and Environmental Factors

Compliance with environmental regulations (such as waste disposal and emission controls) may affect production costs and may affect pricing.

5052-H32 Aluminum Sheet Available Sizes

| Product | Width (In.) | Length (In.) |

| 0.032" 5052-H32 Aluminum Sheet | 48.00" | 120.00" |

| 0.032" 5052-H32 Aluminum Sheet | 48.00" | 96.00" |

| 0.04" 5052-H32 Aluminum Sheet | 48.00" | 120.00" |

| 0.04" 5052-H32 Aluminum Sheet | 48.00" | 96.00" |

| 0.05" 5052-H32 Aluminum Sheet | 48.00" | 120.00" |

| 0.05" 5052-H32 Aluminum Sheet | 48.00" | 96.00" |

| 0.063" 5052-H32 Aluminum Sheet | 48.00" | 120.00" |

| 0.063" 5052-H32 Aluminum Sheet | 48.00" | 96.00" |

| 0.063" 5052-H32 Aluminum Sheet | 60.00" | 120.00" |

| 0.08" 5052-H32 Aluminum Sheet | 48.00" | 120.00" |

| 0.08" 5052-H32 Aluminum Sheet | 48.00" | 96.00" |

| 0.08" 5052-H32 Aluminum Sheet | 60.00" | 120.00" |

| 0.09" 5052-H32 Aluminum Sheet | 48.00" | 120.00" |

| 0.09" 5052-H32 Aluminum Sheet | 48.00" | 96.00" |

| 0.09" 5052-H32 Aluminum Sheet | 60.00" | 120.00" |

| 0.1" 5052-H32 Aluminum Sheet | 48.00" | 120.00" |

| 0.1" 5052-H32 Aluminum Sheet | 48.00" | 96.00" |

| 0.125" 5052-H32 Aluminum Sheet | 48.00" | 120.00" |

| 0.125" 5052-H32 Aluminum Sheet | 48.00" | 96.00" |

| 0.125" 5052-H32 Aluminum Sheet | 60.00" | 120.00" |

| 0.19" 5052-H32 Aluminum Sheet | 48.00" | 120.00" |

| 0.19" 5052-H32 Aluminum Sheet | 48.00" | 96.00" |

| 0.19" 5052-H32 Aluminum Sheet | 60.00" | 120.00" |

-

5052 Aluminum Plate Sheet

5052 aluminum plate is mainly composed of magnesium and chromium. It has good processability, medium static strength, high fatigue strength, and good weldability. The fatigue strength of 5052 aluminum alloy is higher than most aluminum alloys.

-

5052 h34 Aluminum Plate Sheet

5052 h34 aluminum plate has enhanced corrosion resistance, workability, strength, good formability and weldability.

-

5052 h38 Aluminum Plate Sheet

5052-H38 aluminum is 5052 aluminum in H38 condition. This is the strongest state usually produced by strain hardening and stabilization. It is closely related to H18.

People also searched for Aluminum Plate

-

5005 Aluminum Plate Sheet

5005 aluminum is a medium-strength aluminum alloy with a small amount of magnesium as the main alloying element. It has good formability and is often used in applications requiring anodized surface treatments.

-

5005 h32 Aluminum Plate Sheet

5005-H32 aluminum is 5005 aluminum in the H32 condition. To achieve this state, the metal is strain-hardened and then stabilized to about one-fourth the strength between annealed (O) and fully hard (H38).

-

5005 h34 Aluminum Plate Sheet

5005 H34 aluminum has stable properties, it can stabilize mechanical properties and eliminate residual internal stress, and generally improves ductility.